Report

Share

Download to read offline

Recommended

Recommended

More Related Content

What's hot

What's hot (18)

Compressive and Split Tensile Strength of Chopped Basalt Fiber Concrete

Compressive and Split Tensile Strength of Chopped Basalt Fiber Concrete

hair fibre reinforced concrete vs plain cement concrete

hair fibre reinforced concrete vs plain cement concrete

SANDWICH DESIGN MODEL FOR ALUMINUM AND KENAF-POLYESTER COMPOSITE

SANDWICH DESIGN MODEL FOR ALUMINUM AND KENAF-POLYESTER COMPOSITE

Strength and behaviour of sifcon with different types of fibers

Strength and behaviour of sifcon with different types of fibers

Annular nanolayer film extrusion may 2016 2 27-2017

Annular nanolayer film extrusion may 2016 2 27-2017

Study and Analysis on Mechanical and Wear Behavior of SiC Filled Epoxy Composite

Study and Analysis on Mechanical and Wear Behavior of SiC Filled Epoxy Composite

2012 11-15-high-value-manufacturing-sirris-magnien

2012 11-15-high-value-manufacturing-sirris-magnien

Hybrid natural fiber reinforced polyester composites

Hybrid natural fiber reinforced polyester composites

Performance of Polypropylene Fibre Reinforced Concrete

Performance of Polypropylene Fibre Reinforced Concrete

Viewers also liked

Viewers also liked (6)

Shear Strength Of Rockfill, Interfaces And Rock Joints, And Their Points

Shear Strength Of Rockfill, Interfaces And Rock Joints, And Their Points

Deformability modulus of jointed rocks, limitation of empirical methods, and ...

Deformability modulus of jointed rocks, limitation of empirical methods, and ...

Class 6 Shear Strength - Direct Shear Test ( Geotechnical Engineering )

Class 6 Shear Strength - Direct Shear Test ( Geotechnical Engineering )

Similar to KrumheuerLast_Effects of Parameters on Bonding

Similar to KrumheuerLast_Effects of Parameters on Bonding (20)

Correlation between the Interface Width and the Adhesion Strength of Copper F...

Correlation between the Interface Width and the Adhesion Strength of Copper F...

New workA)Transfer It Please respond to the following· U.docx

New workA)Transfer It Please respond to the following· U.docx

Use of Laser Generated Shocks to Improve Metals & Alloys

Use of Laser Generated Shocks to Improve Metals & Alloys

ABSTRACTThe report describe the results obtained from a tens.docx

ABSTRACTThe report describe the results obtained from a tens.docx

An experimental investigation on flexural behaviour of fibre reinforced robo ...

An experimental investigation on flexural behaviour of fibre reinforced robo ...

Electrical Properties of Thermally Evaporated In40 Se60 Thin Films

Electrical Properties of Thermally Evaporated In40 Se60 Thin Films

Experimental Study of Strength Parameters of Hybrid Fibre Reinforced C...

Experimental Study of Strength Parameters of Hybrid Fibre Reinforced C...

An Experimental Analysis to Determine Ultimate Tensile Strength of Jute Reinf...

An Experimental Analysis to Determine Ultimate Tensile Strength of Jute Reinf...

Experimental study of effect of fiber orientation on

Experimental study of effect of fiber orientation on

Energy Release Rate for Fiber Reinforced Polymer Composite

Energy Release Rate for Fiber Reinforced Polymer Composite

Experimental Evaluation of effect of filler on tensile behaviour of E-glass/e...

Experimental Evaluation of effect of filler on tensile behaviour of E-glass/e...

Effects of Carbon Nanotubes on the Compressive and Flexural Strength and Micr...

Effects of Carbon Nanotubes on the Compressive and Flexural Strength and Micr...

Study Of High Strength Fibre Reinforced Concrete Beams With Fibre Reinforced ...

Study Of High Strength Fibre Reinforced Concrete Beams With Fibre Reinforced ...

KrumheuerLast_Effects of Parameters on Bonding

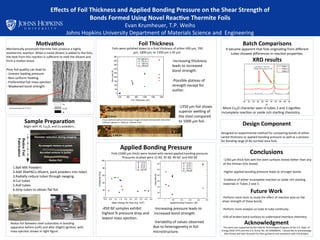

- 1. Effects of Foil Thickness and Applied Bonding Pressure on the Shear Strength of Bonds Formed Using Novel Reac@ve Thermite Foils Evan Krumheuer, T.P. Weihs Johns Hopkins University Department of Materials Science and Engineering Mo@va@on Mechanically processed thermite foils produce a highly exothermic reacDon. When a metal diluent is added to the foils, the heat from this reacDon is sufficient to melt the diluent and form a molten braze. Poor foil quality can lead to: -‐ Uneven loading pressure -‐ Non-‐uniform heaDng -‐ PreferenDal foil mass ejecDon -‐ Weakened bond strength Sample Prepara@on Design Component Designed an experimental method for comparing bonds of either varied thickness or applied bonding pressure as well as a process for bonding large (4-‐8x normal) area foils. Foil Thickness Applied Bonding Pressure Conclusions Future Work Acknowledgment This work was supported by the Vehicle Technologies Program of the U.S. Dept. of Energy (DOE-‐VTP) and the U.S. Army, No. DE-‐EE0006441. I would like to acknowledge Alex Kinsey and Kyle Slusarski for their guidance and assistance with this project. Batch Comparisons It became apparent that foils originaDng from different tubes showed differences in reacDve properDes. XRD results -‐More Cu2O character seen in tubes 2 and 3 signifies incomplete reacDon or oxide rich starDng chemistry. Foils were polished down to a final thickness of either 400 µm, 700 µm, 1000 µm, or 1350 µm ± 45 µm. Redox foil between steel substrates in bonding apparatus before (Lee) and aeer (Right) igniDon, with mass ejecDon shown in right figure. -‐Increasing thickness leads to increased bond strength. -‐Possible plateau of strength except for outlier. 1. Ball Mill Powders 2. Add 30wt%Cu diluent, pack powders into tubes 3. Radially reduce tubes through swaging 4. Cut tubes 5. Roll tubes 6. Strip tubes to obtain flat foil Begin with Al, Cu2O, and Cu powders… Foils (1000 µm thick) were tested with varied applied bonding pressure. Pressures studied were 15 lbf, 45 lbf, 90 lbf, and 450 lbf. -‐1350 µm thick foils wet the steel surfaces tested beker than any of the thinner foils tested. -‐Higher applied bonding pressure leads to stronger bonds. -‐Evidence of either incomplete reacDon or oxide rich starDng materials in Tubes 2 and 3. -‐Perform more tests to study the effect of reacDon area on the shear strength of these bonds. -‐Perform more analysis on tube to tube conDnuity. -‐EDS of broken bond surfaces to understand interface chemistry. -‐Increasing pressure leads to increased bond strength. Cross secDonal opDcal microscope images of bonds formed with foils either 1350 µm (above) or 1000 µm (below) thick. -‐1350 µm foil shows superior welng of the steel compared to 1000 µm foil. -‐450 lbf samples exhibit highest % pressure drop and lowest mass ejecDon. 400 600 800 1000 1200 1400 0 50 100 150 200 250 300 350 400 450 400 µm 700 µm 1000 µm 1350 µm MaxLoad(N) Foil Thickness (µm) Unreacted redox foil 2” by ¼” 0 100 200 300 400 500 50 100 150 200 250 300 350 15 lbf 45 lbf 90 lbf 450 lbf LoadHeld(N) Applied Bonding Pressure ( (lbf) 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 0 20 40 60 80 100 15 lbf 45 lbf 90 lbf 450 lbf %PressureDrop Mass Change Per Area (mg / mm 2 ) -‐Variability of values observed due to heterogeneity in foil microstructure. 30 32 34 36 38 40 42 44 46 48 50 2T Tube 1 Tube 2 Tube 3 Cu2O Peak at ~36° and masked by shoulder at ~42° Cu Cu2O Al