David E. Kline Maintenance Resume

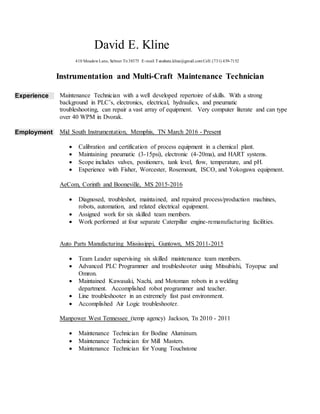

- 1. David E. Kline 410 MeadowLane, Selmer Tn38375 E-mail: Tanabata.kline@gmail.comCell: (731) 439-7152 Instrumentation and Multi-Craft Maintenance Technician Experience Maintenance Technician with a well developed repertoire of skills. With a strong background in PLC’s, electronics, electrical, hydraulics, and pneumatic troubleshooting, can repair a vast array of equipment. Very computer literate and can type over 40 WPM in Dvorak. Employment Mid South Instrumentation, Memphis, TN March 2016 - Present Calibration and certification of process equipment in a chemical plant. Maintaining pneumatic (3-15psi), electronic (4-20ma), and HART systems. Scope includes valves, positioners, tank level, flow, temperature, and pH. Experience with Fisher, Worcester, Rosemount, ISCO, and Yokogawa equipment. AeCom, Corinth and Booneville, MS 2015-2016 Diagnosed, troubleshot, maintained, and repaired process/production machines, robots, automation, and related electrical equipment. Assigned work for six skilled team members. Work performed at four separate Caterpillar engine-remanufacturing facilities. Auto Parts Manufacturing Mississippi, Guntown, MS 2011-2015 Team Leader supervising six skilled maintenance team members. Advanced PLC Programmer and troubleshooter using Mitsubishi, Toyopuc and Omron. Maintained Kawasaki, Nachi, and Motoman robots in a welding department. Accomplished robot programmer and teacher. Line troubleshooter in an extremely fast past environment. Accomplished Air Logic troubleshooter. Manpower West Tennessee (temp agency) Jackson, Tn 2010 - 2011 Maintenance Technician for Bodine Aluminum. Maintenance Technician for Mill Masters. Maintenance Technician for Young Touchstone

- 2. ThyssenKrupp Elevator Manufacturing Walnut, MS 2008-2010 Quality Technician for an Electronics Manufacturing Facility. Responsible for maintaining quality systems through scheduled and spot audits and supplier auditing. Maintained trend charts, Pareto charts, and other Six Sigma programs. Judge Technical Group Providence, RI 2008 U.S. Aerospace Selmer, Tn 2007 to 2008 Avionics Technician Component level troubleshooting of Avionic Systems Soldering and de-soldering on PCB’s and connectors Utilized Schematics and Blueprints as an aid in troubleshooting Yachad ,LLC Selmer, Tn 2002 to 2007 Scheffenacker Vision Systems Selmer, Tn 2000 to 2002 Injection Molding Set up / Maintenance Technician Set and started single and multi-color injection presses Adjusted simple processing during production runs Performed all maintenance on presses and ancillary equipment Yachad Home Maintenance Selmer, Tn 1997 to 2000 Contract Manufacturing Corp. Corinth, Ms 1995 to 1997 Electronics Technician Troubleshooting of many kinds of PCB’s for an assembly line in a manufacturing environment Certified in surface mount and through hole soldering All soldering done through a micro-scope or magnifier Utilized Schematics and Blueprints as an aid in troubleshooting Lockheed Missile and Space Corp St.Mary’s Ga 1995 Electronics Calibration Technician Calibration and repair of test equipment in a Depot level laboratory

- 3. United States Navy 1985 to 1994 Aviation Electronics Technician First Class (E-6/ Air Warfare) Calibration and repair of electronic test equipment (NEC 1588) 2M Mini level Soldering Certified (NEC 9527) Utilized Schematics and Blueprints as an aid in troubleshooting Navy Achievement Metal for meritorious service Valley Lutheran High School Diploma, Saginaw, Mi – June 1985 Avionics “A” School, Millington, Tn - April 1986 PMEL/Microwave Calibration School, Denver Co - July 1986 Electronics AVI-C7 School (Honor Grad), Millington, Tn - April 1991 Mil-Spec Soldering Certified, Jacksonville, Fl – Feb 1993 U.S Navy Leadership Academy, Jacksonville, Fl – Feb 1994 Weapons Spec Soldering Certified, St.Marys Ga – Jan 1995 Certified Genie BoomOperator – March 2011, July 2015 Maintenance Refresher, ICC Belden, MS, December 2011 Education