More Related Content

Similar to Opf0417feature2

Similar to Opf0417feature2 (20)

Opf0417feature2

- 1. 16 Opflow April 2017 www.awwa.org/opflow

2017 © American Water Works Association

Disinfection

The most reliable chloramination control method is to monitor the target

disinfectant, monochloramine, as well as free and total ammonia. Other water

quality parameters, such as free chlorine, may serve an auxiliary role and

provide valuable information for process and instrumentation troubleshooting.

BY VADIM B. MALKOV

Use Process Control as the Basis

for Efficient Chloramination

T

http://dx.doi.org/10.5991/OPF.2017.43.0022

Vadim B. Malkov is a product applications manager

with Hach (www.hach.com), Loveland, Colo.

HE MAJOR conventional drink-

ing water treatment phases and

associated processes are well

known and shown in Figure 1.

They consist of the following:

■■ Preliminary treatment (prefiltration

phase)—preoxidation, coagulation/

flocculation, and sedimentation

■■ Filtration—conventional (sand, gravel,

coal) or membrane (microfiltration,

ultrafiltration, nanofiltration, reverse

osmosis)

■■ Postdisinfection—usually chlorination

or chloramination (both in-plant and

in the distribution system)

Disinfection, a cornerstone of the

treatment process, has a discrete set

of problems. Preliminary treatment

(Figure 1, Section A), entails adding oxi-

dants to raw water in a process called

preoxidation, or primary disinfection.

This phase of the water treatment pro-

cess is designed to achieve the following:

■■ Destroy or deactivate pathogens

■■ Prevent biogrowth on equipment and

pipes

■■ Improve water taste and odor (T&O)

■■ Minimize the formation of disinfection

by-products (DBPs)

■■ Help remove dissolved metals, such as

iron and manganese

■■ Aid coagulation

Several different oxidants/disinfec-

tants are frequently used in a preoxida-

tion phase, depending on the challenges

a utility faces. For example, natural

organic matter or other organic pollut-

ants may cause high concentrations of

organic carbon that serve as DBP pre-

cursors; pathogens such as viruses,

Giardia, Cryptosporidium, etc., pre-

sent a general health threat. Utilities

must make difficult choices to econom-

ically and sufficiently inactivate harm-

ful microbes, remove dissolved metals

and total organic carbon (TOC), mini-

mize DBP formation, and optimize treat-

ment processes.

PHOTOGRAPH:CITYOFDALLAS/GRAPHICS:HACH

Alkalinity

Aluminum

Fluoride

Hardness

Iron

Nitrate

Organics

Ozone

Particle

Counting

pH

TOC

Turbidity

Chlorine

Copper

Hardness

Monochloramine

Nitrate

Particle Counting

pH

Phosphate

Turbidity

PUMP

RAW WATER

MIXER

FLOCCULATOR

CLARIFIER

SLUDGE

FILTERS CLEAR WELL

TO DISTRIBUTION

SYSTEM

PUMP

Suspended

Solids

pH

Turbidity

pH

Suspended Solids

Alkalinity

Particle Counting

Turbidity

Turbidity Aluminum

Fluoride

Iron

TOC

SECTION A SECTION B SECTION C

BACKWASH

WATER

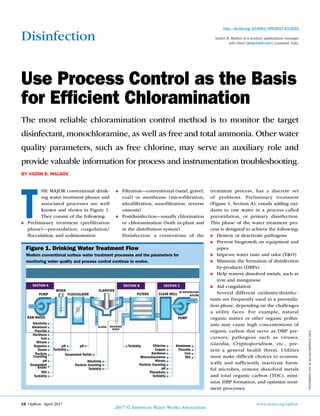

Figure 1. Drinking Water Treatment Flow

Modern conventional surface water treatment processes and the parameters for

monitoring water quality and process control continue to evolve.

- 2. www.awwa.org/opflow April 2017 Opflow 17

2017 © American Water Works Association

The Bachman Water Treatment Plant in Dallas controls chloramination

by measuring monochloramine (as a main part of total chlorine)

and free ammonia instead of free chlorine. The plant implemented

chloramination control protocols requiring online monitoring of key

parameters and regular grab sample analyses for verification.

Usually chlorine is used in the preox-

idation phase if the source water is min-

imally contaminated with organics or the

source water contains a low concentra-

tion of difficult-to-treat microorganisms

such as Giardia or Cryptosporidium. If

the source water is more contaminated

and challenging, ozone, chlorine dioxide,

or chloramine are used for primary dis-

infection and oxidation. There are also

situations when chemical treatment is

combined with ultraviolet light and sev-

eral oxidants, but such advanced oxida-

tion processes are beyond the scope of

this article. Other aspects of preoxidation

that shouldn’t be underestimated help

operators aid coagulation, keep filters

operating longer by preventing exces-

sive biogrowth, and remove dissolved

metals (e.g., manganese) to prevent fil-

ter contamination and aesthetic issues

downstream.

Secondary or postfilter disinfection

(Figure 1, Section C) requires operators

to maintain sufficient disinfectant resid-

ual beyond point of entry, which in the

United States is the last control and regula-

tory reporting point before the first tap or

customer in the distribution network, and

throughout the distribution system. Parts

of the water distribution network may be

in remote locations, and delivering safe tap

water can be challenging. Therefore, water

utilities must choose the right disinfectant,

and the choice may vary with seasons and

events affecting source water quality.

Table 1 shows various oxidants and

their advantages and disadvantages,

which may differ for primary and sec-

ondary disinfection. The focus here is

on chlorine and chloramine disinfection,

the most commonly used oxidants in

Disinfectant

Primary Disinfectiona Secondary Disinfectiona

Positive Negative Positive Negative

Chlorine gasb Strong,

inexpensive

High DBP,

safety/security

Strong,

inexpensive

Taste and odor

(T&O), DBP, safety

Monochloramine Less DBP Cost, process

control

Longer living,

less DBP

Nitrification, T&O

Chlorine dioxide

Kills Giardia,

oocyst,

less DBP

Cost, safety Long living,

active

Chlorite/chlorate,

cost

Ozone Strong,

less DBP

Bromate, little

residual, cost NA No residual

Hydrogen

peroxide/PAAc

Strong, easy

to handle

Bromate, no

residual, cost NA No residual

Permanganate Strong, easy

to handle

MnOx (staining) NA MnOx

(staining, etc.)

UV Strong,

no DBP Cost, no residual NA No residual

a Disinfectant activity comparison is based on CT values.

b Hypochlorite is frequently used as an alternative to reduce risk of gaseous chlorine leaks and simplify application.

c Hydrogen peroxide is often used in mixture with peroxyacetic acid (PAA) to increase the oxidant’s stability and efficiency.

Table 1. Disinfection Techniques Commonly Used in

Drinking Water Preparation

The pros and cons of various oxidants may vary for primary and secondary disinfection.

- 3. 18 Opflow April 2017 www.awwa.org/opflow

2017 © American Water Works Association

primary and secondary disinfection. If

chloramination is selected, its specifics

and requirements must be well under-

stood. It’s important to focus on forma-

tion, monitoring, and control of the target

disinfectant, monochloramine, while

optimizing the entire process. Table 2

highlights the main characteristics of

chloramination.

Chloramines have lower reactivity

compared with free chlorine, and they

react less intensely with various impu-

rities in raw water, particularly organic

substances. This results in the formation

of fewer DBPs, primarily trihalometh-

anes (THMs) with carcinogenic proper-

ties. This is one of the most important

factors contributing to the demand for

replacing chlorination with chloramina-

tion. Also, because of reduced oxidizing

power, chloramine creates a substantially

smaller disinfectant demand, which sig-

nificantly reduces chlorine consumption

to maintain a desired total chlorine resid-

ual in the water, which lowers the treat-

ment cost.

As shown in Table 2, one of the main dif-

ferentiators in chloramination monitoring is

measuring total chlorine concentration ver-

sus the free chlorine residual in regular

chlorination processes. According to simpli-

fied chemistry, Total Chlorine (TC) = Free

Chlorine (FC) + Combined Chlorine (CC).

Although this equation may seem correct,

don’t forget the target disinfectant in chlo-

ramination is monochloramine, not com-

bined chlorine. To understand the basics, it’s

necessary to review the chemistry behind

free and total chlorine formation and

nuances of the analysis. Figure 2 presents the

chemical reactions leading to the for-

mation of major free and total chlorine

species. Special attention should be paid

to the monochloramine-formation step and

that these reactions are reversible; equilib-

rium between the species depends on water

pH and temperature.

If the TC = FC + CC concept is fol-

lowed, the differentiation between free

and total chlorine seems to be simple—

one can just measure free and total chlo-

rine with appropriate analytical methods,

and the difference should give mono-

chloramine concentration. However, the

reality isn’t that simple.

As can be concluded from the chemical

reactions presented in Figure 2, monochlo-

ramine can be formed either by adding

free chlorine to ammonia or the other way

around. Both ways are equally important

and used in the water industry, especially

if there’s naturally occurring ammonia in

the source water. As explained by the

breakpoint chlorination curve shown in

Figure 3, when chlorinating water with

ammonia present (moving left to right

along the chart), the measured concentra-

tion of total chlorine undergoes strange

and seemingly illogical swings as the chlo-

rination proceeds (red line). This happens

because chlorine demand is satisfied first,

and then chloramines are formed accord-

ing to the chemical reactions presented in

Figure 2.

In general, the processes presented in

Figure 3 correlate with the reactions in Fig-

ure 2, and the chloramination process can

be narrowed down to the following simpli-

fied equation: Free Chlorine + Ammonia =

Combined Chlorine.

However, results of the predominant

chemical reactions shown in Figure 3’s three

regions are different and can be illustrated

by the following:

Region I. Cl2:N < 5:1 – NH3 + HOCl

↔ H2O + NH2Cl – monochloramine

Region II. Cl2:N > 5:1 – NH2Cl + HOCl

↔ H2O + NHCl2 – dichloramine

Region III. Cl2:N > 9:1 – NHCl2 + HOCl

↔ H2O + NCl3 – nitrogen trichloride

(trichloramine) => decomposes with for-

mation of free chlorine and nitrogen gas

Advantages Disadvantages

Main Monitoring

Requirements

■■ Reduced DBP

formation

■■ Reduced taste-and-

odor issues

■■ Prolonged useful

life of disinfectant

(monochloramine)

■■ Monochloramine is a

weaker disinfectant

than free chlorine and

requires longer CT

■■ Risk of nitrification in

the distribution system

■■ Total chlorine analysis

■■ Tighter process control

■■ Multiparameter monitoring

Table 2. Main Traits of Chloramination for Water Disinfection

Operators who work with chloramination should focus on monochloramine formation,

monitoring, and control.

Figure 2. Common Disinfection Equations

A set of basic chemical reactions describe the formation of chlorine species classified as

free, total, and combined chlorine.

Disinfection

Free chlorine (strong disinfectant):

Cl2 + H2O ↔ HOCl + OCl– (hypochlorous acid + hypochlorite ion)

Chloramines (combined chlorine):

NH3 + HOCl ↔ H2O + NH2Cl (monochloramine) – TARGET!

NH2Cl + HOCl ↔ H2O + NHCl2 (dichloramine)

NHCl2 + HOCl ↔ H2O + NCl3 (nitrogen trichloride – unstable)

Organic chloramines (very weak disinfectants):

Org-NH + HOCl ↔ Org N-Cl

Major source of

“chlorine” taste

and odor

- 4. www.awwa.org/opflow April 2017 Opflow 19

2017 © American Water Works Association

Thus, the following substances can

be observed in the process of drink-

ing water chloramination: chloramines,

free and total ammonia (sum of mono-

chloramine and free ammonia concen-

trations) and free chlorine. Basically, all

chlorine species can be present in the

water during chlorination/chloramina-

tion. The question is, which species are

present sustainably and which are mostly

equilibrial (short-living, transitional spe-

cies) in each region?

The transitional concentrations can be

measured, but such analysis would reflect

only a momentary state of the equilib-

rial reaction. This can be illustrated as a

series of snapshots of a dynamic process.

Some of the compounds (with stable con-

centrations) are shown on all the pho-

tographs with a constant image quality,

whereas others are shown in only some

of the photographs, and the image quality

may vary (transitional, unstable spe-

cies). The reality of the situation can be

determined from a relatively simple anal-

ysis of each reaction, based on statistical

factors and knowledge of the analytical

methods, as summarized in Table 3.

By understanding the dynamics of the

transformation of chlorine- and nitrogen-

containing compounds in the described

processes, operators can establish key

monitoring parameters needed to keep

chloramination and chlorination under

control. Table 4 shows key monitoring

parameters for chloramination.

FREE CHLORINE OR FREE AMMONIA?

Because successful chloramination is

based on sustainable monochloramine

formation from free chlorine and ammo-

nium/ammonia, the process requires

strict control to prevent unintended con-

sequences such as nitrification in the

water distribution system. To achieve the

necessary control and optimize water

treatment processes, operators must care-

fully monitor the chloramination process.

In doing so, they often rely on monitor-

ing the concentration of free ammonia or

free chlorine as the primary index. Both

approaches have supporters, and the best

method is widely debated in the indus-

try—measuring free and total chlorine

versus measuring total chlorine and free

ammonia. The latter method should be

positioned as measuring monochloramine

Region I Region II Region III

Cl2: N < 5:1

NH3 + HOCl ↔ H2O + NH2Cl

monochloramine formation

Cl2: N > 5:1 and < 9:1

NH2Cl + HOCl ↔ H2O + NHCl2

dichloramine formation

Cl2: N > 9:1

NHCl2 + HOCl ↔ H2O + NCl3

Stable compounds:

Monochloramine, total and free

ammonia

Transitional: Free chlorine

Measured concentrations: Total chlorine

is slightly above monochloramine;

total ammonia > monochloramine,

difference = free ammonia.

Stable compounds:

Monochloramine and total ammonia

Transitional: Free chlorine

Measured concentrations:

Total chlorine > measured monochloramine;

monochloramine = total ammonia, no free

ammonia.

Unstable trichloramine (nitrogen

trichloride) formation and release of

free chlorine

Stable compounds: Free chlorine

Measured concentrations:

Total chlorine = free chlorine;

no monochloramine or any ammonia is

detected.

Table 3. Transitional Concentrations

Chlorine speciation can be determined from a relatively simple analysis of each reaction.

Overall, comprehensive and accurate in-plant chloramination

control helps operators maintain water quality at point of entry

and avoid unwanted consequences in the distribution system.

TotalandFreeAmmonia

Chlorine Added

TotalResidualChlorine

Monochloramine

Formation

Free Ammonia

Total Ammonia Dichloramine

Formation

Free Residual

Chlorine

Breakpoint Curve for Chlorination and Chloramination

Breakpoint

Region I Region II Region III

Cl2

:N < 5:1 Cl2

:N > 5:1 Cl2

:N > 9:1

Figure 3. Breakpoint Chlorination Curve

A breakpoint chlorination curve illustrates the phases of water chlorination in the presence

of ammonia (regions I, II, and III) and the behavior of the main analytical parameters

- 5. 20 Opflow April 2017 www.awwa.org/opflow

2017 © American Water Works Association

and free ammonia, because this combina-

tion is more specific and therefore pro-

vides better process control.

The theoretical analysis of chemical

reactions describing the formation of var-

ious chlorine species and their sustain-

ability calls for more experimental data

to support one approach or another. Fig-

ure 4 shows data collected recently when

monitoring the chloramination process

from Region I to II at sample pH of 8–8.5

and temperature around 20˚C. The results

show the specificity that measuring free

ammonia has in demonstrating the tran-

sition between Region I and II, while the

measured free chlorine concentrations

were more erratic during the same transi-

tion. The low absolute levels of free chlo-

rine, along with its transitional nature in

the chloramination process, make it dif-

ficult to pinpoint the moment of the tar-

get change, whereas this change is much

clearer when measuring free ammonia, as

shown in Figure 4.

Based on years of research and the

results of many field studies presented

at water conferences (e.g., see Chlorami-

nation Process Control: Comparing Mon-

itoring Technologies and Techniques

at www.awwa.org/chloramination), the

most reliable way to control chlorami-

nation is by monitoring the target disin-

fectant, monochloramine, as well as free

and total ammonia. Other water quality

parameters, such as free chlorine, etc.,

may serve an auxiliary role and provide

valuable information for process and

instrumentation troubleshooting.

Directly measuring key parameters

with a colorimetric method allows oper-

ators to effectively control monochlora-

mine formation. Implementing online

instrumentation has demonstrated more

efficient process control compared with

intermittent laboratory measurements.

Also, process analyzers built on colo-

rimetric technology deliver accurate,

real-time information to ensure reliable

chloramination control. Overall, compre-

hensive and accurate in-plant chlorami-

nation control helps operators maintain

water quality at point of entry and avoid

unwanted consequences in the distribu-

tion system.

Acknowledgments: The author would

like to express gratitude to Hach col-

leagues for their support and personally

to Luke Johnson for his help with labora-

tory experiments.

Primary Parameters Secondary Parameters Additional Control*

■■ Total residual chlorine (regulatory

reporting)

■■ Monochloramine (process control)

■■ Free ammonia (process control)

■■ Free residual chlorine (process control)

■■ Total ammonia (process control)

■■ pH (process and nitrification control)

■■ Nitrite (nitrification control)

■■ ATP (nitrification control)

■■ Dissolved oxygen (nitrification

control)

Table 4. Key Monitoring Parameters

Analytical parameters for chloramination monitoring and control should be considered for the plant and the water distribution system.

* These monitoring parameters become very important to control nitrification in the distribution system that may occur with formation of extra ammonium in the water, especially in warmer climates that can promote biogrowth.

Disinfection

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.00

0.50

1.00

1.50

2.00

2.50

3.00

FA,FC—ppm

TC,TA,Mono—ppm

Chloramination—Lab Test (all parameters)

Monochloramine

Total Ammonia

Total Chlorine

Free Ammonia

Free Chlorine

Region I Region II

NH4

+

+Cl2

NH4

+

+ Cl2

(excess)

Figure 4. Lab Results

A recent chloramination study revealed an increasing Cl2:N ratio and exemplifies

multiparameter monitoring.