Welding Inspector Mohammad Taher .docx

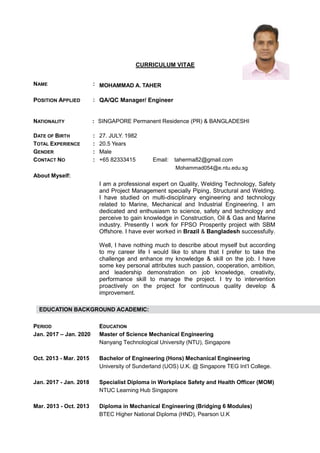

- 1. CURRICULUM VITAE NAME : MOHAMMAD A. TAHER POSITION APPLIED : QA/QC Manager/ Engineer NATIONALITY : SINGAPORE Permanent Residence (PR) & BANGLADESHI DATE OF BIRTH : 27. JULY. 1982 TOTAL EXPERIENCE : 20.5 Years GENDER : Male CONTACT NO : +65 82333415 Email: taherma82@gmail.com Mohammad054@e.ntu.edu.sg About Myself: I am a professional expert on Quality, Welding Technology, Safety and Project Management specially Piping, Structural and Welding. I have studied on multi-disciplinary engineering and technology related to Marine, Mechanical and Industrial Engineering. I am dedicated and enthusiasm to science, safety and technology and perceive to gain knowledge in Construction, Oil & Gas and Marine industry. Presently I work for FPSO Prosperity project with SBM Offshore. I have ever worked in Brazil & Bangladesh successfully. Well, I have nothing much to describe about myself but according to my career life I would like to share that I prefer to take the challenge and enhance my knowledge & skill on the job. I have some key personal attributes such passion, cooperation, ambition, and leadership demonstration on job knowledge, creativity, performance skill to manage the project. I try to intervention proactively on the project for continuous quality develop & improvement. EDUCATION BACKGROUND ACADEMIC: PERIOD EDUCATION Jan. 2017 – Jan. 2020 Master of Science Mechanical Engineering Nanyang Technological University (NTU), Singapore Oct. 2013 - Mar. 2015 Bachelor of Engineering (Hons) Mechanical Engineering University of Sunderland (UOS) U.K. @ Singapore TEG Int’l College. Jan. 2017 - Jan. 2018 Specialist Diploma in Workplace Safety and Health Officer (MOM) NTUC Learning Hub Singapore Mar. 2013 - Oct. 2013 Diploma in Mechanical Engineering (Bridging 6 Modules) BTEC Higher National Diploma (HND), Pearson U.K

- 2. 2 Apr. 2010 - Nov. 2011 Advance Diploma in Industrial Engineering & Management NGEE ANN Polytechnic, Singapore Aug. 1998 - Jul. 2001 Diploma in Marine Engineering Bangladesh Institute of Marine Technology, Bangladesh Apr. 1997 - May. 1999 Higher Secondary Certificate (HSC) ‘A’ level Equivalent R.K.Chowdhary Degree College, Bangladesh Jan. 1992 - Mar. 1997 Secondary School Certificate (SSC) ‘O’ level Equivalent Bawany Adarsha Biddyalaya, Bangladesh PROFECIENCY CERTIFICATES WELDING INSPECTION & TECHNOLOGY 1. Welding Inspector CSWIP 3.1 (Level 2) : Expiry 09 July 2023 2. Snr. Welding Inspector CSWIP 3.2.2 (Level 3): after 10 years Renewal in progress) 3. ASNT level II (RT, UT, MT & PT) (Expiry June 2024) 4. IRCA Certified Auditor/ LEAD Auditor ISO 9001:2008 5. Material Test (Ferrite Number) on SS Steel 6. WSQ Perform Welding Inspection, Singapore TRAINING WORKPLACE SAFETY, HEALTH, TECHNOLOGY MANAGEMENT COURSE PERIOD TRAINING DESCRIPTION July.2021 – Apr.2022 Advance Certificate in Learning and Performance (ACLP) Institute of Adult Learning, Singapore May.2021 – May.2021 WSQ Assess Shipyard Safety for Hot Work Assessor Vision Global Engineering & Safety Services Pte Ltd, Singapore Aug. 2020 - Sep. 2020 Data Science: 1/5 Crafting Data Science Problem statements, 2/5 Identifying & Categorizing data 3/5 Exploring & Summarising Data 4/5 Communicating effectively with Data Visualization 5/5 Introduction of Machine Learning Nanyang Technological University, Singapore May. 2018 - May. 2018 Perform Work in Confined Space Operation NTUC Learning Hub, Singapore Aug. 2016 - Aug. 2016 Shipyard Supervisor Safety Course (SSSC) Safety Connect, Singapore May. 2011 - May 2011 Building Construction Supervisor Safety (BCSS) Absolute Kinetics Consultancy, Singapore

- 3. 3 Oct. 2016 – Oct. 2016 Basic Concept in Construction Productivity Enhancement Building Construction Authority, Singapore Dec. 2009 - Dec. 2009 Oil/Petrochemical Industry Safety Course for Supervisor (OPSC) NTUC Learning Hub, Singapore Mar. 2009 - Mar. 2009 Exxon Mobil Leadership in Safety Workshop 100, ExxonMobil, Chemical Plant, Singapore Sep. 2009 - Sep. 2009 Safety Instruction for Supervisor (Manhole) NTUC Learning Hub, Singapore Mar. 2008 - Mar. 2008 Construction Safety Orientation Course NTUC Learning Hub, Singapore Apr. 2003 - Apr. 2003 Fire Prevention & Fire Fighting Oct. 2002 - Oct. 2002 Elementary First Aids Singapore Polytechnic (Maritime) (STCW Code) WORK EXPERIENCE NOV. 2019 – TILL NOW SBM OFFSHORE EXXONMOBIL LIZA UNITY 2 FPSO (SAILED) & PROSPERITY FPSO IS RUNNING QUALITY VERIFIER SITE LEAD ENGINEER (PROJECT & WELDING TECHNOLOGY) Project Brief FPSO Construction Project Piping, Structural Fabrication, Integration & Completion, New built process modules, Flare tower, Riser & Umbilical Balcony and architectural works. Roles & Responsibilities : Study & Review the FPSO construction Project specification, Project Quality Plan, Project Requirements and project management strategy process including quality and safety. Demonstration the contractor quality team, production tool box meeting, quality walk and implement Material & Corrosion Protection Piping Fabrication, Welding and Examination Supporting Specification on the job. Review piping, & mechanical procedures and inspection and test plans (ITP) raised NCR and issues IN, yellow green card as part of quality management. Review and approval the welders list, validity and pass number as per project and code requirements. Surveillance the overall module KO drum, Chemical process and laydown platform fabrication on primary, superstructure at workshop with FCAW, SAW and SMAW process. Verify the WPS, in process welding for Inconel 625, APL 5L X52, X65, S31803, S32750 SDSS, SS316L, Cu-Ni, CRA piping welding integrity, and purging, shielding, interpass temperature for various process Inspection skids fabrication, valve installation overall piping and

- 4. 4 mechanical related job. Review the piping test pack, ECOM used for data entry and approved ITRs for piping test pack as per mechanical completion, Witness mechanical test for PQR at laboratories. Achievements : Facing the challenging, improved lesson learn, till now project quality and safety rules are in place and continual achievement. JUN. 2019 - SEP. 2019 SB RENOVATION & CONSTRUCTION PTE LTD CONSTRUCTION PROJECT, SINGAPORE SNR. INSPECTOR (WELDING, M&E) Project Brief : Laying the Potable water for domestic and Industrial CS & CRA Pipeline size 24” Sch 80, install the pump station. Roles & Responsibilities : Study the plant 2D, 3D and Isometric Piping layout drawing and conduct the meeting with site personnel for execution and implementation for chill water system, utilities, fresh water, fire water system fabrication and erection at site Review the Quality plan for piping, structural and mechanical equipment installation. Review and endorse the RT films and reports. Verify the site mechanical Pump Installation, Pump alignment with dial gauge and keeping the pre- commissioning records and coordinate clients site engineer. Project progress with High standard Quality and excellence Safety. Achievements : Project Progress with high standard of Quality Control and Safety Excellent. RT Success rate is high. SEP. 2017 - APR. 2019 WOODSIDE ENERGY LTD (GLOBAL SCS PTY LTD, AUSTRALIA) FPSO NGUJIMA YIN (GED) AND SUBSEA PIPELINE SNR. WELDING AND PIPING INSPECTOR Project Brief : Modification and Upgrading FPSO vessel installation of new customised water flood (CWF) module, turret risers and power and control module; as well as modification of swivel system, marine and topside related Piping, with CS, LTCS & CRA. Roles & Responsibilities : Study the FPSO construction Project spec, Project Quality Plan, Project Requirements and project management strategy. Review for contractors proposed pWPS, witness for PQR coupon welding, review the WPS, Welder list summary and approval as per ASME IX, B31.3 and EN ISO 15609-1, control the TDRQ database, attend for quality progress meeting with Keppel Quality team Review the NDT procedures, NDT equipment calibration validity, Inspector list, technician list, PWHT, Leak test, Welding and fabrication procedure, Tank Gauging, materials receiving procedure

- 5. 5 and attend the Pre-Inspection Meeting for subcon prior to fabrication Witness for Mechanical Testing at laboratory i.e. Tensile test, Charpy V-notch, Bend, CTOD Hardness test and G48 corrosion test (for duplex & super duplex piping) including Ferrite test as per Norsok and ASME code. In process monitoring for Duplex piping 22% Cr, (UNS-S31803) Super Duplex 25% Cr (UNS-S32750), API 5L, X52, X65, ASTM A333 LTCS, ASTM A106 B, A105, A350, CS Product Specifications Levels (PSL) piping fabrication fit-up, welding, monitoring with SMAW, SAW, GTAW process, leadership and demonstrate quality control at site. Demonstrate and Summaries the site quality issues as part of Quality Management through Green and Red cards, NCR, QDR, IN and understating the meeting white board matrix for short- and long-term concern strip management system Coordinate and advise the co-employee inspector in the WEL department and solve the technical issues together with Project Manager and superintended. Direct report to WEL Quality Manager for overall progress of the project. Update the HSEQ dashboard Review Piping NDT reports, RT films, inspection piping fit-up, visual inspection and signed the reports, Tracking the quality lesson learnt and safety HAZrep for the projects. Review and close out MDR Piping leak test pack review and approval, confirm the test ends, update the P& ID drawing according to ISO drawing, witness of the test, reinstatement as per test package ITR. Demonstrate to piping supervisor for piping line check, punch list close out prior to approve the piping test packs Structural Top side Module, Column, Crane Column, Bearing, Stool, Turret swivel structure, Marine tank, shell plate installation platform fabrication and inspection with Keppel. The structural fabrication complies with standard AWS D1.1, D10.10, IACS and LRS standard To make sure all materials, including weld consumables are to be approved by the Classification Society as per the approved construction drawings and meet the respective IACS, All materials used should be manufactured at a works approved by the Classification Society (LRS) for the type and grade supplied as per WPS. Achievements : Best Quality provides for the project delivery on time with having great challenging job Nov. 2015- May. 2016 WOODSIDE ENERGY LTD (INTERTEK INDUSTRY SERVICE) FPSO OKHA PROJECT SNR. INSPECTOR (PIPING & WELDING TECHNOLOGY) Project Brief : Modification and Upgrading FPSO vessel installation of new Piping CRA SDSS for Seawater system. Turret Gas line newly installed

- 6. 6 Roles & Responsibilities : Study the construction drawing, Piping ISO drawing, update The spread sheet, register welder list, WPS and monitoring the daily progress and report to the QA manager of WEL. Attended the Quality and Productivity meeting with the main Con Sembawang project team. Review the Quality plan for piping, Support, hull structural and mechanical equipment installation. Demonstrate the WPS approval, WQT approval, Surveillance for the piping NDT request as per weld map. Review the Radiography Test films & report and witness the Dye Penetrant (PT), MPI & UT test Daily inspection for Piping fit-up, nozzle, flange managements, spools alignments, support fit-up as per ISO drawing. Daily attend and monitoring the in-process piping welding, heat input monitoring record sheet verification, right consumables for the right job. Surveillance and verify the approved welders are at workshop and on board. Attend with Sembcorp QC for Piping line check as per test pack, update the P&ID, redline marking, confirm the end point for the hydrotesting, Hi-Lo point and number of test gauges to be used and confirm the calibrated test gauge certificates. Close the “A” punch list prior the hydrotest. “B” punch closed at re-instatement. To confirm as per spec typical structural butt weld plate edge preparation, 2r radius (manual and semi-automatic welding), and control the quality for all the major remedial work is subject to reporting by shipbuilder to the Classification Society for approval in accordance with their work instruction for new building modules, tanks Daily update & track the record and direct report to the woodside QA/QC lead. Review the inspection report, endorsed and surveillance the MDR filling. Review the final MDR and keep records during delivery the project. Achievements : Successfully Completion the Project on time delivery. WEL testify as the best Quality Works achieved on the project. JAN. 2013 - SEP. 2015 DNV-GL (GL NOBLE DENTOL OIL & GAS) PROJECTS: JACK UP RIG DRILLER OFFSHORE B CLASS (B337, B338 FOR CP LATINA, B340 (UMW NAGA 5 AND NAGE 8), B349, B350 FOR PEMEX, B372 & 372 (FECON #1, #2), B339, B351, B352 (ARAB DRILLING) MECHANICAL/ PIPING (WELDING) INSPECTOR Project Brief : New Construction Offshore Rig Driller with high pressure Piping & tubing size 6”, 8” x 42 to 45 mm thk wit cladding. and other marine system Piping installation & Machinery Equip.

- 7. 7 Roles & Responsibilities : Attend with joint inspection for Vendor supply equipment with Procurement Quality Plan. Project planning. monitoring, execute, and ensure project progress ahead schedule through Gantt chart. Attend the Piping Fabrication fit-up, welding, inspection, testing and reinstatement i.e. high-pressure mud line Piping (Hydrotest pressure max. 22000 Psi), tubing, suction line, stand pipe manifold, low pressure piping i.e. Fuel oil, fire water, air instrument system, compressed air system, lube oil system and fresh water piping, Foam & firefighting, Brain system Mostly used API 16D for well control, API 16 C for Manifold and API RP53, RP 64 for Diverter. Review the piping welding RT reports and films, UT, MPI & PR reports for the all system Review and verified construction drawing such as VCD, GA, P&ID, ISO under customers approved supplier list. To check all the certificates, Equipment physical condition such as JIS check sheet as per Projects specification or VCD. The inspection covers the Mechanical Valve, Diverter, Oilfield Equipment etc. Prepare the Quality Observation report, Non-Conformity Reports & Punch list if the items not comply the specification Attended weekly quality & production meeting, surveillance (BOP), shale shaker, rotary table, turntable VCD, endurance testing monitoring for the process machinery system. surveillance the derrick hydraulic system equipment with NOV technician, Jack up leg as well endurance test for the ship. Attend Mechanical Pump installation, Alignment, coupling face levelness, seat seam levelness and pre-commissioning for the system, Inspection for flowmeter, heater, filters, pressure gauge, heat transmission thermometer, sensors etc Achievements : Project Completion Continually 9 projects successful in record and best championship. JUL. 2012 - MAR. 2013 SHAWSTONE AND WEBSTER ASIA, INC (TECHNIP) EXXONMOBIL SPT OLEFINS RECOVERY PROJECT, SINGAPORE

- 8. 8 QC PIPING INSPECTOR Project Brief : Hydrocarbon Plant Piping Installation in ExxonMobil Chemical and Oil refinery Projects. Roles & Responsibilities : Review the daily basis piping test packages for pre-test and post-test. Review the welder performance and NDT completion as per line class and Shawstone, Exxonmobils GP’s requirement. Pre-Commissioning and daily site basis Piping inspection, surveillance, line walk-down, raising and close out the punch and outstanding piping job as per P&ID. To check and make sure before and after test all the Welding, NDT, PMI, PWHT and erected materials MTR completed, and reported in accordance with the ASME & ASTM code. Plan, organize, coordinate and monitoring and Leading subcontractor QC and give guidance to perform the job as accordingly Daily completed package updated list report to direct EM QA/QC Lead and Shawstone QA/QC Manager. Attend the QC internal audit with ExxonMobil and weekly progress meeting. Attend inspection for pre commissioning activities, flange management, such as flange final box-up, re-instatement according code ASME 16.5 & 40 and coordinate with ExxonMobil Representative at site. Witness for Air leak test, Tightness test and final box-up, prepare rejection report for the damage flanges as per PCC1. Achievements : Job completed with high standard quality and achieve goal point. JUL. 2008 - JUL 2012 FOSTER WHEELER ASIA PACIFIC LTD & GAMMON CONST. LANXESS BTR SINGAPORE PROJECT EXXON MOBIL SPT IN REFINERY PROJECT, JURONG ISLAND WELDING INSPECTOR (QA/QC) Project Brief : Pipeline laying in Oil terminals to Chemical Plants and Sub. marine line laying from Jurong Island to EM shipyard road 600 km length various pipe size. Underground pipe for the Cooling system size 56” dia x 22 mm thickness Roles & Responsibilities : Daily Welding visual inspection for Carbon Steel, Stainless Steel 316L/304L, 22% Cr Duplex Stainless Steel, and 25% Cr Super Duplex Stainless Steel, and 5%-9% CrNi steel for Ethylene (LEG), Methane (LNG) service line. Witness for PQR for the Materials such as Hastelloy ASTM B622 (P No. 43) to A 106 Gr B (P No.1), P10H,

- 9. 9 ASTM B729 (UNS-N08020) beside having experience SA 790 UNS S31803 (P10H) and 25% Cr Super Duplex Stainless Steel UNS S32550 and ASTM A790 UNS S32750 with the Welding process GTAW. Experience with Dissimilar welding i.e SS to CS, Duplex to CS. Witness for PQR for the Materials such as Hastelloy ASTM B622 (P No. 43) to A 106 Gr B (P No.1), Duplex Stainless-Steel ASTM B729 (UNS-N08020) beside having experience SA 790 UNS S31803 (P10H) and 25% Cr Super Duplex Stainless Steel UNS S32550 and ASTM A790 UNS S32750 with the welding process GTAW. Experience with Dissimilar welding i.e SS to CS, Duplex to CS. Daily basis inspection on Piping oxygen line, Crude oil line, Utilities line, Sea water / fire water line, Cement line, Impact tested Carbon steel, Acid service line and other lines welding process for the materials UNS alloys NO4400 ('Monel 400') UNS alloys NO6600 ('Inconel 600') UNS alloys N10276 ('Hastelloy C-276') UNS alloys NO8020 (‘Alloy 20’) with the process of GTAW, SAW & SMAW, as per WPS. The requirements shall contain full details of backing gas conditions including gas composition, flowrate, closing type and maximum oxygen content in backing gas closure Review the Piping and tankages RT films, endorsed the NDT reports, coordinate with sub con QC for in process fabrication and erection activities. Having Familiarization with PAUT reports review, and computer operation for AUT A, B,C scan view reports. Inspection for Shut-down Turnaround SRU-1 & 2, Oil Tankage, LNG tank with low temperature storage as per API standard 620, API 650 with materials of Welding of 5 %, 9 % nickel steels and Austenitic CrNi steels Inspection and surveillance for 6 no’s of Subsea Line and piping welding, RT films review and workman ship in ExxonMobil SPT project in Jurong Island Channel. Achievements : Completion and Best Leadership on the project total management. SEP. 2006 - JUN. 2008 HIAP SENG ENGINEERING PTE LTD SHELL HOUDINI ECC SINGAPORE PROJECT NWS LNG PHASE V EXPANSION (WOODSIDE ENERGY LTD)

- 10. 10 QC INSPECTOR (WELDING /PIPING) Project Brief : CS, CRA Piping Fabrication 30000 dia inch of LNG & Chemical Gas plant. Inspection and leadership for fabrication. Roles & Responsibilities : Process control and monitoring, inspection for piping and welding With GTAW and SMAW, FCAW, SAW as per the project Specification, international Standards. Worked and Dealt with ASME B31.3, B31.1, ASME SEC VIII, ASME SEC V, ASME SEC IX, ISO 9001, AWS D1.1, API 1104, and various standards. Prepare PQR, Welder performance report Welding Inspection for Piping fabrication. Dimension control for piping spools, fit up inspection, alignment, orientation as per approved Isometric drawing. Any discrepancy on the fabrication has prepare for quality deficiency records to control the production quality. All the piping joints fit-up record, welding records, NDT Records all weld and materials traceability records preparation and submission to QC lead. Piping materials for CS welding, 316L, 304L materials welding, purging control, and random monitoring sheet control as per Project Quality Plan (PQP). Achievements : Successfully Piping Fabrication, Orientation maintains with the best Quality Standards. JUL. 2001 - AUG. 2006 JURONG SHIPYARD PTE LTD (SEMBCORP) & MAUA-JURONG (BRAZIL) FPSO P-54 (PRTROBRAS_BRAZIL) FPSO CONVERSION BRIGHT JEWEL FPSO CONVERSION RONCADOR FIELD DEVELOPMENT FPSO CONVERSION CNR BAOBAB FIELD DEVELOP. (T.T. NINA) FSO CONVERSION CHAD OFFSHORE FACILITIES (EXXON MOBIL) DEVELOPMENT RIG DRILLER GLOBAL SANTAFE I & II QA/QC INSPECTOR (PROJECT) Project Brief : Marine Industry challenging project Newcon, development and repair vessel, piping modification, installation in various system and size diameter. Demonstration and inspection the project. Roles & Responsibilities : Attend daily quality & safety meeting. Update the database for NDT test report and WQR. Attend Inspection in fabrication shop to check welding on piping & hull structure. Daily basis inspection with client inspector on board and Report to Surveyor, Superintend and JSL QA/QC Manager Achievements : World class new technology project Successfully Delivery with customer satisfaction and maintain the project.

- 11. 11 LANGUAGE FLUENCY MOTHER TONE : BENGALI (BANGLA VASHA) SECOND : ENGLISH References Persons from Woodside & SBM Offshore: 1. Mr. Jamie Patten (FPSO GED Project Delivery Manager) Woodside Energy Ltd Email: Jamie.Patten@woodside.com.au 2. Mr. Glenn Foster (FPSO GED Project Snr. Quality Manager) Woodside Energy Ltd Email: Glenn.Foster@woodside.com.au 3. Mr. Franck Fougeron (FPSO LIZA Unity Project Snr. Quality Verifier Manager) SBM Offshore. Email: franck.fougeron@sbmoffshore.com