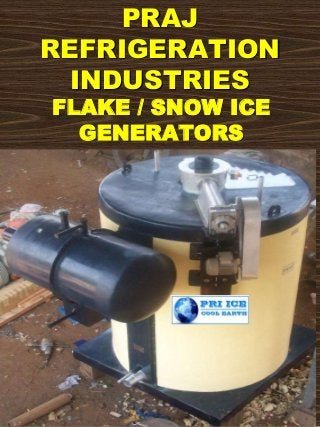

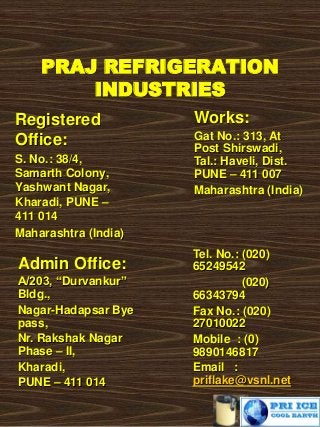

We, “Praj Refrigeration Industries”, have emerged as a vital name in the domain engaged in manufacturing, supplying and exporting Refrigeration Equipment. The range of products offered by us is durable and offers trouble free operation. The products are of international standards and can be availed from us at market leading prices.

Backed by a superior infrastructure and dedicated team of professionals, we are capable to perform mass production. Our fault free range of products is timely delivered to the client`s site. Owing to the quality assurance policies, all our products undergo stringent quality checks by our team of quality experts. State-of-the-art infrastructure along with quality assurance policies has helped to build a valuable client-base which includes the names of ColourTex Industries Limited, Frick India Limited, L&T Limited, Hindustan Uni Lever Ltd, Micro Inks Ltd.

Our managing director, “Mr.Ramdas Lagad” is a man of in depth technical expertise. The effective combination of technical abilities and managerial skills has escalated the success of the firm.

Website : www.prajrefrigerationindustries.com