Designing Ceramic/Polymer Composites for 3D Printing

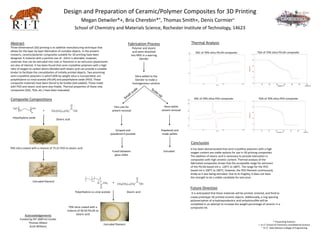

- 1. Design and Preparation of Ceramic/Polymer Composites for 3D Printing Megan Detwiler*+, Bria Cherebin*°, Thomas Smith+, Denis Cormier° School of Chemistry and Materials Science, Rochester Institute of Technology, 14623 Abstract Three-dimensional (3D) printing is an additive manufacturing technique that allows for the layer by layer fabrication of complex objects. In the present research, ceramic/polymer composites suitable for 3D printing have been designed. A material with a particle size of ̴10nm is desirable, however, materials that can be extruded into rods or filaments in an extrusion plastometer are also of interest. It has been found that semi-crystalline polymers with a high ratio of oxygen to carbon atoms blended with stearic acid can provide a suitable binder to facilitate the consolidation of initially printed objects. Two promising semi-crystalline polymers in which 60% by weight silica is incorporated, are polyethylene-co-vinyl-acetate (PEcVA) and polyethylene oxide (PEO). These composite materials have been found to be fusible (extrudable). Those made with PEO and stearic acid were also friable. Thermal properties of these new composites (DSC, TGA, etc.) have been evaluated. * Presenting Authors + R.I.T. School of Chemistry and Material Science ° R.I.T. Kate Gleason College of Engineering Acknowledgements Funded by RIT AMPrint Center Thomas Allston Scott Williams Silica added to the blender to make a homogeneous solution Extruded Resin kettle solvent removal Powdered and made pellets Polymer and stearic acid were dissolved into MEK in a warring blender Fabrication Process Stearic acid Polyethylene oxide Polyethylene-co-vinyl acetate Film cast for solvent removal Scraped and powdered if possible Fused between glass slides + Extruded filament 70% silica coated with a mixture of 75:25 PEO to stearic acid Extruded filament Thermal Analysis Conclusion DSC of 70% silica PEcVA composite TGA of 70% silica PEcVA composite DSC of 70% silica PEO composite TGA of 70% silica PEO composite Stearic acid + + Future Direction It is anticipated that these materials will be printed, sintered, and fired to create prototype 3D printed ceramic objects. Additionally, a ring opening polymerization of α-hydroxyisobutiric acid anhydrosulfite will be completed in an attempt to increase the weight percentage of ceramic in a composite ink. It has been demonstrated that semi-crystilline polymers with a high oxygen content are viable options for use in 3D printing composites. The addition of stearic acid is necessary to provide lubrication in composites with high ceramic content. Thermal analysis of the fabricated composites shows that the acceptable range for extrusion of the PEcVA-based ink is 120°C to 180°C. The range for the PEO- based ink is 100°C to 180°C; however, the PEO filament continuously broke as it was being extruded. Due to its fragility, it does not have the strength to be a viable candidate for extrusion. Composite Compositions 70% silica coated with a mixture of 50:50 PEcVA to stearic acid