Report

Share

Download to read offline

Recommended

Recommended

T cell convergence refers to the phenomenon whereby antigen-driven selection enriches for T cell receptors (TCRs) having a shared antigen specificity but different amino acid or

nucleotide sequence. T cell recruitment and expansion within the tumor microenvironment (TME) may be directed by responses to tumor neoantigen, suggesting that elevated T

cell convergence could be a general feature of the tumor infiltrating T cell repertoire. Here we use the Ion AmpliSeq™ Immune Repertoire Assay Plus – TCRβ to evaluate evidence

for T cell convergence within melanoma tumor biopsy research samples from a set of 63 subjects plus peripheral blood leukocytes (PBL) from four healthy subjects. We find that the melanoma TME is highly enriched for convergent TCRs compared to healthy donor peripheral blood. We discuss the potential use of TCR convergence as a liquid biopsy compatible predictive biomarker for immunotherapy response.Evidence for antigen-driven TCRβ chain convergence in the melanoma-infiltrati...

Evidence for antigen-driven TCRβ chain convergence in the melanoma-infiltrati...Thermo Fisher Scientific

Overview of IDT nucleic acid products for clinical research and diagnostics.Oligonucleotides for Next Generation Sequencing Research and Clinical Diagnos...

Oligonucleotides for Next Generation Sequencing Research and Clinical Diagnos...Integrated DNA Technologies

During leukemia treatment mixed chimerism occurs in which both recipient and donor cells are present in the bone marrow or peripheral blood after transplantation.

Chimerism analysis is performed to monitor peripheral blood or bone marrow in the recipient after allogenic stem cell transplantation to monitor for leukemic relapse. Observation of increasing mixed chimerism after transplantation is associated with a higher risk of relapse in acute leukemia. Previously, a quantitative PCR (qPCR) technique, using INDEL polymorphisms, was found to predict relapse in 88.2% vs. 44.4% of individuals analyzed by VNTR markers with a median anticipation period of 58 days and a sensitivity of 0.01% vs. 3%. Here we present results from research experiments performed to determine if a digital PCR (dPCR) method is able to predict relapse earlier and with greater accuracy than the qPCR method using retrospective leukemia samples. Research results showed that dPCR using data generated by the QuantStudio™ 3D Digital PCR System and the qPCR method yielded similar percent recipient chimerism values when recipient DNA was present above the 1% level. Furthermore, dPCR using the system was found to be more sensitive than the qPCR method based on the ability to detect the recipient DNA in a relapsed individual about 2 months earlier where the percent recipient chimerism was 0.2% or less. The false positive rate was close to the complete chimerism value of 0.01% for peripheral blood samples.Quantification of Donor/Recipient Chimerism in Leukemia Samples by Digital PCR

Quantification of Donor/Recipient Chimerism in Leukemia Samples by Digital PCRThermo Fisher Scientific

More Related Content

What's hot

T cell convergence refers to the phenomenon whereby antigen-driven selection enriches for T cell receptors (TCRs) having a shared antigen specificity but different amino acid or

nucleotide sequence. T cell recruitment and expansion within the tumor microenvironment (TME) may be directed by responses to tumor neoantigen, suggesting that elevated T

cell convergence could be a general feature of the tumor infiltrating T cell repertoire. Here we use the Ion AmpliSeq™ Immune Repertoire Assay Plus – TCRβ to evaluate evidence

for T cell convergence within melanoma tumor biopsy research samples from a set of 63 subjects plus peripheral blood leukocytes (PBL) from four healthy subjects. We find that the melanoma TME is highly enriched for convergent TCRs compared to healthy donor peripheral blood. We discuss the potential use of TCR convergence as a liquid biopsy compatible predictive biomarker for immunotherapy response.Evidence for antigen-driven TCRβ chain convergence in the melanoma-infiltrati...

Evidence for antigen-driven TCRβ chain convergence in the melanoma-infiltrati...Thermo Fisher Scientific

Overview of IDT nucleic acid products for clinical research and diagnostics.Oligonucleotides for Next Generation Sequencing Research and Clinical Diagnos...

Oligonucleotides for Next Generation Sequencing Research and Clinical Diagnos...Integrated DNA Technologies

During leukemia treatment mixed chimerism occurs in which both recipient and donor cells are present in the bone marrow or peripheral blood after transplantation.

Chimerism analysis is performed to monitor peripheral blood or bone marrow in the recipient after allogenic stem cell transplantation to monitor for leukemic relapse. Observation of increasing mixed chimerism after transplantation is associated with a higher risk of relapse in acute leukemia. Previously, a quantitative PCR (qPCR) technique, using INDEL polymorphisms, was found to predict relapse in 88.2% vs. 44.4% of individuals analyzed by VNTR markers with a median anticipation period of 58 days and a sensitivity of 0.01% vs. 3%. Here we present results from research experiments performed to determine if a digital PCR (dPCR) method is able to predict relapse earlier and with greater accuracy than the qPCR method using retrospective leukemia samples. Research results showed that dPCR using data generated by the QuantStudio™ 3D Digital PCR System and the qPCR method yielded similar percent recipient chimerism values when recipient DNA was present above the 1% level. Furthermore, dPCR using the system was found to be more sensitive than the qPCR method based on the ability to detect the recipient DNA in a relapsed individual about 2 months earlier where the percent recipient chimerism was 0.2% or less. The false positive rate was close to the complete chimerism value of 0.01% for peripheral blood samples.Quantification of Donor/Recipient Chimerism in Leukemia Samples by Digital PCR

Quantification of Donor/Recipient Chimerism in Leukemia Samples by Digital PCRThermo Fisher Scientific

What's hot (20)

Development and Implementation of a Platform Process for HIV Vaccine Candidat...

Development and Implementation of a Platform Process for HIV Vaccine Candidat...

Evidence for antigen-driven TCRβ chain convergence in the melanoma-infiltrati...

Evidence for antigen-driven TCRβ chain convergence in the melanoma-infiltrati...

Multicopy reference assay (MRef) — a superior normalizer of sample input in D...

Multicopy reference assay (MRef) — a superior normalizer of sample input in D...

Potable Reuse as a New Source of Supply for Gulf Coast Water Authority

Potable Reuse as a New Source of Supply for Gulf Coast Water Authority

Long Acting Injectables - A New Dimension for Proteins and Peptides

Long Acting Injectables - A New Dimension for Proteins and Peptides

Oligonucleotides for Next Generation Sequencing Research and Clinical Diagnos...

Oligonucleotides for Next Generation Sequencing Research and Clinical Diagnos...

Rapid automated-sars-cov-2-workflow-genexus-app-note

Rapid automated-sars-cov-2-workflow-genexus-app-note

Advancing Microbiome Research: From challenging samples to insight with Confi...

Advancing Microbiome Research: From challenging samples to insight with Confi...

MelTree: A Novel Workflow for the Automated Identification of a Large Number ...

MelTree: A Novel Workflow for the Automated Identification of a Large Number ...

Quantification of Donor/Recipient Chimerism in Leukemia Samples by Digital PCR

Quantification of Donor/Recipient Chimerism in Leukemia Samples by Digital PCR

IRJET- Analysis of Hybrid Purity in Watermelon using Microsatellite Marker in...

IRJET- Analysis of Hybrid Purity in Watermelon using Microsatellite Marker in...

Similar to ASGCT 2015 Poster (Final)

Similar to ASGCT 2015 Poster (Final) (20)

Up to Speed: Cell Culture Development. European Biopharmaceutical Review July...

Up to Speed: Cell Culture Development. European Biopharmaceutical Review July...

Webinar: Evaluating Viral Clearance for Continuous Processes

Webinar: Evaluating Viral Clearance for Continuous Processes

HIV Vaccines Process Development & Manufacturing - Pitfalls & Possibilities

HIV Vaccines Process Development & Manufacturing - Pitfalls & Possibilities

Quantification of a Novel Peptide, CPT31 in Rat and Monkey Plasma by LC-MS

Quantification of a Novel Peptide, CPT31 in Rat and Monkey Plasma by LC-MS

Scalability of Cell Culture Processes in Single-use Bioreactors using Differe...

Scalability of Cell Culture Processes in Single-use Bioreactors using Differe...

High Throughput Bioreactor Mimetic in Early and Late Stage Process Development

High Throughput Bioreactor Mimetic in Early and Late Stage Process Development

Developing a Scalable Upstream Bioreactor Process for Lentiviral Vector Produ...

Developing a Scalable Upstream Bioreactor Process for Lentiviral Vector Produ...

Developing a Scalable Upstream Bioreactor Process for Lentiviral Vector Produ...

Developing a Scalable Upstream Bioreactor Process for Lentiviral Vector Produ...

Microbial community analysis in anaerobic palm oil mill effluent (pome) waste...

Microbial community analysis in anaerobic palm oil mill effluent (pome) waste...

ASGCT 2015 Poster (Final)

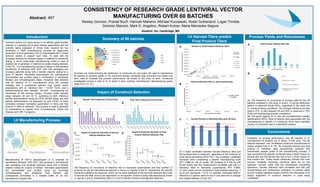

- 1. CONSISTENCY OF RESEARCH GRADE LENTIVIRAL VECTOR MANUFACTURING OVER 60 BATCHES Wesley Gorman, Pranali Buch, Hannah Maheno, Michael Kuczewski, Nolan Sutherland, Logan Trimble, Dominic Mancini, Mark D. Angelino, Robert Kutner, Maria Mercedes Segura bluebird bio, Cambridge, MA Abstract: 467 Abstract Process Yields and Robustness Conclusions Lentiviral vectors (LV) have shown to be efficient gene transfer vehicles in a growing list of gene therapy applications and are currently being evaluated in clinical trials. bluebird bio has developed a GMP manufacturing process for large-scale production of third generation VSV-G pseudotyped HIV-1 based lentiviral vectors to support such trials. To cope with the increased demand for research-grade LV material for preclinical testing, a mirror small-scale manufacturing model is used at bluebird bio to generate LV batches at scales ranging between 2 and 10L. The manufacturing process is based on the transient transfection of adherent HEK 293T cells with packaging and envelope plasmids along with a transfer plasmid coding for a gene of interest. Harvested supernatants are subsequently concentrated and purified using a combination of membrane filtration and chromatography steps. Analytical data obtained over 60 batches of LV manufactured using this process indicates that it consistently delivers high quality vector preparations with an infectious titer > 1E+08 TU/mL and a particle/infectious ratio between 100-500, emphasizing the robustness of the process design. Process yields typically range between 30 and 60 %, according to both infectious particle determinations using the HOS cell titer assay and total particle determinations as assessed by p24 ELISA. A linear correlation between harvested supernatant LV titers and final product LV titers is observed. This process is used to generate LV preparations to support ALD, β-Thalassemia, Sickle Cell Disease and CAR-T programs. Introduction Impact of Construct Selection 0 1 2 3 4 5 6 7 Harvest Titer Frequency of Occurrence 0 1 2 3 4 5 6 7 Final Titer Frequency of Occurrence 0 2 4 6 8 10 12 14 16 18 20 10% 20% 30% 40% 50% 60% 70% 80% TotalNumberofBatches Process Recovery (%) Final Process Yield by HOS Titer LV Manufacturing Process Purification Formulation Ion- Exchange Tangential Flow Filtration Cell Factories Transient transfection Final Product Harvest FilterFilter Manufacturing of VSV-G pseudotyped LV is achieved by transfecting adherent HEK 293T cells growing in cell factories with packaging and envelope plasmids along with a transfer plasmid coding for a gene of interest. Harvested supernatants are concentrated and purified using ion exchange chromatography and Tangential Flow Filtration and subsequently formulated in a suitable buffer for ex vivo transduction of target cells . 84.5% 2.8% 8.5% 4.2% Pass Failure due to low yield Failure due to low harvest titer Failed due to other reasons (i.e. operator error ) LV Harvest Titers predict Final Product Titers y = 6E-06x + 18.107 R² = 0.8979 0 20 40 60 80 100 120 140 160 180 0.00E+00 5.00E+06 1.00E+07 1.50E+07 2.00E+07 2.50E+07 Harvestp24concentration(ng/mL) Harvest infectious titer (TU/mL) Harvest Infectious Titer vs. p24 Concentration Evaluation of process performance over 60 batches of LV manufactured at bluebird bio is shown in this work. The 60 batches represent over 30 different constructs manufactured at scales ranging from 2 to 10L. By analyzing harvest and final product LV infectious titers representing upstream and downstream sample points in the manufacturing process, it was concluded that specific constructs have a direct impact on harvest titer and the harvest titer has in turn a direct impact on final product titer. These results collectively indicate that most process variability impacting infectious titers lie on the upstream process rather that the downstream processing operations. Harvest infectious titers correlated well with p24 concentrations and, furthermore, evaluation of process yields around multiple operating scales confirms the robustness of its design regardless of construct selection or scale being considered. Summary of 60 batches (A) A linear correlation between harvest infectious titers and final product titers is observed regardless of the construct or scale being considered (R²=0.797). The correlation coefficient increases when considering a specific manufacturing scale (R²= 0.866 for the 2L scale). (B) Analysis of 6 lots by p24 ELISA shows that this measurement correlates well with LV infectious titers in harvested supernatants (R²= 0.898). (C) p24 values can be converted to total particles assuming 1 ng of p24 represents 1.2x107 LV particles. Estimated total-to- infectious LV particle ratios for the 6 runs were 84 on average and ranged between 70 and 103. (A) The frequency of occurrence of process yield for the 60 batches evaluated in this study is shown. A normal distribution pattern is observed (mode 40%), regardless of the scale and LV construct being considered. The average infectious process yield is 37%. A yield between 30 and 50% is observed in 75% of all runs emphasizing process consistency. (B) The great majority of LV lots met pre-determined release specifications (85%). Most lot failures were associated with the manufacturing of specific LV constructs which were identified as poor LV producers due to unidentified reasons. A B A B C BA BA DC 12% (7 runs) 3% (2 runs) 7% (4 runs) 8% (5 runs) 13% (8 runs) 5% (3 runs) 52% (31 runs) Construct 1 Construct 2 Construct 3 Construct 4 Construct 5 Construct 6 Other 65% (39 runs)7% (4 runs) 13% (8 runs) 15% (9 runs) 2L 3 L 4 L 10 L 1.41E+08 2.84E+08 4.21E+08 3.28E+08 1.20E+08 6.98E+08 0E+00 1E+08 2E+08 3E+08 4E+08 5E+08 6E+08 7E+08 8E+08 9E+08 1E+09 FinalProductTiters(TU/mL) Impact of Construct Selection to Final Process Yield by Infectious Titer 1.08E+07 1.89E+07 1.44E+07 6.07E+06 4.22E+06 2.18E+07 0.0E+00 5.0E+06 1.0E+07 1.5E+07 2.0E+07 2.5E+07 3.0E+07 HarvestTiters(TU/mL) Impact of Construct Selection to Harvest Yield by Infectious Titer 0.00E+00 2.00E+08 4.00E+08 6.00E+08 8.00E+08 1.00E+09 1.20E+09 1.40E+09 1.60E+09 1.80E+09 0.00E+00 1.00E+07 2.00E+07 3.00E+07 4.00E+07 5.00E+07 FInalProductInfectiousTiter(TU/mL) Harvest Infectious Titer (TU/mL) Harvest vs. Final Product Infectious Titers 2L scale 3 L scale 4 L scale 10 L scale R² = 0.797 (all 60 runs) R² = 0.866 0 20 40 60 80 100 120 Run 1 Run 2 Run 3 Run 4 Run 5 Run 6 HarvestP/IRatio Harvest Particle to Infectivity Ratio over Six Runs Summary pie charts showing the distribution of constructs (A) and scales (B) used to manufacture 60 batches of research grade LV for preclinical studies. Analytical data extracted from these runs were used to evaluate the process performance, as shown in this body of work. Constructs investigated include a total of 30 of which 6 were routinely manufactured. Manufacturing scales range from 2 to 10 L. The frequency of occurrence of infectious titer in harvested supernatants and final purified LV products for the 60 manufactured batches is shown in Figures A and B, respectively. No specific distribution patterns are observed, which can be partly attributed to the fact that infectious titers both in harvest and final product are dependent on the specific construct being manufactured as shown in Figures C and D, respectively. Bars in C and D indicate construct average titer observed.