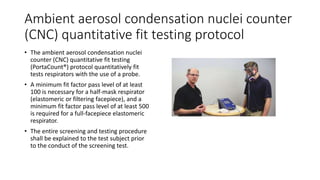

The document summarizes new OSHA protocols for quantitative respirator fit testing using ambient aerosol condensation nuclei counters (CNC). The two new protocols have fewer exercises and a shorter duration compared to the original protocol. With these additions, OSHA's appendix now contains a total of six approved quantitative fit test protocols. Employers are not required to update their current fit testing methods. The new protocols became effective in September 2019.