Automobile - CNG in Engines & Vehicles

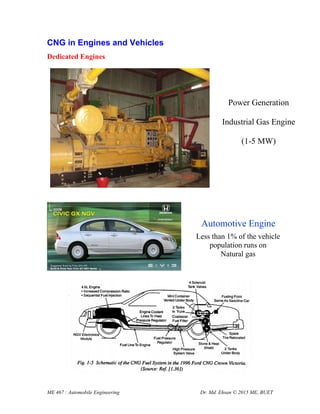

- 1. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET CNG in Engines and Vehicles Dedicated Engines Automotive Engine Less than 1% of the vehicle population runs on Natural gas Power Generation Industrial Gas Engine (1-5 MW)

- 2. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Changes expected in a Dedicated NGV Increase in engine compression ratio, to use higher SIT of NG. Stronger engine construction to withstand higher compression ratio. NG based ECU, programmed to be compatible with parameters like – NG spark advance, Intake manifold vacuum, Throttle position requirement. Mixing chamber (for Carburetion) design would be in accordance to gaseous fuels, relaxing some requirements. Cooling capacity corrected for higher exhaust temperature. Exhaust valve and other component life designed for the elevated temperature. For NGVs chassis design may be modified to accommodate safe and space efficient placement of CNG cylinders. AFratio biasing made compatible with the catalytic converter used. Fuel system component life designed for dry gaseous fuel.

- 3. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Retrofitted Engines Bi-Fuel Engines : Only one fuel runs the engine at a time Example – Petrol/CNG, Petrol/Alcohol, Petrol/LPG, Diesel/Bio diesel Dual Fuel Engines : Both fuels run the engine at a time Example – Diesel+CNG, Diesel+LPG, Diesel+Biogas Retrofitting SI Engines Gas Fumigation System Mixes gas with the intake manifold air at sub-atmospheric pressure (using intake suction) Gas Injection System Mixes gas with the intake manifold air at above-atmospheric pressure (using pressurized gas injection). This could be of SPFI or MPFI type Both the systems may be Open-loop or Closed-loop in operation Retrofitting CI Engines : Turning it in to SI engine • Changing the Compression ratio • Adding CNG/NG Fuel system • Removing Diesel Fuel System • Adding Spark Ignition System

- 4. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Automotive CNG kit for Carburetor System Automotive CNG kit for EFI System

- 5. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Diesel Engine converted to run with CNG only.

- 6. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Dual Fuel Engines : Some diesel used to initiate ignition Major part of diesel replaced by another fuel 640 kVA MAN Diesel-NG Dual Fuel Generator < Single Cylinder Diesel-NG Dual Fuel Engine (16 hp, 2200 rpm)

- 7. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET CNG Engine Technology CNG Conversion Components A typical standard CNG conversion (retrofit) system essentially consists of the following components, the locations are indicated in figure-1. 1. CNG Storage Cylinder 2. Fuel Selector Switch 3. High Pressure Piping 4. Refueling Valve 5. Pressure Regulator 6. Gas-Air mixing Chamber 7. Petrol Solenoid Valve 8. Gas Vapor Enclosure Automotive CNG kit for Carburetor System Figure-1 : CNG conversion components of a vehicle

- 8. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Pressure Gauge Solenoid Valve Pressure Regulator Filling Receptacle NZ type Spark Timing Advance LP Tubing Gas-Air Mixer Indicator Resistance Radiator Vacuum Diaphragm for AC Air Cleaner Flow Adjustment Valve Main Components of a CNG Conversion System HP Tubing

- 9. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET A typical automotive CNG conversion (retrofit) system consists of the following components: 1. The Cylinder is used to store CNG at a working pressure of 200 bar. It is fitted with a shut-off valve and a safety burst disc. Cylinders may be of seamless steel structure or reinforced carbon fiber composite. 50,60,90 water liter size cylinders are commonly used. At a pressure of 200 bar and ambient temperature CNG is compressed to about 3.7 times of equivalent petrol volume. Due to the cylindrical shape and wall thickness the packing efficiency is poor and the real car space blocked by the cylinders is much more. The shut-off valve with the cylinder may have overflow limiter facilities built-in. 2. The Selector Switch is fitted at the dash board, enabling the driver to choose either the CNG mode or the petrol mode of operation. The electronics built in this unit also ensures safety by switching off the gas solenoid whenever the engine is switched off. It also indicates the quantity of CNG available in the cylinder. 3. The High Pressure Pipe connects the refueling valve to the CNG Cylinder and Pressure Regulator. 4. The Refueling Valve is used to refuel the CNG cylinder. 5. The Pressure Regulator has a solenoid valve to shut-off gas supply to the engine. The CNG stored at a high pressure in the cylinder, is reduced to just below atmospheric pressure by this unit. This negative pressure is also a safety feature that will not allow gas to pass through when the engine is not running. Generally this is provided with a gas filter element. 6. The Gas- Air Mixer is a unique component, specially designed to suit each engine model. It precisely meters gas fed into the engine. 7. Petrol Solenoid valve is used to cut off petrol supply to the engine when it is run on CNG. 8. Fitted near the cylinder, the Vapour bag/enclosure is used to enclose the cylinder valve and the pipes connecting it and is vented out of the car. In addition to these basic components the conversion system may have few more components, generally if the engine is equipped electronic fuel injection system and electronic control unit (ECU). These include the following:

- 10. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Selector Switch Different Types of Gas-Air Mixers Spark Timing Advance Processor (STAP/TAP) : The slower flame propagation speed in methane-air mixture make it necessary to increase the spark advance for CNG operation of a petrol engine. This unit allows optional spark advances (eg. additional 6,9,12,15° BTDC), generally during accelerating conditions. The processor modifies the spark advance signal to the electronic ignition system accordingly. Use of this improves the peak power and acceleration performance of the vehicle running on CNG, while retaining the performance with petrol. Emulator/Simulator : The EFI injectors are generally kept non-functional at CNG operation. On the other hand, in some engines feedback signals from the fuel injectors operation is fed back to the electronic control units(ECU). Under CNG operation the emulator simulates dummy feedback signals to the ECU, maintaining its normal operation as with petrol. This component may not be necessary for all models of EFI engines.

- 11. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Filling Charge Valve -Type_NZ TRD with Burst Disk CNG Safety Devices Burst Disc : Prevents excessive pressure to enter the cylinder during refilling. PRD : Pressure Release Device, Relives excessive pressure in the cylinder TRD : Thermally Activated Release Device, Relives excessive pressure in cylinder Excess Flow Valve : Prevents excessive flow of gas from cylinder

- 12. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Conventional Pressure Regulator Regulator type: 3 stages with electronic starting device and idling at negative prs. Heating: Engine cooling circuit liquid Test pressure: 300 bar Inlet pressure: 220 bar First stage adjustment pressure: 4 bar Second stage adjustment pressure: 1.5 bar Power supply: 12 V DC High-pressure solenoid valve coil power capacity: 20W Automotive device which reduces and stabilizes the natural gas pressure, in order to properly feed the engine. The three reduction stages provide stability at both high and low pressures. The pressure regulator is equipped with a pressure relief valve and a low pressure solenoid valve fitted upstream of the third stage. The necessary operating heat is provided by a connection with the engine coolant system. The engine idling gas flow is activated through the gas pipe main flow as a result of the negative pressure generated by the engine. These may be equipped with an electronic starting device with a built-in safety system which closes the gas solenoid valve when the engine stops. Three Stage Pressure Reduction

- 13. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Types of CNG Cylinders • There are 4 basic types of tank designs. • Which design to use depends on need to reduce weight and cost. • All designs have equivalent safety, as all meet requirements of same standards. • Design type can also determine how a tank may be handled, and how it may be filled. Type 1 - All metal (aluminum or steel (Cr-Mb)) Cheap but heavy Since the 1940’s seamless steel cylinders have been by far the most widely used for storage of CNG on vehicles. The introduction of Italian high-strength lightweight cylinders in the late 1970’s was a very significant step forward in the development of the industry and since then this type of product has been adopted all over the world. Some standards also allow welded steel cylinders, but require a higher safety factor. Aluminium cylinders have also been used for on-board storage of CNG and can provide a lighter weight alternative. Suppliers of Steel CNG containers include - White Martins (Cilbras), Inflex and Faber. Luxfer offers a small range of 7000 series aluminium CNG cylinders.

- 14. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Type 2 - Metal liner reinforced by composite wrap (glass or carbon fiber) around middle (“hoop wrapped”) Liner takes 50% and composite takes 50% of the stress caused by internal pressurization Less heavy, but more cost Type 2 fuel containers have a metal liner and a composite reinforcement on the straight side only; a hoop overwrap. Products on the market steel or aluminium liners and a glass, aramid, or carbon fibre reinforcement. Type 2 cylinders are designed to have a liner with sufficient thickness and strength to contain the service pressure, even without the composite overwrap. They provide a compromise between the low cost of Type 1 cylinders and the lightest weight Type 3 and 4 cylinders. Suppliers of Type 2 containers include - Faber, Mannesmann, and Luxfer. Type 3 - Metal liner reinforced by composite wrap around entire tank (“full wrapped”) Liner takes small amount of the stress Light-weight, but expensive

- 15. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Type 3 CNG cylinders have a seamless metal liner over wound on all surfaces by a composite reinforcement that provides between 75 and 90% of the strength to the vessel. The liner provides the rest of the strength, plus acts as a rigid membrane to hold the gas and provide extra impact resistance to the product. Type 3 cylinders are used in a wide range of applications where weight reduction is important, for example in transit buses and delivery trucks. Type 3 cylinders have also been used on various OEM vehicles such as the Volvo and Volkswagen CNG cars. Suppliers of Type 3 containers include - Luxfer, Dynetek, and Structural Composites.

- 16. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Type 4 - Plastic gas-tight liner reinforced by composite wrap around entire tank (“full wrapped”) Entire strength of tank is composite reinforcement Light-weight, but expensive Type 4 fuel containers have a plastic liner and a full overwrap of carbon fibre or mixed fibre construction. The liners of Type 4 tanks provide no structural strength to the product and act only as a permeation barrier. Although these liners are not gas tight, the rate of permeation has been found acceptable for use with CNG. As a rule Type 4 CNG cylinders are fitted with impact protection on the domes, as the plastic liner does not provide a rigid backing to the composite overwrap. Again, Type 4 cylinders are used where weight is important such as on buses, trucks and OEM vehicles such as the Honda Civic. Suppliers of Type 4 containers include - Quantum, Ullit, Lincoln Composites, and Ragasco. Comparison of Cylinder Types

- 17. ME 467 : Automobile Engineering Dr. Md. Ehsan © 2015 ME, BUET Mandatory for CNG Driven Vehicles (Ref : RPGCL web site) Essential steps for CNG driven vehicles: 1 Vehicles should be converted by RPGCL approved workshops with GOB approved international standard NGV cylinders 2 No NGV cylinder manufactured in Bangladesh & nobody is given the permission for manufacturing NGV cylinders in Bangladesh 3 NGV cylinders should be tested after every 5(five) years of use 4 Unauthorized cylinders like Oxygen cylinders, acetylene cylinders, LPG cylinders or any other cylinders should not be used in CNG driven vehicles 5 Safety instruments like excess flow device, PRD etc & Conversion plate must be attached to the converted vehicles. If any Conversion Workshop does not attach conversion plate, then please inform it to RPGCL. 6 Conversion Certificate from the Workshop after Conversion must be issued 7 Do not receive or deliver CNG to the vehicles at or above 200 barg (3000 psig) pressure 8 Repair works of CNG vehicles should be done by approved CNG workshops 9 No welding work should be done on high pressure pipe line 10 Repair works on CNG driven vehicles should be done after evacuating CNG from the cylinders or removing CNG cylinders from the vehicles 11 CNG vehicles should be checked by approved CNG workshops after every 1000 km run 12 Maintenance works of CNG driven vehicles should be done by trained mechanics (trained by RPGCL or BPI) 13 Government has made the use of `Electrically Operated Solenoid Valve with Cylinder Shut-off Valve’ compulsory for heavy vehicles run on CNG 14 For more information on CNG, please contact to RPGCL. Phone Nos: 8914682, 8917137-221, 01713-018117, 01717-106934