The document discusses the composite redesign of an Olympic diving board, focusing on utilizing an e-glass/epoxy composite for improved performance and cost-effectiveness compared to a traditional aluminum board. Key aspects include the selection of materials, manufacturing processes such as pultrusion, and finite element analysis to ensure the new design meets strength and resilience requirements. The final conclusion highlights the comparable strength of the composite board along with advantages in chemical resistance and reduced cost, although it may have a shorter lifespan due to material fatigue.

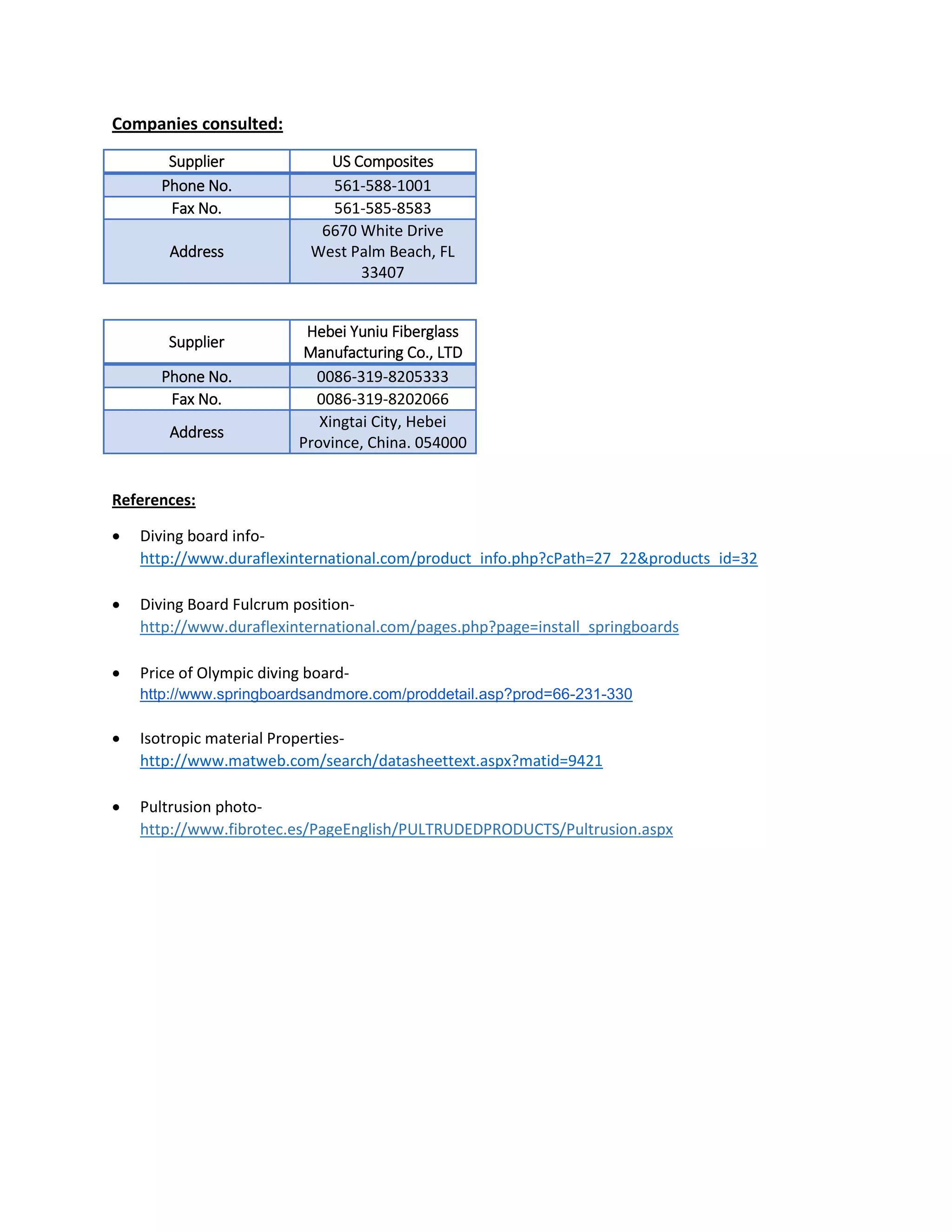

![At first we analyzed the orientation of the lamina for the laminate using an anti-

symmetric four layer arrangement of . This was done to eliminate all

coupling so that the board will behave as much like the isotropic case as possible when loads

are applied. It was found that the max von Mises stress was 3882.6psi for top and bottom layer

and the inverse Tsai Wui criteria was each layer was far below failure. Then another analysis

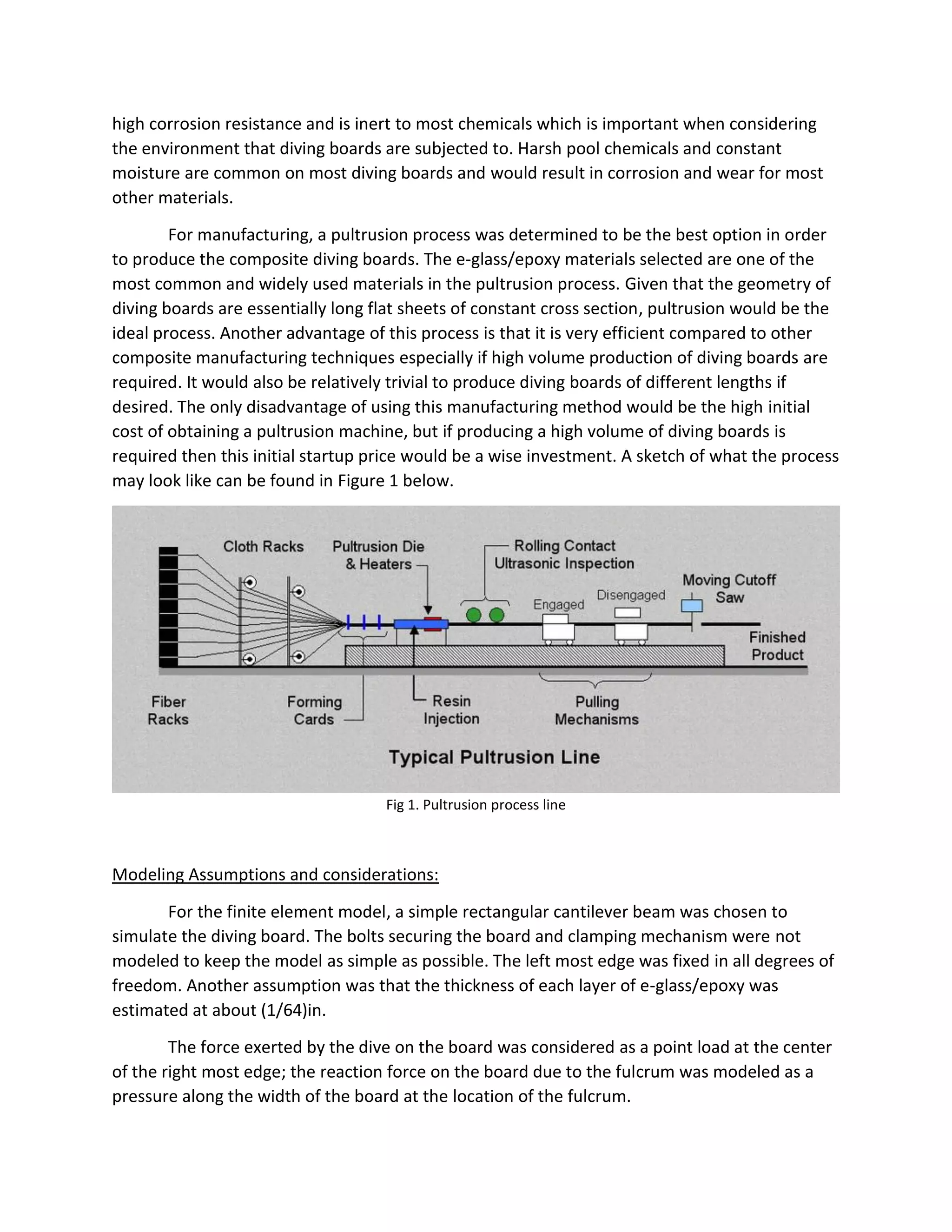

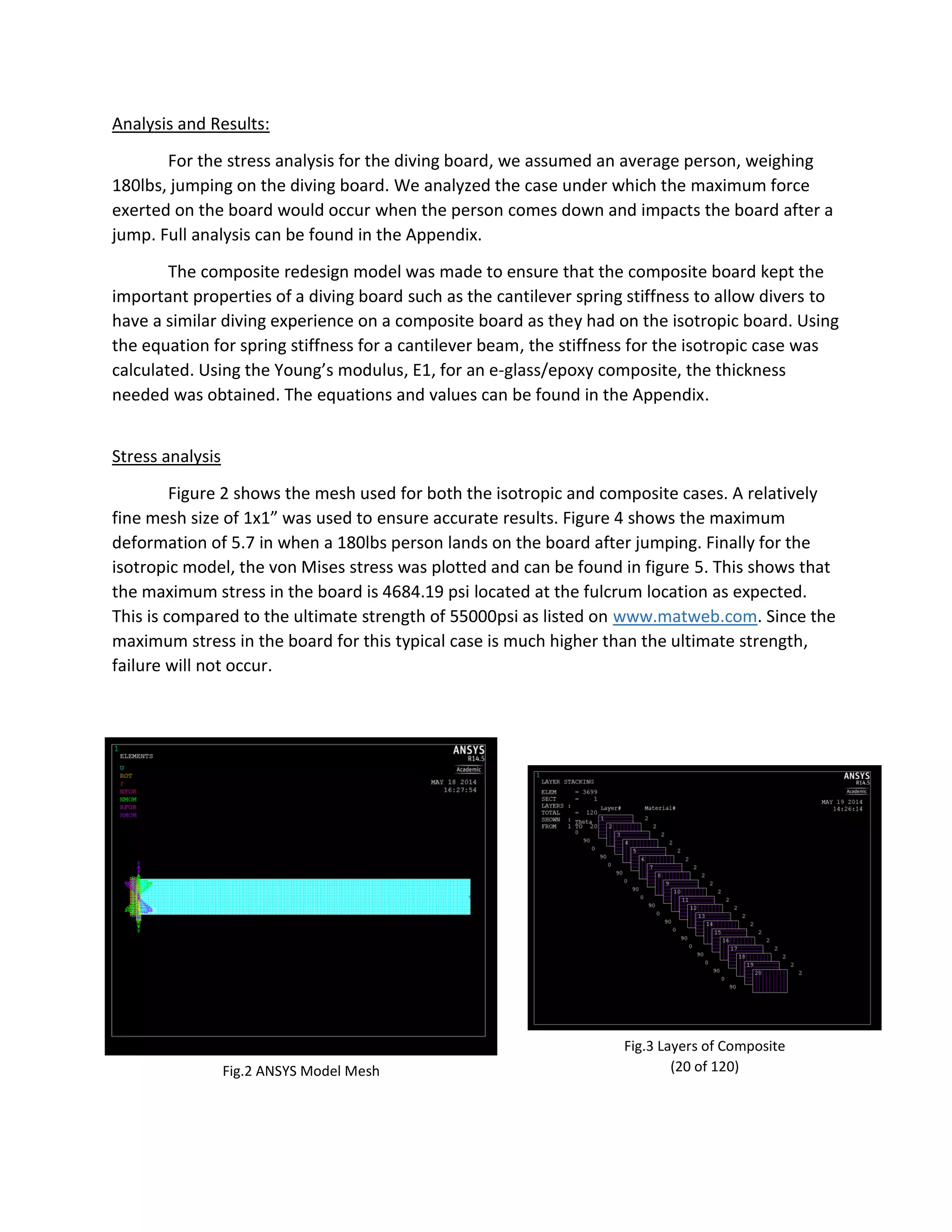

was performed for an orientation scheme of , (layers 1-20 can be seen in Figure 3),

which would also eliminate all of the couplings and it was found that from the von Mises

analysis the max stress in the top layer was 5409.18psi which is higher than for the four layer

arrangement case for that particular layer, but when the inverse Tsai Wui criteria were plotted,

max values were found to be around the same range depending on the layer’s orientation. So

either orientation would be acceptable for typical loading of the diving boards, both being very

far from failure. Comparisons can be found in in table 1.,the deflection of the composite can be

found on figure 5 above. The max Von Mises occurring at the top layer can be seen on figure7.

the Tsai Wui plots for the 0/90 orientation for the top middle and bottom layers can be found in

figures 8,9 and 10.

Isotropic [(45,-45,-45,45)_15]A [(0,90)_30]s

Max Von Mises (top layer) 4684.19 3882.63 5409.18

Max Von Mises (Middle layer) - 230.346 193.294

Max Von Mises (Bottom layer) - 3882.63 5409.18

Inverse Tsai Wui (top layer) - 0.2597 0.043595

Inverse Tsai Wui (Middle

layer)

- 0.015286 0.012822

Inverse Tsai Wui (Bottom

layer)

- 0.16765 0.040243

Inverse Tsai Wui (Max value) - .259742 0.246253

Table 1. Comparison of Stress Values

Fig 4. Isotropic Deformation Shape Fig5. Composite Deformation Shape](https://image.slidesharecdn.com/ab87927d-0186-44d2-bee5-f8e51de16f69-150428170820-conversion-gate01/75/Analysis-of-Modeled-Composite-Diving-Board-4-2048.jpg)

![Appendix

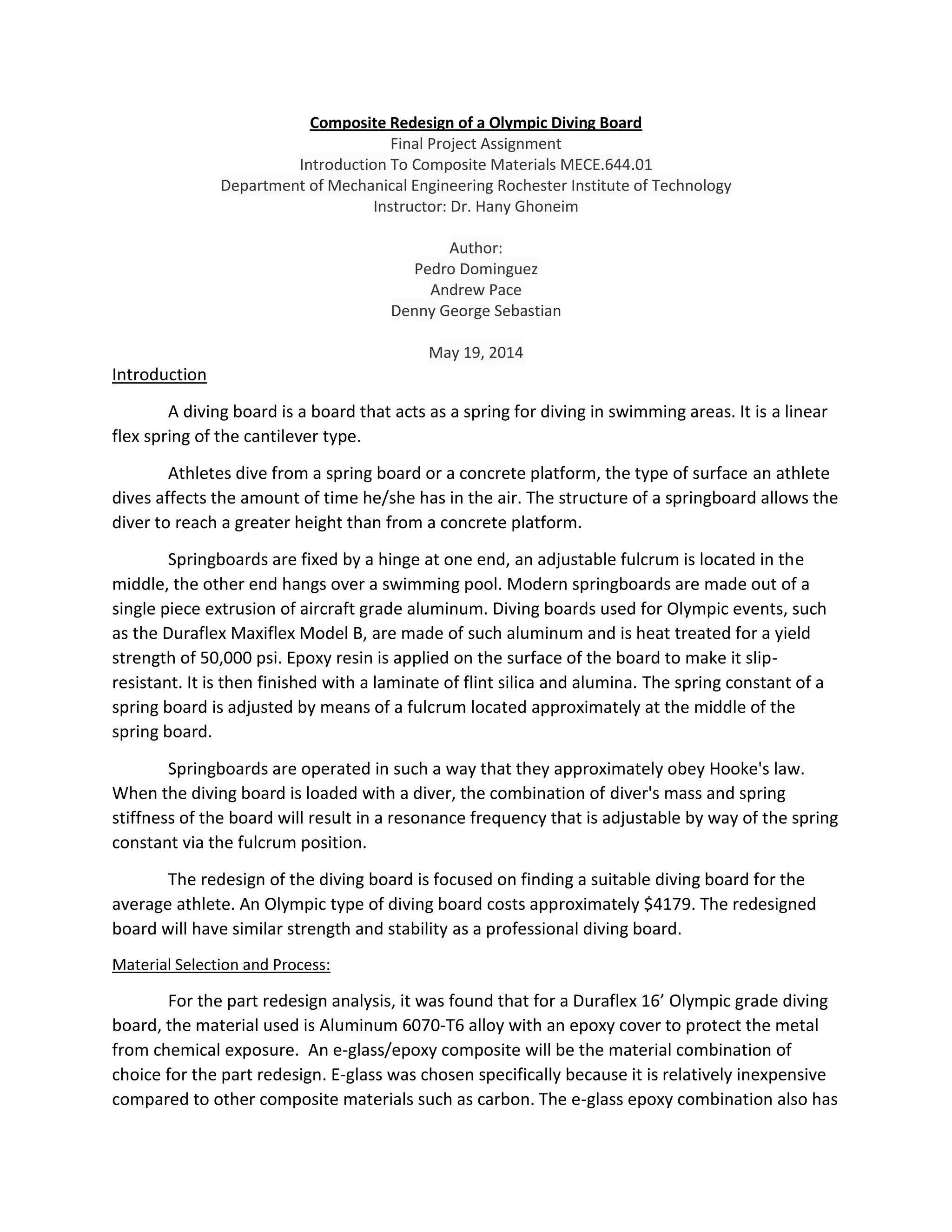

Parameters and Properties:

Parameters Description

W Diver weight lbs

h Diver jump height ft

g Gravity acceleration 2

ft s

d Deceleration distance ft

v Velocity at impact ft s

a Deceleration rate 2

ft s

G G-Force

iF Force at impact lbs

Material: E-glass/epoxy

Longitudinal modulus 1[ ]E Msi 6.527

Transverse modulus 2[ ]E Msi 1.741

Shear modulus 12[ ]G Msi 0.798

Shear modulus 23[ ]G Msi 0.508

Poisson's ratio 12 0.19

Parameters Description

k Diving board stiffness lbs in

w Diving board width in

L Diving board length in

fL Fulcrum length in

t Diving board thickness in

R Fulcrum reaction force lbs

Material: Aluminum

Modulus of elasticity [ ]E Msi 10

Shear modulus [ ]G Msi 3.77

Tensile strength [ ]Ksi 51

Shear strength [ ]Ksi 34

Poisson's ratio 12 0.33](https://image.slidesharecdn.com/ab87927d-0186-44d2-bee5-f8e51de16f69-150428170820-conversion-gate01/75/Analysis-of-Modeled-Composite-Diving-Board-7-2048.jpg)