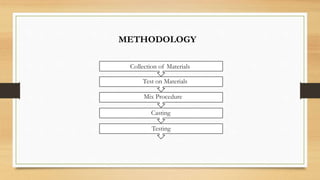

The document discusses pervious concrete and its properties. It summarizes several studies that aimed to improve the strength of pervious concrete by adding fibers and other materials. The main goal of the project was to increase the compressive strength, flexural strength, and permeability of pervious concrete. Studies found that the addition of polypropylene fibers, steel fibers, nano-silica, and GGBS increased the strength of pervious concrete compared to conventional concrete. The document outlines the methodology that will be used to test different fiber mixtures and admixtures to determine which provides the highest strength pervious concrete.