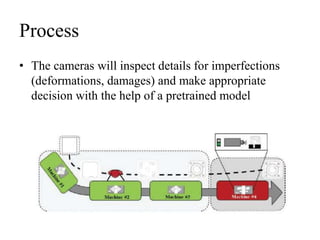

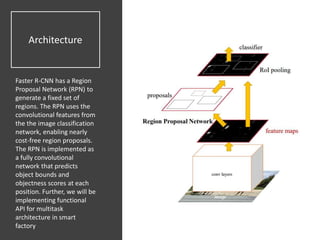

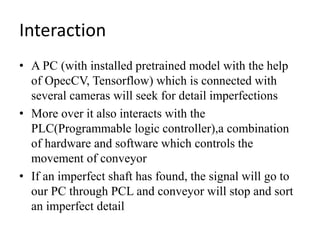

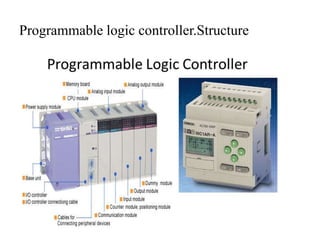

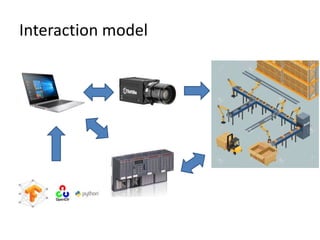

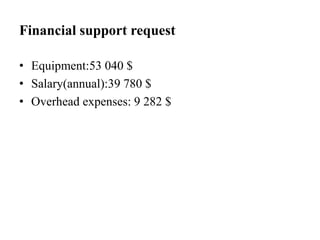

This document summarizes a smart factory project using object recognition to identify defects. It will use cameras and a pretrained model with TensorFlow and OpenCV to detect imperfect objects on a conveyor belt. When a defect is found, the conveyor will stop and sort the object. A PC will interact with the cameras and PLC to control the conveyor. The system aims to provide flexibility over scripted automation and make real-time decisions. Faster R-CNN will be used to generate region proposals and predict object bounds and classes. The team requests financial support for equipment, salaries, and overhead to implement this quality control solution.