5T Intemediate Frequency Furnace

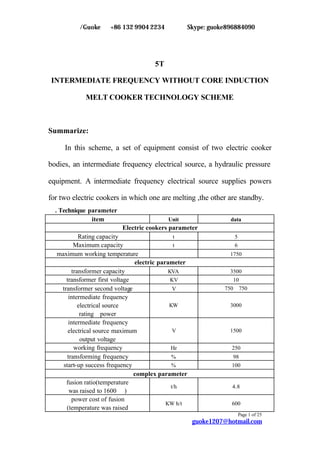

- 1. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 1 of 25 guoke1207@hotmail.com 5T INTERMEDIATE FREQUENCY WITHOUT CORE INDUCTION MELT COOKER TECHNOLOGY SCHEME Summarize: In this scheme, a set of equipment consist of two electric cooker bodies, an intermediate frequency electrical source, a hydraulic pressure equipment. A intermediate frequency electrical source supplies powers for two electric cookers in which one are melting ,the other are standby. Ⅰ. Technique parameter item Unit data Electric cookers parameter Rating capacity t 5 Maximum capacity t 6 maximum working temperature ℃ 1750 electric parameter transformer capacity KVA 3500 transformer first voltage KV 10 transformer second voltage V 750、750 intermediate frequency electrical source rating power KW 3000 intermediate frequency electrical source maximum output voltage V 1500 working frequency Hz 250 transforming frequency % 98 start-up success frequency % 100 complex parameter fusion ratio(temperature was raised to 1600 ℃) t/h 4.8 power cost of fusion (temperature was raised KW·h/t 600

- 2. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 2 of 25 guoke1207@hotmail.com to 1600 ℃) working noises db =85 hydraulic pressure system station capacity L 500 working pressure Mpa 13 hydraulic pressure medium grease cooling water system flow quantity t/h 144 water supply pressure Mpa 0.25-0.35 input water temperature ℃ 5-35 output water temperature ℃ <55 Ⅱ. Technical criterion and working condition of equipment The parts of the equipment accord corresponding technical criterion listed behind. 1. GBl0067.3— 88 the basic technical condition of galvanothermy equipment— induction galvanothermy equipment. 2. GBl0063.3— 88 the experiment method of galvanothermy equipment— non-core induction melting cooker. 3. GB5959.3-88 the safety of galvanothermy equipment— special require on inductive and conductive heater and inductive melting equipment. 4. JB4086-85 intermediate frequency non-core induction heat-up use the technical condition of the equipments controlled by electricity. 5. JB / T4280— 93 intermediate frequency non-core induction cooker. 6. GB/T14549-93 the quality of power— the performance and

- 3. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 3 of 25 guoke1207@hotmail.com technical parameter of the resonance-wave equipment used in electricity network reach the regulation of technology specification book. Ⅲ. Normal working condition of the equipment listing behind 1. Environment a. Altitude is below 1000 m. b. Surroundings temperature is between 5 ℃ and 40℃. c. Relative humidity is not above 90% (25℃). d. No conductive dust, explosive gas and causticity gas which can damage metal and insulation. e. No obvious vibration and jounce. 2. Power supply demand a. Power supply voltage in main circuit is 1OKV, fluctuation is less 5% and three phase imbalance is less 5%. b. Power supply voltage in control system is 220 V and fluctuation is less 5%. c. Power supply voltage in main circuit and control system must be sine wave whose shape aberration is less 10%. 3. The demand of cooling water in outside cycle a. Overall rigidity is less 60 mg equal quantity per liter. b. dissolutive solid substance < 300 mg/L. c. PH 7— 8.5. d. suspension solid substance < lOmg/L.

- 4. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 4 of 25 guoke1207@hotmail.com e. conductance rate <500µs/cm. f. input water temperature =35℃. Ⅳ. Technique explanation of electric parts The electric parts of equipments consist of electrical source commutation transformer, Intermediate frequency electrical source cabinet, compensation capacitor groups, and high voltage switch cabinet. 1. Electrical source transformer The electrical source transformer is used to drop 11KV high voltage electricity in electric network to one which can fit Intermediate frequency electrical source. The equipment adopts special commutation transformers which self-cooling dipped in oil. 1.1 commutation transformer used for fusion: rating capacity 3500 KVA the first voltage 10 KV, the second voltage 750 V。 impedance in short circuit between 6% and 8% non-load switch installed on the high voltage side and used to regulate voltage by hand can adjust on three stages -5%,0,+5%.

- 5. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 5 of 25 guoke1207@hotmail.com 1.2. Intermediate frequency electrical source The type of intermediate frequency electrical source in the electric cooker is KGPS -3000 /0.25. Circuit principle drawing is listed below. 2. Intermediate frequency electrical source main loop principle chart 2.1 Commutate part control silicon adopt up to date fold installed radiator groupware as following chart This kind of install mode is more convenience and science to remove and install control silicon .When change control silicon, only loosen tip tighten bolt, you can change anyone control silicon component in groupware. Radiator component has scale which can consult when fasten, and this guarantee right pressure during control silicon and radiator. Moreover, this kind of installs mode minish control silicon groupware

- 6. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 6 of 25 guoke1207@hotmail.com volume, which makes operation room in electric cabinet bigger. 2.2 Great capacity direct current sieve wave reactor Sieve wave reactor is very important for solid electrical source,it has two function ,the one is to make output current smooth and stable;the other is when athwart change control silicon short circuit,it circumscribe short circuit increase rate and the biggest short circuit 。If sieve wave reactor parameter design inconsequence,iron core material is not good or production techniques do not pass the test ,all those may influence reliability of intermediate frequency electrical source。 2.3 Athwart change circuit adopt great speediness control silicon To guarantee athwart change circuit reliability,athwart change control silicon adopt two big capacity KK silicon in series 2.4. Adopt series-parallel connection compensate circuitry to minish wastage of transmit electricity circuitry To minish intermediate frequency transmit electricity circuitry wastage, athwart change circuit compensate capacitor adopt series-parallel connection, as follows: C1 L Intermediate C2 Frequency output This kind connection can enhance cooker output voltage twice as

- 7. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 7 of 25 guoke1207@hotmail.com athwart change circuit. And at the same output power output electrical current become only 50% as before, which make intermediate frequency transmit circuitry wastage minish to 1/4. 2.5 Main circuit parameter and component selection foundation When adopt 6 pulse wave rectifiers, commutate control silicon average electrical current can be calculated according to the following formula: Ikpmax=Id max/2.72 Athwart change control silicon average electrical current can be calculate according to the following formula: Ikkmax=0.45XIdmax Choose control silicon standard and select 2.6 Characteristic of intermediate frequency electrical source 2.6.1 Control system total numeric, without continue electricity control Control system adopt ISP program logical array module to integration control. Its core apparatus adopt high performance, high density ,great standard special ASTC-2 integration circuit ,which is made in USA, and this makes all signal dispose and correspondence operation carry out automatism according to program. Replace all kind of continue electricity control

- 8. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 8 of 25 guoke1207@hotmail.com with data control system to finish the function. 2.6.2 Unique browse frequency model startup mode has 100% startup succeed rate. Athwart change part adopt browse frequency zero pressure soft startup ,which has better performance than common zero pressure soft startup circuit。Browse frequency model startup process as following: before startup,touch off athwart change crystal brake pipe with stimulating signal whose frequency is higher than slot route syntony, moreover control stimulate signal frequency to browse from high to low,when the frequency is near slot route syntony, intermediate frequency voltage is set up .To prevent intermediate frequency voltage startup failure occasionally,our company design automatism startup circuit,ensure 100% startup succeed rate,moreover , its response time is very short,it only takes less than 500 MSEL to finish a automatism startup. 2.6.3 Adjuster with quick respond identity Our company have design particular adjuster in control circuitry whose responding time is very short, the adjuster is completely fit for the use demand of speediness respond in the condition of the load break of intermediate power supply. 2.6.4 Electrical source constant power is output to ensure supernal power

- 9. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 9 of 25 guoke1207@hotmail.com factor The impedance adjuster is devised especially which can inspect the change of the impedance and deliver it to circuit interior processing figure operation and adjust automatically matching load to make intermediate frequency power supply reach constant power. At the same time, the running power factor of the whole set equipment reaches above 0.93 because of using impedance adjuster in the course of melting. The relation graph of constant power intermediate frequency voltage US and its corresponding power factor φcos is given in following drawing. COS? 0 1050V 1300V Us (Constant power intermediate frequency voltage and its corresponding power factor connection graph) 2.6.5 Having outstanding anti-striking load capacity There leave enough space in choosing main apparatus in system., which guarantee each apparatus outstanding anti-striking capacity。Our firm provides especial device in control part of system on software, and

- 10. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 10 of 25 guoke1207@hotmail.com this makes system running more stationary and reliable and prevent monocrystalline silicon efficiently from damage of electric impulse while adding material .Thus, the equipment’s good capability of impulsion resistance is ensured and the equipment can run on the safe side in long period. 2.6.6 Perfect and reliable protection function Such protection measure of overflow, overload, over press,phase shortage, lack of voltage of controllable power, too low cooling water pressure, too high temperature of cooling water and too low water flux are provided in this controlling circuitry. These protection functions are analyzed and realized by ASIC-2 integrate circuit, which ensures the sensitivity and reliability of those protection function. This system is water cooling equipment, real time inspection to cooling water on many point has to be carried out for equipment runs on the safe side. Our firm devises a set of characteristic inspect instrument for a special purpose aim at importance of water inspection. Two temperature inspection points is set on each controllable silicon, and the same points is set on each syntonic capacitor and every induction loop. This makes each part of water cooling of this system be inspected at real time. It is impossible to damage part of apparatus which have too high water temperature on one point. 2.6.7 Advanced auto identify function of phase order

- 11. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 11 of 25 guoke1207@hotmail.com A auto identify circuit of phase order is contained in controllable system, which makes system need not install synchronic transformation and excuse phase order modulation and the job to synchronize while debugging and maintaining. 2.6.8 abundant outside controllable interface It is set on the equipment that Out/In transformation, Auto/Hand control switch and their interface, which can realize auto controlment from long distance conveniently. And outside temperature ring controllable interface is set to combine infrared temperature inspect instrument and temperature auto controlling system, which can realize the auto modulation of program enactment temperature rising to output power of electrical source and makes final calefaction temperature of steel tube reach anticipated temperature. 2.6.9 Light isolation impulse output In controlling system, there are double isolation measures in springing impulse between controlling board to controlling pole of controllable silicon. Light isolation apparatus with its pressure endurance over 2500V is used on controlling board to insulate springing impulse from light or electricity, and transformer groupware with its pressure endurance grade of over 3000V is used on impulse transformer. Even though controllable silicon is stroked out because of over pressure, it has little influence on controlling system.

- 12. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 12 of 25 guoke1207@hotmail.com 2.6.10 Simple and convenient to debug and maintain The major parameters’settings on controlling board are finished by internal circuit of controlling board. There are only six potentiometer parameters’settings which can be modulated by user. So the controlling board is perfectly universal and reciprocates, and it is simple and convenient to debug and maintain. 2.7 Cooker leaking protection and earthling alarm brake function A special detector of cooker liner’s thickness is set on controlling system. The working theory is to verdict the perfection of cooker liner through leaking current between inductive loops and charging. Because leaking current must amply while cooker liner becomes thin. Alarm current of cooker liner thickness detector can be modulated. Appropriate alarm current must be modulated gradually while it is being used according to different size of cooker and different material of cooker line. Cooker liner thickness detector cann’t runs correctly 100 percent. It can only offer reference of judging cooker liner thickness. The cooker liner thickness detector is connected between side pole and bottom pole directly. 2.8 Compensating capacitor groups

- 13. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 13 of 25 guoke1207@hotmail.com To minish waste of big current circuit, compensating capacitor groups are set on the position next to electric cooker in basement as possible as they can.. All capacitor are new innoxious water cooling intermediate frequency big capacity capacitors, which have such merit as big capacity of each one, low waste of medium and small area of containing ground. Digital temperature inspecting component is installed on each capacitor, which can auto stop intermediate frequency electric source through working temperature inspected by especial temperature inspection appearance developed by our firm while temperature is over high and alarm signal is come up. Capacitor groups all use big section water cooling copper arrange. Working temperature of copper arranges must not beyond C0 45 to cut down transmission waste of parallel connecting syntonic circuit. Five.Part of electric cooker It contains electric cooker body, water cooling cable, high fire endurance pastern, speedy extrusion equipment of cooker liner and copper arrange of main circuit. 1. cooker body Cooker body contains induction loop, magnetic yoke, cooker frame, leaning oil jar and cooker cover. 1.1 Inductive loop

- 14. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 14 of 25 guoke1207@hotmail.com The inductive loop is circled by 99.99 percent rectangle copper cube. Insulation on the inductive loop surface is smeared a flat of high strength insulated colophony using static gushing craftwork, whose insulation can endure voltage more than 6000V. Inductive loop is fixed up by lists of bolts sealed around its circumference and insulated supporting bar. After loop is fixed up, its error of circle distance is no more than 2mm. Copper water cooling circles are set on the top and the bottom of inductive loop to make cooker liner material is heated evenly in axial direction and to prolong the working life of cooker liner. On the outside surface of inductive loop, couples of temperature explorer stationeries are welded on waterway subsection to fix up temperature measure component. While one of water way is jammed, alarm is given off immediately and the intermediate frequency electric source ceases automatically. 1.2 Magnetic yoke The magnetic yoke is made up of cold rolled silicon and steel of high magnetism transmit rate. The thickness of silicon and steel is o.3mm. Profile modeling configuration is used in the magnetic yoke, whose internal arc face radian is equal to outer circle’s radian of inductive loop. This make the magnetic yoke can cling to outer side of inductive loop, and inhibit the magnetic field emanated out by loop to decrease magnetic

- 15. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 15 of 25 guoke1207@hotmail.com block of outer magnetic circuit. The magnetic yoke is hold by stainless steel plates on both sides and stainless steel clamps. It is weld to root. Cooling water cubes are weld on the stainless steel plates on both sides to cool magnetic yoke. The cooling water cube can endure 0.45Mpa water pressure and has no leaking out in 15min. After the magnetic yokes are installed completely, the camber is no more than 4mm, the warp of theoretical center line and practical center line are no more than 3mm. 1.3 cooker frames The cooker frames divide into active part and stationary part. Active cooker frame is used to install inductive loop and magnetic yoke, which is weld by profiled bar and armor plate and utilize framework configuration. The framework has removable cover board, which is convenient for examine and repair. Deepen armor plates are used on the operation flat roof on the top of cooker frame to enhance the intensity and bearing ability of the cooker frame. There is a cooker cover on the top of active cooker frame, and hydraulic pressure driving fashion is used. The ascendance and rotation of it are accomplished by two ole jars to ensure cooker cover to run in gear and reliably The stationary cooker frame is set on the groundsill to hold the active

- 16. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 16 of 25 guoke1207@hotmail.com cooker frame. There are leaning rolling axes connected to the cooker frame over the stationary cooker frame, which can make active cooker frame rotate 0 95 ahead. A fast cutting valve which can prevent breaking and limit velocity is set on the bottom of the leaning cooker oil jar. In the course of inclining cooker, if the ole jar is broken, the cutting valve which can prevent breaking and limit velocity will act to cut off the returning oil circuit of the oil jar and make the electric cooker state on the original position. There is a very big safety factor remained in the period of dividing. This ensures that the cooker frame has enough rigidity and run placidly when it bears the most loads. Induction winding and charging parameter: Induction winding and charging parameter is optimize designed by special computer ,which guarantee the best electromagnetism coupling efficiency at same capacity. Considering electric cooker need over take, we design that rating capacity is bigger than standard .Only that can guarantee charging liquid surface would not exceed water-cooling circle upper surface at the biggest charging capacity. Since the part above water-cooling circle is not cooled, if the part touches charging for long time, it will produce high temperature, which makes cooker liner craze at water-cooling circle. 2. water-cooling cable

- 17. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 17 of 25 guoke1207@hotmail.com water-cooling cable joint adopt cool pressure molding techniques to press with copper wind line,which joint fastness,contact resistance small,do not damnify copper wind line. The single tie-in and copper line can endure more than 8t pull Water-cooling cable outer bushing adopt special hinder-burning rubber pipe, which is not flammability. Intension is good,which can endure 0.45Mpa water pressure.,no leak,no break。 material, which smear among circumference and inside induce winding ,has following function: (1)It makes induce winding whole,reduce vibration and noises when work. (2)when charging leak ,it can protect induce winding. (3)It makes for pulling cooker liner. 4. Pulling cooker liner rapidly equipment Pulling cooker liner rapidly equipment,which include tip push block, tip push oil jar and operation framework, is used for getting rid of old ones rapidly. Tip push block,under cooker liner,is linked with tip push oil jar through the bottom of cooker. when pushing out old cooker liner ,turn the electric cooker 90 degree,fix tip push oil jar with bolt and joint flange. Operate handy valve to press oil jar ,then old cooker liner is pushed out .

- 18. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 18 of 25 guoke1207@hotmail.com Six .hydraulic pressure Including hydraulic pressure pumping station and leaning cooker manipulation platform: Hydraulic pressure pumping station is used for supplying power to leaning cooker, cooker lip drive oil jar, cooker liner push oil jar. Pumping station rating work pressure is 11Mpa. Hydraulic pressure medium is hydraulic pressure oil. Leaning cooker manipulation platform is used for controlling the cooker to lean, turn round, switching cooker lip and pushing cooker liner。 It adopt handle valve, act placidity, no impulsion. All hydraulic pressure components adopt joint venture high quality product. Seven: cooling water system Cooling water system adopts cooling tower of FBNL close type or FKHL open type whose concrete parameter select may refer to the data of sample production. Eight: installation and base map The installation of the facility and base map are showed in attached drawing. Nine: technique datum and drawing

- 19. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 19 of 25 guoke1207@hotmail.com We supply following technique datum when the equipment leave factory. 1. machine part It includes electric cooker exterior drawing, base drawing, plane lay drawing, land build demand, the data of flat roof and cooling water system, easy damage piece drawing. Equipment fixing and debug instructor, the guidance book of use and maintenance about electric cooker. Hydraulic pressure principle drawing, the guidance book of the Hydraulic pressure system. The guidance book of the water system. 2. electric part It includes the principle drawing of the electric and circuit, exterior wiring diagram, electric component table, the guidance book of intermediate frequency power supply, the guidance book of control system malfunction inspection exclusion. Ten: Equipment beforehand validate and training When all the equipment manufacture is over, we will invite the buyer technician to the equipment manufacture factory, take part in the equipment beforehand check , accept and training. 1. beforehand check and accept content:

- 20. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 20 of 25 guoke1207@hotmail.com (1) commonly inspection (2) security inspection (3) the cooker assemble dimension examination (4) inductorium manufacture quality examination and insulation, pressure endurance experimentation (5) measurement the electric gap between inductorium and cooker shell (6) measurement insulated resistance between inductorium and cooker shell (7) measurement insulated resistance between inductorium and magnetism yoke (8) intermediate frequency cooker insulated, pressure endurance test (9) pressure test of hydraulic pressure system (10) leaning cooker manipulate test of leaning cooker transmission framework (11) induction winding hydraulic pressure test (12) electric linkage and spillage cooker alarming equipment experiment (13) electric malfunction display, monitor, alarm etc protect functional inspection (14) match inspection, including model, standard, up to grade certificate leaving factory

- 21. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 21 of 25 guoke1207@hotmail.com (15) supply good range, technique document integrality test 2. Training (1) The seller supply user the following technical training the equipment installation training (2) Electric control design principle training.(Including: electric design protection, inspection, malfunction display) (3) Equipment maintains and daily maintains work training (4) Equipment ordinary malfunction and special malfunction elimination training 3. All the beforehand check and accept item and test data should be got when two sides attend and signature, supply user the data at the same time. 4. Only when all the check work is over and two sides agree to sign it, the seller can package and consignment the equipment Twelve install, debug and the final check and accept. Eleven: Installation, Debug and final check and accept. 1. When the equipment installation is over, our company will send respect specialist install spot to check the installation and precision, and then debug the equipment 2. The seller specialist will train the user employee to handle and repair the equipment at the spot

- 22. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 22 of 25 guoke1207@hotmail.com 3. The equipment final check and accept should be held at user spot, the item including: (1) all the check item and completely safety check; (2) Induce cooker heat preservation power parameter measurement; (3) Induce cooker heat preservation power measurement,temperature rising productivity measurement (4) Induce cooker electricity consume and melt rate measurement (5) Refrigeration medium temperature rising measurement (6) The cooker component temperature measurement (7) Charging temperature measurement (8) Noises measurement (9) Check after heat condition experiment (10) Alarm system dependability and sensitive degree examination; (11) According to technical demand clausal validate When all the item have been checked, tested, write out the final examination report, both sides get agreement, the contract get into effect Twelve: product quality control measure 1. Our company is strictly according to ISO9001 quality standard at quality control, set up a completely quality system document and get across quality authentication. When we select the oral material and in addition fitting, we set up a whole and up to grade provider, to be sure the

- 23. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 23 of 25 guoke1207@hotmail.com quality of oral material. 2. In the process of the production, every spare part has quality responsibility track card, which record every step responsibility and the final check .to the pivotal part such as inductor ,magnetism yoke etc, we have special technique regulations, which ensure that only the up to grade part from last working procedure can get across the next. 3. We will checkout the product before leaving factory. Which include appearance examination, mechanism measurement, induce winding insulation checkout, bear the press and water trial. The lean movement of .electric cooker examination cooker lid rise drop and circumrotate examination. 4. Hydraulic pressure system check-out and each intermediate frequency electrical source parameter examination ,when all the examination is up to grade ,the checkout will fill product checkout certificate, and record all kinds of examine data ,which guarantee product quality can trace back Thirteen: product quality guarantee 1. The electric cooker facility is made up with bran-new, high–quality material which can compare with equipment technique standard explanation book; all substantiality facets are fitted with equipment technical standard explaination book. 2. All the main outer fitting of equipment have product check-out

- 24. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 24 of 25 guoke1207@hotmail.com certification. 3. We guarantee to keep the electric cooker equipment in good repair for twelve month since the final check-out. During the guarantee period, all the malfunction caused by the equipment manufacture badness or low quality of outer fitting, we will repair and change relevant part. 4. We provide 24 hour respond service .we will send to serve the user during 24 hour in the country ,to abroad the time should take transaction go abroad procedure into account depend on the government work efficiency. 5. To be certain stability of production, we provide customers spare part at benefit price which is lower than market price at same time.

- 25. 郭珂/Guoke +86 132 9904 2234 Skype: guoke896884090 Page 25 of 25 guoke1207@hotmail.com The whole equipment sets includes number device name model quantity 1 Frequency thyristor converter KGPS KGPS-3000KW/0.25KHz 1 2 Link copper Between the power supply to the capacitor 1 3 Capacitor bank 0.25KHz 1 4 Water-cooling cable set 2 5 Induction melting assembled unit GWJ-5.0t 2 6 Hydraulic System 1 7 Crucible mould 2 8 Water Distributor 2 9 Operation Platform 1 10 Furnace leak alarm system 1 11 Lining ejector 1