Report

Share

Recommended

Recommended

More Related Content

What's hot

What's hot (6)

IRJET- Feasibility of Use of Duckweed for Treatment of Sludge Water

IRJET- Feasibility of Use of Duckweed for Treatment of Sludge Water

Hydrogen Bonding -The Key to Desalination (A Review)

Hydrogen Bonding -The Key to Desalination (A Review)

IRJET- Experimental Study on Replacement of Coarse Aggregate by E-Waste in Co...

IRJET- Experimental Study on Replacement of Coarse Aggregate by E-Waste in Co...

Similar to RET poster D2

Similar to RET poster D2 (20)

AN ALGAE RESEARCH FACILITY FOR BIOFUEL AND BYPRODUCT DEVELOPMENT INTEGRATING ...

AN ALGAE RESEARCH FACILITY FOR BIOFUEL AND BYPRODUCT DEVELOPMENT INTEGRATING ...

mechanical eng anna university final year Project thesis of bio plastics

mechanical eng anna university final year Project thesis of bio plastics

Seminar on conversion of plastic wastes into fuels

Seminar on conversion of plastic wastes into fuels

fuel from plastic wastes( conversion of waste plastic into useful fuels)

fuel from plastic wastes( conversion of waste plastic into useful fuels)

Conversion of Plastic Wastes into Fuels - Pyrocrat systems review

Conversion of Plastic Wastes into Fuels - Pyrocrat systems review

FABRICATION OF A SIMPLE BUBBLE COLUMN CO2 CAPTURE UNIT UTILIZING MICROALGAE

FABRICATION OF A SIMPLE BUBBLE COLUMN CO2 CAPTURE UNIT UTILIZING MICROALGAE

Composition and Toxicity of Biogas Produced from DifferentFe.docx

Composition and Toxicity of Biogas Produced from DifferentFe.docx

Development of an experimental rig for bioremediation studies

Development of an experimental rig for bioremediation studies

Bioremediation and biodegradation ellis 2012 final

Bioremediation and biodegradation ellis 2012 final

Life Cycle Assessment of Wastewater Treatment Plant.pptx

Life Cycle Assessment of Wastewater Treatment Plant.pptx

Development and evaluation of some of the mechanical properties of kenaf poly...

Development and evaluation of some of the mechanical properties of kenaf poly...

RET poster D2

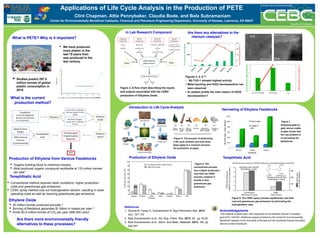

- 1. Applications of Life Cycle Analysis in the Production of PETE Clint Chapman, Attie Pennybaker, Claudia Bode, and Bala Subramaniam Center for Environmentally Beneficial Catalysis, Chemical and Petroleum Engineering Department, University of Kansas, Lawrence, KS 66047 50 nm What is PETE? Why is it important? 50 nm In Lab Research Component Acknowledgements This material is based upon work supported by the National Science Foundation grant EEC-1301051. Additional support provided by the Center for Environmentally Beneficial Catalysis at the University of Kansas and the Southeast Kansas Education Service Center-Greenbush. References 1. Ghanta M, Fahey D, Subramaniam B. Appl Petrochem Res. 2014. 4(2): 167-179 2. Bala Subramaniam et al.. Ind. Eng. Chem. Res. 2013, 52, pp 18-29 3. Bala Subramaniam et al.. Micro. And Meso. Materials. 2014, 190, pp 240-247 Introduction to Life Cycle Analysis Harvesting of Ethylene Feedstocks Production of Ethylene Oxide Terephthalic Acid Are there any alternatives to the rhenium catalysts? 0 200 400 600 800 1000 1200 Ethanol Ethane Naptha KgCO2equiv/tonneethylene Feedstock Gate to gate Cradle to gate Figure 6. The process of performing a life cycle analysis and how those steps apply to a common process, the production of paper. Figure 7. Analyzing gate-to- gate versus cradle- to-gate shows that the real problem is in harvesting the feedstocks. Figure 8. The conventional process has a higher production cost than the CEBC process, however it results in less greenhouse gas emissions. Figure 9. The CEBC spray process significantly cuts both cost and greenhouse gas emissions by eliminating the hydrogenation step. Figure 2. A flow chart describing the inputs and outputs associated with the CEBC production of Ethylene Oxide. Studies predict 297.5 million tonnes of global plastic consumption in 2015 • We have produced more plastic in the last 10 years then was produced in the last century Figures 3, 4, 5 2,3 • Nb-TUD-1 showed highest activity. Metal leaching and H2O2 decomposition have been observed Is catalyst acidity the main reason of H2O2 decomposition? Are there more environmentally friendly alternatives to these processes? From: https://creeklife.com/blog/six-reasons-why-plastic-is-bad-for-the-environment (From: http://www.mr-dt.com/materials/paperandboard.htm) From: http://www.iftf.org/future-now/article-detail/our-plastic-century/ • Organic building block to chemical industry • Most produced organic compound worldwide at 133 million tonnes per year1 Production of Ethylene from Various Feedstocks • Conventional method requires harsh conditions, higher production costs and greenhouse gas emissions • CEBC spray method cuts out hydrogenation section, resulting in lower operating costs as well as reducing greenhouse gas emissions Terephthalic Acid Ethylene Oxide • 20 million tonnes produced annually 2 • Burning of feedstock generates $1 billion in losses per year 2 • Emits $3.4 million tonnes of CO2 per year (566,000 cars)2 What is the current production method? 0 10 20 30 40 50 60 70 80 90 100 4100 4200 4300 4400 4500 4600 4700 4800 4900 5000 5100 Nb-TUD-1(200) MTO (Re) Ag H2O2selectivitytoproducts,% EOproductivity,mgEO/h/gMetal