Old_Glory_Archive_-_Issue_9_-_26_August_2022.pdf

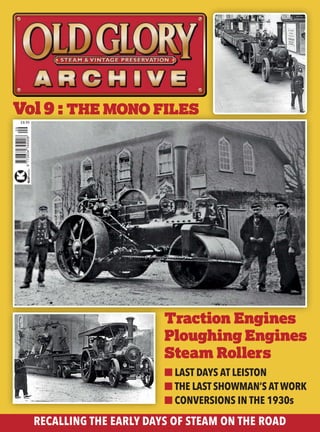

- 1. ■ LAST DAYS AT LEISTON ■ THE LAST SHOWMAN’S ATWORK ■ CONVERSIONS IN THE 1930s RECALLING THE EARLY DAYS OF STEAM ON THE ROAD Traction Engines Ploughing Engines Steam Rollers Vol9 : THE MONO FILES £8.99

- 2. ORDER ONLINE: shop.kelsey.co.uk/OG OR CALL: 01959 543747 (Lines open 8.30am-5.30pm Monday to Friday) *see website for overseas rates ALSO AVAILABLE BY POST IN THE OLD GLORY ARCHIVE SERIES OUR HERITAGE: AFLOAT PADDLE STEAMERS ★ STEAM SHIPS ★ STEAM TUGS & MORE Vol 7 : ON THE WATER £8.99 OG Colour Files 07 200x270.indd 1 10/02/2022 09:16 THE END OF WORKING STEAM ON THE ROAD, RAIL AND WATER IN THE 1960s STEAM RALLIES IN THE 1960s AND 1970s Vol5 : THE COLOUR FILES Mike Swift&Roy Miller £8.99 OG Colour Files 05 200x270.indd 1 12/08/2021 09:41 Nick Baldwin Vol6 £8.99 Nick Baldwin Part 2 Vol8 £8.99 Rallies in the 1950s and 1960s The making of the famous film THE IRON MAIDEN Engines at the end of their life Vol 1 : COLOUR FILES John Crawley £8.99 OG Colour Files 01.indd 1 12/08/2020 14:22 Vol8 STEAM WAGONS Undertypes and Overtypes Allchin ★ Clayton ★ Foden ★ Garrett ★ Hindley ★ Mann ★ Sentinel ★ Straker ★ Tasker ★ Thornycroft ★ Yorkshire Vol 2 : THE MONO FILES John Crawley £8.99 OG Colour Files 02.indd 1 12/11/2020 09:11 TRACTION ENGINES IN TROUBLE “ROLL UP, ROLL UP” FAIRS & FAIRGROUNDS ON THE ROAD WHEN FOWLER’S HAD A FIELD DAY Traction Engine Rarities and Oddities John Crawley Vol 3 : THE MONO FILES £8.99 OG Colour Files 03 200x270.indd 1 12/02/2021 15:41 £8.99 each inc p&p UK only*

- 3. Welcome to Old Glory Archive Volume 9 Front Cover: Various images from the Old Glory Archive. Series Editor: Colin Tyson Designer: Anita Waters, Publishing Works Managing Director: Phil Weeden Publisher: Paul Appleton Advertisement Sales: Sue Fixter, Publishing Works Tel: 01507 499081 sue@publishing-works.com Published by: Kelsey Publishing Ltd, The Granary, Downs Court, Yalding Hill, Yalding, Kent, ME18 6AL. Telephone 01959 541444, Fax 01959 541400, www.kelsey.co.uk T he archive of photographic images lodged with Old Glory magazine built up considerably over the three decades between 1990 and 2020 and it was always a pleasure to help enginemen by locating images of their engines from their commercial past. Contents Distributed by: Marketforce (UK) Ltd., 3rd Floor, 161 Marsh Wall, London E14 9AP. Tel: 020 3787 9001 Printed by: Pensord, Blackwood, South Wales © Kelsey Media 2022 all rights reserved. Reproduction in whole or in part is forbidden except with permission in writing from the publishers. The views expressed in this publication are not necessarily those of the Editor or the Publisher. Kelsey Media accepts no liability for products and services offered by third parties. ISBN: 26347458 First Published August 2022 We were also fortunate that during that time our Senior Correspondent and eminent early steam preservationist John Crawley provided a host of features drawn from his own incredible photo archive. The auction of material after his passing also enabled the magazine to purchase several volumes of photographs from engine manufacturers that were ‘thin on the ground’ in our own archive. After John died, another of our regular correspondents, Mike Dyson, who had already produced the popular ‘Road Test’ articles, where he was invited to drive other people’s engines, kindly offered to fill the gap left by John by running a series of archive features for the magazine drawn from his own collection. Mike owns a Garrett tractor and invited me aboard at an Old Warden rally – steering between trees and picnicking families certainly concentrated the mind! This volume is therefore a tribute to Mike’s efforts, before we return once again to our own archive and that of John Crawley’s. I hope you enjoy the issue. Colin Tyson Series Editor Fysons of Soham 4 London Haulage Contractors 8 Tasker Steam Wagons 12 Conversions in the 1930s 16 Savage Traction Engines 20 Wallis & Steevens Road Engines 24 Wallis & Steevens Steam Tractors 28 Wallis & Steevens Advance Rollers 32 Bernard Fielding Showman’s 36 The Last Days at Leiston 40 Single Cylinder Ploughing Engines 44 Merseyside Showman’s Engines 48 McLarens of Leeds 52 Burrell Single Crank Compounds 56 Showman’s built in 1920 60 Fowells of St. Ives 64 The Last Showman’s at Work 68 Tasker ‘Little Giants’ 72 Round Timber Haulage 76 Late Design Aveling Rollers 80 Lancashire Showman’s Engines 84 Showman’s Engines Lifting 88 John Crawley’s Traction Engines 92 Rollers with Scarifiers 96 3 OLD GLORY ARCHIVE

- 4. A FENLAND TRACTION ENGINE BUILDER C J R Fyson of The Mount Works, Soham Cambridgeshire millwrights and general engineers C J R Fyson & Son of the Mount Works, Soham built just 17 traction engines between 1894 and 1924 and sadly none have survived into preservation, says Mike Dyson R ichard Fyson the founder of the business, started as a millwright repairing and later building windmills and wind-pumps. As wind- pumps were quickly becoming obsolete and being replaced by steam engines, so Fysons moved with the times and became involved in the installation and maintenance of steam pumps – so essential for keeping the Fenland free from floods. At the same time, he became an agent for several agricultural machinery manufacturers. In 1891 a portable engine was completed with varying reports as to its size but probably an 8nhp. The boiler was hand rivetted, but the cylinder came from a scrapped engine. It was used by a local farmer for threshing and it was last heard of driving a stone crusher in the 1920s. Encouraged by the success of the portable and the increasing demand for engine repairs, it was decided to enlarge the premises to include a foundry. Most of the engines when completed were used by Fysons in their own contract threshing business, some hired out and some later sold. Eventually buyers would be The first traction engine built was T1, seen here with Charles Fyson standing on a stepladder holding his son. OLD GLORY ARCHIVE 4 THE MONO FILES

- 5. found but they were all in the immediate area with one engine escaping over the border into Norfolk and another into Suffolk. In 1894 the first traction engine, T1, was completed. This was remarkably like a Burrell with a three-shaft layout and two speeds with the gears outside the hornplate. The boiler, cylinder casting and motion were supplied by Burrells. Although the boiler for the portable had been built by Fysons, they were not confident they could provide one that would stand the stresses of a traction engine. The crankshaft, countershaft and back axle were provided by Robeys with the gears coming from Fowells. The rest of the engine including the wheels and tender were made by Fysons. The arrangement of buying in all the major components continued with the later engines. Most of the boilers came from Dodman of Kings Lynn with some from the Grantham Boiler & Crank Co. Cylinders were supplied by Burrells with gears usually sourced from Fowells of St Ives. Clarke’s Crank & Forge Co of Lincoln supplied a number of crankshafts. No T1 was used by Fysons in their own threshing business and was later sold to Summerlees of nearby Littleport – probably during WW1 where it was worked until the business closed in 1947. It was sold at auction complete with thrashing tackle to a local scrap merchant and cut up. T2 followed the next year and like all their engines was to be an 8nhp, 3-shaft single cylinder engine. As they were designed to work in the fens, brakes were considered unnecessary but when parking it was essential to remember to chock the wheels. A pump was fitted but an injector was thought to be an unnecessary expense. The engine was used by Fysons and then annually hired out for the threshing season to Josiah Aves, a miller at nearby Isleham. At the end of the season, usually June, it would be back at Soham for an overhaul. It was later sold to Lewis Pate of Little Downham, eight miles north of Soham. In 1922 it was sold back at Fysons who then fitted a new firebox and used it in their own threshing business until it sold in 1926 to J W Brooks of Little Downham where it worked until 1945 when it was scrapped. Eight miles to the west of Soham at T2 in the ownership of Fysons setting out at the beginning of the threshing season under hire to J Aves.The engine appears to have received a fresh coat of paint. HUGH DYSON COLLECTION Note the curved flywheel spokes of T3 that were a feature of the early Fyson engines. It would be easy to mistake the layout of the motion for a Burrell. This 1940 photograph shows T4 positioning the threshing machine alongside a corn stack in readiness for a day’s threshing. HUGH DYSON COLLECTION OLD GLORY ARCHIVE 5

- 6. The annual Soham Baptist Church Sunday School outing on its six-mile trip around the area hauled by T10.The engine is displaying its new registration number – CE 7801 which was issued in 1921 so by this time the engine will have been at least 10 years old. Fysons used T9 for over 35 years.The poor quality photograph shows ten men at work. HUGH DYSON COLLECTION Haddenham, William Burkitt ran his threshing business using a portable engine. Both he and Charles Fyson were friends and members of the Baptist church. In 1898 T3 replaced the portable and many years later it passed into the ownership of William’s son, Percy Burkitt. When the business closed in 1939 T3 was purchased by Frederick Peacock & Sons of Haddenham and continued in work but was out of use by the early 1950s, then sold for scrap in 1953. Fysons were usually busy on general engineering work but when times were slack progress could be made on building an engine. This ensured the skilled workforce would not be laid off when there was little regular work. In 1900 after a gap of two years T4 was finished and put to work. Some years later it was sold to the Summerlee brothers at Littleport joining T1. It was probably out of use by the end of WW2 and sold for scrap. T5 was finished in 1901, T6 in 1905, T7 in 1905 and T8 in 1907. Two engines were to be used by Fysons and there were customers for the other two. Their design was in many ways a hybrid of a Burrell and a Fowler. One conspicuous difference was the rear wheel spokes which were not rivetted to the rim but held in place by three taper bolts. It is claimed in the 1960s by one member of the Fyson family that they never had any problems with loose spokes! In 1908 T9 was completed and was hired out to Josiah Aves to replace T2. This was the first engine to be fitted with Pickering governors. It remained with Fysons until the end of the war and then scrapped. It was another two years before T10 was finished. From 1910 to 1944 it worked for Fysons until it was sold by auction in July 1944. The catalogue described it as “Boiler fully insured and recently inspected”. The accompanying equipment included a Clayton threshing machine and a Fyson built elevator. Thomas Read & Son bought the engine for use on their farm at March. It was out of use after the war and then scrapped. The only compound engine to be built was T11 which was constructed from the remains of Fowler No 11276. This was a class B6 which was built in 1908 and whilst en route to its new owners it was lost at sea. The remains consisting of the boiler and top works which were salvaged and purchased by Fysons. The rebuilding was finished in 1911 and used by Fysons. For some unknown reason it was not a popular engine with its drivers. Later, it was sold to Baldocks of Haverhill and soon returned to Soham. It was out of use in the yard but was not included in the 1944 auction and was later scrapped. By 1914 T14 was under construction and later exhibited at the local Ely County Show presumably with the intention of finding a buyer. However, the engine was put to work in the firm’s own fleet of threshing engines and continued in use until 1948 when it was sold to Peacocks of Haddenham. It is possible this was used to replace T3 which required a new firebox. By the early 1950s it was out of use and in 1954 sold for scrap. In 1915 another boiler arrived from Dodmans and work started on the construction of T15 which was completed the following year. It was used by Fysons but by 1945 a crack had developed in the firebox and thought too expensive to repair. It was purchased by Peacocks of Haddenham as a source of spare parts for their other Fyson engines. It was finally scrapped in 1953. The boiler for T16 was completed by Dodmans in June 1921 and ready for an OLD GLORY ARCHIVE 6 THE MONO FILES

- 7. T14 parked in Peacock’s yard at Haddenham.The ashpan lays underneath the engine and the smokebox door is open. Note the Cambridgeshire licence plate No 278 attached to the hornplate. T15 threshing at Wicken with perhaps the farmer’s wife standing on the footplate. She is certainly not dressed for work! HUGH DYSON COLLECTION The rather poor-quality photograph of T17 shows it on the belt but with no sign of a driver! Notice this engine, like other later engines, has the usual straight spokes for the flywheel. HUGH DYSON COLLECTION Almost certainly, the only part of a Fyson engine to survive is this nameplate. hydraulic inspection by Fysons. Work on this engine did not start immediately as it took some time to order the many components. By September John Browns of Sheffield were supplying the T-rings and spokes for the wheels. Clarke’s of Lincoln were not able to have “the axle forging and single bent crankshaft” ready until the end of the year and Penney & Porter also of Lincoln did not have the gears ready until early December. The engine was finally finished in April 1922 and joined the firm’s own fleet. At the 1944 auction, T16 was described as “Boiler fully insured and recently inspected” and sold to Arthur Goodman of Ramsey. It was still in use in 1950 and later scrapped. The final engine built at Soham was T17 which emerged in 1924 and joined the fleet of Fyson’s threshing engines which did include Burrells, Fowlers, a Garrett, and an Allchin. However, T17 was not included in their 1944 auction and is believed to have finished work in 1951. supply almost everything to the local farming community. No job was too small – even a couple of hen coups were supplied to a customer. The vast amount of paperwork generated before the introduction of the telephone is unbelievable. Letters, postcards and telegrams arrived each day in large numbers. Keeping control of finances must have been a nightmare with many farmers for months on end and then often only paying off part of their debt. It was vitally important that Fyson representatives were at Ely’s Thursday market to meet farmers and remind them how much money they owed. Post war, Fyson continued as general and agricultural engineers eventually specialising in the building of elevators for agriculture and the bulk loading and unloading of ships. In 1991 the business finally closed and the works were demolished. The site is now a housing estate but a little further down the street is the house that was lived in by Charles Fyson and his family. Fysons could never be regarded as traction engine builders. Their engines, although well made, appeared on the market too late to compete with the established manufacturers. With major components being supplied by established builders, I am sure there was an understanding that if they sold their engines, they would not try to sell them cheaper. Only five of the 17 engines were sold directly to customers. I am indebted to the late Tony Brown and his father Reg for giving me copies of their research into Fysons. Without their timely intervention many of the records of this small company would not have survived. Currently a 4in scale model of a Fyson engine is being built but I am assured this is a long-term project and will not be completed for some time. ■ Although only a small business when compared with other traction builders, they employed a large number of people. In addition to the repair of farm machinery, they were agents for Clayton & Shuttleworth selling a number of their threshing machines and also agents for Ruston & Hornsby oil engines. They could OLD GLORY ARCHIVE 7

- 8. SOME LONDON HAULAGE CONTRACTORS There were a number of steam haulage contractors in and around London capable of moving large loads such as boilers and transformers around the capital, says Mike Dyson N ames such as Rudd, Hickey, Coulson and Ward worked around the city demonstrating their skills and expertise in managing large engines and sometimes not such A big load for Ward’s Garrett tractor No 3270 which is fitted with wood-block wheels.The economy boiler weighs around 25 tons! OLD GLORY ARCHIVE 8 THE MONO FILES

- 9. LEFT: Burrell No 2701 Black Prince is fitted with rubber tyres and has electric lighting supplied by a steam turbo-alternator mounted on its nearside belly tank. A view of Hickey’s yard in 1920 showing Burrell No 3829 His Majesty when fitted with a swan-necked jib which was later replaced with a straight jib. ADAM BROWN COLLECTION RIGHT: Hickey’s Burrell No 3489 City of London is returning to Richmond with a boiler weighing around 15 tons.The engine was photographed before 1923 as it still on steel wheels. Note the large acetylene generator mounted on the belly tank and the three acetylene lamps on the front. large engines with heavy loads. Perhaps the best-known London haulage contractors were Hickeys who were based in Richmond, Surrey. They were established in 1881 as boiler repairers. They soon became boiler makers and machinery dealers and were involved in the haulage of machinery using teams of horses which later gave way to steam power. Their first large haulage engine was a Clayton & Shuttleworth compound road engine named Goliath of which little is known. In 1914 Hickeys purchased a second- hand Burrell engine. This was 8nhp No 2701 named Black Prince which had been supplied to timber merchant James Harris of Hook Norton, Oxfordshire. After an overhaul it was to put to work and in the 1920s the engine was fitted with rubber tyres and new wheels supplied by Burrells. In the early 1930s it was sold to Fred Gray, the well-known showman based at Hampstead in North London. The engine was converted to fairground use and after the war was sold for scrap but not cut up. In 1962 it was rescued by Alan Bloom, the founder of Bressingham Steam Museum and is now preserved in Scotland. In 1919 Hickeys purchased another second-hand Burrell No 3489. This was a 6nhp road engine built in 1913 for Ponsford of Topsham, Devon. It had an overhaul and was named City of London. In October 1923 new wheels complete with endless rubber tyres were supplied OLD GLORY ARCHIVE 9

- 10. Again the same long beam with Fowler No 14861 moved to the front. Note the steel strakes on the rear wheels and rubber tyres on the front. Crossing one of the London bridges with a heavy load is Garrett tractor No 33380 owned by Coulsons. Two policeman are required to assist in the haulage of this very long beam. Coulson’s Fowler No 9904 heads up the road train with Fowler No 14861 at the rear. by Burrells and fitted to the engine. The engine was regularly used for the haulage of boilers and other loads, ranging from barges to ship’s propellers. By 1931 steam haulage was no longer economic and the engine was put up for sale but did not find a buyer until 1935. The new owner was Dagenham showman Swales Bolesworth who converted it to a showman’s engine. Two years later it was sold to Teddy Andrews of Tunbridge Wells who renamed it George VI and it retired from the fairgrounds in 1948. It is now preserved in Oxfordshire. A useful engine for a boiler maker is a crane engine. Hickeys purchased Burrell 6nhp crane engine No 3829 from Hoopers of Liskeard, Cornwall, which had been delivered in March, 1920 and named Mount McKay F W C. after a Canadian mountain. By October of that year it had been purchased by Hickeys, complete with its swan-necked jib. The engine was lettered with Hickey’s name and the engine renamed His Majesty. It was not long before the jib was found to be unsatisfactory and it was replaced with a straight jib. Unlike the other engines it continued to be in use after the other steam engines had been sold. It continued in use until 1950 and was later restored by the firm. It is now preserved in West Sussex. Another haulage contractor operating in the London area were Coulsons based at Park Royal in West London. They had started in business near Sleaford, Lincolnshire, specialising in the haulage of gravel pit barges. By 1925 they had relocated to London moving and erecting heavy machinery. One of their biggest contracts was moving two 75-ton transformers to a hydro-electric power station in Scotland from the local railway station. There were no proper roads across the open moorland and it took three weeks to cover just twelve miles! Coulsons purchased Fowler class R3 No 14861 in 1925. It had been built for the War Dept in 1917 and was bought in 1920 by Edgar G Edgar. For some unknown reason the engine was re- possessed by the War Dept in 1923 and two years later was with Coulsons. The business was taken over by Pickfords in 1941 and the Fowler went out of use. OLD GLORY ARCHIVE 10 THE MONO FILES

- 11. Part of a crane is being hauled through Ipswich by Rudd’s Fowler No 14921.Although fleet No 147, this was the only large engine operated by Rudds. In 1946 it was sold to Allan Knight of Huddersfield and scrapped. Another big engine owned by Coulsons was Fowler class B5 No 9904 which was supplied to E.W Wright of Alton in 1904. Although an old engine, it was purchased in 1929 for the Scottish contract and was used throughout the 1930s. In 1943 it was purchased by Samuel White of Owlesbury, Hampshire, for use as a threshing engine and then sold to a Norfolk nursery for soil sterilisation. It is now preserved in Yorkshire. In addition to the Fowlers, Coulsons owned a number of steam wagons and steam tractors. Garrett 4CD tractor No 33380 was part of a large order by the Ministry of Munitions which left Leiston in 1918. After the war it was purchased by Coulsons initially working in Lincolnshire and later in London. By 1945 it was in the ownership of Hickeys who appear to have had little use for the tractor. It was sold in 1953 for preservation and has now been converted to a showman’s tractor. The Rudd haulage business was started in 1889 with premises in Westminster. It was not long before they made the move to Bow where they were near engineering works, shipbuilders and the docks. Edward Rudd was a great friend of Frank Garrett and it is not surprising he owned a number of Garrett wagons but he was also an agent for Couthard and Sentinel. In 1921 Rudds wanted a large engine and purchased Fowler class TE2 No 14921 which had been built for the War Dept in 1917. It was converted to a crane engine and used frequently for delivering boilers to the docks. It had little use after the war and in 1950 went to Goodmans of Tottenham to be scrapped. In 1933 Rudds had the contract to move a 120-ton transformer from Hackbridge near Croydon to the new Barking Power Station in Essex. To help with the work Hickeys assisted with their Burrells No 3489 City of London and No 3829 His Majesty. The load was too heavy to travel over any of the Thames bridges. It was unloaded at Rotherhithe and lifted onto a barge with a 200-ton floating crane. The barge with the transformer was then taken across to the north side of the Thames where it was re-loaded on to its trailer for the final stage of the journey. Thomas Ward of Silvertown in the east end of the capital were machinery merchants specialising in the supply and erection of boilers. Their main business had been established in Sheffield in 1877 as coal, coke and iron merchants later moving in to the scrap metal business. They did not have any big road locos but a small fleet of overworked Garrett tractors. Garrett 4CD tractor No 32740 was purchased in 1915 and was fitted with Bauly Tangent wheels which had a composite wood and rubber tread, noted for their quiet running and non- slip properties. By the 1930s Ward’s Silvertown operation was concentrating more and more on scrap metal with less work for the tractor and in 1937 it was scrapped. For a short time between the two world wars steam was the ideal method for the haulage of large loads – particularly heavy bulky items such as boilers and transformers. By the 1930s steam was slowly giving way to the likes of Scammell and Albion and after the war steam was no longer being used for heavy haulage. ■ OLD GLORY ARCHIVE 11

- 12. M ARCHIVE TASKER STEAM WAGONS Between 1910 and 1924 Taskers of Andover produced 121 wagons with the majority being 5-tonners, says Mike Dyson F rom the early 1900s Taskers developed their ‘Little Giant’ steam tractors which became one of the most successful on the market. The tractor formed the basis for a 5-ton wagon overtype wagon with the first one completed in 1910 in time to be exhibited at the Gloucester Royal Show. However after the First World War the Tasker wagon design was somewhat dated and sales declined rapidly. The business went into decline and in 1932 the company was saved when it was reorganised as a builder of trailers for commercial vehicles. In 1938 the Air Ministry required a recovery trailer to carry an entire fighter aircraft. On receipt of the tender it took just 10 days for Taskers to not only produce a written and costed proposal, but they also built a prototype trailer. Could a British company respond in a similar way today? Like the steam tractors, much of the design work of the steam wagon was The wagon supplied to Southend-on-Sea Corporation No 1430 was fitted with a firehole door on the side of the boiler, similar to those of Mann wagons. OLD GLORY ARCHIVE 12 THE MONO FILES

- 13. The tipping gear fitted to No 1454 was manually operated although some of the later wagons were fitted with an arrangement driven off the flywheel. Notice the absence of the flywheel at the end of the crankshaft. Wort & Way took delivery of No 1722 in 1917 and it last worked for Arthur T Booth (Manchester) Ltd in the early 1930s. PETER LOVE COLLECTION carried out by George Hoare. It was a typical overtype wagon with a Belpaire boiler and like those fitted to the B2 tractors. However, the boiler was shorter and of greater diameter, so it had a greater heating surface. Some of the boilers had the firehole door at the side, similar to the Mann wagons but this feature was discontinued after 1911 apart from one built in 1922. However, this may have fallen foul of Mann’s patent. The boiler was fitted with 48 1½in tubes and operated at 200psi. It was usual to fit two injectors but a pump could be supplied. The compound engine had cylinders of 4½in and 6½in with a 7in stroke for the 5-tonners but the bore and steam pressure were increased for the four larger wagons that were built. The engine had valves operated by Stephenson link motion but utilised a proper double high system so that high pressure steam could be admitted simultaneously into both cylinders. Like the tractors, the wagons had fast-revving engines and was claimed to produce almost 30bhp at 340rpm. Experiments were conducted to do away with a single flywheel and use four small 15in flywheels instead in an attempt to have a better-balanced engine. However few wagons were produced with this arrangement as it was a lot cheaper to fit a single flywheel. Most wagons had two- speeds but if solid rubber tyres were fitted a third speed was an optional extra. The Commercial Motor was impressed with the differential locking gear which could be operated from the footplate but this was only available as an optional extra. Chain steering was used apart from two which had Ackerman steering. The first wagon to be completed was No 1418 which was dispatched in February 1910. The fourth wagon No 1430 left the works in July 1910 and was described as a “steam watering van” – used for spraying water on dusty roads. To achieve a shorter wheelbase, the wagon was fitted with a side-fired boiler. It was thought the fireman’s perch was rather dangerous and later wagons beginning with No OLD GLORY ARCHIVE 13

- 14. No 1678 might have been the first of a large number of wagons supplied to Dutfields but instead they chose to purchase Sentinels in large numbers. Perhaps the beer drinkers around Bishop’s Waltham had immense thirsts so that a small brewery would require a steam wagon such as No 1616 to make regular deliveries to its 11 pubs. By this time the design had reverted to a standard flywheel. 1475 had the firehole door fitted in the normal position so the fireman could have a safer seat beside the driver. No 1418 was supplied to Southend-on-Sea Corporation which used it up until 1930 by which time most roads had been tarmacked and the wagon was no longer required for spraying dusty roads. It was later sold for scrap. In 1911 the Enderby & Stony Stanton Granite Co Ltd, south-west of Leicester, took delivery of two wagons. Both Nos 1554 and 1455 were tippers and the shorter wheelbase for the tipping gear was achieved by again using a firehole door on the side of the boiler. Wagons working in quarries would have been hard work with excessive strains and wear on all the components. Both wagons were used until 1929 when they were sold for scrap. No 1616 was a more orthodox design with a single flywheel. The 3-ton wagon was supplied in 1914 to Edwards’ Brewery of Bishop’s Waltham, Hampshire, to supply its 11 pubs. In 1923 the Winchester Brewery purchased the business and no doubt cost saving and rationalisation was the order of the day with the wagon scrapped the following year. H & G Dutfield, the heavy haulage contractors of Smithfield purchased five Foden wagons in 1914 and 1915 but at the end of 1915 purchased two 5-ton wagons from Taskers, Nos 1678 and 1681. Taskers did not receive any further orders from Dutfields who went on to purchase 26 Sentinels and a further six Fodens. No 1678 was sold in 1921 to Charles Walker of Canning Town and by 1923 was with J.A King of Hayes, Middlesex, and was eventually scrapped. Tasker’s best customer for steam wagons was the public works contractors Wort & Way of Salisbury who purchased a total of twelve wagons. The first was ordered in 1915 but in 1920 eight were delivered. In 1923 the business together with the fleet of around 50 steam wagons was taken over by Hodgson Road Contractors Ltd of Manchester. Throughout the 1920s many of the wagons were sold but the Tasker wagons continued in use. There were further changes in 1930 when the business became Arthur T Booth (Manchester) Ltd. It was not long before all the steam wagons were scrapped. The Hampshire millers, J.H Bradfield & OLD GLORY ARCHIVE 14 THE MONO FILES

- 15. Although built in wartime, there is little sign that No 1749 was painted with economy in mind. The first of the Forfarshire wagons No 1849 was based at Dundee.The chain drive to the tipping gear can be seen below the motion cover. Son of Stockbridge owned a Tasker Little Giant tractor and two Foden wagons. In 1918 they added to their fleet with the purchase of Tasker 5-ton wagon No 1749. The Fodens were scrapped by the late 1920s but the Tasker continued to work into the 1930s. In 1934 the wagon was sold to the Chichester showman, James Cole who also operated a scrap metal business. Forfarshire County Council purchased two 5-ton tippers in 1921 (Nos 1849 and 1850) to add to their fleet of four Tasker Little Giant tractors. The following year a further order followed for another two 5-ton tippers (Nos 1908 and 1922). All four wagons continued in use until 1932 when they were sold for scrap. When Taskers launched their wagon in 1910 it was similar to many others on the market. The use of the four small flywheels and the placing of the firehole door at the side of the boiler were good features but they were soon discontinued in an attempt to make the wagon cheaper and more competitively priced. They had a reputation as good steamers and were frequently overloaded without causing any problems. The war years limited the scope for improvements to the design but after the war this was vitally important. By this stage other manufacturers had updated their designs and overtypes built by Sentinel, Garrett and Yorkshire were setting new standards in speed and efficiency. Taskers were a small company and did not have the capital to invest in new models. ■ OLD GLORY ARCHIVE 15

- 16. CONVERSIONS IN THE 1930s The conversion of traction engines is not a modern phenomenon. In commercial days it was not unusual to convert an engine for a different purpose if it was financially worthwhile, says Mike Dyson ABOVE: To supply power to even a small Ark a 6nhp engine such as Burrell No 3489 King George VI has to be worked hard. LEFT: Mrs Symonds’ Burrell No 3979 Earl Haig was photographed at one of the London fairs. Notice the canopy stays have not been fitted with twisted brass. ABOVE RIGHT: Burrell No 3836 Starlight at Wormwood Scrubs Easter Fair in 1939.After dark it was generating for the Dodgems although it says ‘Light’ning Skid’ on the canopy. RIGHT: Heal’s engines and rides were always well turned-out and Burrell No 3980 Her Majesty was no exception.The ‘Broadcast Show’ may refer to a radio broadcast from Heal’s fairground. OLD GLORY ARCHIVE 16 THE MONO FILES

- 17. A fter the First World War there was a great increase in road traffic. Large numbers of internal combustion engine lorries became available at war surplus sales. Petrol lorries were ideal for light haulage but the heavier work was more suited to steam. The cost of haulage by road became so much cheaper than sending it by rail. The railway companies argued this competition was unfair. In 1900 the annual cost of roads was £12 million but by 1932 the cost had risen to £61 million. The cost was in effect paid for by taxpayers. The cost of maintaining the railway network was £64 million, paid for by the railway companies. The Salter Report dated July 29, 1932, proposed that mechanically propelled vehicles should contribute the whole of the £61 million with £23½ million coming from commercial road vehicles and £36½ million from other road users. What made matters worse for steam operators was the Report noted that there was a duty of 8d duty on a gallon of petrol but there was no duty to be paid on coal, so there was therefore a hidden subsidy for steam vehicles. The vehicle licence fee was the same for all types of vehicle and this was thought to be unfair as heavy vehicles did more damage to the roads. The Report recommended the licence duty for commercial vehicles should to be based on weight and the findings of the Report formed the basis of an Act of Parliament - ‘The Road and Rail Act 1933’. However, agricultural engines and showmen’s engines were treated less severely and were not subjected to the same increases in duty. The effects of the changes in legislation are well known with steam wagons some almost new being withdrawn from service as the cost of taxation made them uneconomic to operate. Road locos fared little better especially as solid rubber tyres attracted additional costs to the vehicle duty. Showmen realised that good road locos could be purchased very cheaply and once converted with the addition of a dynamo were ideal for hauling and generating for their rides. A converted Burrell engine was a good economic proposition when compared with an Armstrong-Saurer ‘oiler’ which were available after 1930. These were hard times as the country was going through a terrible economic depression with large numbers of people unemployed. The fairground business was obviously affected as people without jobs were not going to have any spare cash to spend at a fair. Many of the conversions were therefore carried out by the showmen themselves utilising old equipment where possible such as the dynamo bracket, dynamo, canopy and supports. Many of these conversions replaced existing engines which needed major repairs. Buying a cheap road loco was preferable to paying to have a new firebox fitted to an existing engine. Burrell No 3489 is an unusual looking 6nhp engine as it was supplied with the usual 6ft 6in rear wheels but had smaller 4ft 1½in ones on the front. It was built in 1913 for Ponsfords of Topsham, Devon, but by 1921 was with Hickeys, the well-known London boilermakers. It was named City of London and in 1923 it had replacement wheels of the same size supplied by Burrells and was fitted with solid rubber tyres. It was converted in 1935 for Swales Bolesworth of Dagenham for use with his new Lakin Ben Hur Speedway. Two years later it was sold to Teddy Andrews of Tunbridge Wells who renamed it King George VI in honour of the new king. The engine went to work with an Orton & Spooner Ark known as the ‘Jungle Thriller’ which is now owned by the Carter family. King George VI was retired in 1948 and soon afterwards purchased for preservation and has now been owned by the Wharton family for over 70 years. Noah Judd of Chackmore in Buckinghamshire took delivery in 1920 of a Burrell 6nhp road loco No 3836 which was named Starlight. The engine was used for timber haulage, passing to new OLD GLORY ARCHIVE 17

- 20. By 1941 Burrell No 4042 Robin Hood was looking a little tired.The canopy reads ‘Robinson’s Tower Speedway’ – an unusual description for an Ark Many of the engines converted in the 1930s spent only a short time on the fairgrounds. Fowler No 13468 Queen Mary was only used for three seasons. owners in 1923 and was finally used by Gloucestershire timber haulier Charles Butler of Blockley. He had two Burrell road engines for sale. In 1934 Bob Edwards the well-known Swindon showman bought both engines selling No 2759 to showman H Jones of St Blazey, Cornwall. Starlight was immediately put to work hauling the Dodgem loads. It was later converted to full showman’s specifications and the canopy lettered ‘Light’ning Skid’ in anticipation of buying a Skid. However, the ride was not purchased. Starlight was the last steamer to be used by the firm. It remained in use up to 1939 when it was retained as back-up for the diesels which by now had replaced the other steamers. Edward Symonds used a Burrell showman’s tractor and after his death his widow, Flo, carried on the business with her sons. She sold the tractor and in 1937 purchased Burrell 6nhp road engine No 3979 from Taylors of Midsomer Norton, Somerset. This had been new in 1924 and had been worked hard on timber haulage. Over the winter of 1937 the family carried out the conversion and named the engine Earl Haig. It was then put to work with Burrell No 3833 Queen Mary with their Lakin Ark which they had purchased new in 1934. The ride called ‘The Jungle Speedway’ was jointly owned with Mrs Symonds brother-in-law, James Cook. The engine was only used for four seasons and in 1943 sold to Darby’s of Sutton in the Isle of Ely to be used for driving a thrashing machine. It was dismantled and remained derelict in the open for more than 20 years when it was purchased for preservation by the late Stan Burgess. Haulage out of the Bath & Portland Stone Firms Ltd quarries was exacting work and required large engines. The headstones for all the war cemeteries across France and Belgium were supplied by these quarries. Burrell 8nhp No 3980 was delivered in 1924. After eight years it must have done some hard work hauling blocks of stone but was purchased by the famous West Country showman Charles Heal to replace Fowler No 9383. The engine was overhauled, converted and repainted and named Her Majesty. The engine was used with a Swirl. In 1941 the engine was sold to Mrs Amy Lock of Plymouth for use with a Noah’s Ark and the following year both ride and engine were sold to William OLD GLORY ARCHIVE 18 THE MONO FILES

- 21. Townsend’s Fowler No 15319 Queen Mary is well-polished and looking very smart. Note the size of the dynamo. For such a large engine, McLaren No 1716 Miracle appears to have very small wheels. Armstrong of Long Eaton, Derbyshire. Her Majesty was out of use at the end of the 1945 season and was later scrapped. Another engine purchased from the Bath & Portland Stone Firms Ltd was Burrell 8nhp No 4042. It was purchased new in 1926 and worked on stone haulage for ten years when it was sold to Ernest Robinson of Barnsley. He converted the engine and named it Robin Hood. The family had purchased a Lakin Noah’s Ark and this was their first traction engine. After the war Robin Hood laid out of use until purchased by the Sheffield Model Engineering Society and later scrapped. In 1914 Fowler class R3 road engine No 13468 was delivered to Kent Haulage at Hoo Street, Weyburgh. They named the engine My Lady of Kent. After the war it was sold and after another three owners was purchased at auction by showman George Rogers of Chipping Sodbury in 1932. It had little use and was sold again in 1936 to Bristol showman, Sam Smart. The engine was now converted with the addition of a full-length canopy and a dynamo unlike their other Fowler road engine No 12702 which was acquired in 1938 and never fitted with a dynamo. No 13468 was named Queen Mary but by 1939 it was all change again as the engine was sold to W.E Chivers for road haulage and later in the war was scrapped. Another engine that entered showland service after working in the Portland quarries was Fowler class R3 road engine No 15319 which was supplied to the War Dept in 1918. It had two commercial owners in Newbury and by 1921 was hauling stone out of the quarries for Frederick Barnes of Easton, Dorset, and named Nellie. By 1936 the engine was out of use and it is claimed the showman, Richard Townsend of Weymouth, purchased the engine plus another for just £25. The engine was converted and named Queen Mary which seems to have been a popular name at that time. Later the brass fittings were chrome plated but this was soon changed back to plain brass! At first the engine worked a set of Gallopers and later with a Lakin Ark. By 1948 Queen Mary was retired and was purchased in 1950 for preservation. Twenty McLaren road engines were converted for use by showmen. In 1923 McLarens exhibited 8nhp road engine No 1716 at the Newcastle Royal Show. It was purchased by Stubleys of Batley, Yorkshire, for the transportation of goods in connection with their woollen mill. By 1933 it had been bought by Christopher Thompson of Keighley to replace 6nhp Aveling road engine No 8336. The McLaren was converted for fairground use possibly using parts from the Aveling. The engine was now named H.R.H Christina Rose but this was soon changed to Miracle. By 1942 it was no longer working on the Yorkshire fairgrounds but was being used for heavy haulage by Bentleys of Bradford. Three years later it was with Allan Knight of Huddersfield who sold it on to Tom Harniess, the Doncaster showman. However, it was scrapped soon afterwards. The 1930s was the last decade of steam on the fairgrounds. Diesel generating sets such as the Fowler-Sanders were more convenient, with no waiting time for raising steam or the need for an engine driver in constant attendance. With the end of the war in 1945 and the availability of large heavy diesel ex-military tractors that were cheap to buy, it was the end of steam. A few traditionalists hung on to their steam engines but they were soon set aside with the march of progress. ■ OLD GLORY ARCHIVE 19

- 22. SAVAGE TRACTION ENGINES Towards the end of the 19th century there were a number of builders such as Dodman, Tuxford and Holmes who built a few traction engines and then quietly disappeared. However, Savages did fare better as they gradually concentrated on producing fairground rides, writes Mike Dyson Samuel Wright, the owner of the chain drive engine, is standing on the footplate.The mounting on the crankshaft next to the chimney was to give sufficient space for the chain drive to the second shaft and rear wheels. OLD GLORY ARCHIVE 20 THE MONO FILES

- 23. S avage’s are best known for the many sets of Gallopers that have survived into preservation. However, Frederick Savage started his business manufacturing agricultural machinery in King’s Lynn in1853. Repair work dominated the order books after the Second World War and the company finally closed in 1973. The business started as a small workshop repairing and making simple farm tools. It was not long before small steam engines were built, with many being supplied for marine purposes. By the end of the 1850s the first portable engines were being built which were soon followed by traction engines. As the popularity of Savage’s products increased, larger premises were needed and in 1873 a large site was acquired whereupon the St Nicholas Ironworks was built, complete with its own foundry. Typical of the early period of traction engine development, the drive from the crankshaft to the rear wheels was via a chain. Various refinements were made to the design but the biggest improvement was the adoption of all gear transmission. By the 1870s two distinct types of traction engine were being produced: the ‘Agriculturist’ and the ‘Sandringham’. The ‘Agriculturist’ could be used as a ploughing engine using the annular space around each of the rear wheels as a winding drum and as a general purpose traction engine. The rear of the engine had to be jacked up so the winding drums could operate using a system of anchors and a plough. It continued in production until 1884. Other attempts at cultivation equipment were the Darby Digger but the successes of Fowler’s double engine system were well established by this time. The ‘Sandringham’ class was a more conventional general-purpose engine and was their most successful design. Various modifications were made including the use of a very slow speed gear. This might not seem important but manoeuvring a thrashing machine in the confined space of a farmyard with a single cylinder engine is very difficult and the extra slow speed gave the driver so much more control. The demand for fairground equipment was so great that the company started to move away from producing agricultural equipment with traction engine No 364 is shown when out of use.The valve chest on this engine is on the flywheel side but there are examples with it on the gear side. A pause in thrashing for the photographer to record No 138 at work with a thrashing machine. Note the drive chain has been disconnected and annular gear on the inside of the rear wheel which is driven by a cog on the end of the second shaft. JOHN SPARROW COLLECTION No doubt this photograph of No 291 was taken after the day’s thrashing. Notice the heavy type of governor has been replaced with a Pickering. DAVID BLISS COLLECTION OLD GLORY ARCHIVE 21

- 24. No 157 at work at Cottenham in 1905.The engine is fitted with an ‘inching gear’, which is a toothed gear on the inside of the flywheel. What appears to be the end of a long working life of over 50 years for No 388. Looking behind the flywheel can be seen the two sections of the hornplate rivetted together. production gradually coming to an end. The identity of the first photograph is somewhat problematic. It could be either No 124, 129, 143 or 149 as all four of these engines were 8nhp chain drive engines supplied to Barford & Perkins of Peterborough. Most of these engines were re-sold to customers who not only bought the engine but also Barford & Perkins ploughing equipment. The engine in the photograph was re-sold to Samuel Wright of Barrowden, Rutland, who was already an established thrashing contractor using portable engines but there is no record of him owning ploughing equipment. Whilst Wright and some of his men were pushing a thrashing machine into a barn, it rolled backwards crushing Wright against the front of the engine and he later died of his injuries. Another chain drive engine but with steering from the footplate is 8nhp No 138 which was purchased by Thomas Martin of Littleport near Ely in 1875. There was an overlap in production of the steering position in front of the smokebox to that of the usual arrangement with steering from the footplate and both types were available in 1875. The general arrangement is much the same with the crankshaft placed next to the chimney although the flywheel is now on the nearside. The wheels are made of wrought iron with spokes rivetted to a T-ring, an improvement on the earlier cast iron wheels. John Maskell of Cottenham near Cambridge took delivery of No 157 in 1876. Again, this is an 8nhp engine but it is fitted with cast iron wheels and the steering is in front of the smokebox. These early designs were all single speed and when driving a thrashing machine, the drive chain had to be disconnected. The final drive from a cog on the end of the second shaft to an annular gear inside the rear wheel must have caused problems with mud and stones being regularly caught in the gears. When on the road sharp corners had to be negotiated by taking one of the driving wheels out of gear. Most engines supplied by Savages were 8nhp. No 291 left the works in 1883 for Thomas Emblin under steam to be driven the 15 miles to Tydd St Giles. OLD GLORY ARCHIVE 22 THE MONO FILES

- 25. The engine eventually passed to Thomas Emblin’s son Ernest and worked for the family until it was joined by a Clayton & Shuttleworth which was purchased new in 1907. Both engines were sold in 1947 to Eric Ladbrook, a scrap metal dealer of Holbeach, Lincolnshire. Although many engines were being scrapped at this time, there was little profit to be made when cutting up an engine. When the cost of gas, wages and transport are taken into consideration, the scrap metal dealer would be lucky to make a profit of £5. No 364 was delivered to Frederick Stratton of Swaffam, Norfolk in 1885 and named Perfection. This was a ‘Sandringham’ class rated at 8nhp with a cylinder of eight and five-eighths inch bore with a 12 inch stroke and is described as having a ‘light pattern’ cylinder which is the same size as the 7nhp engines. The boiler pressure was limited to 120psi with the hornplates made in four pieces, no doubt to avoid infringing the Aveling Patent. By the early 1920s the engine had been sold to Herbert Loveday of Old Buckenham, Norfolk. For some years it was out of use and early in the 1950s it was scrapped. In 1886 William Rust of Buxton Lamas, Norfolk, took delivery of No 388, a 7nhp engine. By 1902 the business was being run by sons, James and Robert Rust. Over the years a number of Savage engines were owned. No 528 a 7nhp engine was purchased new in 1891, No 808 another 7nhp was new in 1903 with No 728 built in 1898 named Enterprise purchased second- hand in 1914 and finally 7nhp No 463 built in 1889 was acquired in 1944. After the war the traction engines were replaced with Field Marshall tractors which in 1947 were used to tow the now redundant engines to John Slender’s yard at North Walsham where they were eventually scrapped. Savage No 614 was supplied new to the well-known South Wales showman John Studt. It was a 7nhp single crank compound named Shamrock and had an annular compound cylinder. Three piston rods were fitted - two for the low-pressure cylinder and one for the high pressure - all working on a common crosshead. This was a very complicated arrangement and only three engines of this type were built. No 614 was not a success and was soon sold. The new owner was also dissatisfied and the engine was returned to King’s Lynn where the compound cylinder was removed and replaced with a conventional single cylinder. The engine was purchased by Richard Drake of Sutton near Ely for use in his contract thrashing and forage business, already the owner of five Savage engines. In 1935 the engine was purchased by Fred Darby & Sons, also of Sutton and worked for them into the 1940s and was scrapped in 1954. Towards the end of the nineteenth century there were a number of traction engine builders such as Dodman, Tuxford and Holmes who built a few engines and then quietly disappeared. However, Savages did fare better as they gradually concentrated their business on the production of fairground rides. For a short time they produced a few steam tractors and steam wagons but these were little more than experiments. Three Savage traction engines survive: a 7nhp ‘Sandringham’ and two replica chain engines which were built in 1975. ■ This photograph of No 614 clearly shows Savage’s patent slow-speed third gear.When the lever is raised vertically and locked into position, the low- speed gear is engaged. OLD GLORY ARCHIVE 23

- 26. OLD GLORY ARCHIVE 24 THE MONO FILES WALLIS & STEEVENS ROAD ENGINES Road engines are not usually associated with Wallis & Steevens. They are famous for their Advance rollers, their oil- bath tractors and their expansion traction engines but not road engines, says Mike Dyson

- 27. OLD GLORY ARCHIVE 25 L ike other traction engine builders, W&S produced road engines but unfortunately most have been scrapped. I understand there is one survivor but it has not been seen for many years. Wallis & Steevens built less than 100 road engines with a substantial number of the smaller sizes being exported. Production was really quite insignificant when compared with Burrell and Fowler. The traction engines built by Wallis & Steevens were popular with estates and large farmers where after the threshing season was completed the engine could be put to work on local haulage such as delivering roadstone to the side of the road in preparation for road improvements. A road engine was a logical development. The first road engines had a single cylinder and were fitted with motion covers, a plated flywheel and belly tanks. Later road engines were substantially built and used compound cylinders. These engines were intended for local haulage and shorter distance work or the haulage of heavy indivisible loads. Significantly many of the Wallis road engines ended up in the latter days of steam being used for agricultural work. Two road engines built in 1903 were 4-shaft (Nos 2643 and 2645) but all subsequent engines used 3-shafts. Initially LEFT: No 2437 is a large engine and curiously fitted with a governor so it could be used for agricultural work. Most of the men in front of the engine are holding the tools of their trade such as the young man on the left holding a spanner. BELOW LEFT: No 2505 looks quite magnificent when new and over the years was to have six different owners. RIGHT: A works photograph of No 2600 prior to delivery to Neaves of Fordingbridge. Notice the Salter safety valves which appear to have been phased out with the introduction of compound engines. BELOW: An 8nhp engine such as No 2452 owned by Oakhill Brewery would have had no trouble hauling these two trailers loaded with beer – even in the hilly area in this part of Somerset. the cylinder had a central steam chest with inclined valve faces – similar to the Fowler design. It is not surprising to learn that Alfred Robinson, the chief draughtsman at Wallis & Steevens had worked at Fowlers! Later designs had a more orthodox cylinder design with outside valves. Wallis & Steevens road engines were rather basic when compared with other makers and any unnecessary brass- work was not included. Boiler work was of a high standard with most of the plates being hand flanged and they did not have the problems associated with hydraulic flanging. However, when compared with other makes the shafts and bearings were not as substantial. As an example the Burrell main bearings were almost double in size to those fitted to a Wallis. Edwin Burt of Holt, Dorset purchased No 2437 in 1898 in part exchange for an 1882 Wallis traction engine. The new engine was an 8nhp single cylinder, sprung with a plated flywheel and belly tanks. By 1907 it had been sold to its final owner, Thomas Scutt of Blandford. As it was not registered for road use in 1921 it is assumed that it was out of use by that date. Another 8nhp single cylinder road engine was No 2452 which was supplied in 1899 to the Oakhill Brewery Co Ltd, Somerset, who produced a very popular stout. Much of their production was

- 28. OLD GLORY ARCHIVE 26 THE MONO FILES No 2728 was photographed at Basingstoke before dispatch. It shows a very compact engine but without a belly tank. Note the cylinder has a central steam chest with inclined valve faces – similar to the Fowler design. The photograph of No 2644 shows a very well-built engine with five rivets for each spoke in the rear wheels. Note the change to Ramsbottom safety valves. transported by the Somerset & Dorset Railway but more local deliveries were hauled by the Wallis. It was later sold to Bushby & Son of Headingley, Leeds, and was soon resold to Holme & King Ltd in Montgomeryshire until it went out of use sometime in the 1920s. In 1902 5nhp compound road engine No 2505 was delivered to George Hickson of Grimsby. This was a fully sprung single cylinder engine with motion covers and a plated flywheel but without belly tanks so obviously long journeys were not planned. The following year it was sold to John Drury of Laceby, Lincolnshire, and by 1921 had been sold to Birmingham showman James Shepherd. The engine was fitted with twisted brass to the canopy but it seems most unlikely that it was fitted with a dynamo. In 1925 it was sold to contractors W.A Bishop & Sons of Burley, Shropshire, sold again in 1928 to E Davies of Shrewsbury and yet again in 1929 to J.L Jones of Adfe, Montgomeryshire. Perhaps the large number of owners might indicate that it was not a good engine. Neave & Co Ltd of Fordingbridge, Hampshire, purchased No 2600 in 1903 which they named Lawrence. This was a 7nhp engine but again only fitted with a single cylinder. It was sold in the 1920s to William Everitt of Gussage All Saints in Dorset and used as part of his contract threshing business. In 1903 10nhp 3-speed compound engine No 2644 was sold to George Carlyon, a haulage contractor at Kenwyn, near Truro in Cornwall. The engine was named General Buller after the famous Boer War general. In 1909 it was sold to another Cornish haulage contractor, Hosken, Trevithick & Polkinghorn of Truro. The loads that were hauled would have included heavy mining equipment for the tin and china clay industry. It would be interesting to know how the engine compared with other makers operating with such heavy loads in a very hilly district. In 1911 General Buller was returned to Wallis & Steevens in part exchange for a new wagon. It was immediately sold to William Flanagan of Belfast where it worked until around 1940. The next owner was James Brogan of Dunloy, Antrim, where it was used on agricultural work. By 1945 it had been sold to J.B Warke & Co of Castlerock, Londonderry, and was later scrapped. Few 5nhp road engines were built because they were so similar in size to steam tractors which had the advantage of being subject to less stringent legislation. A steam tractor could be operated by one man and could travel at up to 12 mph. 5nhp compound No 2728 was built in 1904 for A.W Smith of Feltham, Middlesex. By 1916 it had been sold to E.W Chapman of Great Bardfield, Essex, for driving a threshing machine. By 1921 it had been sold to its final buyer, George Smith of Great Canfield, Essex, where it

- 29. OLD GLORY ARCHIVE 27 Henry Thompson must have been very pleased when he took delivery of No 2866.As the engine is fitted with governors, it could have been used for driving a threshing machine as well as for haulage. LEFT: The last road engine, 5nhp compound No 7881, to be built at Basingstoke closely resembles one of the 7¼ ton tractors built by Burrell or Aveling & Porter. continued to work up until the war when it was scrapped. Henry Thompson of Holbeach, Lincolnshire, purchased 8nhp compound road engine No 2866 in 1904. This seems a curious choice of engine for a small contractor who operated two threshing sets and a pair of ploughing engines. Its next owner was Ewan Macdonald of Louth, who operated an engineering and contracting business which is still in operation today and Glyn Macdonald is chairman of the very successful Lincolnshire Steam Rally. By 1923 the engine had been sold to George Copping of Cabourne, Lincolnshire. It then had three owners in Wales with its final owner being Owen Jones of Aberfan, Glamorgan, who bought the engine in 1939. Production of road engines almost stopped after the First World War with resources concentrated on building rollers including the very successful Advance rollers. However, in 1926 work started on building three 5nhp road engines. Two were exported and the third, No 7881 was completed in 1927 for the Kinson Pottery at Parkstone, Dorset. A 7nhp traction engine, No 7681, was taken in part exchange for the new engine. The engine was named Little Atom and used for the haulage of clay and coal continuing to work up to the war. It was eventually sold in 1950 to Mark Loader & Sons of Bournemouth for just £10! After many years it was restored and is now back in the ownership of the family that purchased it in 1927. The limited success of Wallis & Steevens road engines almost certainly held back further development of these designs. The Basingstoke builders were slow to adopt compound cylinders but the cheaper single cylinder arrangement was no doubt attractive to many potential buyers. The engines that were built were ideal for short distance road haulage and as most were fitted with governors, were easily put to use for driving a threshing machine. Many of these engines were impressive machines but sadly none have survived into preservation. A while ago there were plans to build a replica but unfortunately I understand this will not happen. ■

- 30. WALLIS & STEEVENS STEAM TRACTORS Although Wallis & Steevens were one of the smaller traction engine builders, they were a very innovative company, says Mike Dyson ABOVE: On the motion cover of No 2410 is the name of the owners,Wallis & Steevens Ltd but why it should be hauling barrels of beer seems curious. However, it seems a considerable load for such a small engine! Can a beer expert calculate the weight? LEFT: The load being hauled by Richard Drake’s No 2742 looks impressive but these are bags of chaff which are not heavy.The engine is fitted with auxiliary water tanks mounted high on the side of the boiler. RIGHT: A carefully posed photograph of 4¼ -ton tractor No 2890 prior to delivery in March 1906. OLD GLORY ARCHIVE 28 THE MONO FILES

- 31. E arly successes with their expansion engines were followed by some of the first steam tractors to appear, the first of these being the 3-ton tractors. After 1896 new legislation removed many of the restrictions on the use of traction engines. Light traction engines that could be operated by one man but weighing less than 3-tons were allowed. Wallis & Steevens were the only manufacturers that were able to produce a credible design in this very limiting field. The first of these tractors - No 2380 - which was virtually two-thirds of the size of a traction engine, appeared in the summer of 1897. It was a single cylinder engine fitted with their patent expansion gear. The cylinder was 6in by 10in stroke with a working pressure of 120psi. The second 3-ton tractor to be built was No 2410 and was completed in 1898 for use as a yard engine at the North Hants Ironworks, a job it did for the next 17 years. It was used for shunting dead engines around the works and short trips to the station goods yard and around Basingstoke. It was the last 3-ton tractor to be sold and it clearly never worked hard. In 1915 it was sold to G.W Jones of Newbury and within a year he had sold it to Thomas Clark of Culkerton, near Tetbury, Gloucestershire. It is assumed that it was eventually scrapped. The building of tractors stagnated for a time, partly because the company was A works photograph of No 2514 Pioneer prior to delivery in March 1901. being restructured. In the summer of 1899 further tractors were built with some experimentation with variation in the size of the cylinder and boiler pressure. By 1901 the cylinder bore standardised at 5¼ in with a 9in stroke and boiler pressure raised to 150psi. However, it seems there was no standard design with modifications being constantly made. No 2514 was dispatched in March 1901 to the South Western Mineral Water Co at Wimborne, Dorset, which they named Pioneer. An appropriate name as this was their first venture into steam traction. One can only assume the tractor did not meet their requirements as it was sold to Sidney Munkton of Bournemouth in 1904. It was sold again in 1910 to showman George Coneley of Liss, Hampshire, presumably for the haulage of his equipment with no suggestion of the fitting of a dynamo. Its final owner was another showman, J Whitelegg of Bristol who named the engine Mount Everest. It was offered for sale in 1926 and appears to have been out of use after that. In April 1904 George Gildea, the owner of the Rhee Valley Portland Cement Co at Shepreth in south Cambridgeshire took delivery of No 2742. By 1914 the engine had been sold to Richard Drake of OLD GLORY ARCHIVE 29

- 32. Sutton in the Isle of Ely. Drake was a very successful forage merchant who supplied a patent horse feed to the London market through his premises at Bow in the East End. At that time vast numbers of horses were used in the capital. It is believed the engine was out of use by the 1920s and later scrapped. The 3-ton tractors were ideal for light loads over fairly flat terrain. They were popular with the Middlesex market gardeners taking vegetables into Covent Garden. Between March 1901 and June 1906 some 97 of these tractors were built for the home market. A small number were exported but it is believed these did not strictly adhere to the 3-ton weight limit. Only one compound 3-ton tractor was built; No 2756 which was completed in 1904. It had cylinders of 3¾ in and 6½ in with a 9in stroke working with the motion totally enclosed in a cast steel oil bath. With the extra weight of the cylinder casting and the oil bath it seems unlikely the 3-ton weight limit could have been met. The oil bath was made as light as possible with very thin walls which made casting difficult. With age it was not uncommon for the casting to develop minor cracks which led to a loss of oil. The 1904 Heavy Motor Car Order allowed the weight of the engine to be increased from three to five tons. Wallis & Steevens were quick to develop their oil-bath compound design known as the 4-¼ ton motor with the first appearing in March 1905 – less than four months after the new legislation. The compound engine had cylinders of 4¾ in and 8¼ in OLD GLORY ARCHIVE 30 THE MONO FILES The unladen weight displayed on the side of No 2929 clearly shows 4-tons 9-cwt which is 4-cwt over 4¼ tons. Notice the mechanism for the damper on the side of the smokebox. There can be little doubt about the power of 4¾-ton tractor No 7266 as it transports a tank engine to one of the ironstone quarries in the Kettering area.

- 33. with a 9in stroke and the boiler pressure was increased from 150 psi to 170 psi. In March 1906 4¼ -ton oil bath tractor No 2890 was dispatched from Basingstoke to Duke & Co Ltd of Plymouth. By 1915 it had been sold to W.J Johns of Penzance. It was later purchased by George Lawton of Macclesfield and in 1921 was sold to Jacob Jewell who was a showman. Unfortunately, I have been unable to discover anything about Jewell and his use of the tractor. The following year it was bought by Manders Bros of Wrexham who used it up to the end of 1926 and was later scrapped. Another 4¼ -ton oil bath tractor No 2929 was delivered to J J Prior Ltd of Limehouse, London. Priors were hauliers working in the docks and a steam tractor was no doubt a good substitute for horses which were widely used up until the late 1920s. The tractor was eventually sold to the Earl of Home for use on his Scottish estates. Wallis & Steevens sold 27 single cylinder and 75 compound 4¼ -ton tractors but they were aware that other manufacturers of steam tractors did not adhere to the regulations on weight with most exceeding the 5-ton limit. This put them at a disadvantage as other makers were able to produce more powerful engines without the problems encountered in building smaller engines. This problem was addressed in 1909 with the introduction of the 4¾-ton tractor. The oil bath motion remained the same but a larger boiler was now fitted with slightly heavier wheels. The first to be sold was No 7082 which left the works in March 1909. It should be noted that when the Wallis & Steevens numbering system reached 2999 they jumped to 7000, no doubt to impress customers on the number of engines they had built. Albert Wardle of Kettering took delivery of his 4¾-ton tractor in March 1912. After the Great War it was sold to Thomas and Reginald Le Sueur who farmed at Headley in Hampshire. Its final owner was Sir Jeremy Colman, a member of the famous mustard family for use on his farm at Oakley near Basingstoke. In January 1913 4¾-ton tractor No 7324 was dispatched to John Apps of Bracknell, Berkshire. The engine was sold in 1922 to Richard Sanders of Kensington and within a few months had been bought by showman John Biddall of Hounslow, Middlesex. The engine was converted for fairground use and named Little Mary. It worked up until the war years when it was scrapped. The 4¾-ton tractors sold well with 178 being sold on to the home market by 1919. The following year a larger firebox and solid rubber tyres were available at an extra cost. The last two tractors sold were Nos 7871 and 7872 which left the works in 1926 and 1930. Unlike most steam tractor manufacturers, they kept close to the 5-ton limit to the end of production. There were few changes to the design apart from an increase in size to the access holes at the sides of the oil bath to facilitate easier adjustment of the gland packing. ■ OLD GLORY ARCHIVE 31 John Apps’ No 7324 has the safety valves lifting. Note the contorted blast pipe on this 4¾-ton tractor unlike the better direct free flowing exhaust fitted to the 4¼ -ton tractors.

- 34. Wallis & Steevens were a small company with a number of innovative ideas. They designed the Advance rollers for a specific purpose - rolling asphalt - and it was a very successful machine, says Mike Dyson Looking at the rolls of No 7812 it appears to have been rolling chippings.The bevel gears for the steering can clearly be seen in front of the chimney.The chimney top does not appear to be of the usual Wallis design. WALLIS & STEEVENS ADVANCE ROLLERS No 7782 was photographed in the station yard at Basingstoke prior to delivery to the Limmer & Trinidad Lake Asphalt Co.The canopy of corrugated iron was a cheap feature on what was otherwise a well-made roller. OLD GLORY ARCHIVE 32 THE MONO FILES

- 35. I t is claimed that Francis Wallis attended a conference for road surveyors and heard about the problems of laying the new road materials such as asphalt, using conventional rollers. These machines were quite unsatisfactory as most of the weight was on the rear rolls and the rolls ran parallel with the axle causing the inner edges of the rolls to leave wheel marks. Tandem rollers had been used but were unpopular as they could not be used for consolidating base materials and had a reputation for turning over as they were top heavy. During the meeting Francis Wallis sketched his thoughts on the back of an envelope, later turning them into sketches which were given to the drawing office staff with instructions to produce something along those lines. In July 1923, less than 12 months from the original sketches being produced, the first roller, No 7773, was delivered to Henry Woodham & Sons of Catford, London. He was asked to evaluate the machine and apart from a few teething problems, the reports were very good. ❱ The boiler is a standard locomotive type operating at just 140 psi but the hornplates are extended backwards to support the coal boxes so that a tender is unnecessary. The cylinders are double high pressure with piston valves side by side between the cylinders. The connecting rods drive disc cranks on the end of the crankshaft set at 90˚ for easy starting. The arrangement does away with a flywheel and makes instant reversing possible. Instead of the usual push or pull type regulator, the Advance has a wheel valve which gives fine adjustment to the speed of the roller. When rolling asphalt it is important the roller makes only a momentary stop or the roller sinks to form a hollow in the new road surface. The rear rolls camber to fit the shape of the road. This is achieved by dividing the back axle so that each half pivots in a bracket attached to the hornplate. Where the two half-axles meet in the centre is a large helical spring which allows the rear rolls to flex with the camber of the road. Steering is by worm and quadrant which gives accurate control when rolling close to kerb stones and other items of street furniture. This eliminated the slack associated with chain and bobbin steering. Instead of spokes, the rolls are constructed of steel plates with large holes Another photograph taken in the station yard at Basingstoke, this time showing No 7863.This was an 8-ton machine which is easily identified by the heavy cast iron tyres on the rolls. By the 1950s No 7962 was not looking its best as can be seen by the bent scraper on the front roll. Being a 10-ton roller it was suitable for rolling base materials such as this hardcore. Note the locking pins in the front fork are not fitted allowing the front roll to pivot either side. OLD GLORY ARCHIVE 33

- 36. Clearly No 7967 was photographed after council ownership as the council’s brass plate has been removed from the motion cover. in them. The rear rolls are much wider than usual and the front roll is somewhat narrower. The difference in sizes between the front and rear rolls is greatly reduced on the Advance although they are not the same size. To create as near equal weight distribution as possible, pannier water tanks are mounted on the side. Advance rollers were produced three sizes: 6, 8 and 10 tons. The 6-ton has a smaller boiler with cylinders of 4½in diameter with a 9in stroke but the weight can be increased to 8 tons by the addition of cast iron tyres on the rolls. The 8-ton machines had a larger boiler and cylinders of 5in diameter and 10in stroke and again the weight could be increased using cast iron tyres to produce the 10-ton roller. Later models could be fitted with water ballast rolls so again the weight could be varied to suit the task in hand. The design was far ahead of any of its competitors and it is not surprising that they were built in large numbers at a time when most roller sales were in decline. They continued to build Advance rollers in the 1930s at a time when diesel rollers were fast appearing on the market. The last two, Nos 8114 and 8114, were supplied to the War Dept in 1940. Of the 272 Advance rollers built, it is not surprising there are now 77 in preservation. No 7782, a 6-ton machine, was completed in July 1923 for stock and did not have a buyer until September when it was purchased by the Limmer & Trinidad Lake Asphalt Co. The company was founded in 1881 with the objective of undertaking road contracting using high quality asphalt from Limmer, near Hanover in Germany and from the Pitch Lake in Trinidad, the largest natural deposit of asphalt in the world. The company was based in Fulham and secured major contracts for surfacing the roads of London. They operated a large fleet of rollers, many of which were tandems and by the early 1920s they had purchased 18 Robey tandem rollers. Surprisingly they only purchased three Advance rollers which all worked into the 1950s. No 7782 was finally scrapped in 1954, unlike the Robeys which were scrapped much earlier. Another 6-ton roller was No 7812 which was supplied to the Western Trinidad Lake Asphalt Co Ltd in November 1924. The company was based at Grangetown near Cardiff. Although they owned a number of rollers, they were to purchase only one Advance roller. By 1945 No 7782 had been sold to Davies Bros of Barmouth and sold again in 1963 to J C Wilkins of Dolgellau who owned the Fairbourne miniature steam railway. Two other 6-ton Advance rollers were purchased but No 7782 was eventually scrapped. In March 1926 the Limmer & Trinidad Lake Asphalt Co took delivery of its third Advance roller. This was No 7863, an 8-ton roller which was only used for about a year and then sold to the Three Hills Sand & Gravel Co of Codicote, Hertfordshire. In 1947 it was sold to Wirksworth Quarries Ltd of Woolmer Green, Hertfordshire. No 7863 was used on the many road upgrading projects OLD GLORY ARCHIVE 34 THE MONO FILES