polyurethane rollers.pdf

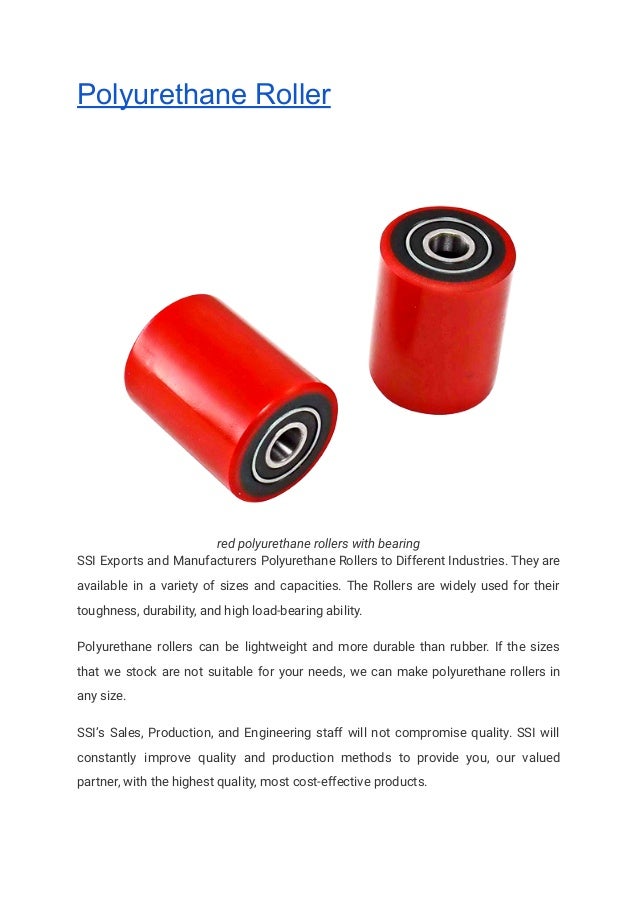

- 1. Polyurethane Roller red polyurethane rollers with bearing SSI Exports and Manufacturers Polyurethane Rollers to Different Industries. They are available in a variety of sizes and capacities. The Rollers are widely used for their toughness, durability, and high load-bearing ability. Polyurethane rollers can be lightweight and more durable than rubber. If the sizes that we stock are not suitable for your needs, we can make polyurethane rollers in any size. SSI’s Sales, Production, and Engineering staff will not compromise quality. SSI will constantly improve quality and production methods to provide you, our valued partner, with the highest quality, most cost-effective products.

- 2. We offer a wide range of polyurethane rollings. High-quality PU Rollers are made from premium-grade polyurethane. The polyurethane rollers are made using high-quality raw materials and advanced technology under the supervision of professionals. This polyurethane roller can be purchased from us at competitive prices and in a short time. SSI Conveyor rollers: These types are common in high-demand manufacturing environments. They are used to move materials and products more efficiently from Point A to Point B. Urethane conveyor belt rolling is made from a chemically-bonded bearing that has been coated with a high-durometer urethane. These custom-cast urethane conveyor belt rolling bearings can be attached to a rack to create a conveyor system. SSI Guide Rollers: Just like a tour guide. Guide rollers make sure things get done the right way. Though they don’t move, these rollers provide support for conveyor systems. SSI Friction Drive Rollers: supply power for conveyor belts and assembly lines. They are often connected to an engine and use friction to generate electricity and momentum. SSI Large Rolls: Larger rollers with a high-quality resin tailored to each application are made at SSI. Large urethane rollers with a 95A hardness coating are available from SSI. However, SSI also offers a complete line of durometers. Our urethane can be modified to improve lubricity and antistatic properties. SSI Convex-coated Rollers: These rollers can be used in various industrial applications. Convex rollers typically have a taper on one-half of their roller. Steel or stainless core can be used for bearing applications, or a bronze bushing might be

- 3. added. Convex rollers can be found on boat trailers and in industrial packaging equipment. SSI Industrial Rollers: These industrial rollers typically measure 3 feet long and have a bearing pressing on one side. The shaft is then coated with a urethane substance to withstand extreme loads. SSI Urethane Rollers: Urethane conveyor rollers are typically made from a steel core coated in polyurethane, commonly used in assembly lines. Urethane conveyor rollers have replaced rubber, plastic, and metal rollers in today’s highly competitive manufacturing environment. Belt drive systems can run longer, with lower maintenance costs and shorter lead times. SSI Polyurethane Idler Rollers: Polyurethane idler rollers are incredibly resistant to abrasion, wear and damage. We can assemble and finish polyurethane idler rollers to your exact specifications. These rollers often last longer than OEM replacements. Urethane Idler Rollers have the best wear and abrasion resistance, and SSI offers a complete line of post-secondary services. We can finish and assemble your urethane idler rollers to your exact specifications. All colors and durometers are available. SSI Urethane V Rollers: Urethane-based v-rollers can be found in many areas, including shipping centers and assembly lines. Urethane v.rollers can absorb impact and return to their original form even after years of abuse, making it the most popular choice for material. SSI Urethane drives rollers: are common in shipping facilities, assembly lines, and industrial equipment. A urethane coating on urethane drive rollers will remove the steel contact and be ideal since urethane will dampen any harsh slamming or loads applied to the roller.

- 4. Our PU coatings are made from the best polymers and unique covers and are highly suitable for different sizes of press rollers. Polyurethane Rollers: The Advantages Polyurethane rubbers like nitrile or neoprene are all part of elastomers. These materials can be used as covers for rollers due to their elastic properties. There are many advantages to polyurethane rollers over rubber rollers, and they are more durable than other types due to their impressive mechanical properties. Here are some benefits of using polyurethane rolling. Product marring: Rubber can leave black marks when it comes in contact with products. Polyurethane does not leave marks on any material, whether infused with pigment or in its natural state. Wet environments: Polyurethane is more effective than rubber when submerged or exposed to wet environments for long periods. Rubber would rot. High friction and dynamic loads can cause rollers to experience high abrasion. In both these cases, polyurethane is superior to natural rubber. Cost and Lead Time The main point to remember about rubber tooling is its high price. These molds can be compressed under high pressure, and they must withstand that pressure without exploding. It will require weeks of work and must harden the metal. Polyurethane can be made much faster if your rollers are processed through an open casting process. These molds are made of aluminum and don’t require hardening. A wide range of physical properties Polyurethane can be tailored to any use. Polyurethane is versatile and can be engineered with different mechanical properties.

- 5. Better durability Polyurethane is versatile and has superior mechanical properties to other rubber types. Polyurethane is a durable material, regardless of its hardness. Its inherent toughness and resilience make the material very resilient. Polyurethane roller covers last longer than rubber rollers. Water and oil resistance Polyurethane can withstand oils and water depending on the polymer system. Rollers subject to wet service or require frequent washing must have water resistance. For hydrocarbon-based solvents and chemicals like inks, oil resistance is necessary. Hardness. Hardness refers to the material’s relative resistance to surface deformation. It is often determined by measuring the depth indentation of the material with a standard indenter or ball. Materials are rated according to how hard they are relative to each other. The Shore Hardness Number determines elastomers’ hardness, and a durometer measures this number. There are 12 Shore Hardness Scales, and each scale has its indenter configuration, profile, and force. Shore A and Shore D are used to measure the hardness of polyurethanes. Shore A measures soft, semi-rigid, and semi-rigid polyurethanes. Shore D measures hard rubbers or rigid polyurethanes. High hardness doesn’t necessarily mean high rigidity or strength. Abrasion Resistance There are two types of abrasion: impingement and sliding. Slide abrasion is when a hard material, such as ceramic or metal, rubs against a softer surface. Impingement abrasion occurs when particles strike the surface and cause erosion.

- 6. Polyurethanes with low friction and high tear strength are suitable for sliding resistance. Polyurethanes that have good resilience can be used for impingement abrasion. Polyurethanes that are resilient can be elastic, allowing the forces of impacting particles to be distributed onto the surface. The suitable composition of the polyurethane rubber can provide abrasion resistance. Polyesters are the most resistant to tear and abrasion among all polyol compounds used in making polyurethane. Tear strength Tear strength refers to the rubber lining’s ability to resist applying tensile force that tends to tear the material and spread the tears throughout the material. The force applied to the material, and the material’s microstructure can affect the rate at which tears are propagated. Sometimes, tear strength can be related to abrasion resistance, and polyurethanes have excellent tear strength and abrasion resistance. Impact Strength. Polyurethanes are resistant to abrasion and have excellent resilience, and they also have good impact strength. Rollers’ polyurethane linings can elastically stretch to absorb impact energy and return to their original form. Fatigue Resistance Because of its flexibility, polyurethane is very resistant to fatigue. Polyurethane can flexibly deform in cyclic conditions and not fail to do so. It is suitable for high-speed applications like printing and milling.

- 7. Low heat dissipation is a problem for polyurethanes in these environments, with significantly thicker linings. The material can be weakened by high heat, which can accelerate creep. Thermal Aging Resistance Thermal aging refers to the gradual degrading of elastomers in high temperatures and low oxygen levels. It causes a loss in strength and elasticity, and this irreversible process determines the material’s operating temperature limits. When formulated with certain compounds, polyurethane has excellent thermal resistance. Polyurethanes typically operate at temperatures between 90 and 100 degrees Celsius, and some formulations are more expensive and can reach 150°C. Friction The coefficient of friction (COF) for polyurethanes tends to be related to their hardness. These properties are in an inverted relationship, and the COF is increasing while the hardness is decreasing. The hardness of polyurethanes can also be easily adjusted by blending to achieve the desired COF. Machinability The property of Machinability can be found in hard polyurethanes, and this property allows polyurethanes can be shaped into precise geometries. It is beneficial for polyurethane rolling wheels, as they need to be machined to achieve the desired profile. Chemical Resistance Polyurethanes’ chemical resistance depends on the polyol used in their polymer systems. Systems based on ether are more resistant to water and suitable for wet applications. Ester-based systems, on the contrary, are more resistant to oils, solvents, and most petroleum compounds.

- 8. Manufacturing Process A simple process is required to make a polyurethane roller. It includes the construction of the core of the roller, balancing, bonding, polyurethane blending, bonding, building, curing, and quality testing. Similar to other types of rubber rollers, the fabrication process is identical. The cover building is the main difference since polyurethane resin comes in liquid form. Processing is simple Polyurethane processing does not require complicated or expensive equipment. The only equipment needed for simple blending operations is a batch mixer, and no heating equipment is necessary. It contrasts with other rubber types that require heating and mastication equipment. Mark products and surfaces with a pen or pencil. Carbon black is often used as a filler or reinforcing component in rubber roller linings. If rolled against a hard surface, they can leave unpleasant marks, especially for applications like finished goods handling or printing. This problem is not present in polyurethane rollers, as they don’t use carbon black. Roller Balancing Dynamic and static two types of imbalance can occur in a roller core. When the roller is allowed to turn freely, static imbalance refers to the roller moving to its heavier side. The dynamic imbalance creates vibration or rocking motion when the roller is rotated at its maximum speed. Dynamic imbalance is usually corrected on polyurethane rollers. A computer-controlled, dynamic balancing system tests the roller for dynamic balance, and it determines where and how much counterweight is needed for proper balance.

- 9. Building and bonding Bonding refers to adhering the rubber covering to the roller core’s surface, and it is accomplished by applying a chemical bonding agent to the roller core’s outer surface. Injection molding and casting are the two main methods of making polyurethane, and both these processes use liquid resins. Casting places the core roller into a mold where the polymer can be transferred or poured. Casting is a cost-effective way to make polyurethane castings, and casting is less costly than injection molding. Injection molding is a less well-known option. Injection molding requires more sophisticated equipment and tools to shape the rollers. why people prefer urethane rolling to steel, rubber, and plastic ones: They last longer: Although it varies by industry, an average rubber roller will last around 1000 hours. Polyurethane rollers can last for approximately 4000 hours before showing signs of age. FDA Approves Them for Food Processing: Rubber and plastic rollers can leave marks on food and leave a residue, and the polyurethane rollers do not leave such marks. They reduce downtime and boost profits: Durable Urethane rollers last for many years. They are also more productive because you don’t need to replace them often. The Polyurethane Rollers Provide Better Traction: Although rubber is soft, it can’t grip smoother materials such as glass and sanded wood. These objects can be grabbed and moved much more quickly with polyurethane, mainly if it is grooved. They are versatile: Polyurethane rollers come in various durometers, ranging from 10A to 75D. Polyurethane is adaptable to make your rollers as brutal or gel-like as a bowling ball.

- 10. They are also easier to produce and cheaper. Thrifty prices Solvent Resistant Vibration Dampening Applications for Food Grade Fire retardant Designed with precision Very high mechanical strength Energy efficient Resistance to high dynamic loads Hydrolytic stability Greater open space availability and lower energy consumption Excellent elastic memory and flexible It can resist oil, corrosion, ozone, and low-temperature radiation. It also cancels out noise during production. Precision & smooth finish Strongly bonded to PU by the metal part. We can make custom sizes and lengths A wide range of colors Many manufacturing processes use polyurethane rollers to perform operations such as:

- 11. FOOD PROCESSING AUTOMOTIVE MANUFACTURING AVIATION MINING PACKAGING PRINTING AGRICULTURE CONSTRUCTION STEEL CUTTING Material Conveying Squeezing Pressing Laminating Feeding Spreading Coating Chemical fiber Grains Milling Wood processing Plastic processing machinery Sewage treatment equipment

- 12. They are used for the production, conversion, transport, and storage of foils/films for food processing, Packaging, & Textile industries, Packaging, Material Handling, Engineering, Cement, Sports, and Leisure industries.