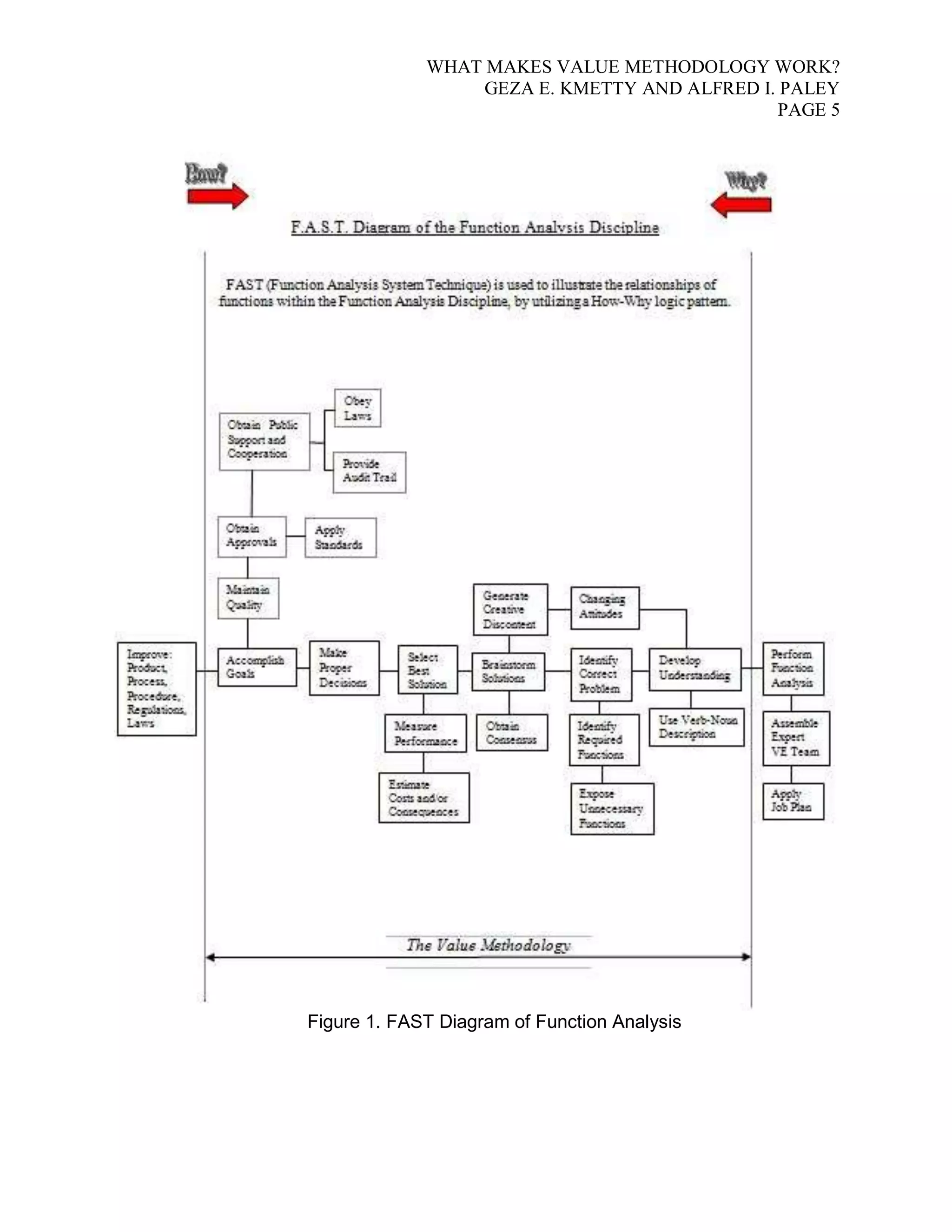

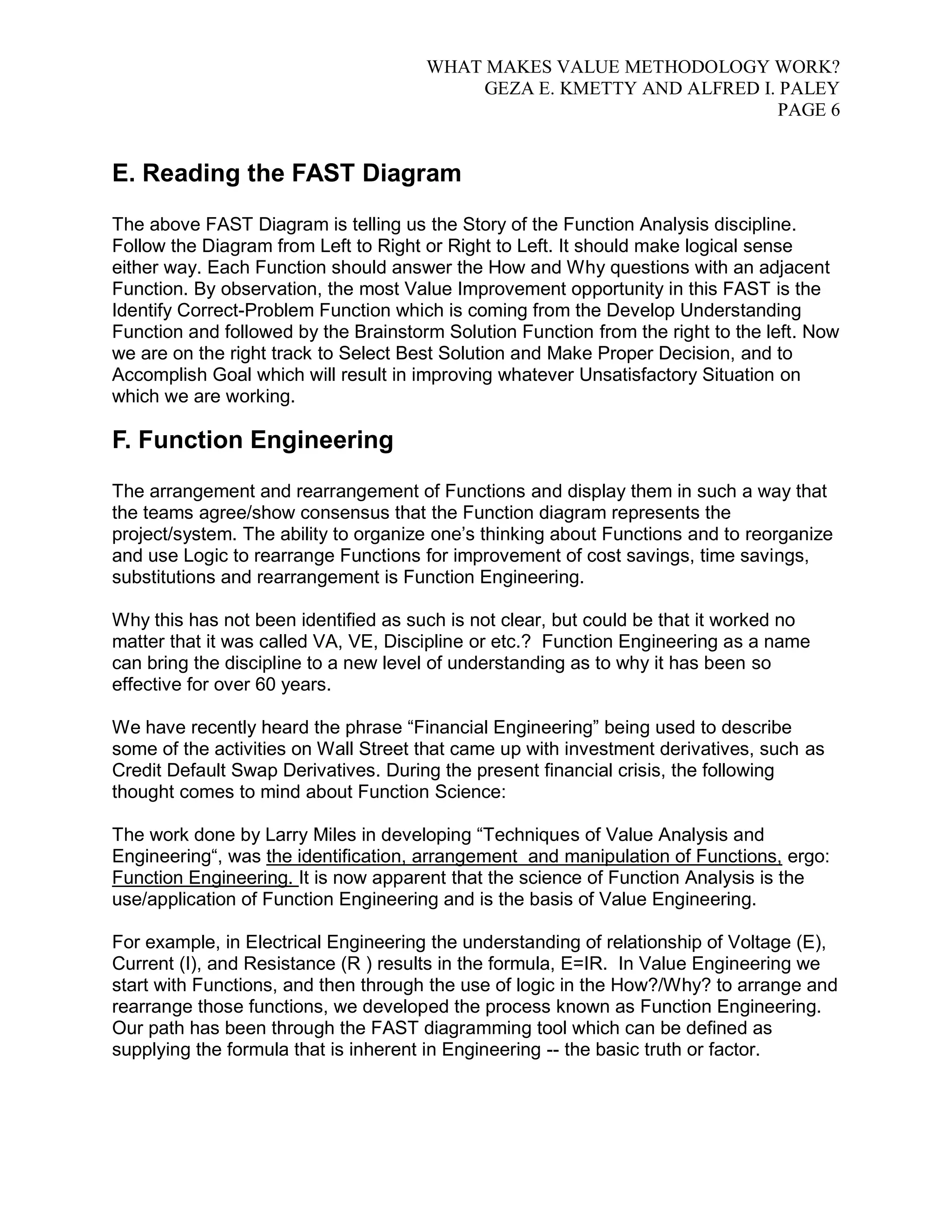

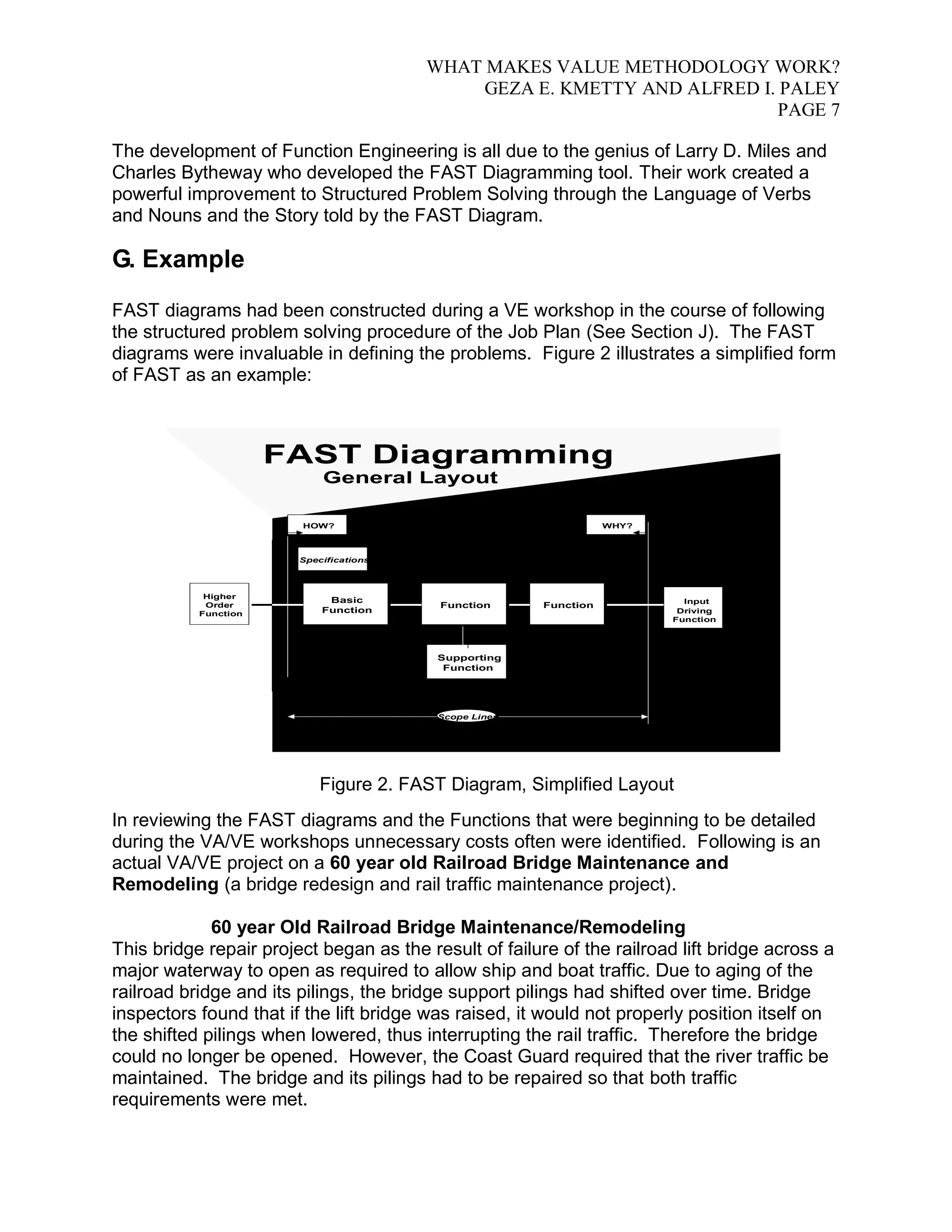

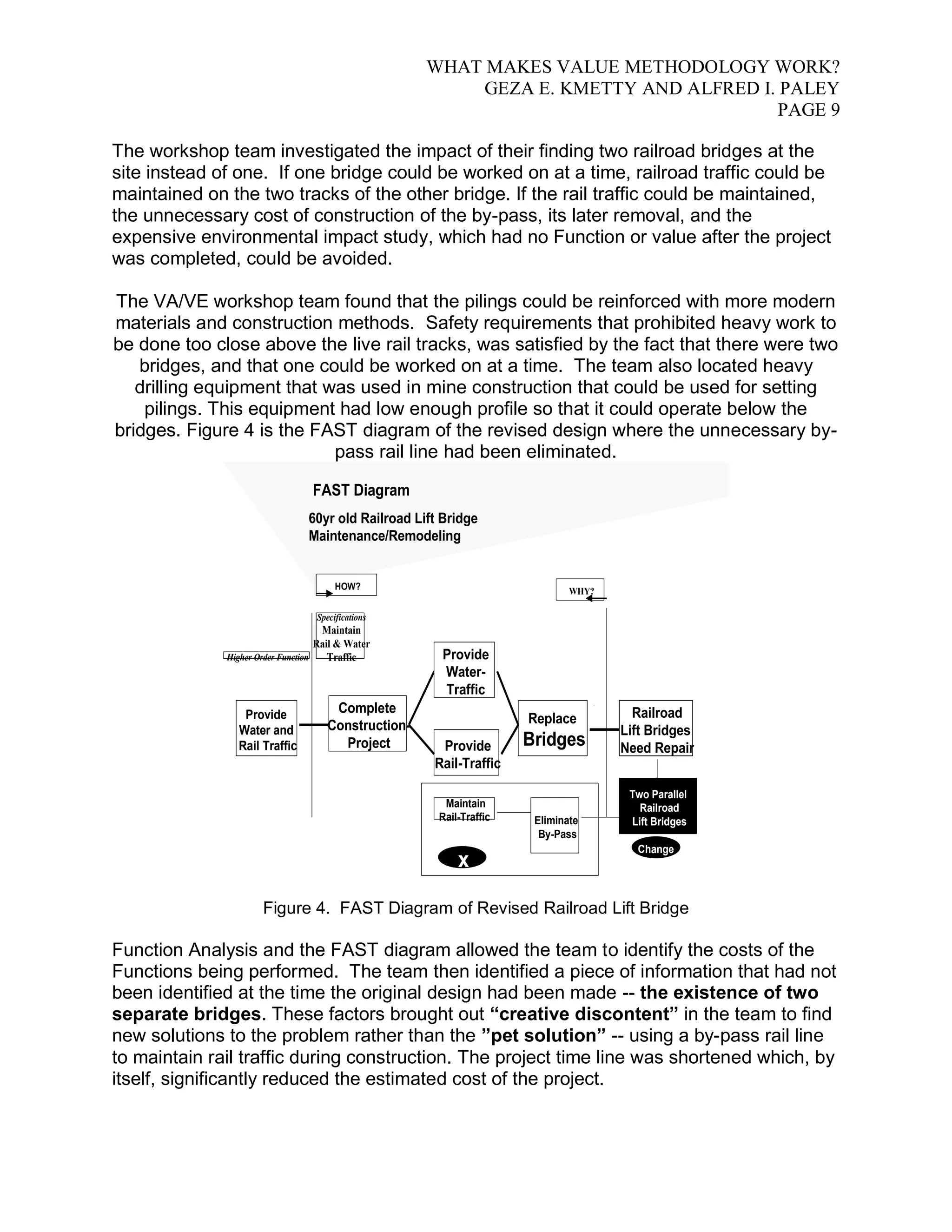

The document discusses how function analysis, a core component of value methodology, is able to effectively solve problems. It does this by focusing analysis on the functions of an item rather than the item itself. This allows alternative solutions to be identified that can fulfill the necessary functions at a lower cost without reducing performance. The document also outlines the origins and development of function analysis, including how it was pioneered by Lawrence Miles at GE after WWII to reduce costs through identifying unnecessary expenses. It was further developed through the creation of the Function Analysis System Technique (FAST) diagramming method to clarify functional relationships and build team consensus.