Project File

- 1. 1

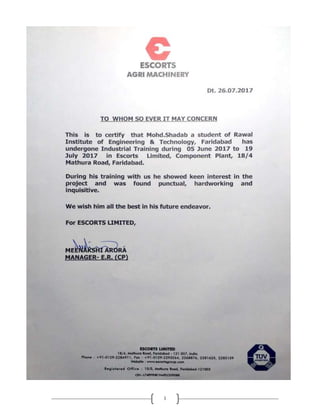

- 2. 2 ACKNOWLEDGEMENT The authors are highly grateful to the Dr. B. K. Singh, Director, Rawal Institute of Engineering and Technology, Faridabad, for providing this opportunity to carry out the 6 week industrial training at ESCORTS LIMITED COMPONET PLANT, FARIDABAD. The constant guidance and encouragement received from Er. Shiv Mittal T&P, RIET, Faridabad has been of great help in carrying out the project work and is acknowledged with reverential thanks. The authors would like to express a deep sense of gratitude and thanks profusely to Ravi A. Menon CEO of Company, Escorts group Without the wise counsel and able guidance, it would have been impossible to complete the report in this manner. The help rendered by Mr Vinod Kumar, Supervisor (Gear Manufacturing Division ) for experimentation is greatly acknowledged. The author expresses gratitude to Mr Deepak Sharma HOD, Mechanical Engineering department and other faculty members of the department for their intellectual support throughout the course of this work.

- 3. 3 PREFACE Industrial training now a day’s one & the only one method to make students familiar with the modern techniques, latest equipments& methods used in various industries. During industrial training, students visit to various companies and make themselves familiar with the practical aspect of the production method. This training has provided and ultimate experience& opportunity to have practical knowledge which has increased my level of thinking and dealing with different kinds of people in all walks of life. It helps us a lot while appearing to the interviews. Industrial training in proves the theoretical and the practical concept of the student about engineering. The well planned, properly executed & evaluated industrial training helps a lot in inculcating good work culture. It provides linkage between the students & the industries in order to develop and awareness of industrial approach to problem solving based on broad understanding of plant.

- 4. 4 Table of content Certificate 1 Acknowledgement 2 Preface 3 Escorts group- An introduction Escorts Agri Machinery 5 Construction Equipment Limited 5 Escorts Railway Products 6 Escorts Auto-Products 6 Escorts and Technology 7 Timing Gears 411 8 206 13 212 16 Hydraulic Pack Hydraulic Pack Components 19 Operation 20 Maintenance 20 Report Sheets 21 TPM(Total productive maintenance) Process of doing TPM 23 Objective of doing TPM 24 Conclusion 25 References 26 Site map of industry 27

- 5. 5 ESCORTS GROUP An introduction The Escorts Group is an Indian multinational engineering conglomerate that operates in the sectors of Agri- machinery, construction and material handling equipment, railway equipment and auto components. Headquartered in Faridabad, Haryana, the company was launched in 1944 and has operations in more than 40 countries. Escorts Agri-Machinery (EAM) Built with a mission to improve agricultural productivity and improve the quality of life in rural India, it pioneered farm mechanization in the country and since then has played a pivotal role in the agricultural growth of India for over five decades. Escorts Agri Machinery has three recognized and well-accepted tractor brands, which are on distinct and separate technology platforms: Farmtrac: World Class Premium tractors, with single reduction and epicyclical reduction transmissions from 34 to 75 HP. Powertrac: Utility and Value-for-money tractors, offering straight-axle and hub-reduction tractors from 34 to 55 HP. India's No.1 economy range – engineered to give spectacular diesel economy.0. Escort: Economy tractors having hub-reduction transmission and twin- cylinder engines from 27 to 35 HP. Pioneering brand of tractors introduced by Escorts with unbeatable advantage Escorts Construction Equipments (ECE) Escorts manufacturers and markets a diverse range of construction and material handling equipment. The company was a pioneer in introducing the concept of Pick 'n' Carry hydraulic mobile cranes in the 70s in India and continues to be the world's largest manufacturer of these cranes, together with being the largest crane manufacturer in the country. Cranes Loaders Vibratory rollers Forklifts

- 6. 6 Escorts RailwayProducts (ERP) Escorts has played a major part in the growth and modernization of the railway equipment business in India for nearly five decades. It has a rich experience of manufacturing critical railway products. Since 1962, the company has remained as one of the reliable partners of Indian Railways throughout its journey of modernization. Escorts Railway Products (ERP) is an ISO 9001 certified company that manufactures critical railway components including. Brakes Couplers Shock absorbers Rail fastening systems Composite brake blocks Vulcanized rubber parts. Escorts Auto Products (EAP) The leading manufacturer of auto products in India for over four decades, Escorts Auto Products exhibits quality and reliability through its products in the automobile industry worldwide. Escorts presents a combination of integrated manufacturing facilities, in-house state-of-the-art research and development, as well as advanced production, testing and validation facilities, which have enabled us to bring new and reliable products on a global platform. Products Include: Shock Absorbers Telescopic Front Forks McPherson Struts Steering Components Special Dampers

- 7. 7 Technologyand Escorts: Throughout the evolution of Escorts, technology has always been its greatest ally for growth. In the over six decades of our inception, Escorts has been much more than just being one of India's largest engineering companies. It has been a harbinger of new technology, a prime mover on the industrial front, at every stage introducing products and technologies that helped take the country forward in key growth areas. Over a million tractors and over 16,000 construction and material handling equipment that have rolled out from the facilities of Escorts, complemented by a highly satisfied customer base, are testimony to the manufacturing excellence of Escorts. Recent Additions to the Market: Ferrari, a 26 HP model that has all four equal sized wheels, an all-time 4- wheel drive and oscillating chassis system suited for use in vineyards and orchards in India. The Farmtrac Executive tractor series focused on the comfort of its operator has an Independent PTO with a safety device, a new scissor seat with a recliner, stylish fenders, suspended clutch and brake pedals, a digital speedometer and LED head-lamps. Slew Cranes, with 360 degree continuous boom rotation, Increased shock load bearing capacity, enhanced safety due to higher ground clearance, and independent crane control with 3 way proportional control valves . Inverter Tractor, a technology that offer farmers an integrated multi-purpose vehicle that can be used as a tractor for Agri-operations and with the help of an in-built battery system, can generate electricity helping farmers light up their homes. Beyond manufacture, Escorts has made substantial investments towards the modernization of farm technology. The Escorts Training & Development Centre (ETDC) at Bangalore is a unique center where training is imparted in operation, maintenance and repair of farm machinery. Its programs are aimed at encouraging customers, dealers, engineers, mechanics as well as the field staff of Escorts, towards meeting its objective of enhancing agricultural productivity and improving quality of life in rural India.

- 8. 8 TIMING GEARS Timing gears are the gears through which the crankshaft drives the camshaft and thus controls valve timing in a four-stroke cycle internal-combustion engine, which ensures the correct timing to best fill the cylinder with an air/fuel mixture as well as to release all of the spent fumes from the exhaust cycle of the cylinder. In the perfect relationship of timing, the timing gear can be set, so that the intake valve will begin to open as the piston is still moving downward in the cylinder walls and sucking the fuel into the cylinder. This would aid in getting as much fuel as possible into the combustion chamber. Also, the exhaust valve would remain open as long as the piston was moving upward in the cylinder and pushing the exhaust fumes out of the combustion chamber so that there is no contamination to the incoming fuel mixture. There are 3 Timing Gears that combine to form a drive, which transfers motion from the crankshaft to the camshaft. 411: This is the gear that is mounted on the crankshaft. The following flowchart depicts the manufacturing processes that this gear undergoes: Fig 1: Process of making timing gear411

- 9. 9 Dimensions and PartDrawing: Fig 2: Dimensions of timing gear411 Details about Manufacturing Processes: 1. Turning (1st Setup): Fixture: Standard GMT 3 jaw power chuck (200 mm diameter), TGR-F-4417, Special Hard jaws Tools: Standard Tool holder PCLNR 2020 K12, with standard insert CNMG 120408 Standard Tool holder MTJNR 2020 K16, with standard insert TNMG 160408 TG Standard Tool holder S32U PCLNR 2020 K12, with standard insert CNMG 120408 TG Gauges: Standard Snap Gauge for 137.96/137.71 TGRG 4416 gauge for 11.1/10.9 TGRG 4422 tool setting gauge for 27 TGRG 4423 tool setting gauge for 55

- 10. 10 No. of teeth 48 Module 2.5 PCD 132.96 mm Helix angle 25-30o Hand of Helix Left Root Diameter 126.7/126.5 mm 2. Turning (2nd Setup) Fixture: Standard GMT 3 jaw power chuck (200 mm diameter), TGR-F-4418, Special Soft jaws Tools: Standard Tool holder PCLNR 2020 K12, with standard insert CNMG 120408 Standard Tool holder MTJNR 2020 K16, with standard insert TNMG 160408 TG Standard Tool holder S32U PCLNR 2020 K12, with standard insert CNMG 120408 TG Gauges: Standard Snap Gauge for 137.96/137.71 Standard Snap Gauge for 20.10/20.50 Standard Plug Gauge for 40.025/40.000 TGRG 4422 tool setting gauge for 27 TGRG 4423 tool setting gauge for 55 3. Hobbing: In this process, 48 teeth are being cut, on 4 components at a time. Time Taken: 4.41 minutes Gear Accuracies (Micron) Bearing 80% Profile Error 25 Lead Error 25 T/C Error 70 T/T Error 20 PCD Root 50 Gear Data Fig 3: Clamping Position of Work piece

- 11. 11 4. Drilling (1 hole (12 mm), on R-31 in relation to punch mark "O") Fig 4: Part drawing showing the dimensions of the drill 5. Drilling (8.5 mm holes and mill 3 slots 8.75+.25 wide, equi-spaced) Fig 5: Part drawing showing the dimensions of the drill

- 12. 12 Number of Teeth 48 Module 2.5 P.C.D 132.96 Helix Angle 25o 30’ Hand of Helix Left Bearing 90% Lead Error 28 Profile Error 28 T/G Error 90 T/T Error 28 P.C.D R/O 64 6. Shaving of 48 Helical Teeth: Fixture: TGR-F- 4177 Shaving Arbor (40.025/40.000) Tool: TGRT- 654 Shaving Cutter Gauge: TGR-G 656 Master Gear TGR-G 7012 Inspection Mandrel Standard Flange Micrometer 50.75mm TGRG- 5826 MOT Gauge Gear Data Gear Accuracies (Microns) 7. Final Inspection: The gears are checked for the following specifications in the final inspection: Gear Characteristics Value T/T Error 22u T/C Error 90u Lead Error 28u Profile Error 28u PCD R/O 64u MOT over 7 Teeth 50.150/50.100

- 13. 13 206: It is the idler gear, which is used to transfer the drive from 411 to 212 in the same direction. The following flowchart depicts the manufacturing processes that this gear undergoes: Fig 6: Process of making timing gear206 Part Dimensions and Drawing: Fig 7: Dimensions of timing gear206

- 14. 14 Material Specifications: Material Steel, IS: 2004-55C8 Treatment Condition Normalized Hardness 201-255 BHN Details about Manufacturing Processes: 1. Turning (Setup 1): Machine/Equipment: MWS Twin Chucker Gauges: Standard Snap Gauge for Outer Dia. 137.96/137.71 mm Standard Bore Gauge for Rough Bore of 41.16/41.00 mm Vernier Calliper for Length of 6.6/6.4 Taper mandrel Dial Indicator for OD run-out of <0.1mm Vernier Calliper Standard bevel protractor for Bore chamfer of 2x45o and Hub face chamfer of 0.7x45o Dial indicator (Least Count 0.01mm) for face run-out of 0.03mm 2. Turning (Setup 2): Machine/Equipment: MWS Twin Chucker Gauges: Standard Snap Gauge for Outer Dia. 137.96/137.71 mm Standard Bore Gauge for Finish Bore of 42.025/42.00 mm Standard Snap Gauge for length of 25.2/24.8 Length Gauge (TGR-G-780) for length of 31.7/31.3 Length Gauge (TGR-G-781) for length of 30.0/29.81 Taper mandrel Dial Indicator for OD run-out of <0.1mm Vernier Calliper Standard bevel protractor for chamfer of 0.7x45o Dial indicator (Least Count 0.01mm) for face run-out of 0.03mm

- 15. 15 3. Shaving (48 Helical Teeth) Machine/Equipment: Shaving Machine Tool Holder: TGR-F-4175 shaving Arbor Tools: TGR-T-674 Shaving Cutter TGR-T-4796 Protection Sleeve Table depicting Error Limits and their Respective Measuring Gauges Product Characteristics Process Characteristics Process Specifications Evaluation/Measureme nt TechniqueLead Error Not to exceed .020mm M&M Gear Analyzer Involute Error Not to exceed .020mm M&M Gear Analyzer Total Composite Error Not to exceed .064mm Dial indicator (LC- .001mm) Range: 0- 1mmTeeth to Teeth Error Not to exceed .016mm Dial indicator (LC- .001mm) Range: 0- 1mmPCD Run-out Not to exceed .044mm Dial indicator (LC- .001mm) Range: 0- 1mmBearing 90% Gear Rolling MOT over 4 teeth 50.03/49.98 Flange Micrometer (LC .01mm) Range:0-1mm Shaving Arbor Run out Not to exceed .005mm Dial indicator (LC- .001mm) Range: 0- 1mmMachine Center Run- Out Not to exceed .005mm Dial indicator (LC- .001mm) Range: 0- 10mm 4. Finish Grind Bore: Machine: Grinding Machine Table showing Error Limits and Respective Measuring Gauges Product Characteristics Process Specifications Measuring Instrument Bore Diameter: 38.025/38 Standard Plug Gauge PCD Run-out Not to exceed .044mm Taper Arbor Dial Indicator

- 16. 16 212: This gear is mounted on the camshaft, enabling it to rotate with the crankshaft. The following flowchart depicts the manufacturing processes that this gear undergoes: Fig 8: Process of making timing gear 212 Details about Manufacturing Processes: 1. Turning (Setup 1): Fixture: Standard GMT 3-jaw power chuck (200 mm diameter), TGR-F-4417, Special Hard jaws Tools: Standard Tool holder PCLNR 2020 K12, with standard insert CNMG 120408 Standard Tool holder MTJNR 2020 K16, with standard insert TNMG 160408 TG Standard Tool holder S32U PCLNR 2020 K12, with standard insert CNMG 120408 TG Gauges: Standard Snap Gauge for 137.96/137.71 TGRG 4416 gauge for 11.1/10.9 TGRG 4422 tool setting gauge for 27 TGRG 4423 tool setting gauge for 55 TGRG 4425 tool setting gauge for 103

- 17. 17 2. Turning (Setup 2): Fixture: Standard GMT 3 jaw power chuck (200 mm diameter), TGR-F-4418, Special Soft jaws Tools: Standard Tool holder PCLNR 2020 K12, with standard insert CNMG 120408 Standard Tool holder MTJNR 2020 K16, with standard insert TNMG 160408 TG Standard Tool holder S32U PCLNR 2020 K12, with standard insert CNMG 120408 TG Gauges: Standard Snap Gauge for 137.96/137.71 Standard Snap Gauge for 25.2/24.80 Standard Plug Gauge for 40.025/40.000 TGRG 798 Length Gauge for 30.70/30.40 TGRG 797 Length Gauge for 31.20/30.80 TGRG 4419 taper arbor gauge to check chamfer De-burring (Helical Teeth on both sides): Fixture: TGRF-3494 De-burring Arbor Tools: Standard Grinding Wheel (diameter 100x3x12.7mm) Fig 9: Diagram showing the clamping position of work-piece during the operation

- 18. 18 Number of Teeth 48 Normal Module 2.5 P.C.D 132.96 Helix Angle 25o 30’ Hand of Helix Left Normal Pressure Angle 20o Measurement over 7 teeth 50.20/50.15 Bearing 90% Lead Error 20u Profile Error 20u T/C Error 64u T/T Error 16u P.C.D run-out 44u 3. Shaving: Fixture: TGR-F-3910 Shaving Arbor Tools: TGR-T-658 Shaving cutter TGR-T-4756 Sleeve Gauges: Standard Flange Micrometer (50.75mm) TGRG-3525 Taper Inspection Mandrel TGRG-795 Taper Mandrel Gear Data Gear Accuracies 4. Broaching (Keyway): Fixture: TGR-F 5519 Broach Plate TGR-F 5764 Broach Puller End TGR-F 5525 Broach Retriever Tools: TGRT- 5521 Flat Keyway Broach Gauges: TGRG 5516 Slip Gauge (for 5.015/4.985 Width) TGRG- 5517 Gauge for 32.40/32.20 TGRG 5518 Gauge to check Angle16o 45’+15’ Standard S punch Fig 10: Dimensionsof broached keyway

- 19. 19 Hydraulic PowerPack Hydraulic power packs are stand-alone devices, as opposed to a built-in power supply for hydraulic machinery. Some power packs are large, stationary units and others are more portable. Hydraulic Pack Components: Hydraulic Pump: This pump is the source of pressure build-up, due to which the fluid is able to travel within the system. Motor: A motor, generally electrical, is present in the HPP to drive the pump Hydraulic Reservoir: This houses the Hydraulic fluid, which is circulated in the system Pressure Regulators: These regulators allow the user to control the amount of pressure the power pack delivers to a valve. Pipelines: The fluid travels to the required location through these pipes. Direction Control Valves: They are used to control the path of fluid flow in the hydraulic circuit. Pressure Relief Valves: The relief valve is used to control or limit the pressure in a system. If excess pressure is encountered in the system, this valve is actuated, and directs fluid flow back to the tank, thus limiting pressure. Breather: In every closed hydraulic tank, an air breather is mounted on air chamber side. Its function is to maintain the pressure on the hydraulic oil, to allow the suction pressure for the pump, and release excess pressure to atmosphere in order to maintain pressure in hydraulic tank It also sucks air from the atmosphere, if pressure drops, thus maintaining pressure Oil Filter: Filter placed on the passage through which oil is poured into the reservoir, which prevents particles such as dust, debris, metal chips etc. from entering the reservoir Oil level Indicator: An indicator, that lets the operator know when the re-filling of the oil needs to take place. Pressure Gauges: A gauge that displays the pressure at which the oil is being supplied to the machine

- 20. 20 Operation: Hydraulic power uses pressurized fluids to run machinery. Hydraulic power packs provide hydraulic power to a valve in another machine Hydraulic power packs typically offer a choice of valve connections, allowing users to connect them to a control valve or valves to power a variety of machines. The power pack supplies hydraulic power through a control valve to run another machine. During normal operation, the hydraulic pack is designed to operate on demand in parallel with the system pump associated with the control valve(s). When product is required through the control valves, other presets signal the HPP to turn on and actuate the control valves. When the complete volume has been delivered, the control valve is closed and HPP is turned off. This reduces the run time of the system, which reduces wear and power consumption. Maintenance: Hydraulic power packs need regular maintenance to extend their life and to allow safe operation. Maintenance includes checking the tubing for dents, cracks or other problems, changing the hydraulic fluid and checking the reservoir for rust or corrosion. The points which were inspected in the Hydraulic Pack were: Condition of Breather cap Condition of Oil filter Oil Level Pressure Gauge Reading Pipe Leakage Overall condition of Hydraulic Pack The Inspection was then carried out for: Gear Box Oil level Presence of Asset code

- 23. 23 TPM (Total productive maintenance) In industry, total productive maintenance (TPM) is a system of maintaining and improving the integrity of production and quality systems through the machines, equipment, processes, and employees that add business value to an organization. TPM focuses on keeping all equipment in top working condition to avoid breakdowns and delays in manufacturing processes. PROCESSOF DOING TPM ON MACHINE During TPM several TPM tags were hanged on machine to describe the fault. The defect is note down on the tag and then hanged on that defective part. During TPM tagging we cover almost every defect either it is very small. Then the maintenance team rectify the defect as soon as possible. On the tag we write down the name of machine , location of defect on the machine, date of detection of defect, name of manager who detected the defect , and the description of defect. Machine before and after tagging of TPM Fig 11: Tag usedfor TPM

- 24. 24 Objective of TPM The main objective of TPM is to increase the Overall Equipment Effectiveness of plant equipment. TPM addresses the causes for accelerated deterioration while creating the correct environment between operators and equipment to create ownership. The objective finally is to identify then prioritize and eliminate the causes of the losses. This is done by self-managing teams that problem solve. Employing consultants to create this culture is common practice. The eight pillars of TPM are mostly focused on proactive and preventive techniques for improving equipment reliability: Focused Improvement Autonomous Maintenance Planned Maintenance Quality management Development management tool Management Training and Education Safety Health Environment

- 25. 25 CONCLUSION Its give me better honour and privilege to conclude the Project report on “STUDY OF TIMING GEARS AND INSPECTION OF HYDRAULIC PACKS VIA TPM ” has been presented in a very concise and lucid manner i indeed have given commitment to the development of my project. The aim STUDY OF TIMING GEARS AND INSPECTION OF HYDRAULIC PACKS VIA TPM is to get knowledge of all process occurs in this industry. This project help me out to get a lot of information not only the processes occur in this line but also different fields like inspection and quality control unit and it also tell me the human relationship which is needed in Between managers, team leaders and employ of the company. It also help me to get knowledge about the tools and there different-different properties and types. Some new things which i learned from this company are Use of different –different gauges. How to inspect the job after each and every inspection How to manage the machine if there is any problem arises in the machine Tools specification and its inserts characteristics. How to manage the task in the given interval of time.

- 26. 26 REFERENCE When we work on any project we need some reference so during my project I take the references of the following: 1. Mr.SUNIL SANDHU (COMPONENT PLANT) 2. MR.VISHAL (COMPONENT PLANT) 3. ER.RISHI MISHRA (GEAR TESTING LAB) 4. DATA FROM COMPANY 5. MANF. ENGG. (WRITER –DR.BS RAGHUWANSHI) 6. MACHINE DESIGN (PC SHARMA) 7. CHAPTER-GEAR PROFILES

- 27. 27 SITE MAP OF EXCORTS LIMITED COMPONENT PLANT