Faizal TMCA CV rev 2

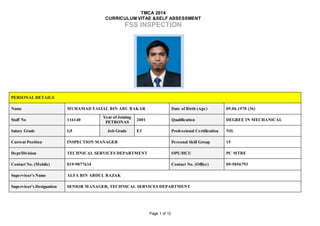

- 1. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 1 of 12 PERSONAL DETAILS Name MUHAMAD FAIZAL BIN ABU BAKAR Date of Birth (Age) 09.06.1978 (36) Staff No 116140 Year of Joining PETRONAS 2001 Qualification DEGREE IN MECHANICAL Salary Grade G5 Job Grade E3 Professional Certification NIL Current Position INSPECTION MANAGER Personal Skill Group 15 Dept/Division TECHNICAL SERVICES DEPARTMENT OPU/HCU PC MTBE Contact No. (Mobile) 019-9877634 Contact No. (Office) 09-5856793 Supervisor’s Name ALFA BIN ABDUL RAZAK Supervisor’s Designation SENIOR MANAGER, TECHNICAL SERVICES DEPARTMENT PLEASE INSERT YOUR RECENT PHOTO

- 2. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 2 of 12 CAREER SUMMARY(IF ANY) (Locations, job positions and roles, responsibilities) No Year (from) Year (To date) Job positions & roles, responsibilities 1 2001 2002 Seeding Engineer at Inspection Section, TSD. 2 2003 2008 Corrosion Engineer at Inspection Section, TSD 3 2009 2014 Inspection Manager,TSD.

- 3. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 3 of 12 TRAINING/SEMINARS ATTENDED (Classroom,Job assignments, etc.) No Date Course Title Organizer Man Days Venue 1 Year 2002- 2006 All require SKG 15 training Level 1 and Level 2 PERMATA 224 hours Various location. 2 Year 2008 API 510 Training and Certification IDC 48 hours Shah Alam 3 Year 2012 MYLS #35 Programs PLC 90 hours Permata 4 Year 2014 ACD Assessor Training PLC 16 hours KL COMPUTER SKILLS (Please Tick the listed programs and add others accordingly) Microsoft Office Word Microsoft Office Power Point Microsoft Office Excel Petronas Risk Based Inspection

- 4. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 4 of 12 SKILL ELEMENTS (Please refer to the Functional Skill Sets for reference and highlight / colour your Self-Assessment Rating). Ensure that your Immediate Superior agrees with your Self-Assessment Ratings. Provide evidence ofactual works done (e.g.project / procedure / study / design / drill / exercise / etc.), role played (e.g. designer / writer / reviewer / approver / leader / member / etc.), and results produced 1. HSE & Leadership Safety

- 5. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 5 of 12 HSEMS Participate as HSEMS Tier-3 Auditor during CUF HSEMS Tier 3 audit in 2007 Participate as assesse (focalperson for Asset Integrity) in MTBE HSEMS Tier 3 Audit in 2010 and 2013 Involved in preparation of HSEMS Legal Registry in 2010 Lead HSEMS Audit for inspection contractor (Escon Engineering Sdn. Bhd) in 2008 Process Safety Team leader Zero Fire/Zero Leak Programs from 2010-2012 Team member for the implementation of original MI back in 2010. Involved directly for the development of PC MTBE MI Top Doc. Identify MI scoping including SOL, SERP and ITPM. Continue with the involvement as a team member of ‘new MI’ started in 2013 based on the latest PTS standard which inclusion of SCE factors. AssetIntegrity Implementation and Monitoring Lead the implementation for Tier-3 Action item closure related to Asset Integrity/Inspection. AssetIntegrity Assurance Lead the intervention of action item closure for Integrated Plant Operations Capability System (iPOCS), focusing on Integrity Management element. Plan, implement and track all action item under Inspection Section. Resulted in improvement of Integrity Management element score from initial 1.85 to 2.49. Involved in MCF Exercise Element 9 Design Involved in Asset Integrity Assurance Tier 2 Audit by DOD in 2013 Involved directly as assesse during MTBE Group Internal Audit in 2011. AssetIntegrity Management Review Act as Element Focal Person (ERP) for the implementation of OEXMS, Element 06 01 (Integrity Management in PC MTBE. Drive the Situational Assessment and OPMW (OEXProgress Measure Workbook) for element 06 01. To proceed with MSR by end of this FY. Statutory Stake Holder Management Conduct formal technical training for DOSH Pahang Officer as part of preparation for TA 2013 and TA 2014. Conduct informal engagement with DOSH Pahang by organizing friendly badminton and bowling match in 2012 and 2014. Conduct networking session between PCGand DOSH Putrajaya during initial introduction of SSI. Self-Assessment Rating Awareness Knowledge Skill Assessor Rating Awareness Knowledge Skill

- 6. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 6 of 12 2. Plant Performance & Turnaround Management Statutory CF Validity and Extension Strategy Team member for Plant Optimized Run Length Task Force. Turnaround Inspection Planning and Execution Management Lead Inspection Section for numbers of TA and shutdown. Involvement start from planning of equipment/asset to be inspected which involved coordination with TA Planning/TACS team, Develop strategy for static equipment inspection through revision of RBI and issuance of SOE. Involved in worklist challenge, identify constraint and major stopper which can prevent flawless TA. Liaison with DOSH Pahang for renewalof CF for DOSH equipment. Lastly, analyse TA performance from asset integrity point of view, review lesson learnt during execution and identify major hindrance for future TA improvement. MTBE Unplanned Coldbox Shutdown September 2014 MTBE Unplanned Feed Dryer Shutdown August 2014 MTBE DOSH TA April 2014 MTBE Unplanned CTP Failure Shutdown June 2013 PDH DOSH TA March 2013 PDH Unplanned HCFE Shutdown Dec 2012 PDH Unplanned LCP Screen Shutdown October and Dec 2011 PDH Planned Shutdown September 2011 MTBE Pit Stop May 2011 PDH Pit Stop Shutdown October 2009 Self-Assessment Rating Awareness Knowledge Skill Assessor Rating Awareness Knowledge Skill 3. Strategic Planning

- 7. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 7 of 12 Integrity Dashboard Setting Introduced Inspection Monthly Reporting, whereby an ‘Asset Integrity Indicator’ was introduced to track and monitor the performance of Static Equipment. The tracking was categorized in three criteria; Not Fit For Service, Potential Threat and NSR. These criteria was based on API 579 and SAP ECC6 definition of priority classification. The reporting was presented in PLT Monthly meeting, and used as reference for tracking, monitoring and rectification of static equipment having integrity issue, including FTD. Main stakeholders is Asset,MTN, Asset Management (Reliability) and TSD. Inspection and Asset Integrity Programs Participate as department representative for MTBE/PP Yearly Strategic Planning session “Roadmap towards Excellence in 2009, 2010, 2011, 2012. Involved in SWOT analysis which then translated into 3 phases of roadmap implementation: - Phase 1: Back to Basic, - Phase 2: Reinforce Capability/Practices, - Phase 3: Center of Excellence. Outcome of the above, staff emulate and lead the implementation of Inspection Department “Roadmap to Excellence”,a 5 years roadmap journey to ensure a complete asset integrity management framework is implemented. The specific roadmap divided into 3 phases: - Phase 1: Plan, Drive and Implement Physical Asset Integrity Management Programs - Phase 2: Reinforce Inspection Capability and Sustain Inspection Practices - Phase 3: Inspection Excellence Physical Asset Integrity Management Framework was later designed in 2010 (during Phase 1) and later further improve by 2012. This is base the backbone of current Asset Integrity Management Programs (AIMP) that was intended to replicate comprehensive and integrated relevant integrity programs between RBI and SAP. Require a switching mindset of tracking inspection work manually to utilization of SAP management tools. Full scale implementation of AIMP using SAP was launched in 2013 until now, with continuous improvement and enhancement done along the way. Self-Assessment Rating Awareness Knowledge Skill Assessor Rating Awareness Knowledge Skill 4. AssetIntegrity Management

- 8. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 8 of 12 Failure Investigation Lead Inspection team for few high profile RCFA PC MTBE involving asset integrity cases (Oleflex outer screen R-202 failures in 2009, CTP failure in 2013, MTBE Coldbox 2014). AssetIntegrity Limit Deviation Management/CMP Lead the implementation of CMP and IOW in 2012. Introduced associated procedures and RACI for the implementation of this initiative in PC MTBE. RBI Management RBI Team Leader for implementation of CF extension/exemption project since 2010, until the inception of SSI in 2014. Provide direction and guidance to the team in managing RBI,tracking and closing the associated gaps, and advice PC MTBE management on recommendation for future improvement Team leader for PRBI V2 migration. Lead the team from various discipline which share similar objectives to conduct situational assessment,technical review and challenge of the new PRBI V2 result, and action item. Work done in phases, starting from 2010 until 2013 for all 3 plant. Integrity Database Management Lead the implementation of Online Reporting System base on PRBI V2 Deficiency Management Module. Provide separate UT database via WinCairs system. Operate and Manage the huge sum of data since 2001. PRD and CF maintaining via hardcopy and softcopy. Equipment Integrity Management Strategy Lead the implementation of Asset Integrity Management Program (AIMP),which is part of overall Inspection Section roadmap. Improved previous Inspection Program by shifting the strategy of doing inspection based on risk instead of time base. Incorporated AIMP into SAP system,and established proper tracking and monitoring of programs. Scheme OfExamination Drive and monitor the implementation of SOE for static equipment. Currently focusing on DOSH/Non DOSH vessel. Piping SOE is yet to be established. Equipment Integrity Technical Solution ALS implementation team member for MTBE and PPM plant. Involved directly starting with data gathering, result analysis, assessment of life cycle cost and gap closure intervention. Focus on the static equipment (pressure vesseland piping system).

- 9. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 9 of 12 Team leader for ZFZL Initiatives from 2010 and 2012. Involvement start with the construction of the ZFZL framework and its associated scoping, monitoring and assessment of the action item, and analysis of the gap identify from the implementation for continuous improvement. Fitness For Service Lead FFS/FEA involving asset integrity deficiency cases (D-105 thinning, C-101 thinning, weldolet F-2001 PDH,weldolet H-201/2/3 MTBE, fire damage assessment for D-1304). Corrosion Control and Monitoring Management Lead the implementation of underground pipelines road crossing corrosion prevention project in 2011. Lead the MTBE CP Revamp work in 2008 Lead the Port Storage CP Rejuvenation work in 2013. Corrective and Recommended Action Closure Management Develop closure plan and subsequently implementation the action item for numbers of audit exercise (HSEMS Tier 3 2010/2013, iPOCS 2009-2012) Self-Assessment Rating Awareness Knowledge Skill Assessor Rating Awareness Knowledge Skill

- 10. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 10 of 12 5. Asset Integrity Deviation Management Non Standard Repair Implementer for NSR Management via MTBE Plant Change Management System Process. Technicalauthority for NSR under static equipment is under custodianship of Inspection Section. Involvement including revision of NSR design, monitoring of its performance and tracking the closure of the NSR during TA/shutdown. Rerating Participated in rerating exercise for PC MTBE boilers B-1001, B-1002, B-1003 and B-1004 based on the latest findings during MTBE TA 2014. Come out the assessment,its associated risk to the overall steam generation system in the plant, and propose to DOSH in obtaining approval. Granted by DOSH Pahang and allow for continuation of boiler operation without affecting plant performance. Deviation and Deferral Led the initiation of AIMP Deviation Management procedure by Inspection Section. The procedure ensure proper control of all the inspection program should require it to be defer due to unavoidable circumstances. The deviation comes together with justification and approval, and ensure a proper tracking between AIMP implementation and SAP Bad Actor Management Assigned by management to carry out Major Bad Actor assessment for CTP failure case in MTBE. The failure has led to 30 days P-P shutdown for rectification. RCFA was done to establish the root cause,and established proper action item. Permanent rectification was done during recent TA 2014, and currently the Bad Actor is under monitoring for 6 months. Self-Assessment Rating Awareness Knowledge Skill Assessor Rating Awareness Knowledge Skill

- 11. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 11 of 12 6. Resource,Capability Management & Competency Development Competency Development and Certification ofMCI Personnel Monitor and track personal development plan for each Inspection staff. Identify gaps from ACD,PECAS and TTS assessment and come out with development plan together with CM Department. Reflect the plan into section training master plan. Involved directly as the TTS Committee member and TTS Assessor for the creation Static Equipment Inspection Trade since 2007. Involvement level includes creation of Skill Criticality Assessment,Skill Inventories and development of Ruler/Descriptors. Performed roles as the ACD Assessor of SKG 15 since 2014. SKG 15 Discipline Resource Person (DRP) Committee Member. Involved in the setting of future way forward of SKG 15 fraternity, in line with the needs of business. At the same time, contributes to the development of SKG 15 TP overall strength in Petronas. Service Provider Competency Assessment and Evaluation Evaluate and monitor the performance of inspection service providers. Identified appropriate SOW and selection technical criteria during the bidding process. This is done for both Price Agreement and once-off contracts,work closely with SMSO. At the same time, evaluation was also carried out for inspection service providers via mock up for NDT supplier (focus on UT base and tubular inspection technique), written and interview test (for 3rd party inspectors). This is done to ensure quality assurance and quality control as far as competency of the contractors is concern. Inspection Contract and Services Involved in the budget preparation of section on yearly basis. Identify appropriate amount of cost and resource (both for Opex and Capex) that need to be put to support implementation of yearly AIMP. Estimate the amount of ACV for PA contract to ensure sufficient allocation is been put for routine and non-routine inspection activities. Work closely with SMSO/TACS. Engineering (Cross Discipline) Acquire good understanding on Mechanical and Process discipline, while having basic understanding on Electrical, Instrument, and Production Planning. Self-Assessment Rating Awareness Knowledge Skill Assessor Rating Awareness Knowledge Skill 7. Technical Governance

- 12. TMCA 2014 CURRICULUM VITAE &SELF ASSESSMENT FSS INSPECTION Page 12 of 12 Statutory and Legal Compliance Requirement Drive and monitor performance of Inspection Section according to requirement of FMA ACT 1967, including the recent FMA (Special Scheme of Inspection) Regulations 2014. Aware in Atomic Energy Licensing Act 1984. Mandatory Control Framework Involvement in the MCF Element 9 Assessment Design and in-Service Engineering Standard Compliance Ensure compliance to applicable company and international engineering standard on any related inspection activities. Most of compliance comes from PTS, ASME and API. Self-Assessment Rating Awareness Knowledge Skill Assessor Rating Awareness Knowledge Skill