Embed presentation

Downloaded 502 times

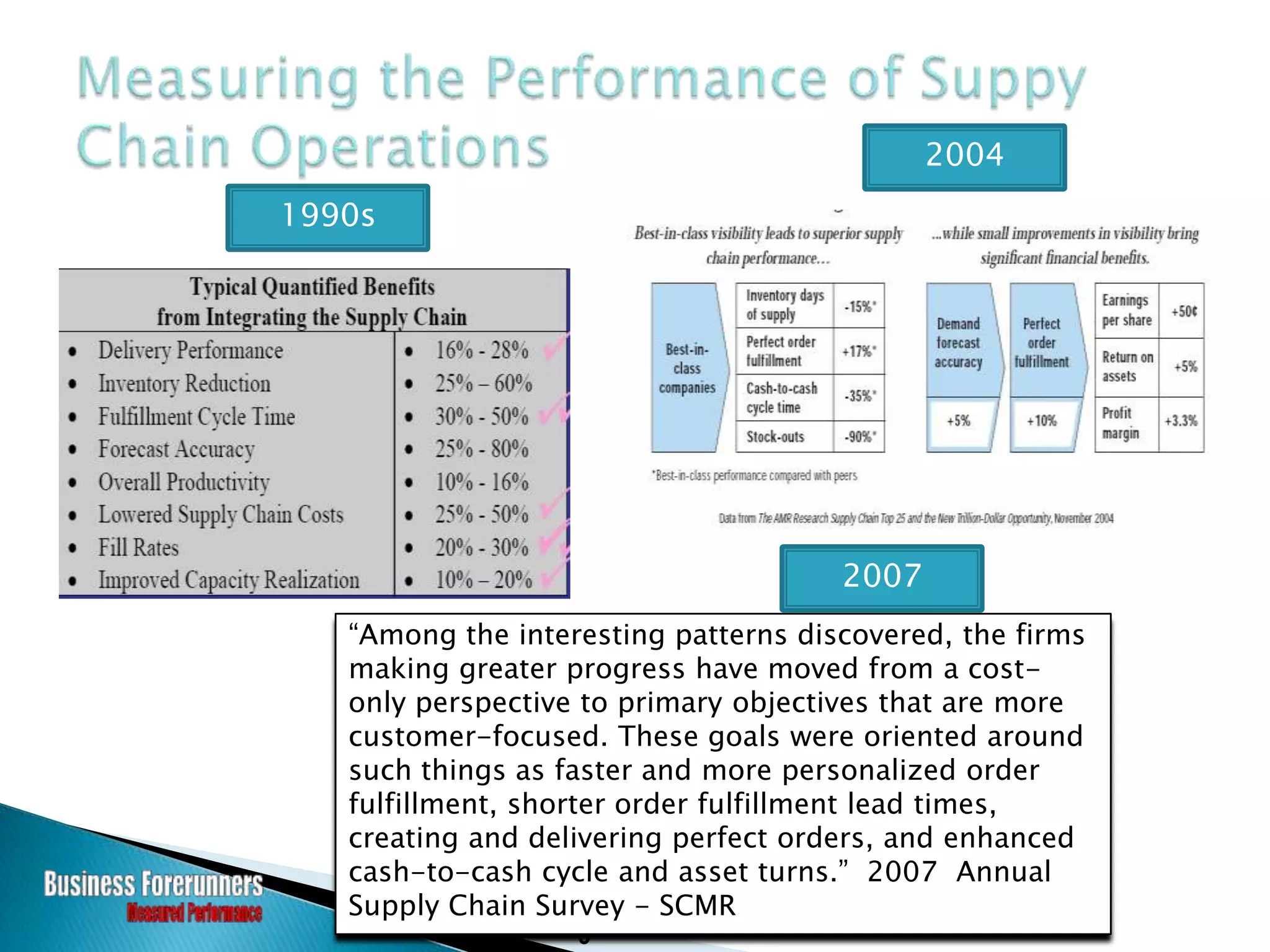

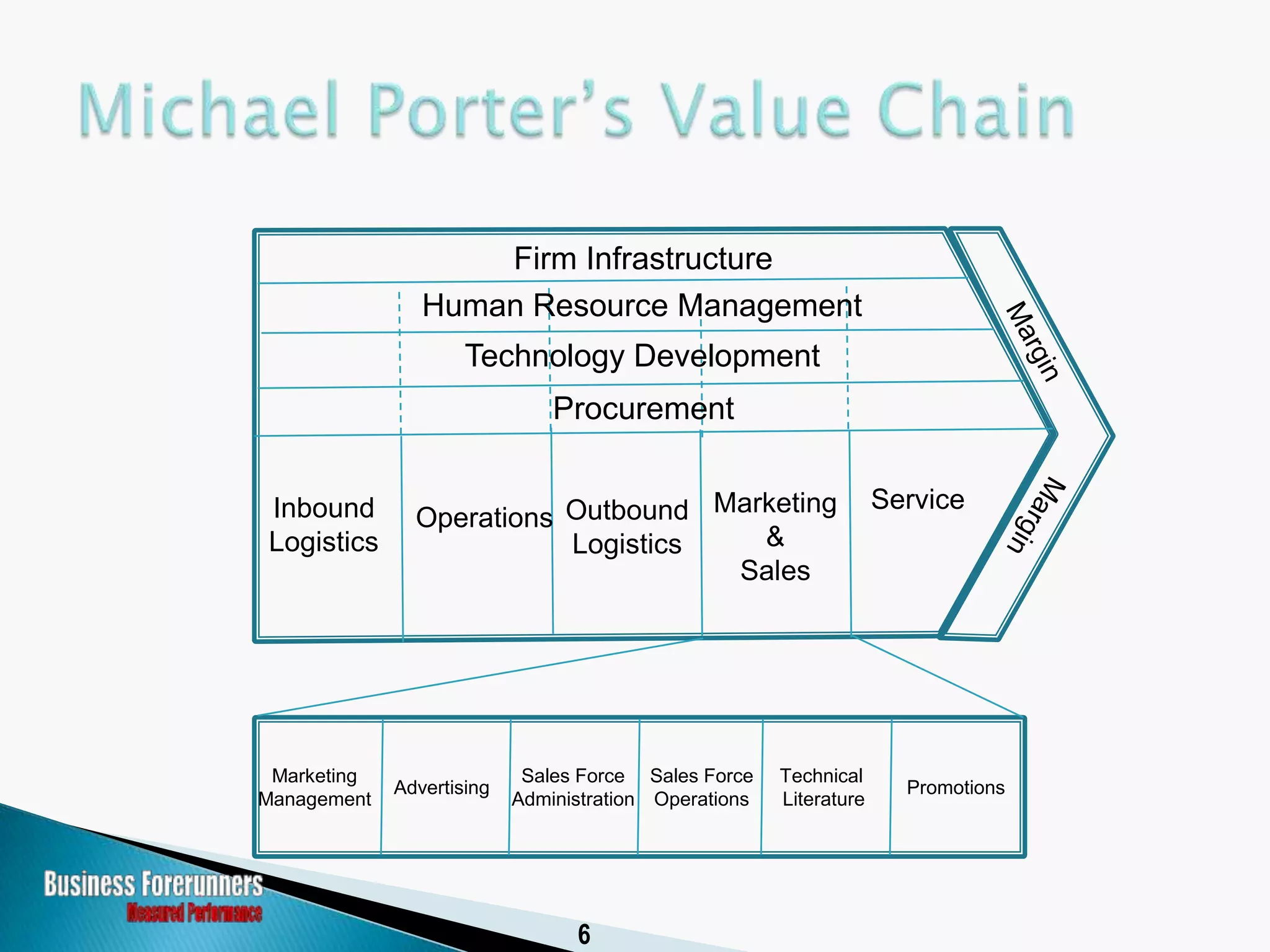

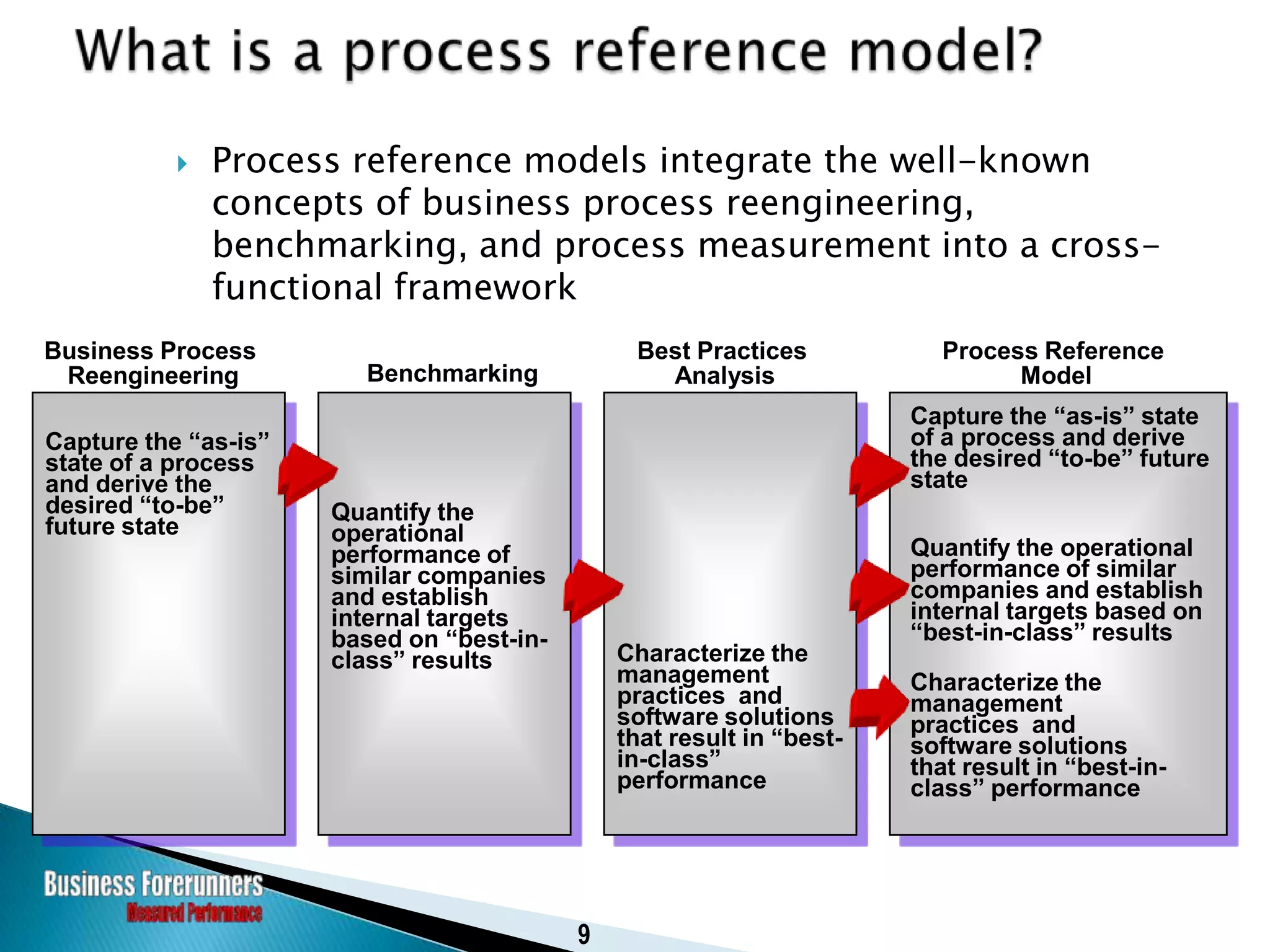

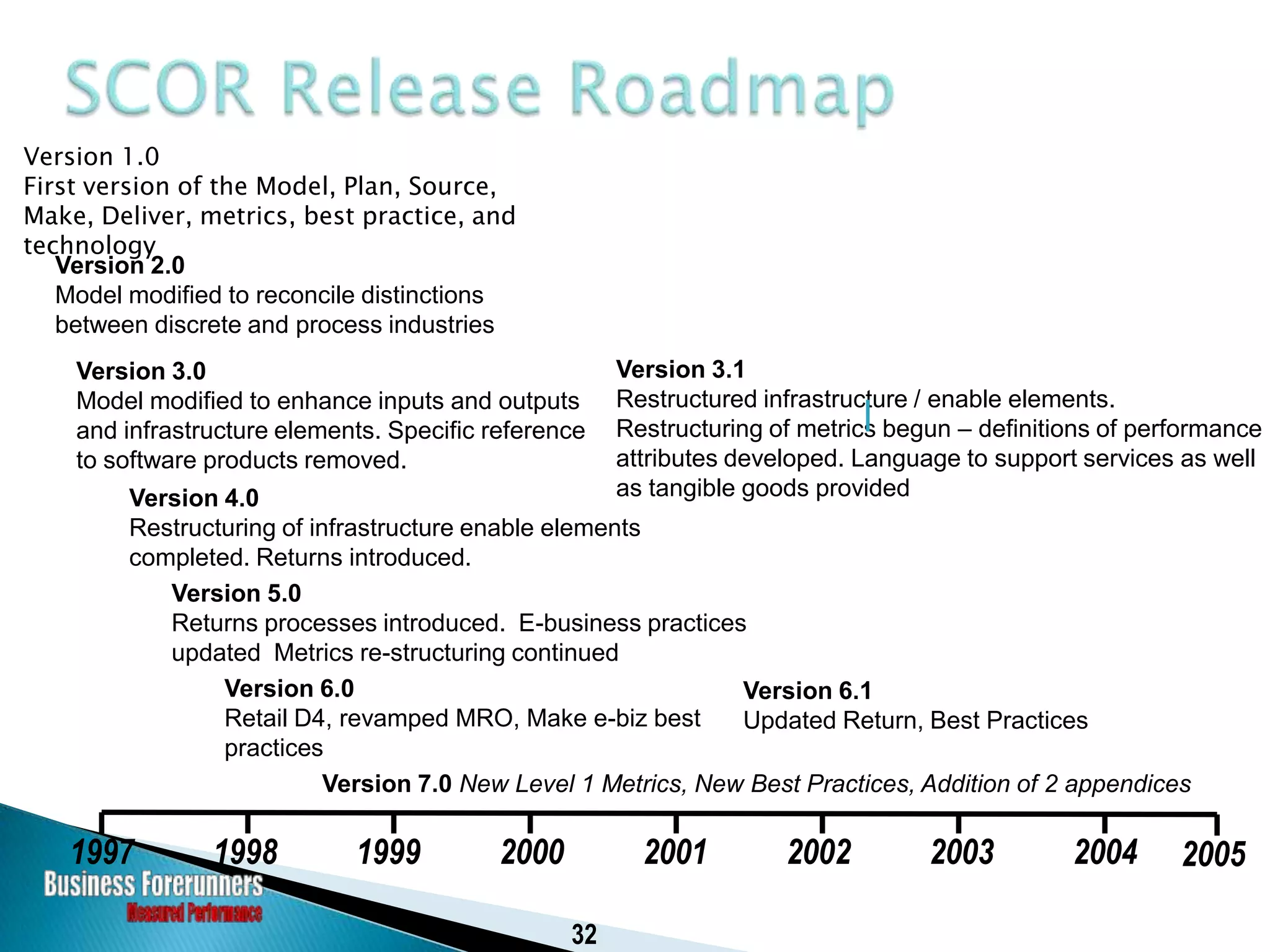

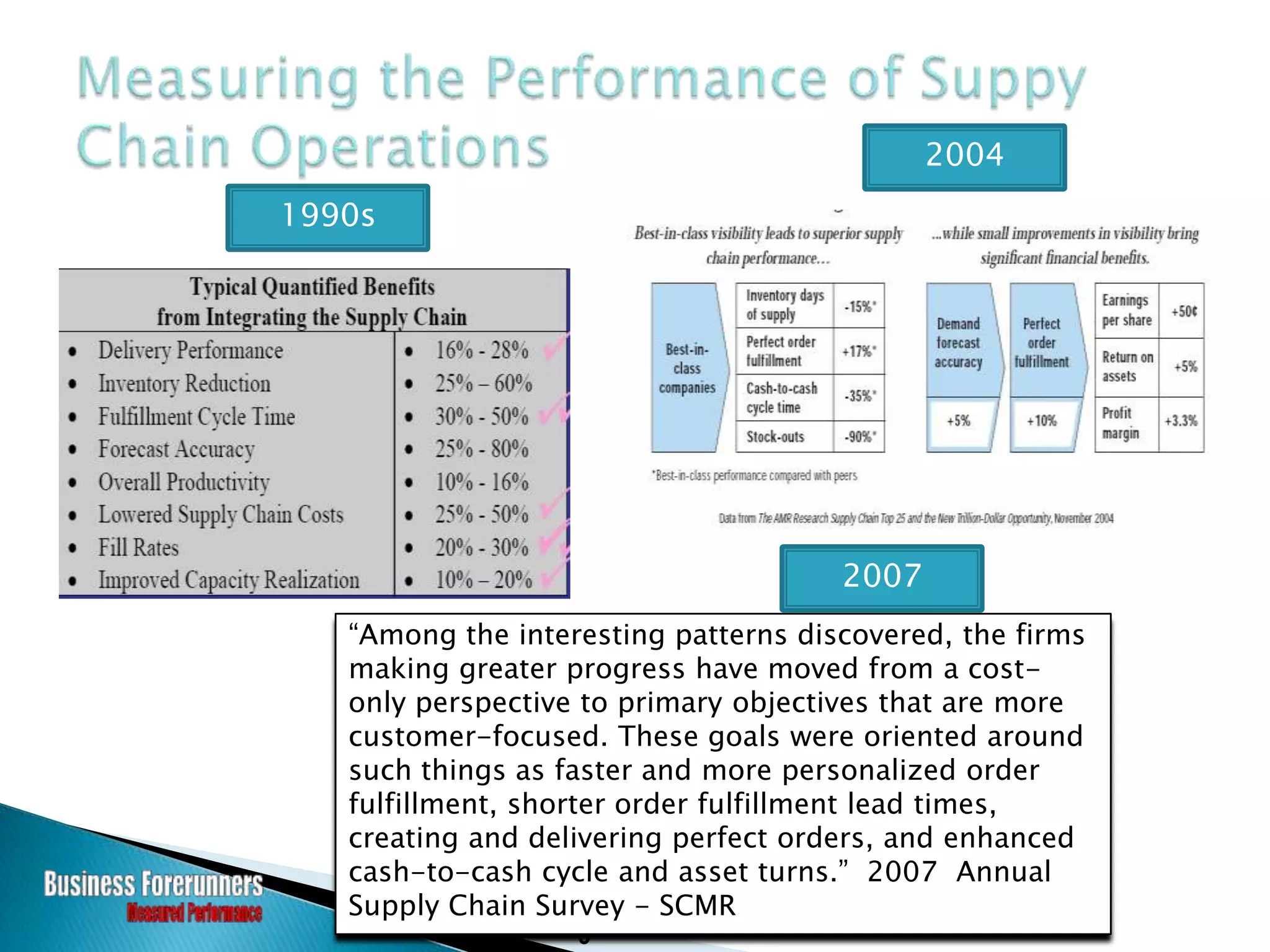

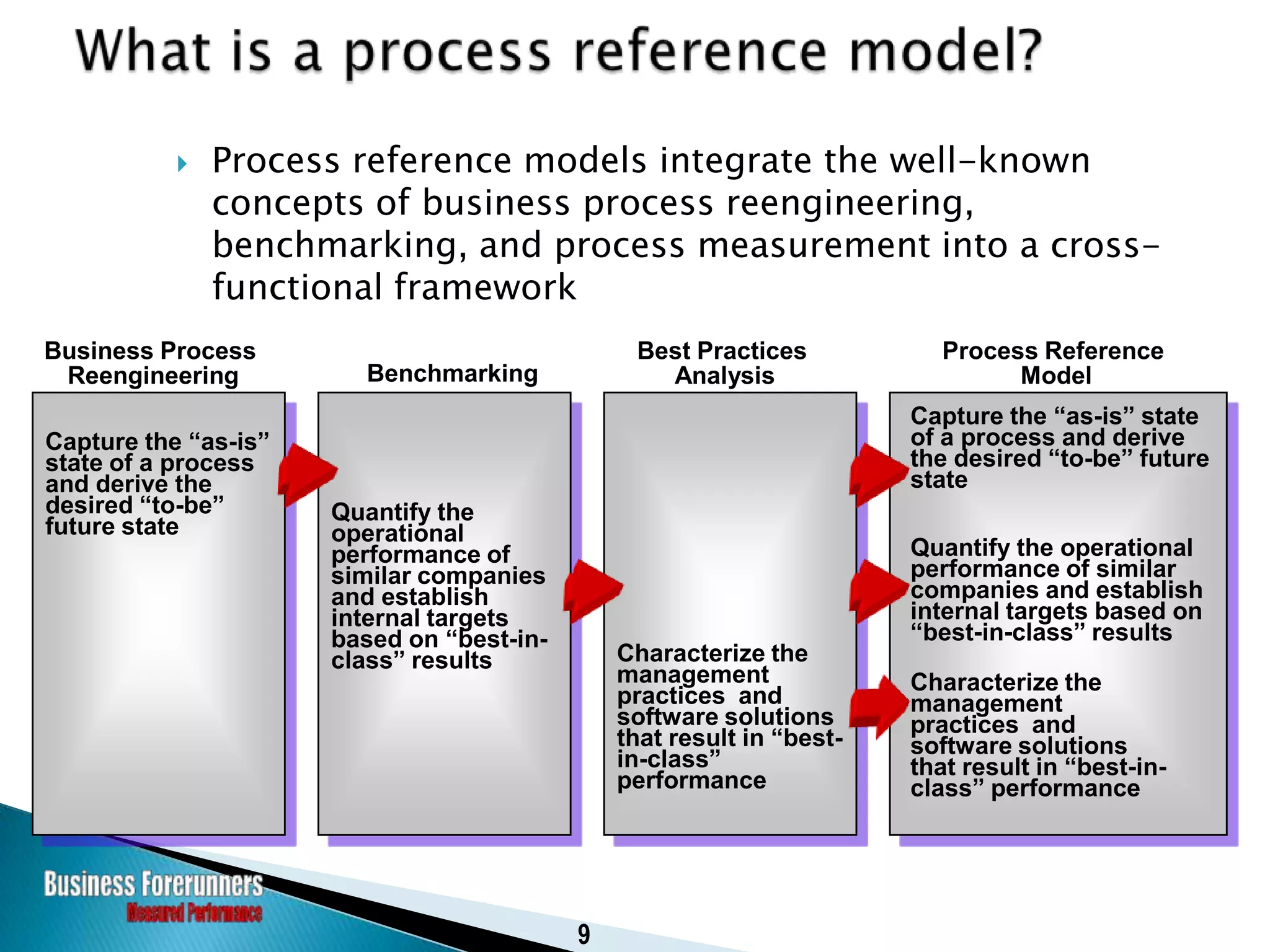

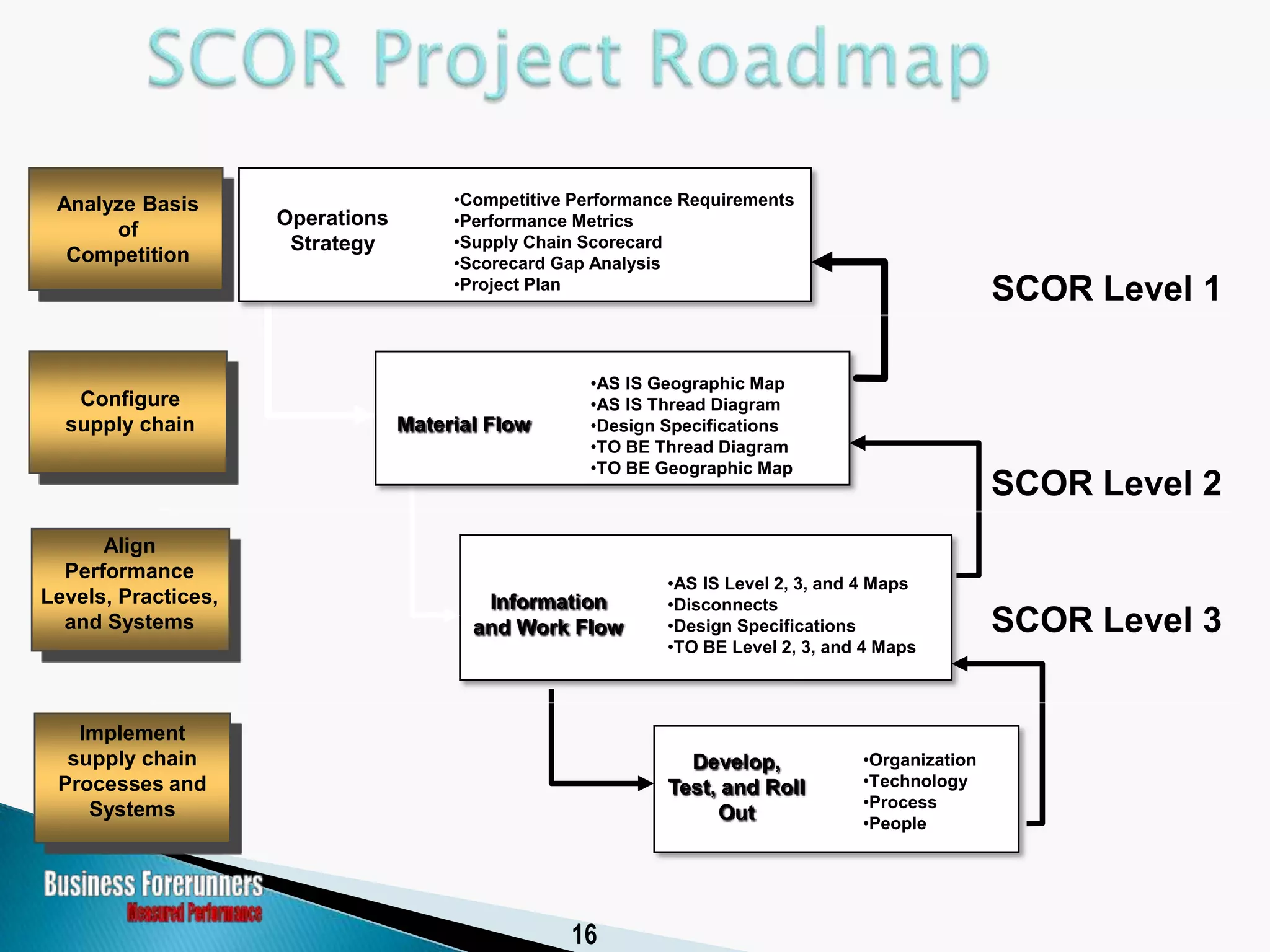

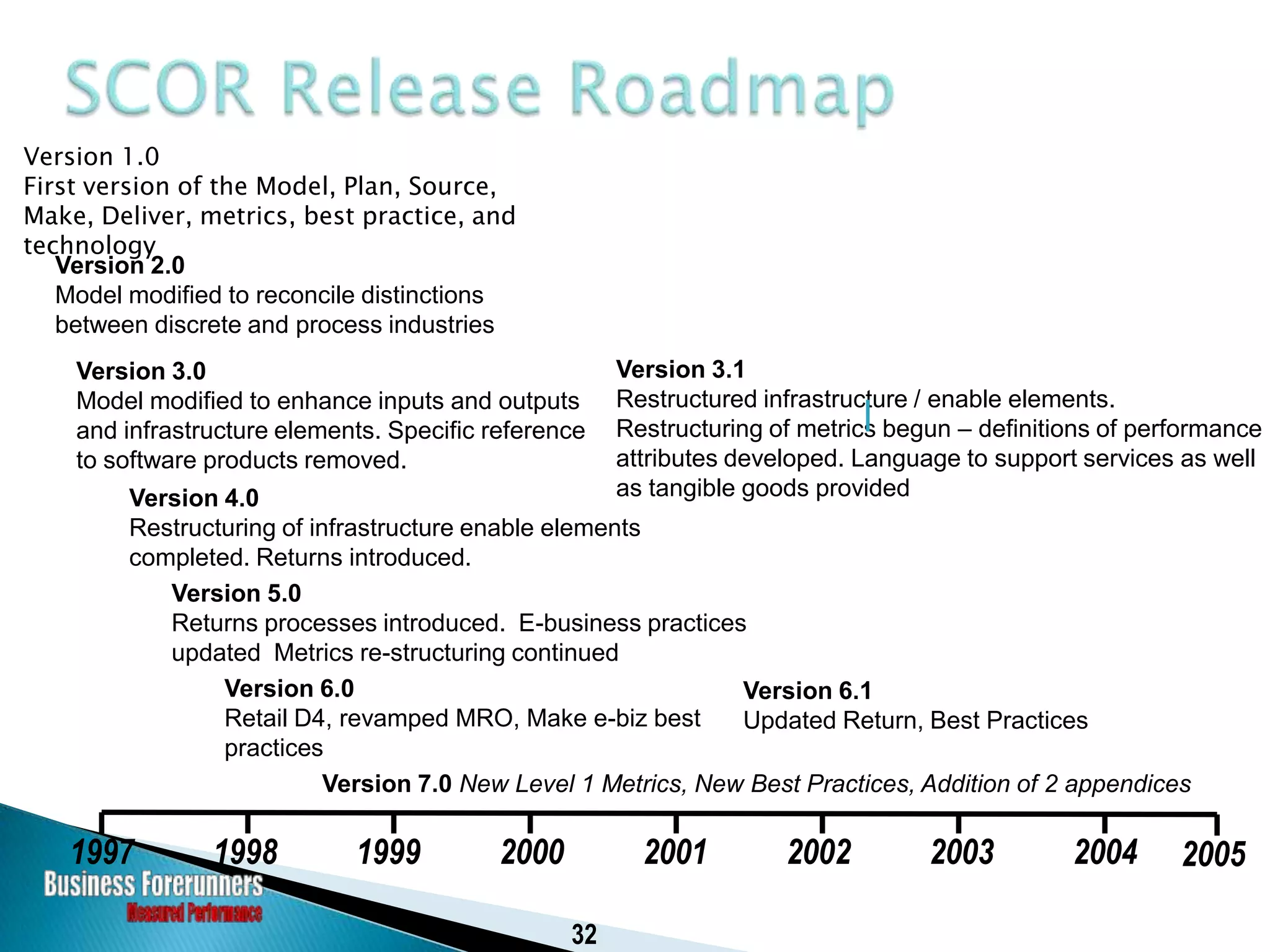

The document discusses the SCOR model, which was developed by business leaders to enhance competitiveness through cost reduction, revenue increase, and asset management efficiency. It emphasizes a transition from a cost-centric approach to customer-focused objectives, highlighting the importance of metrics and process improvement in supply chain management. Additionally, it outlines the implementation of the SCOR model across various operational levels and provides various performance metrics for evaluating supply chain effectiveness.

Introduction of SCOR model focusing on logistics and supply chains, measuring performance with metrics and metrics utilization. Practitioner views on SCOR's impact in competitive strategies involving customer focus and improving fulfillment speed.

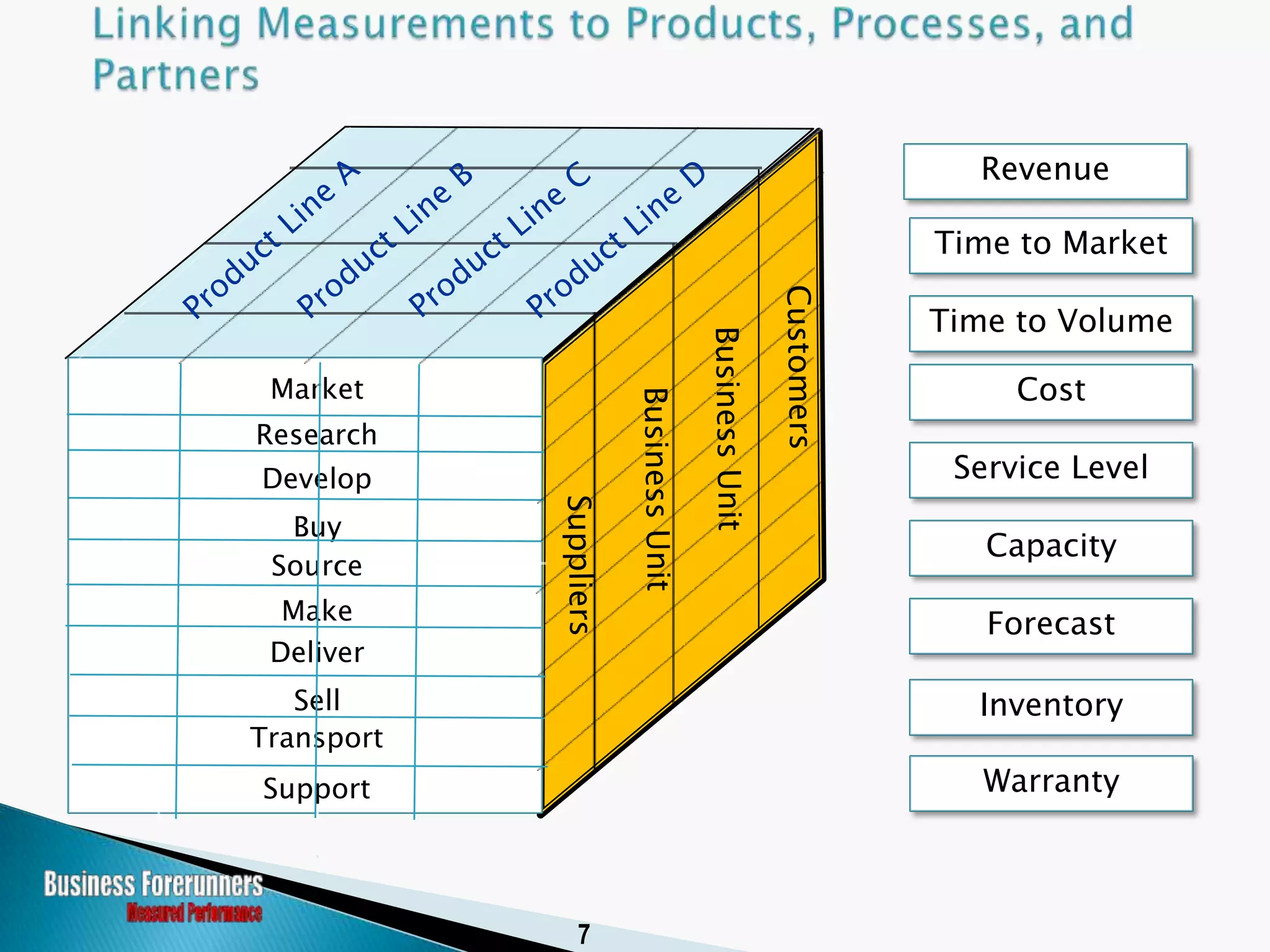

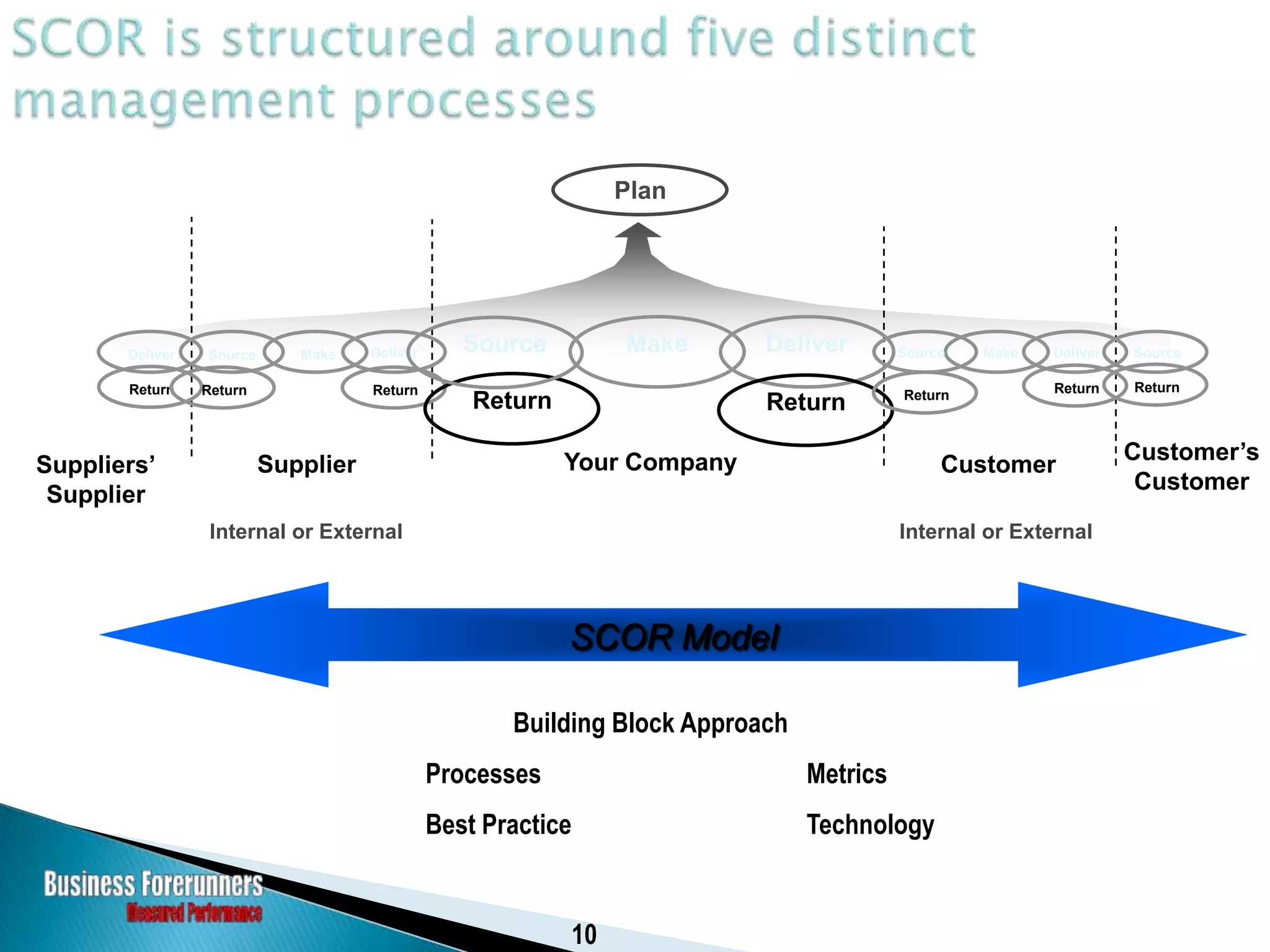

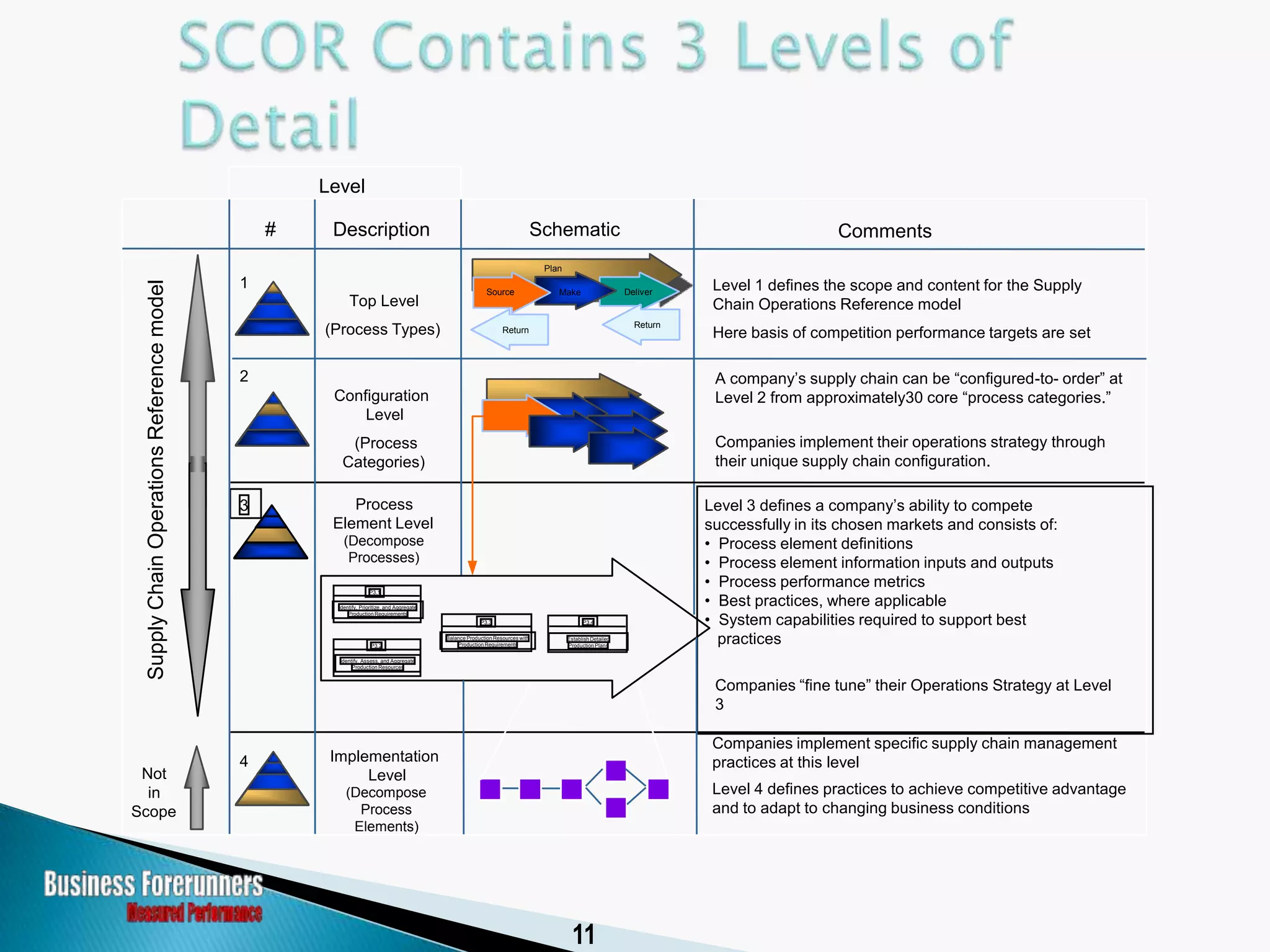

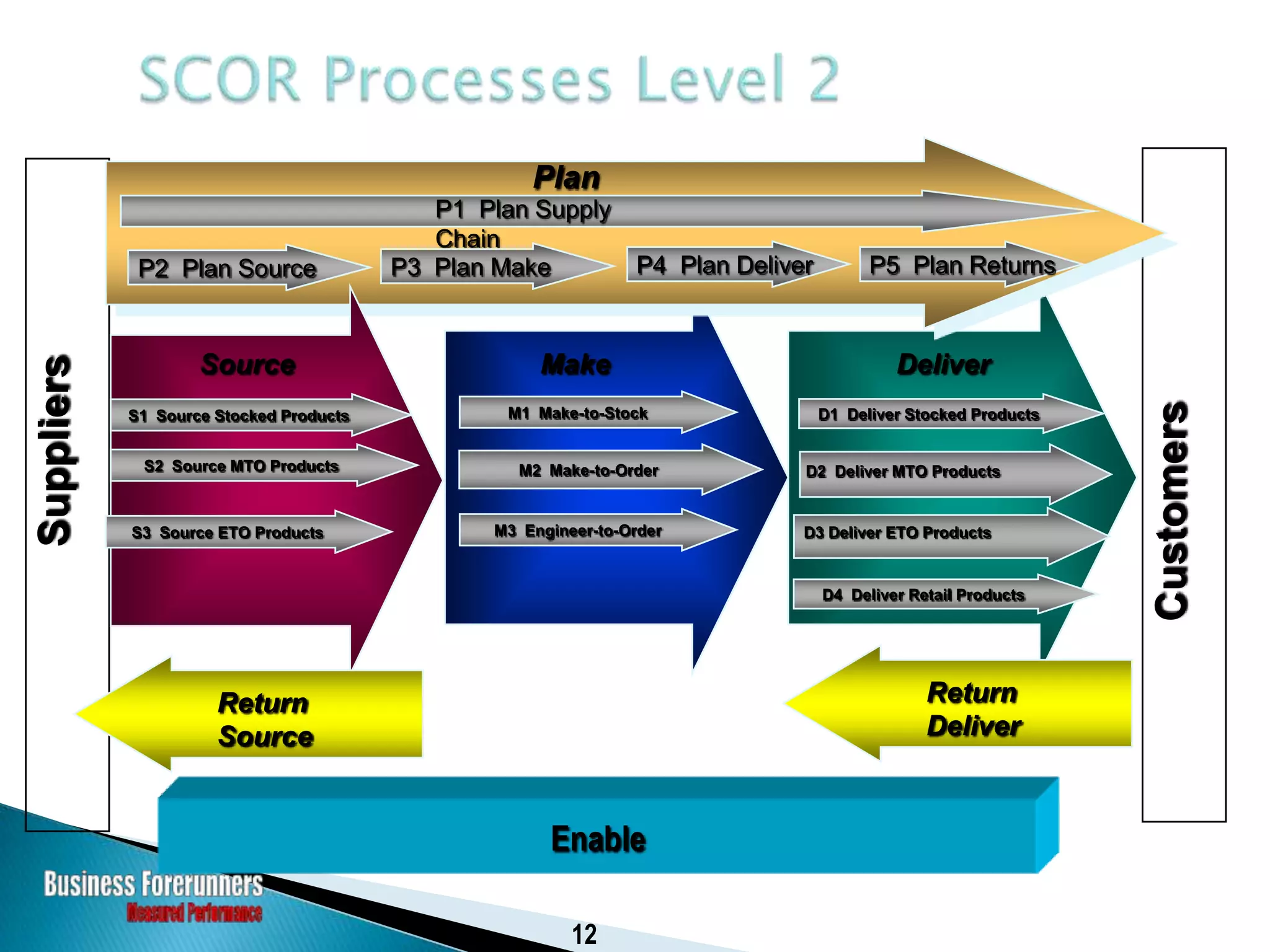

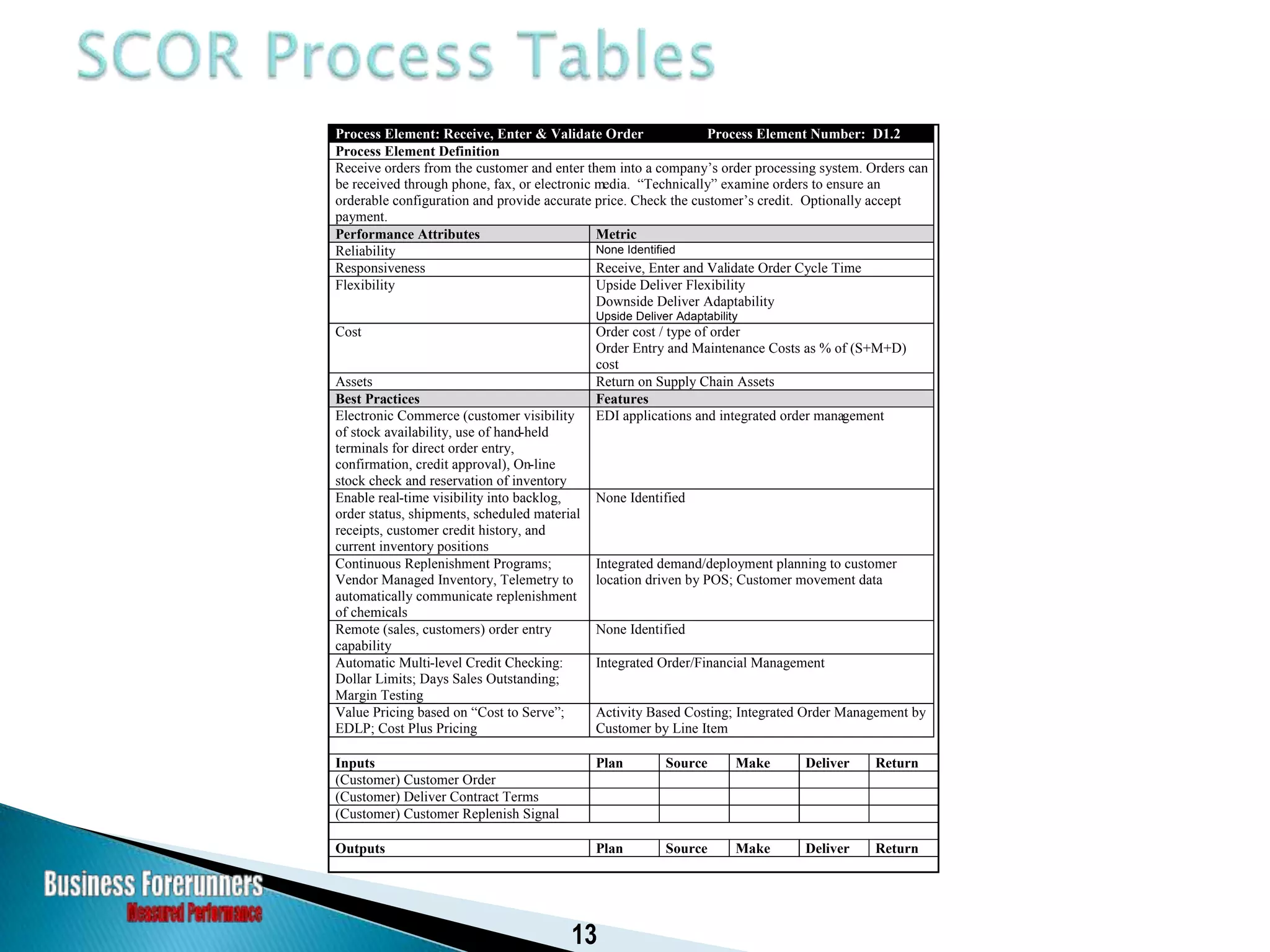

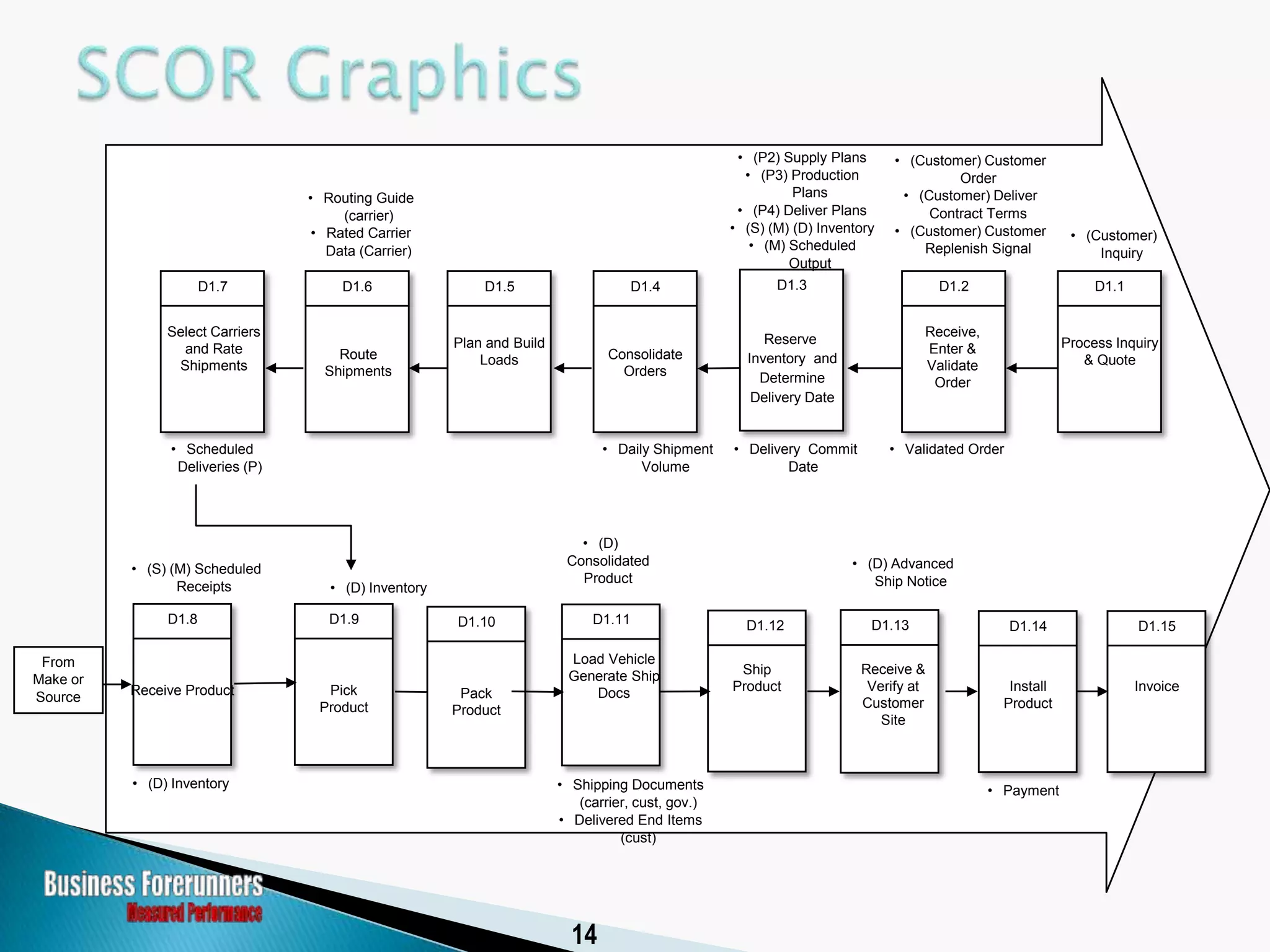

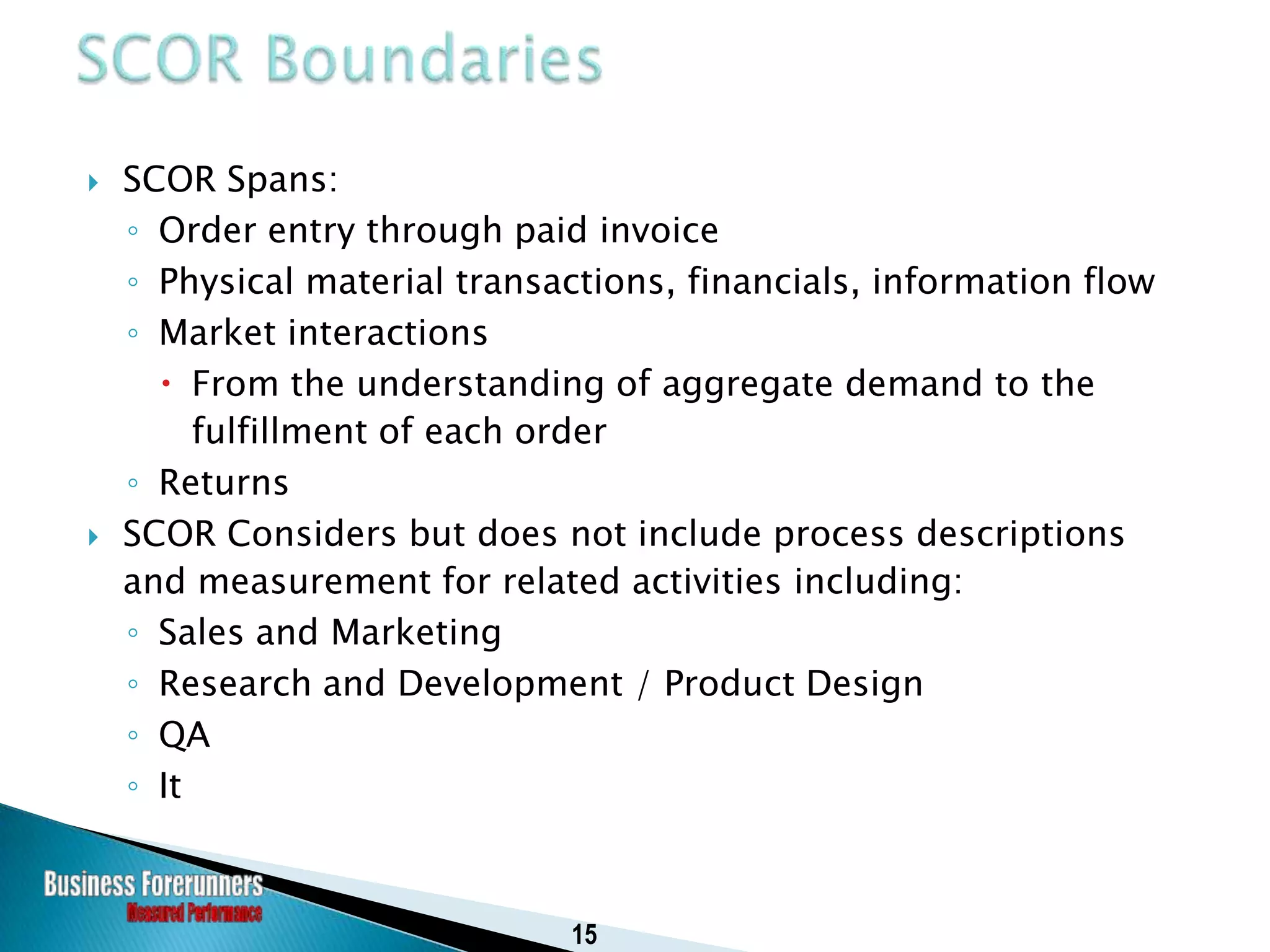

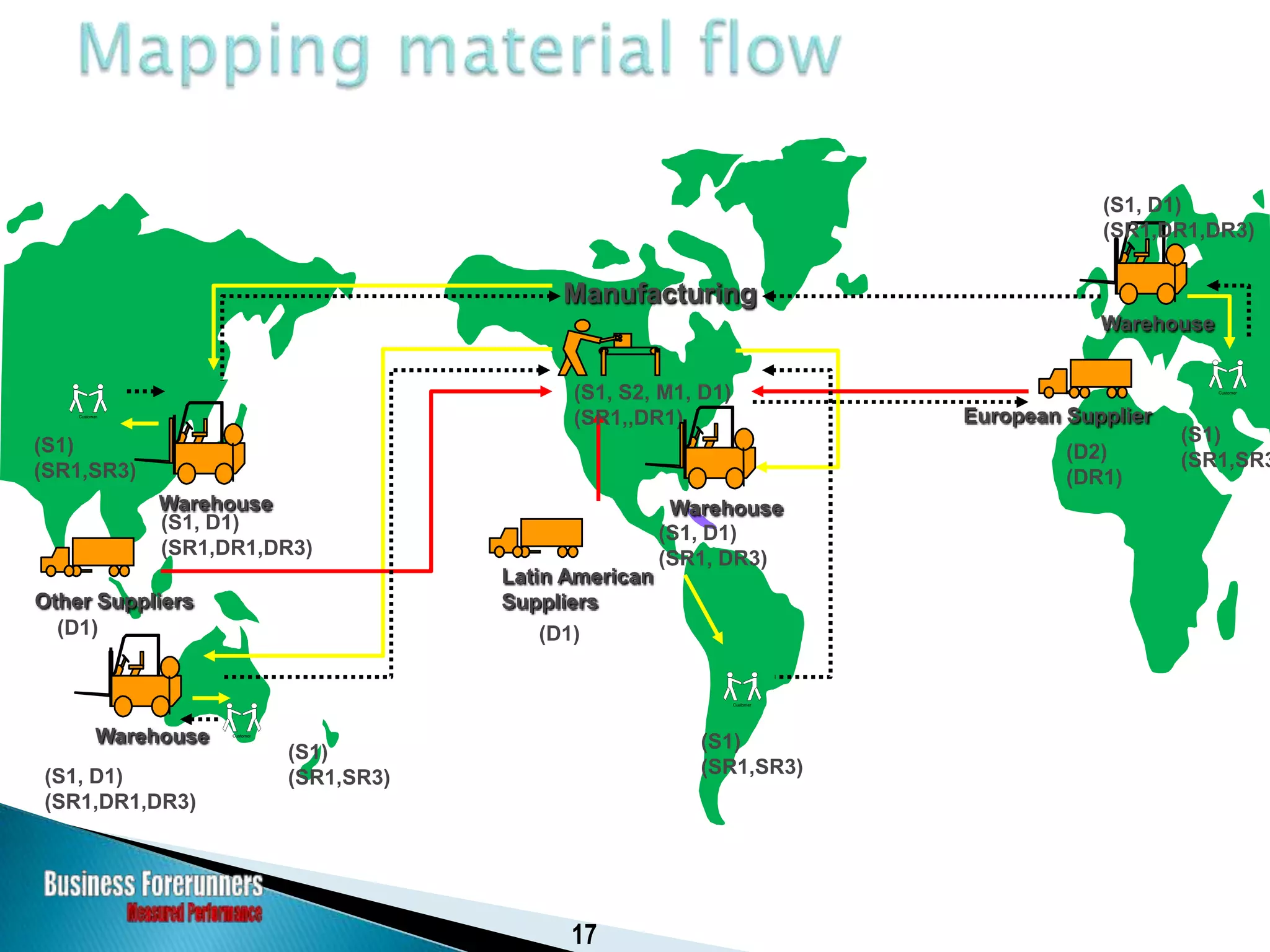

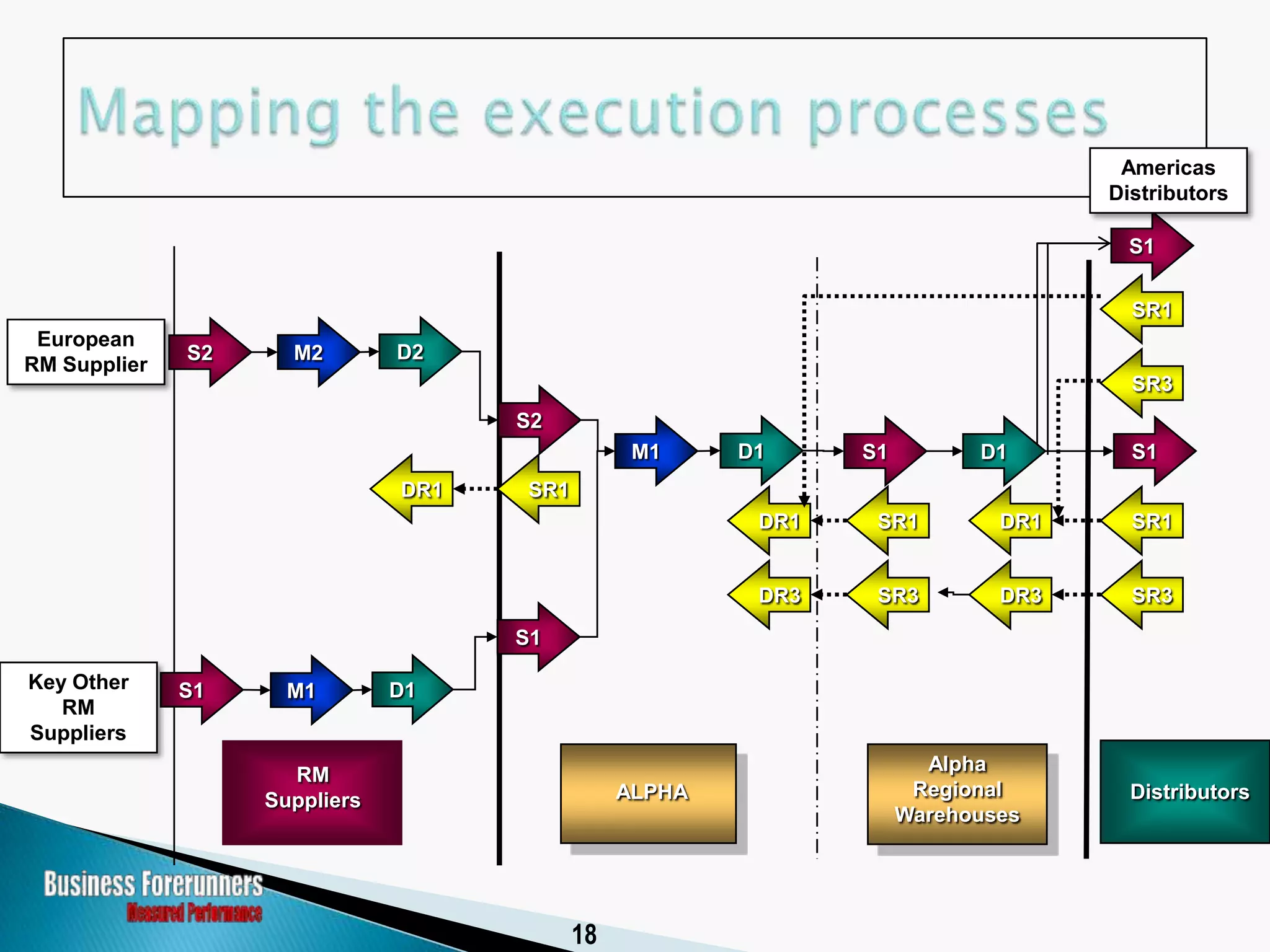

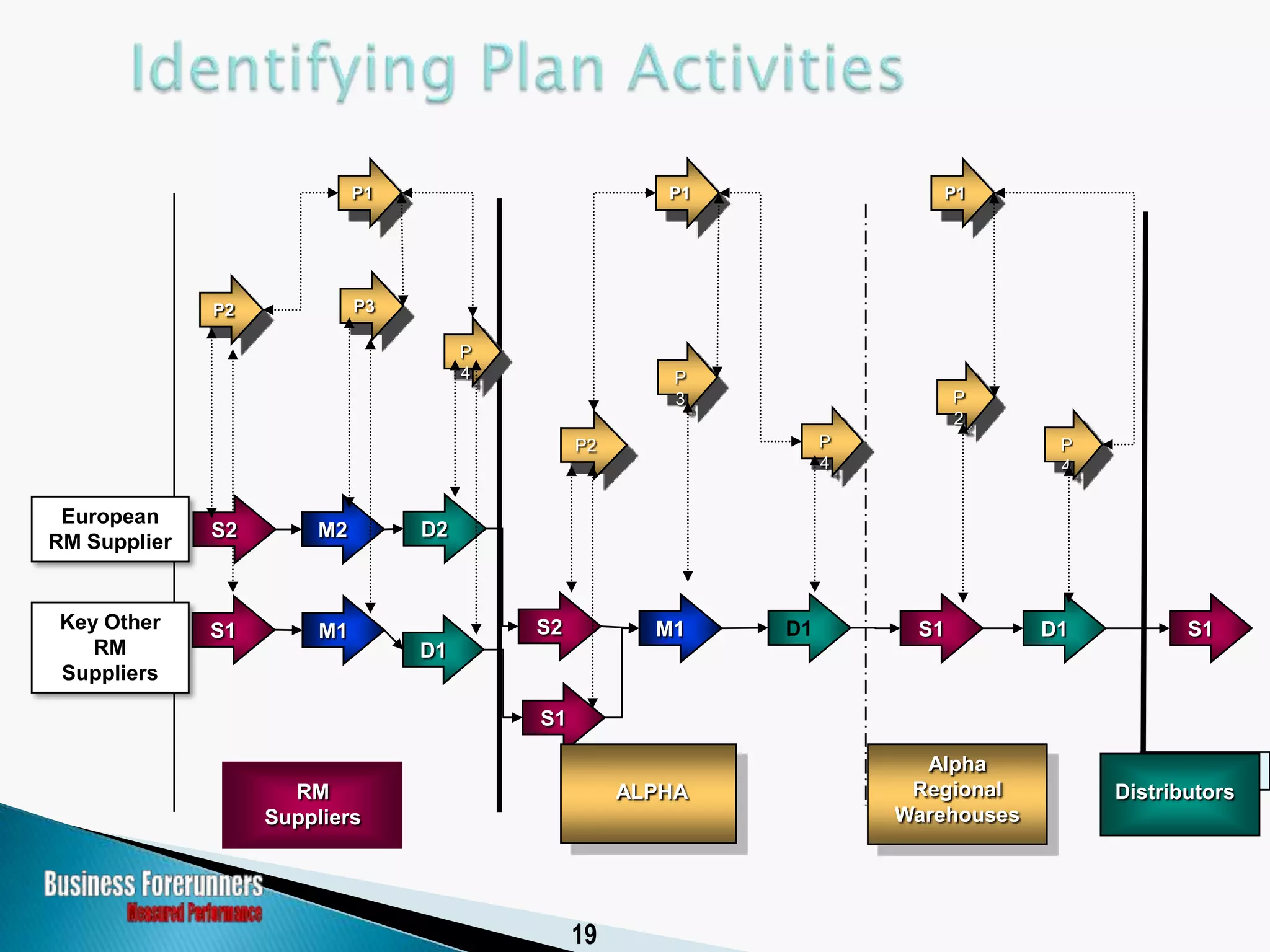

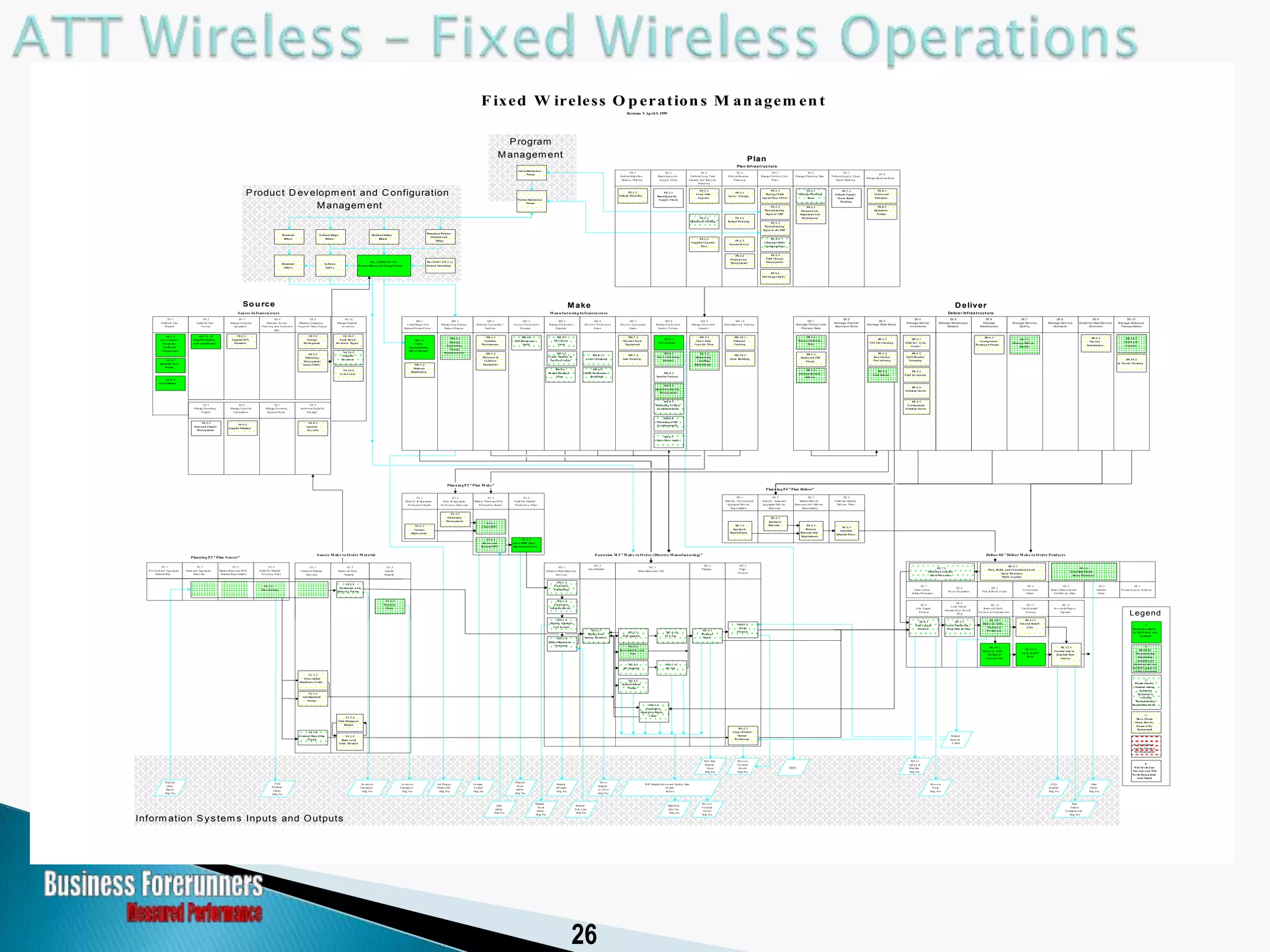

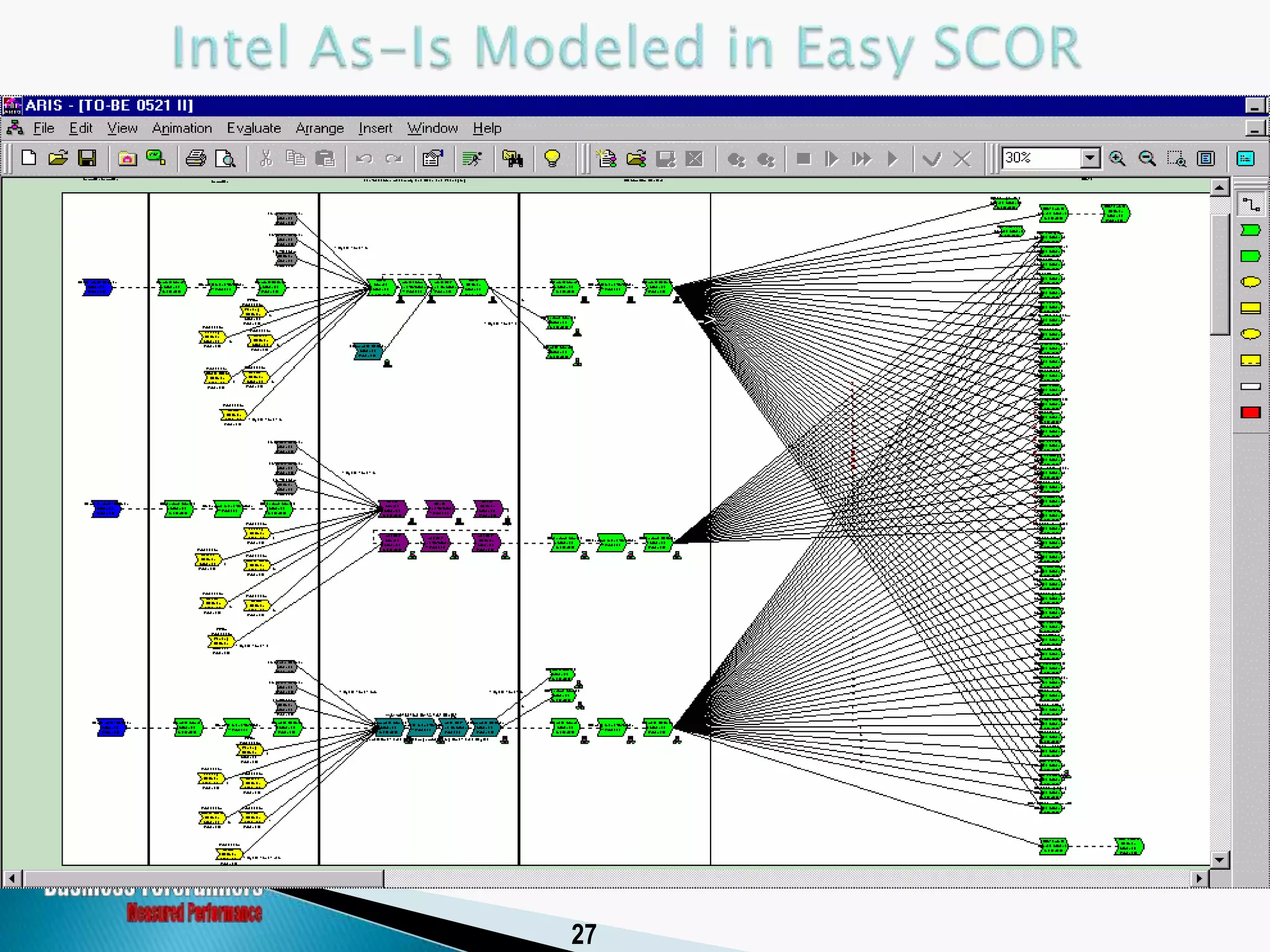

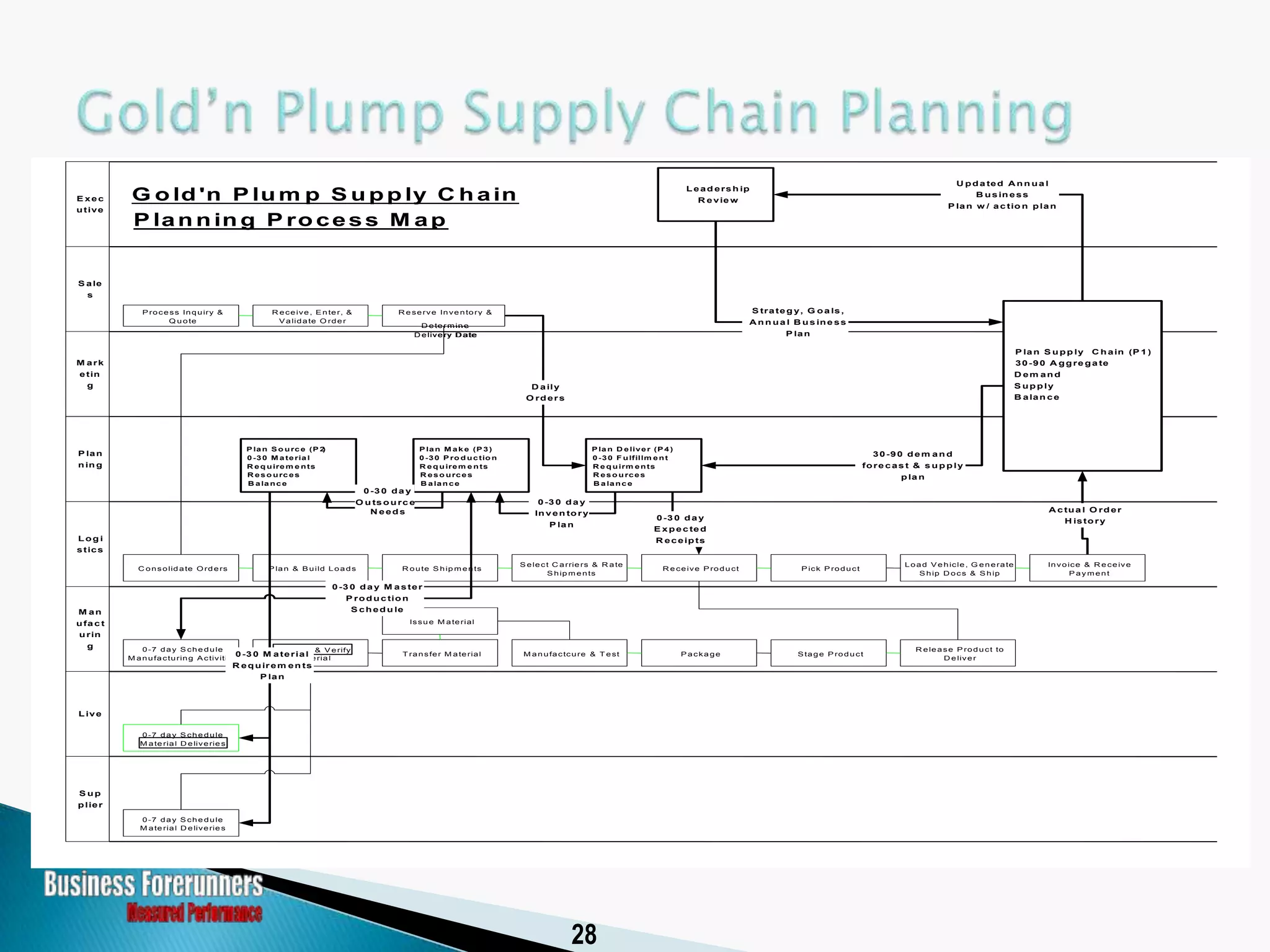

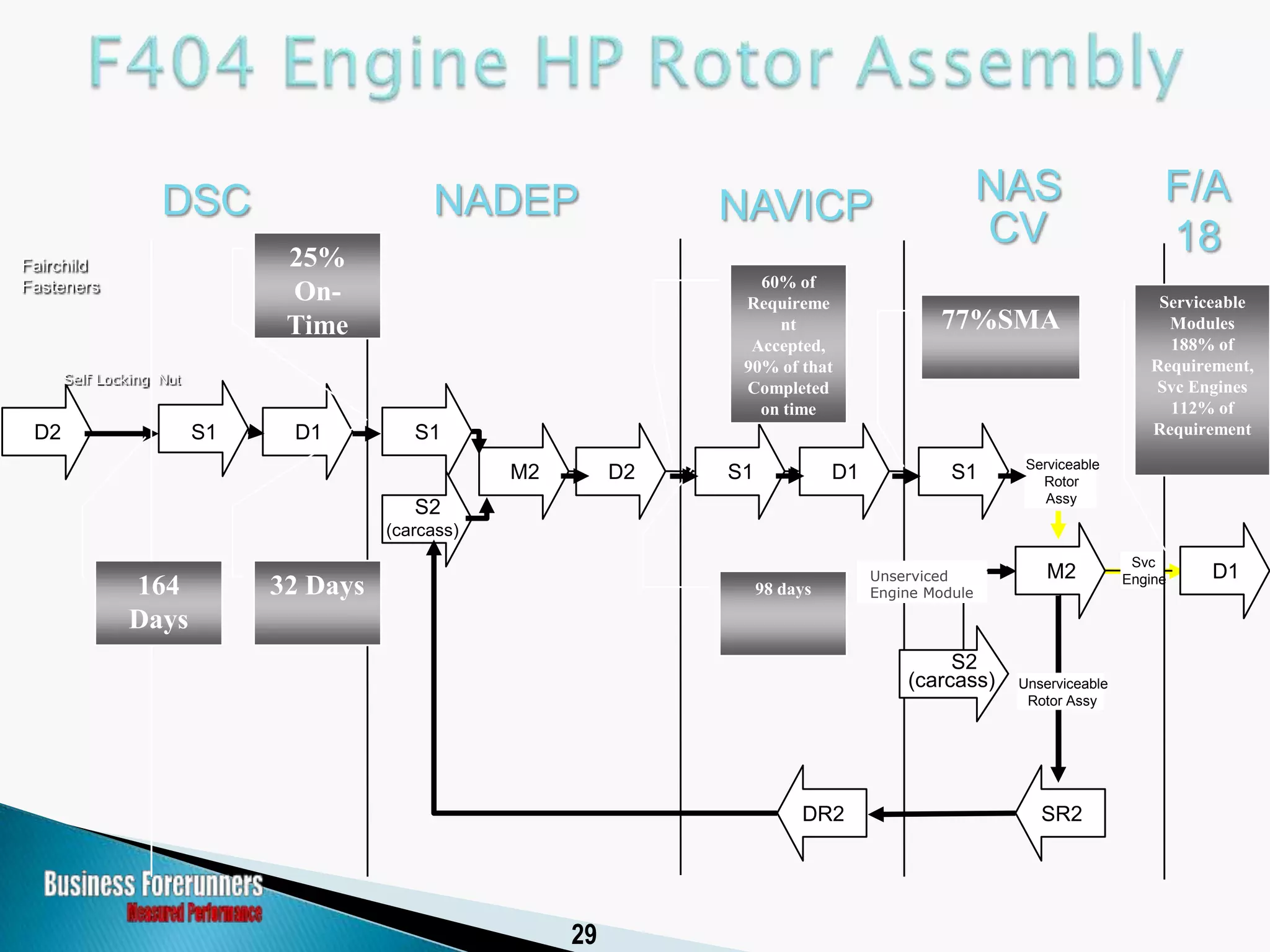

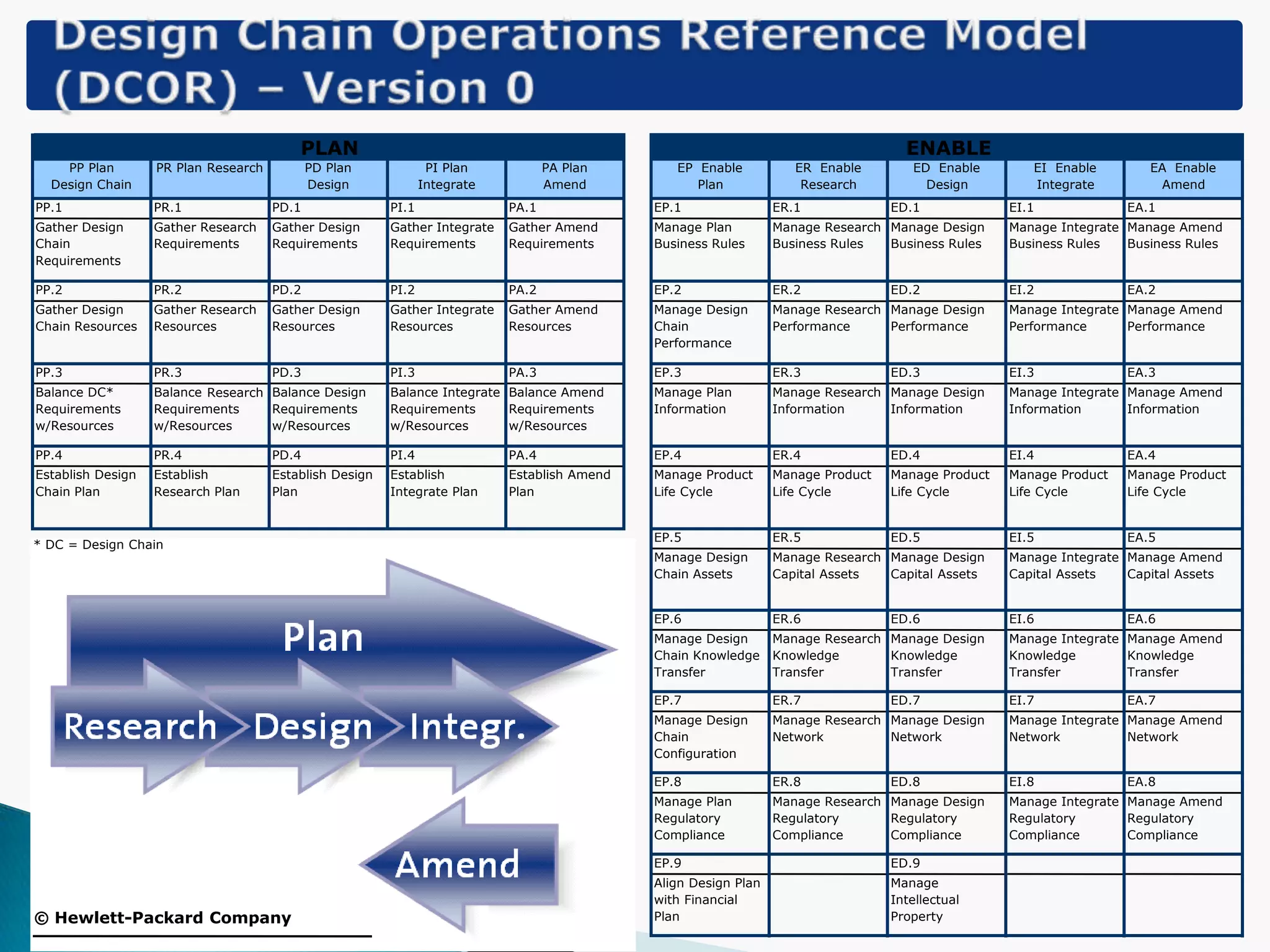

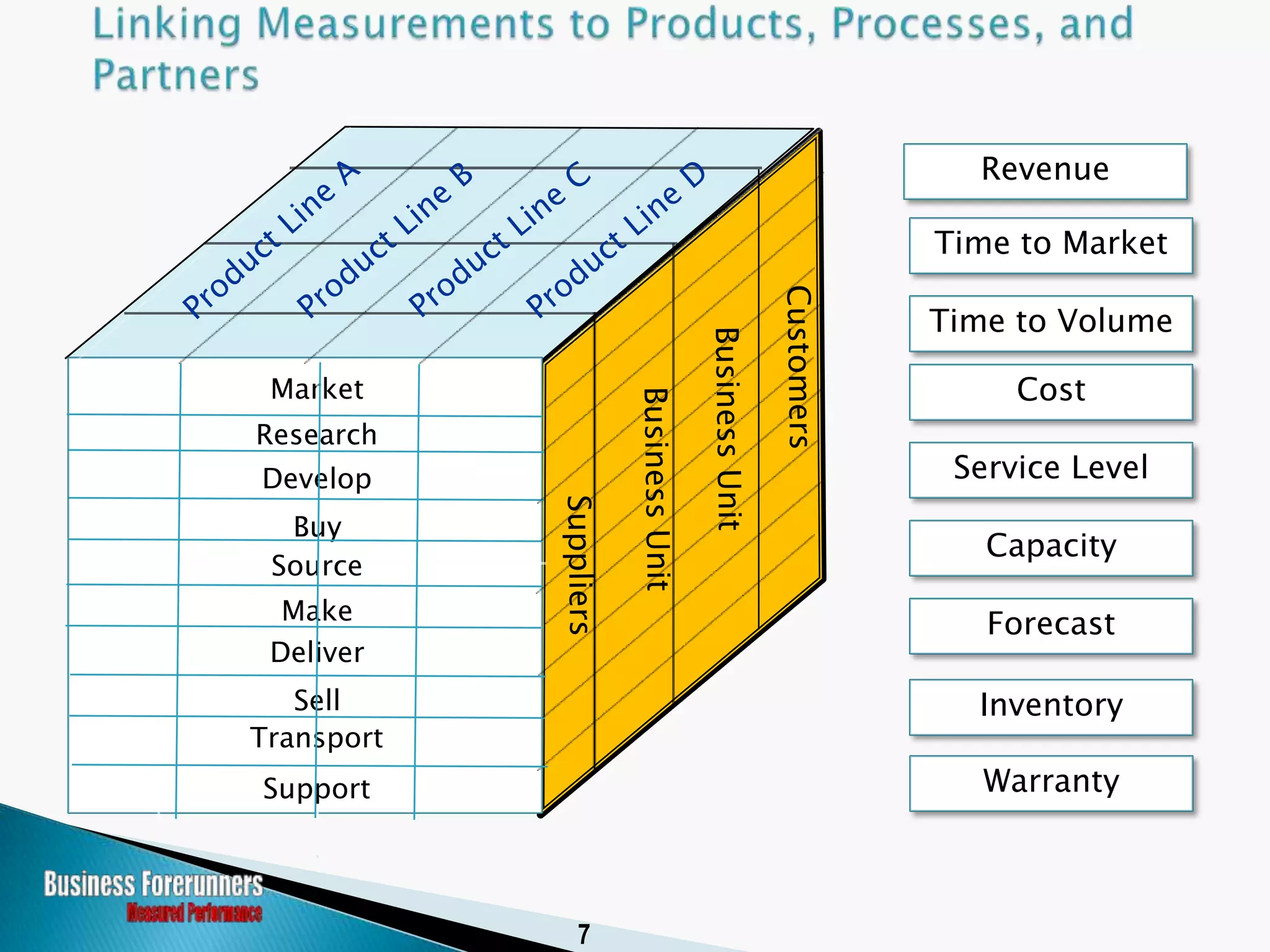

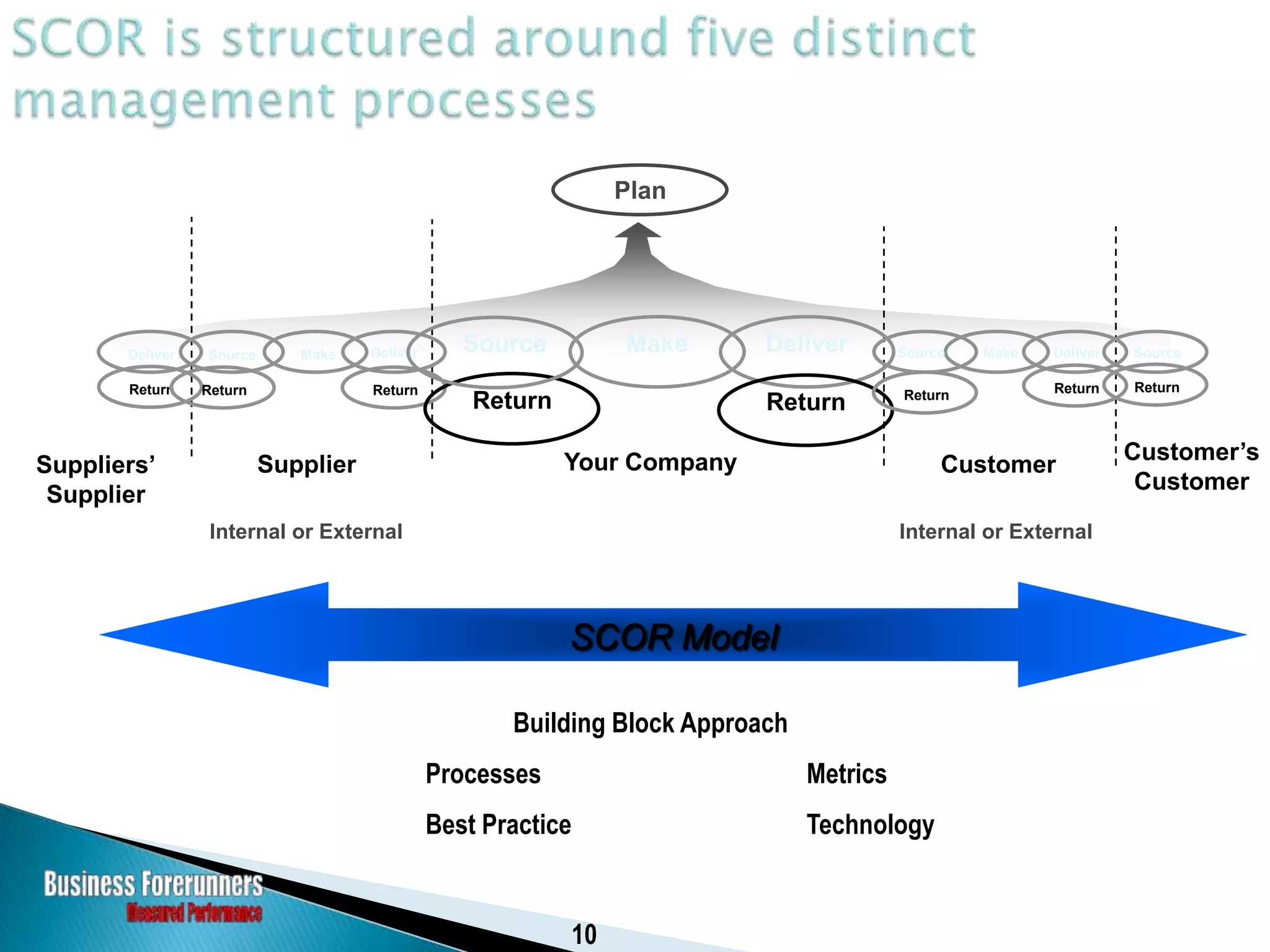

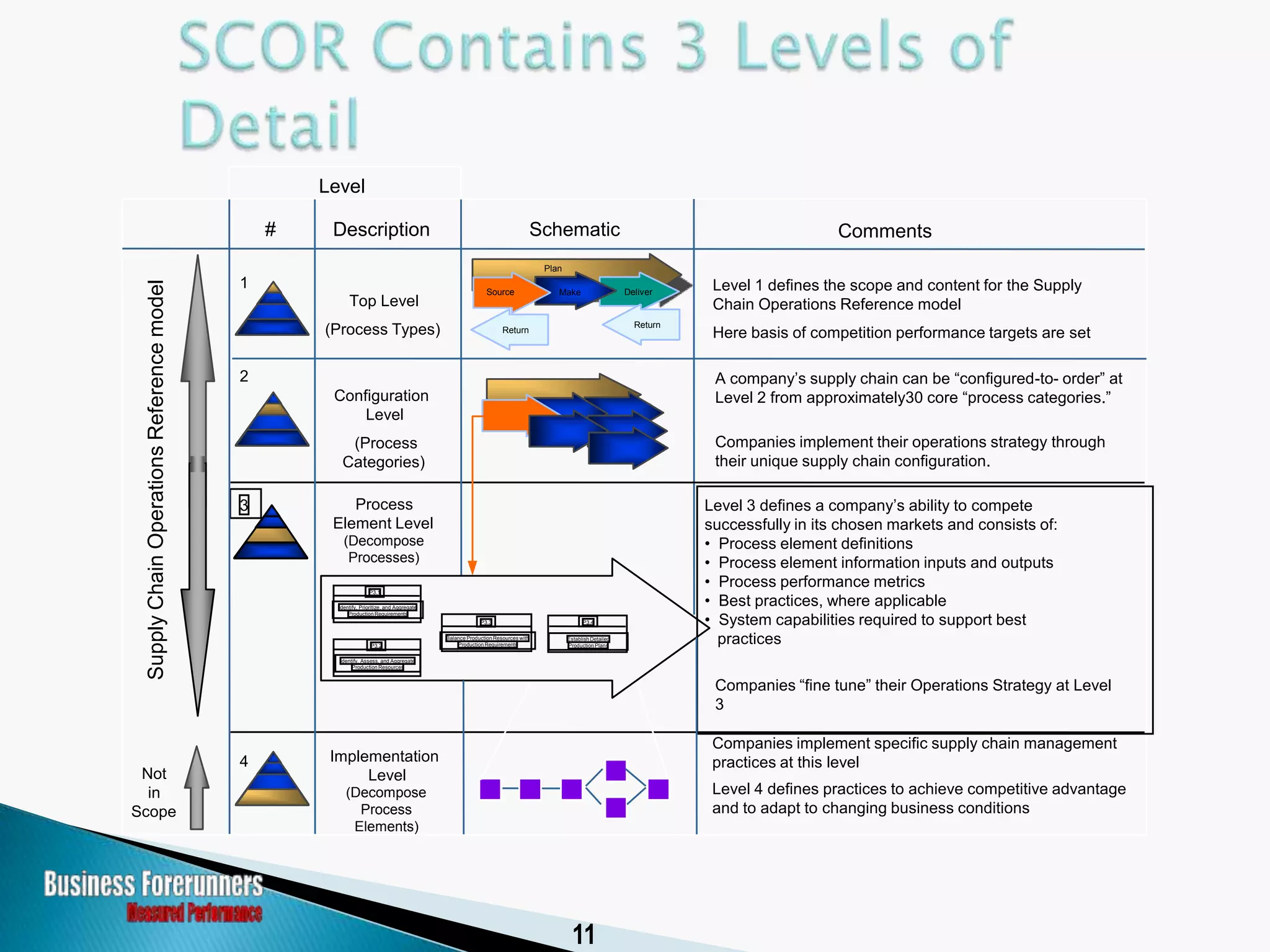

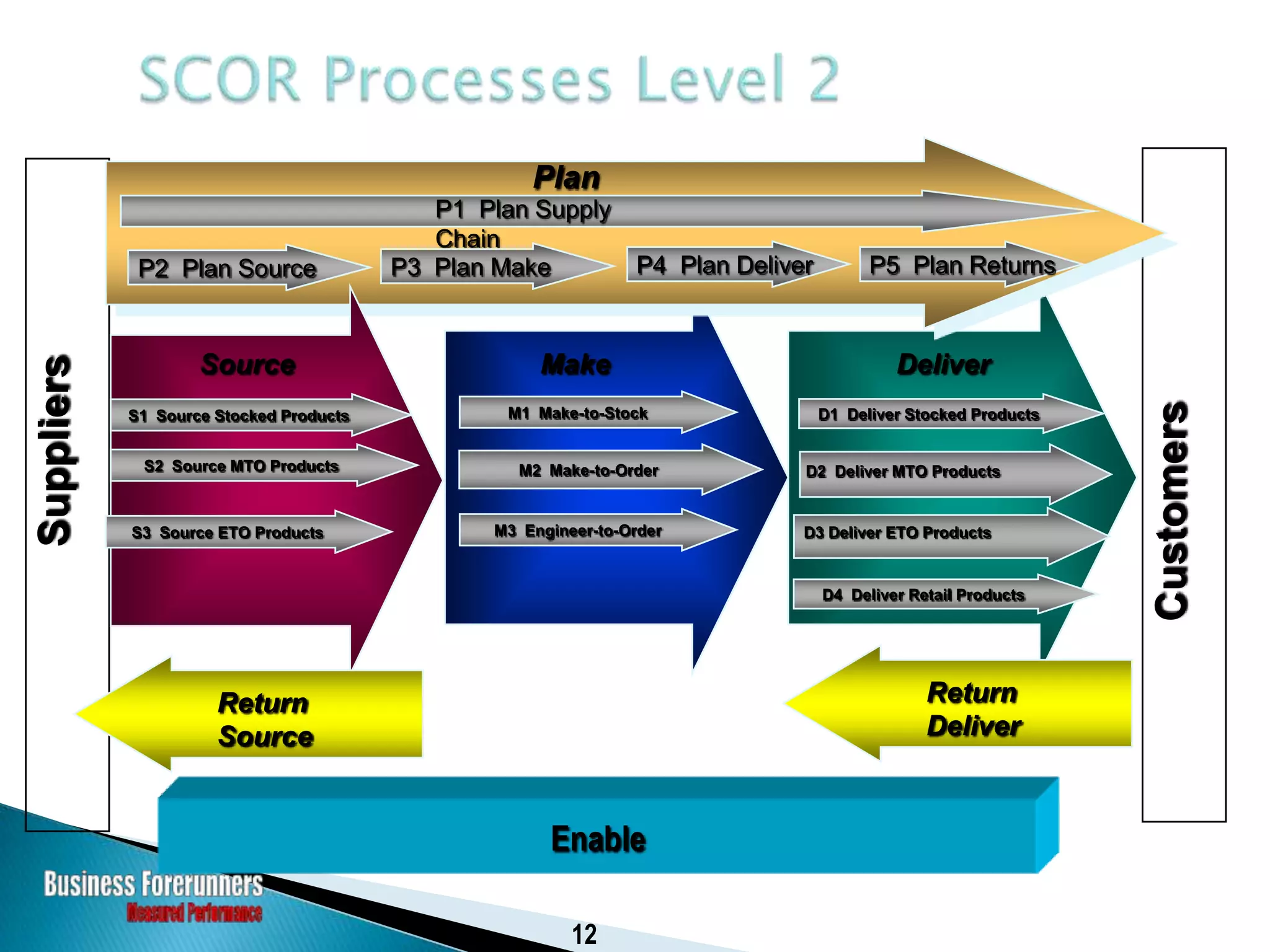

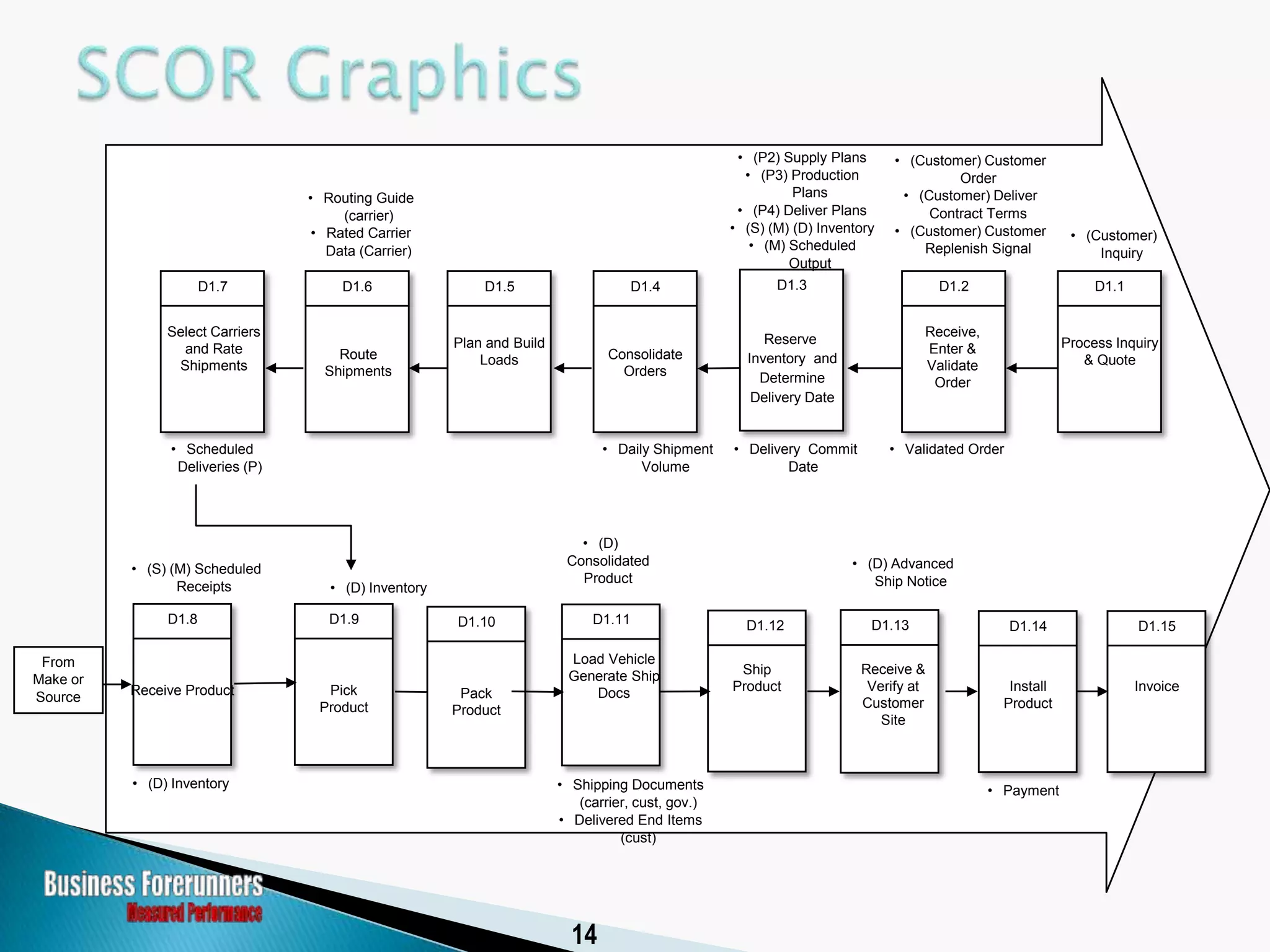

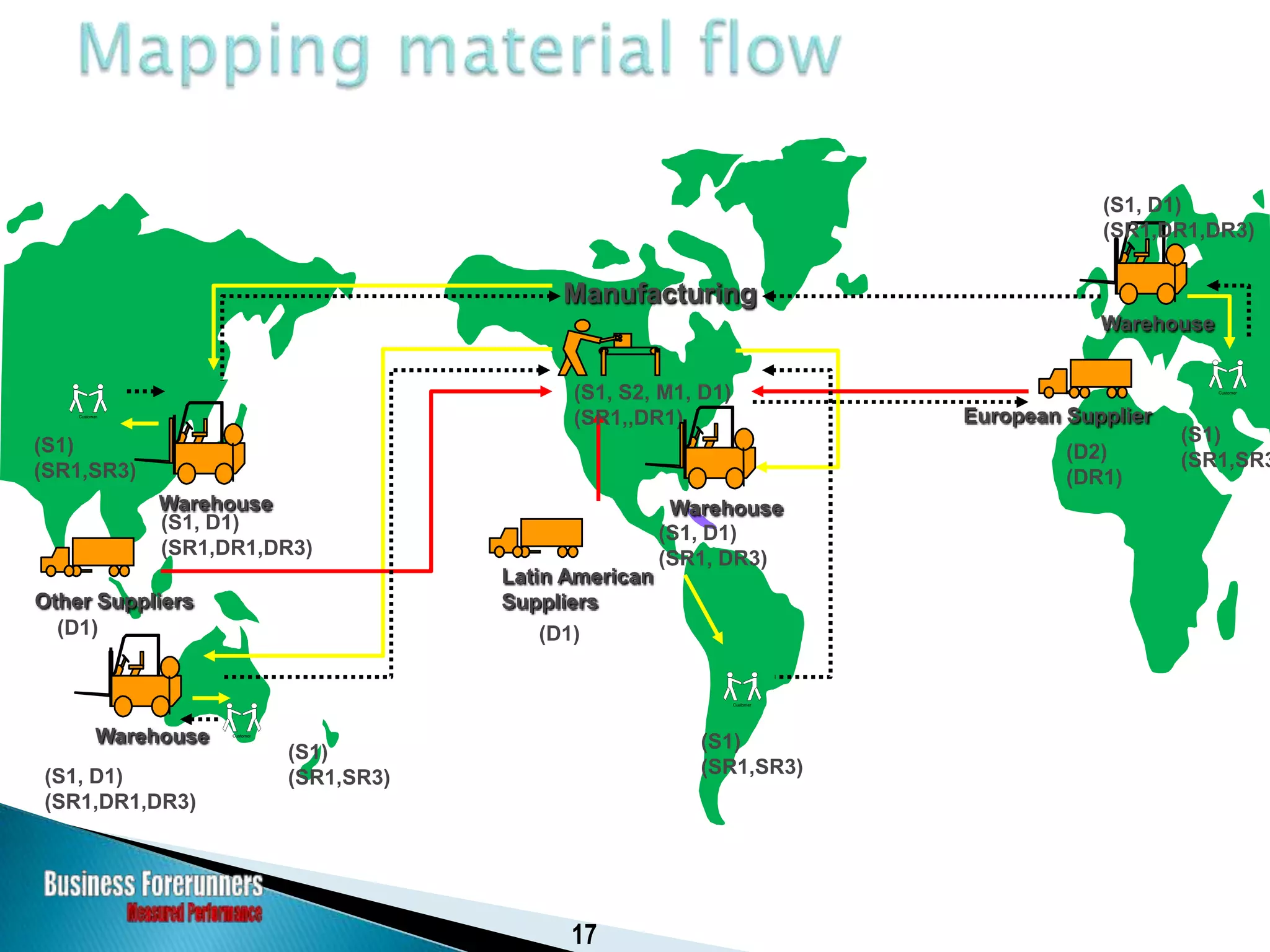

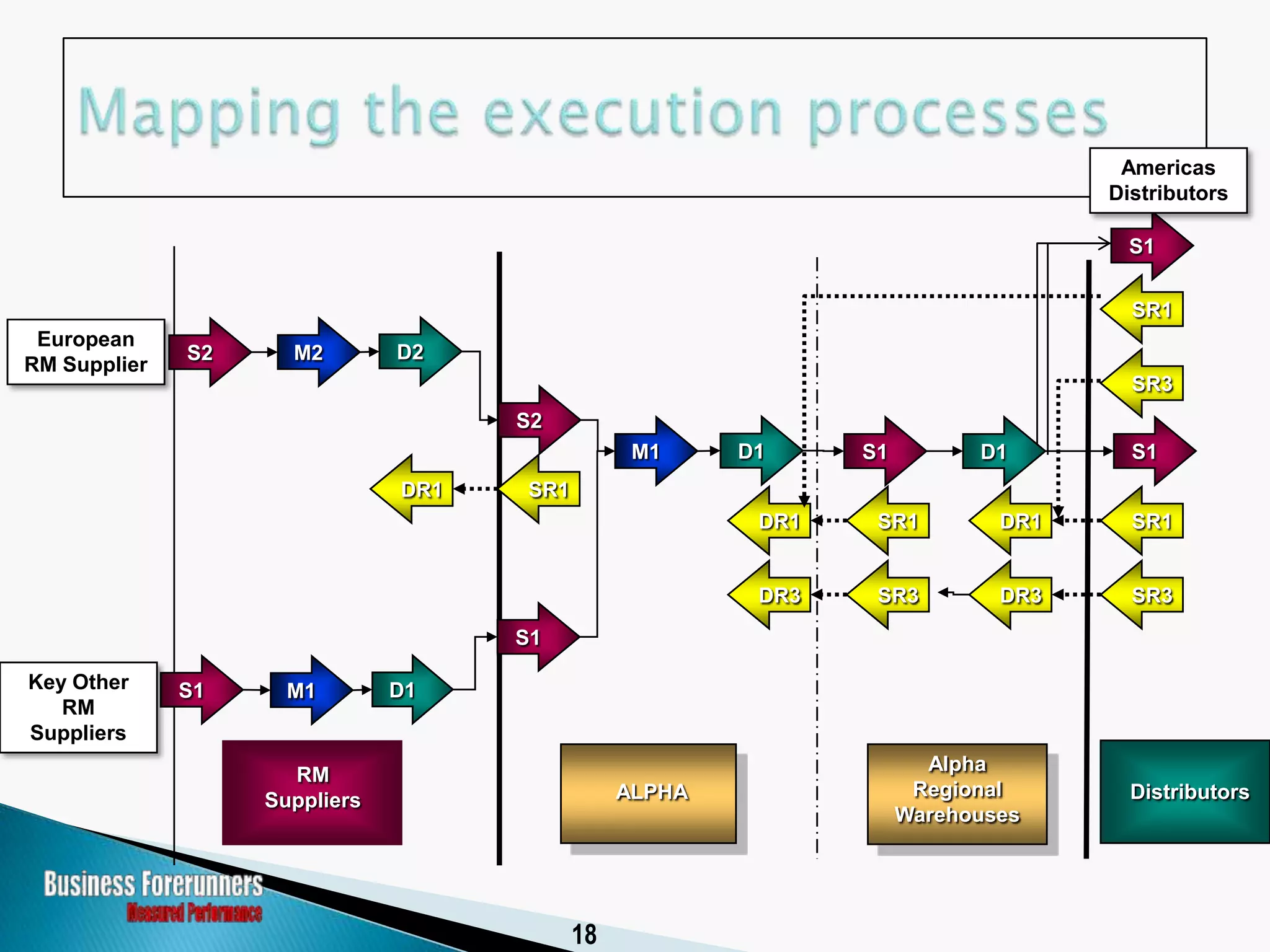

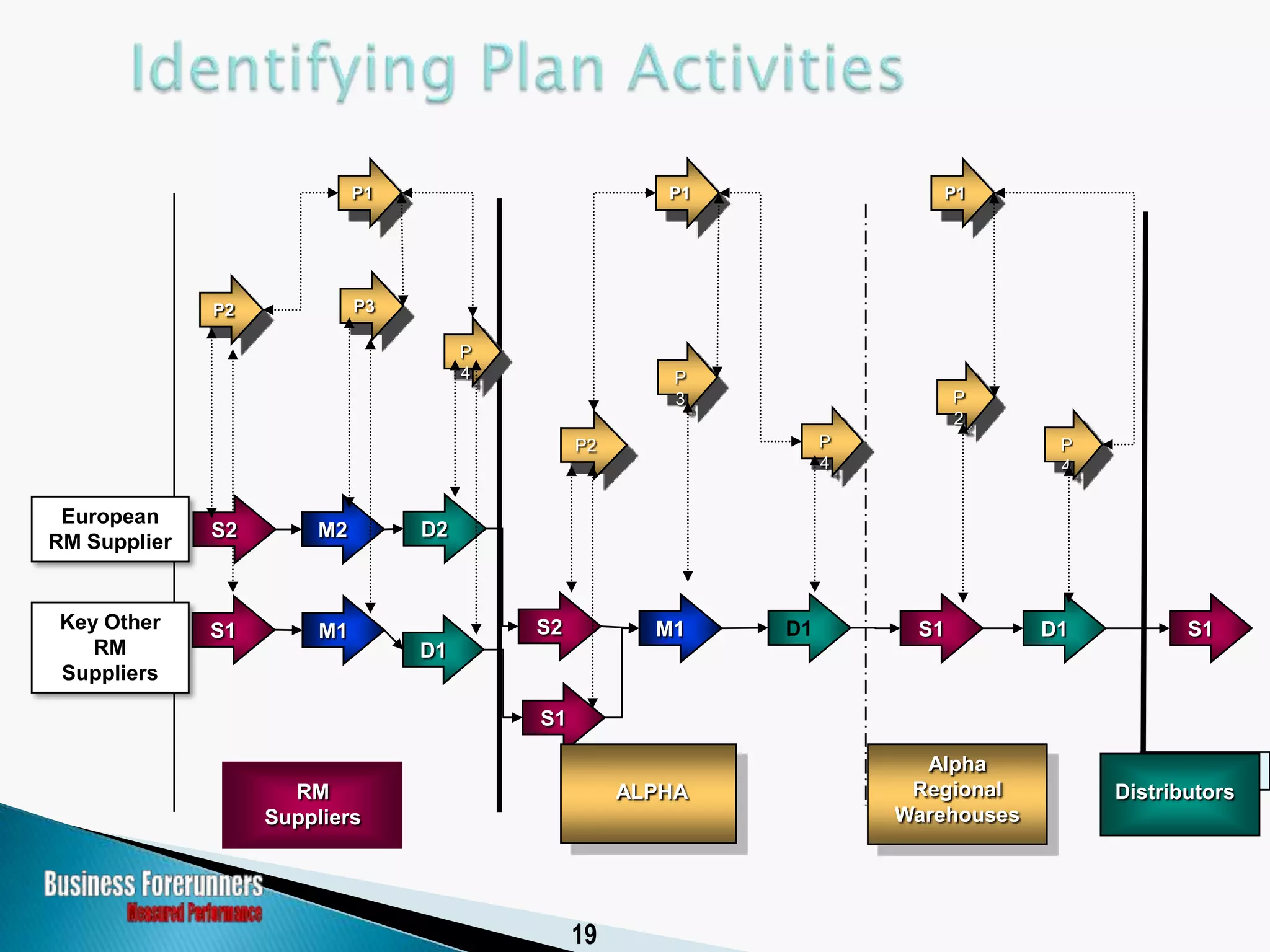

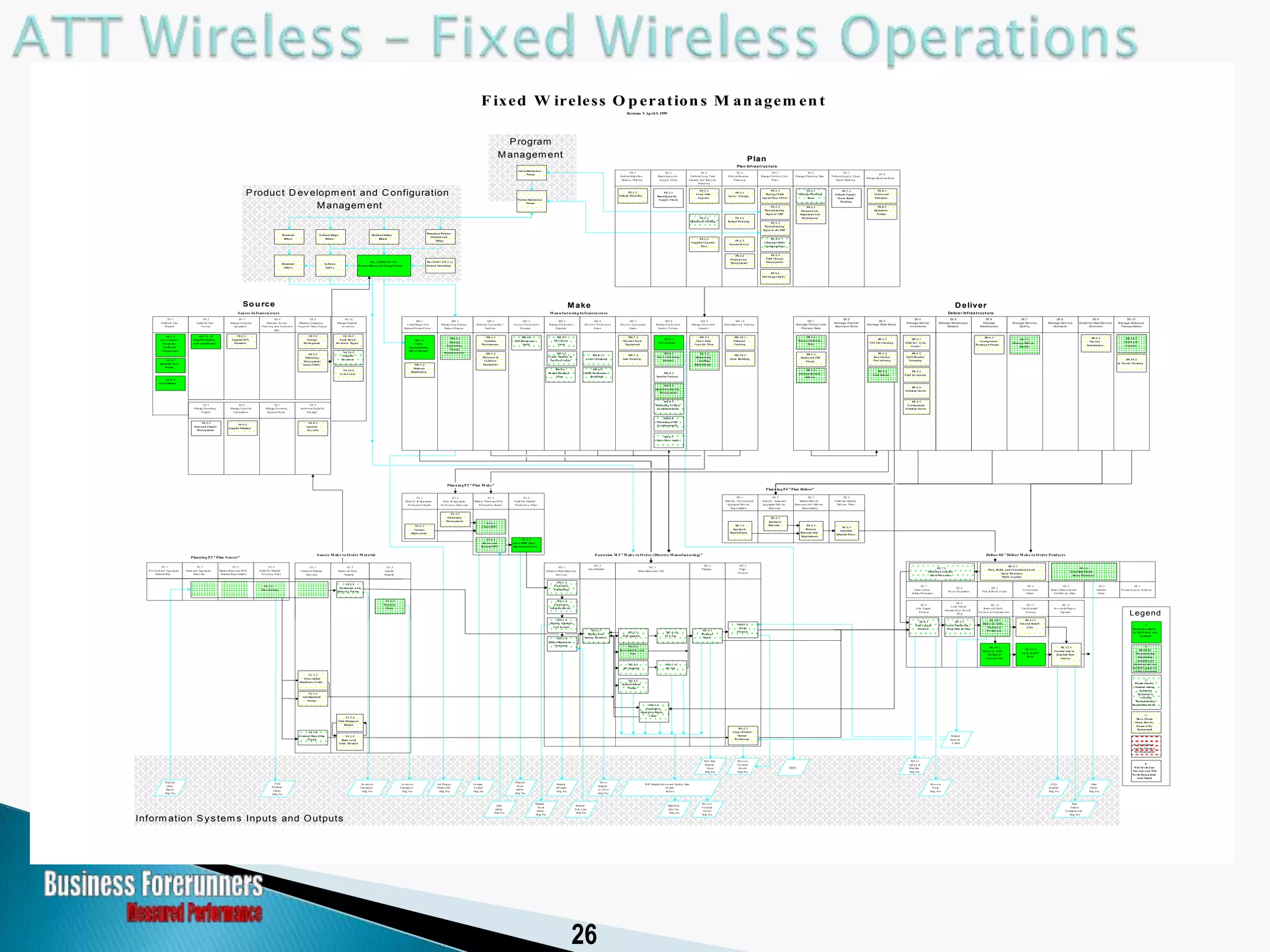

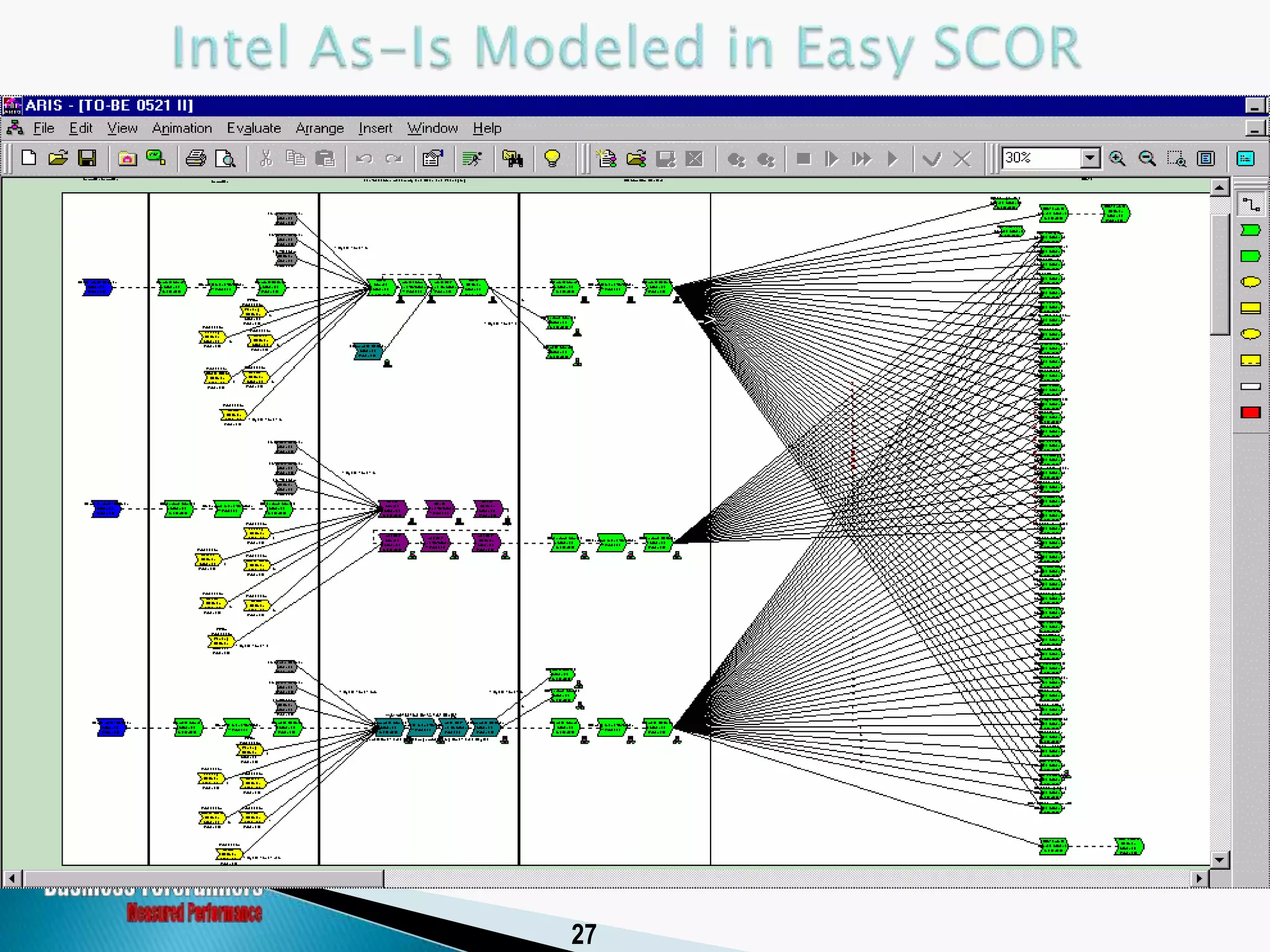

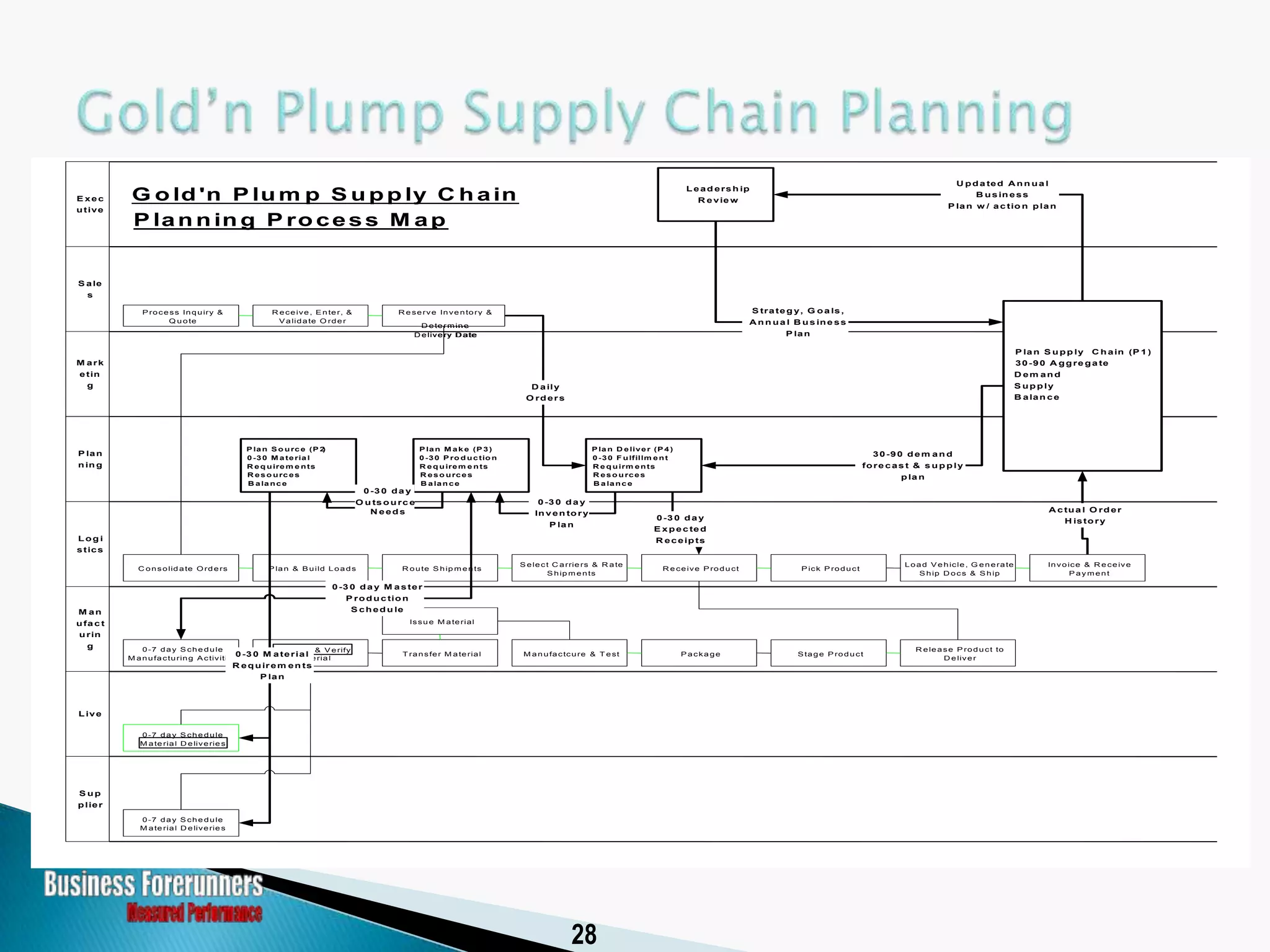

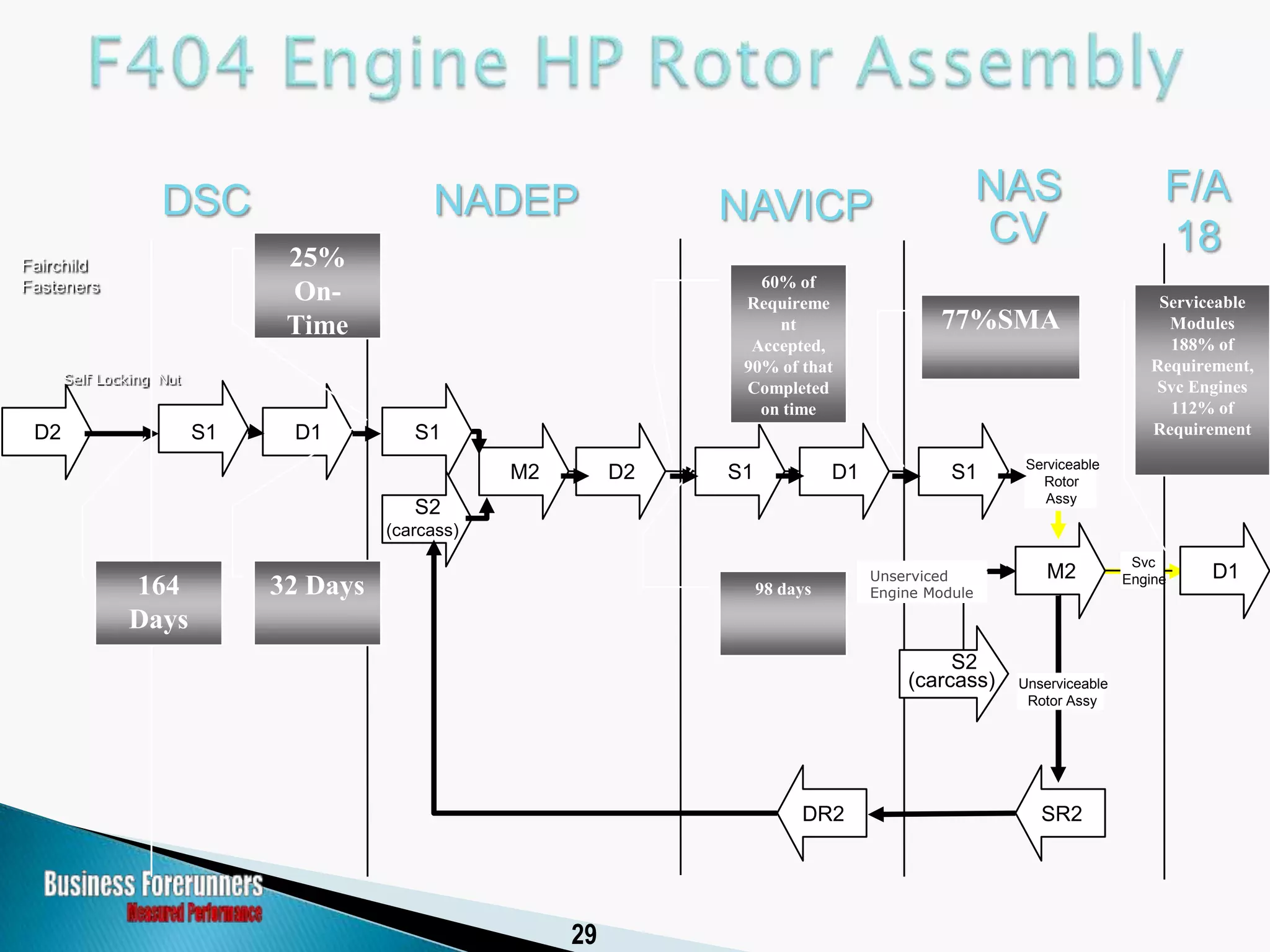

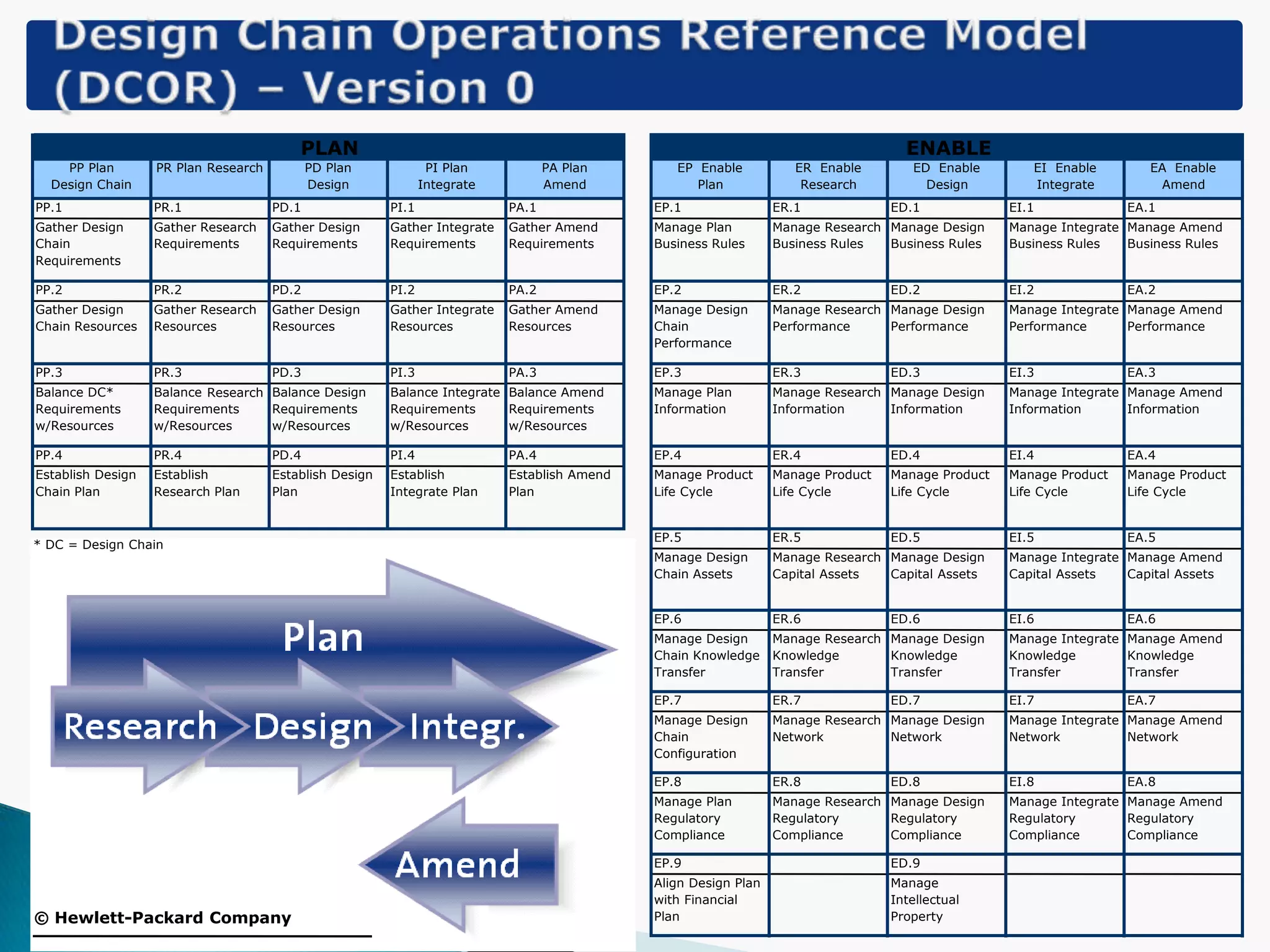

Detailed mapping processes in SCOR model covering main activities: Plan, Source, Make, Deliver, and Return.

Detailed mapping processes in SCOR model covering main activities: Plan, Source, Make, Deliver, and Return.

Detailed mapping processes in SCOR model covering main activities: Plan, Source, Make, Deliver, and Return.

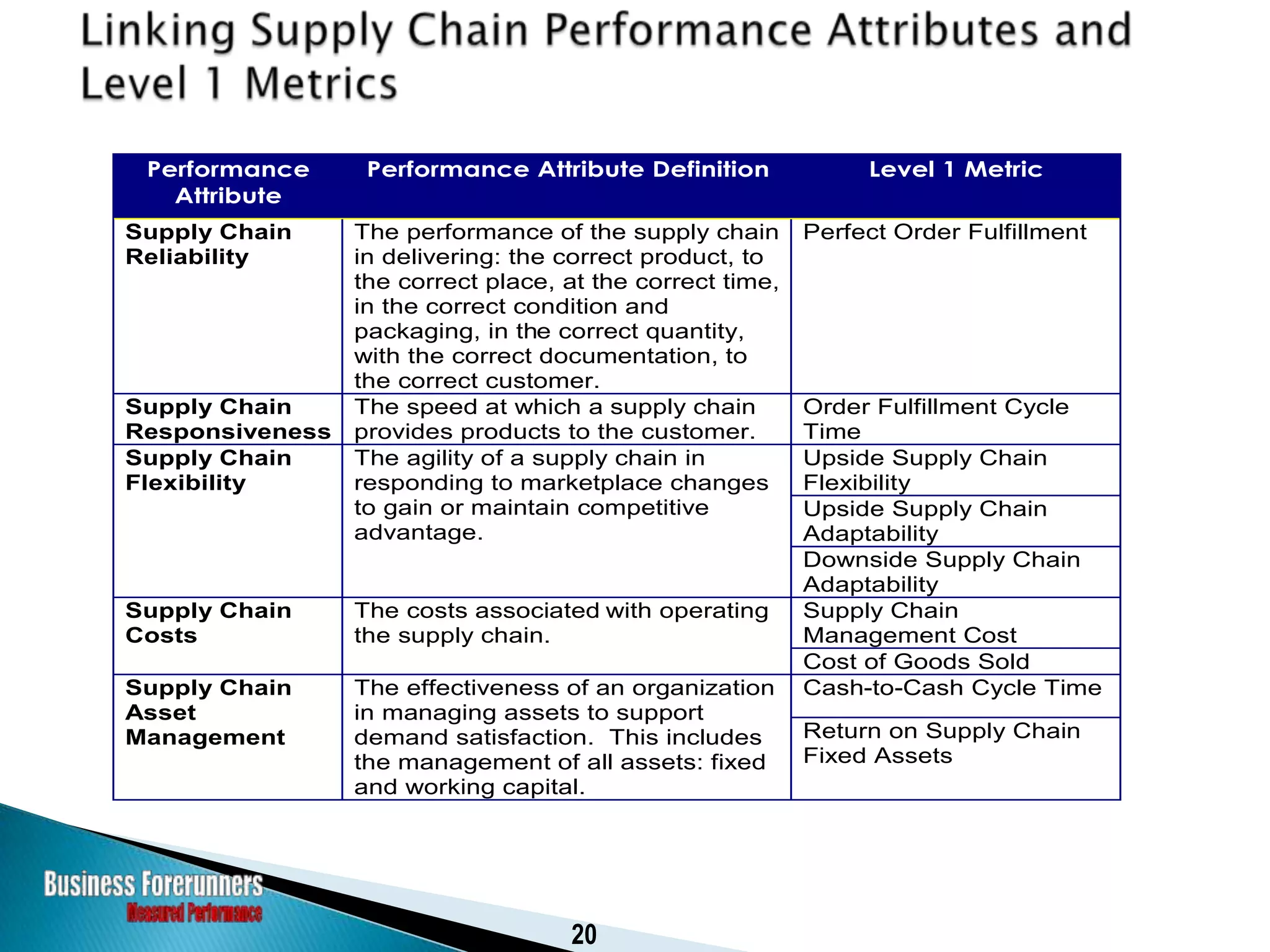

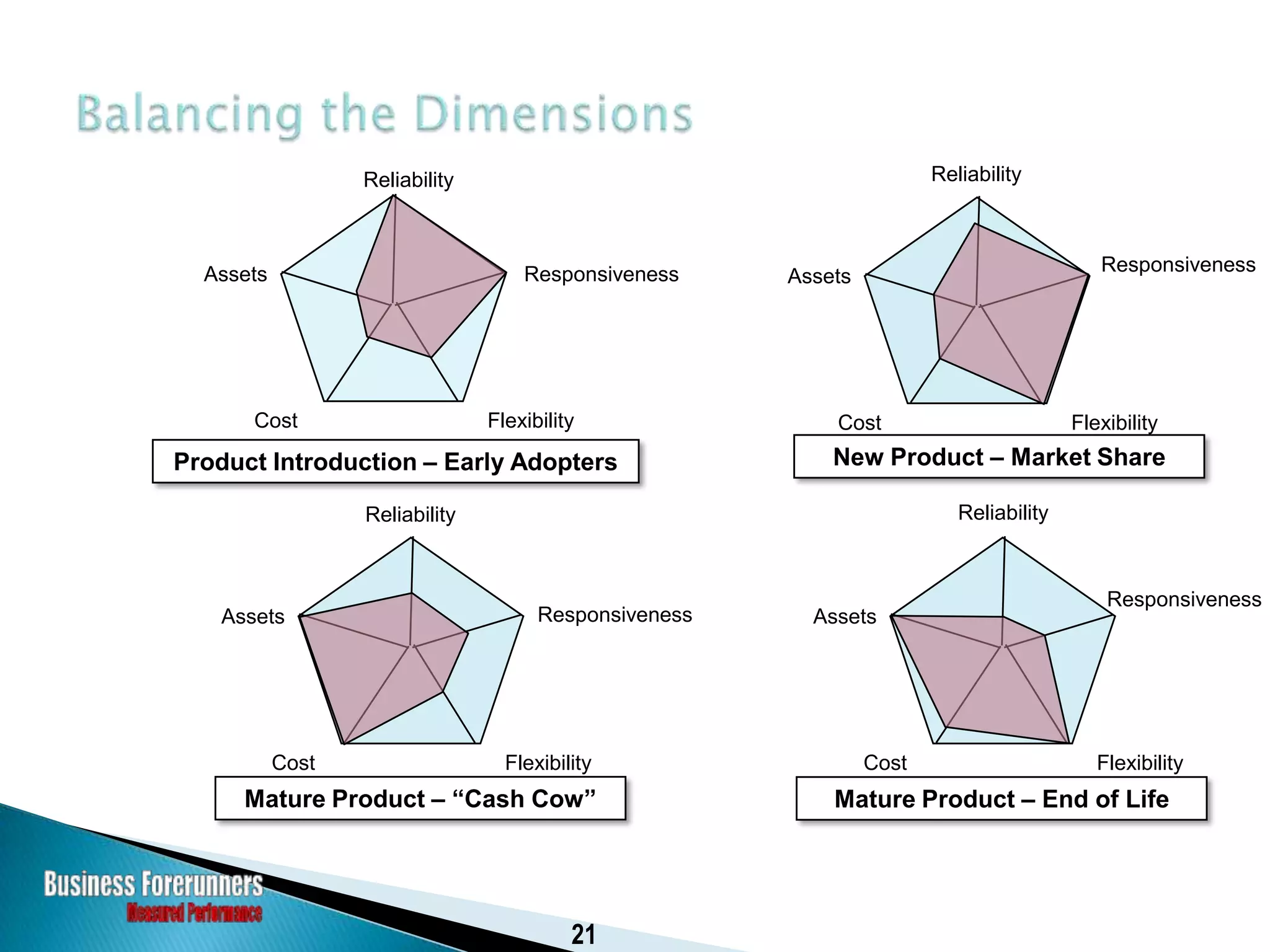

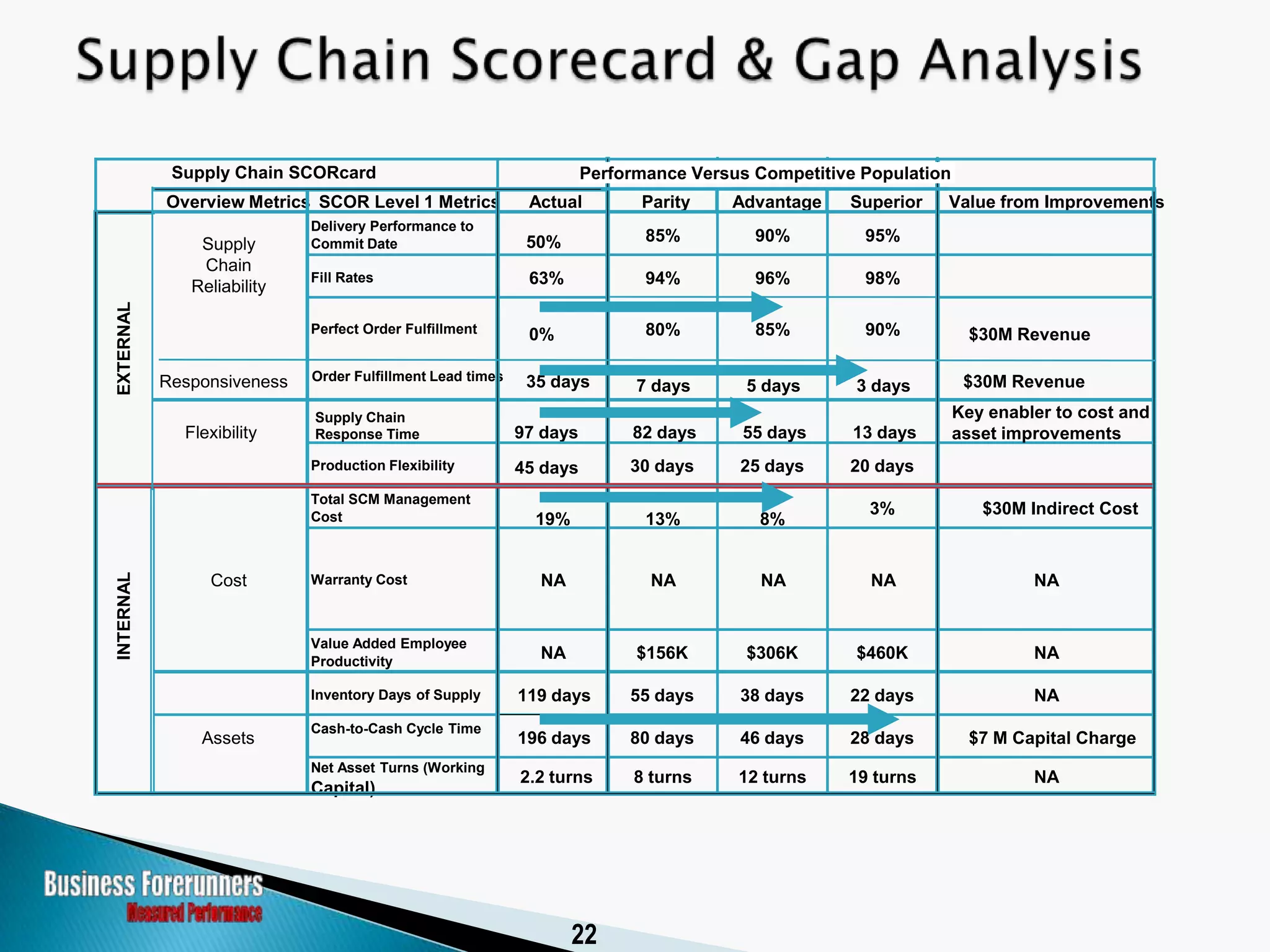

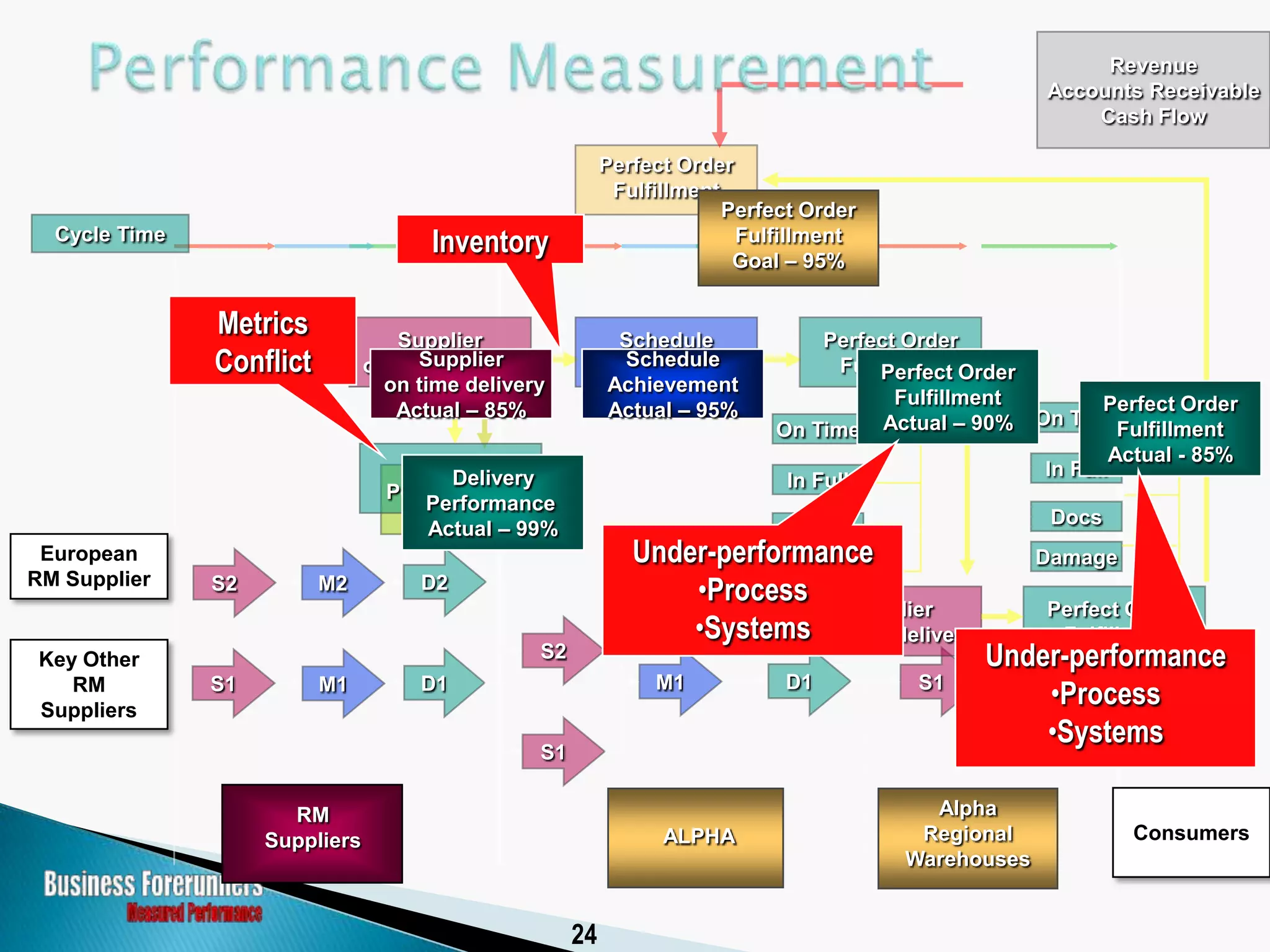

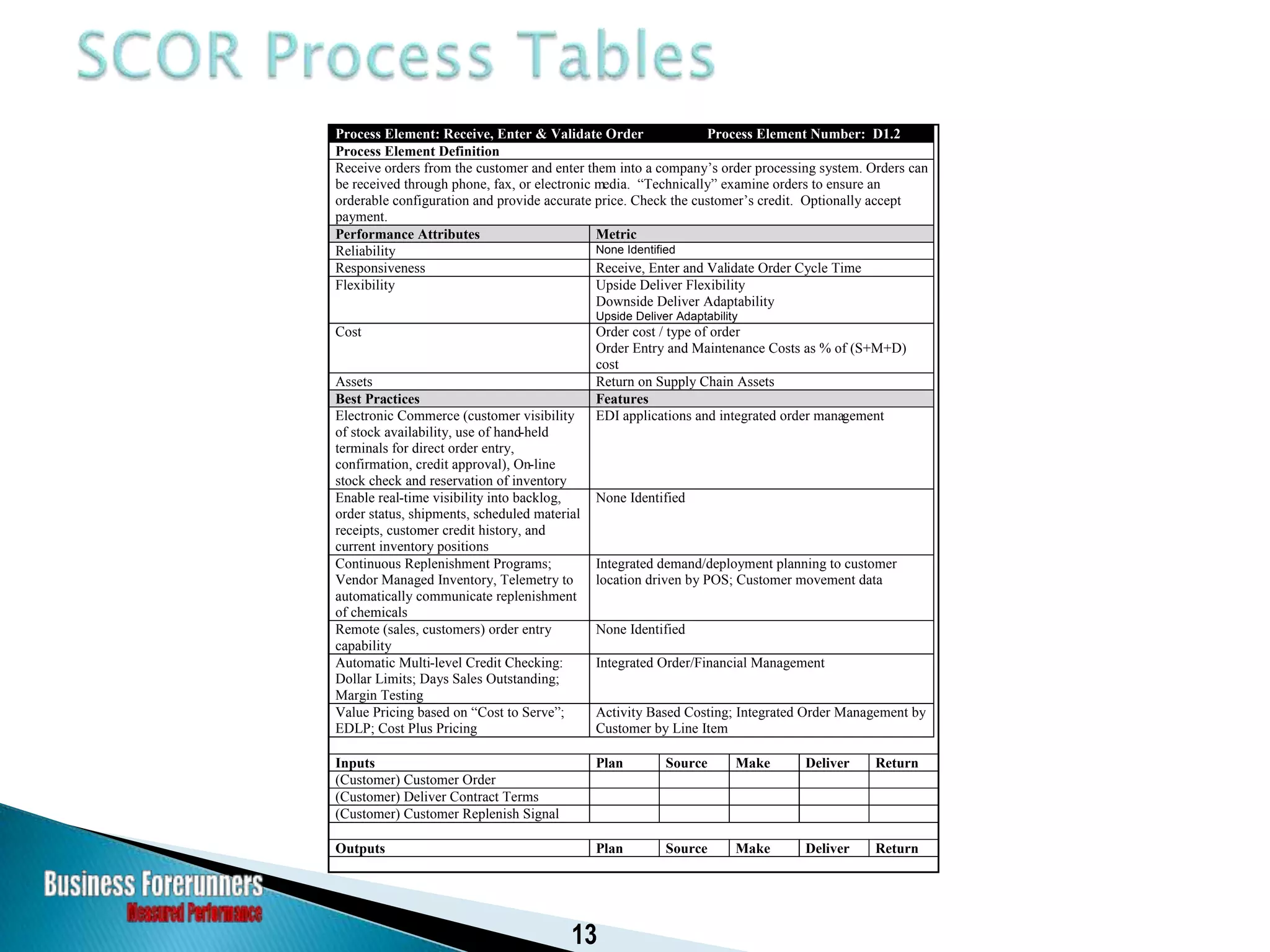

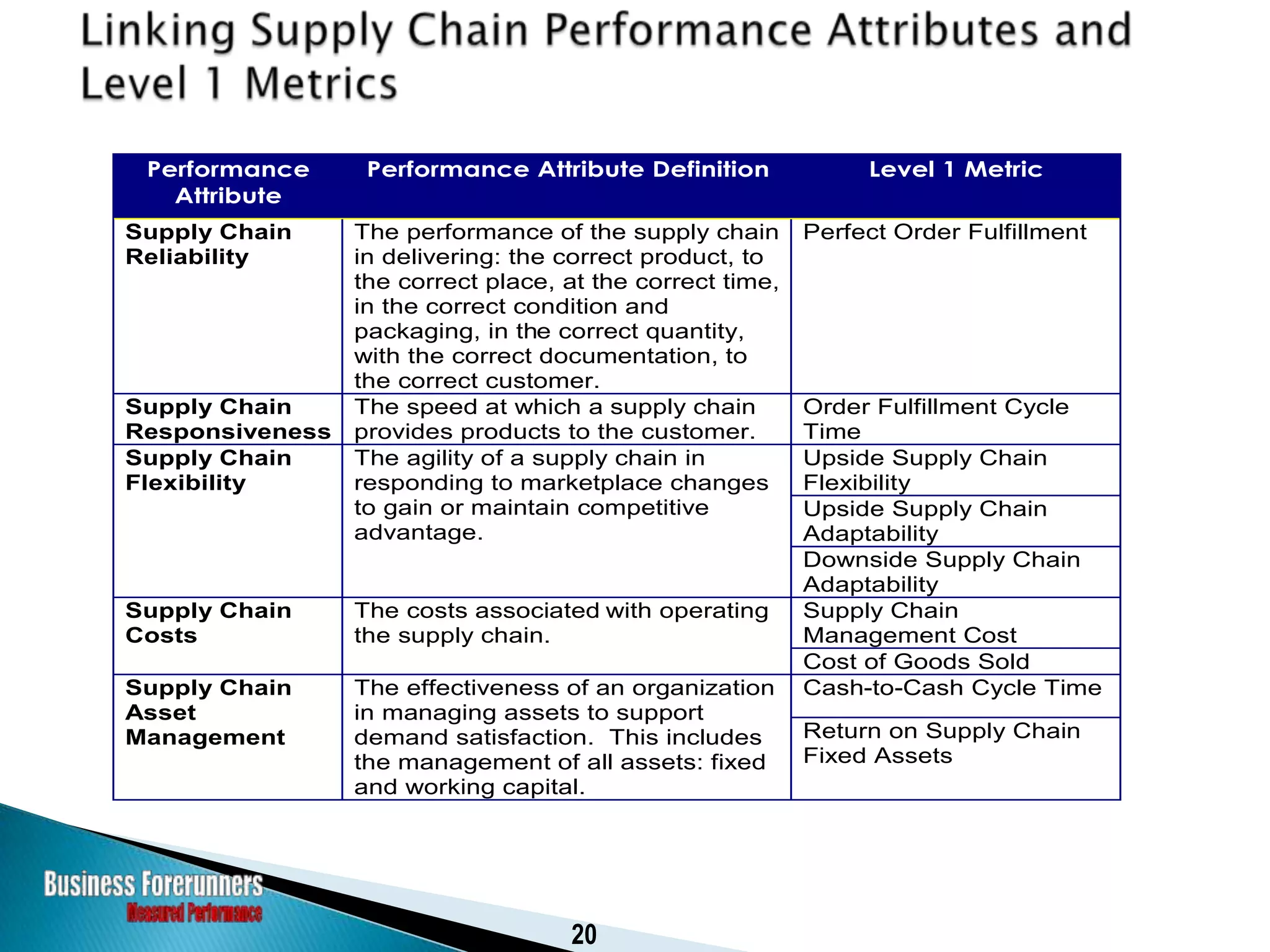

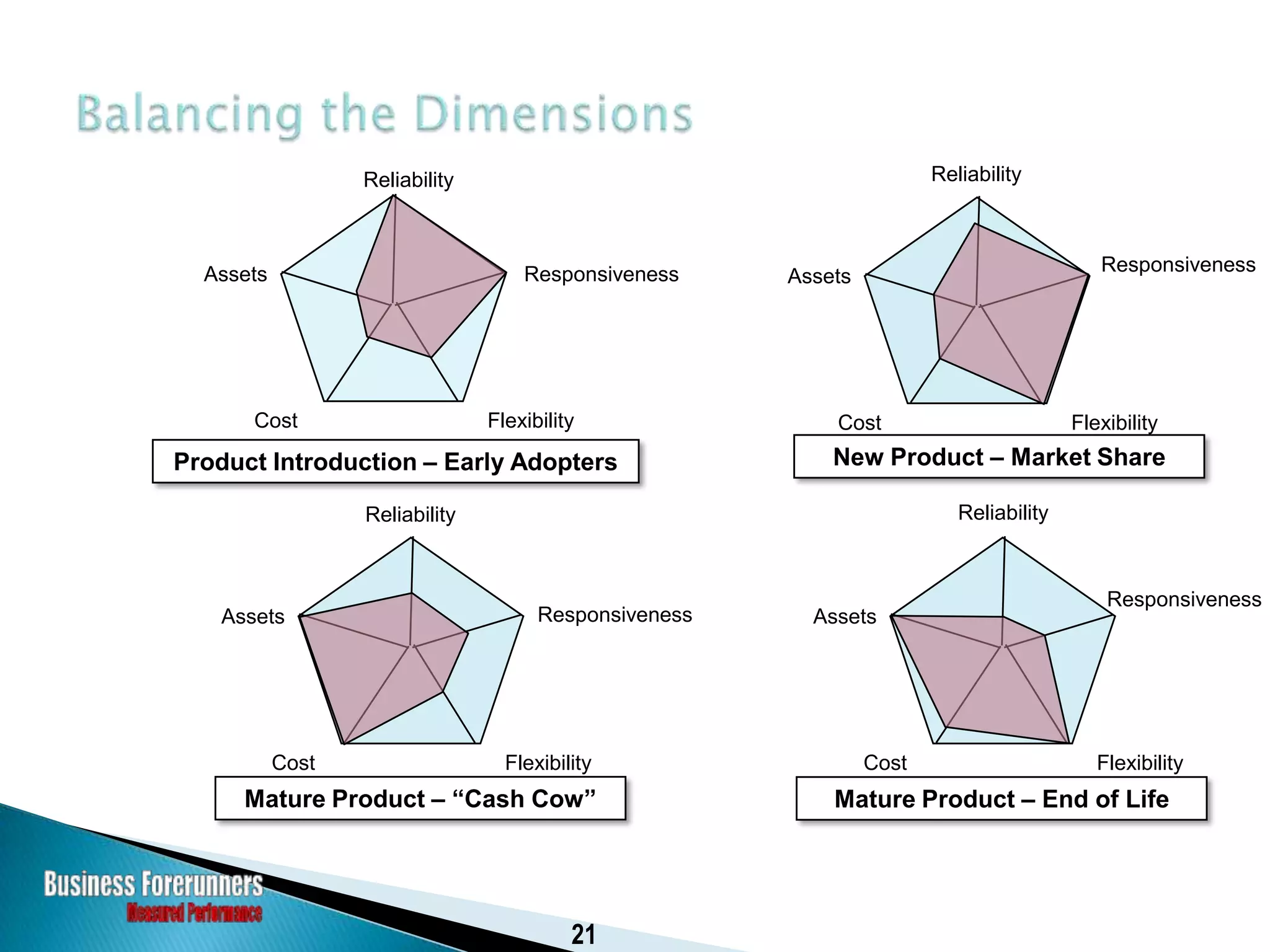

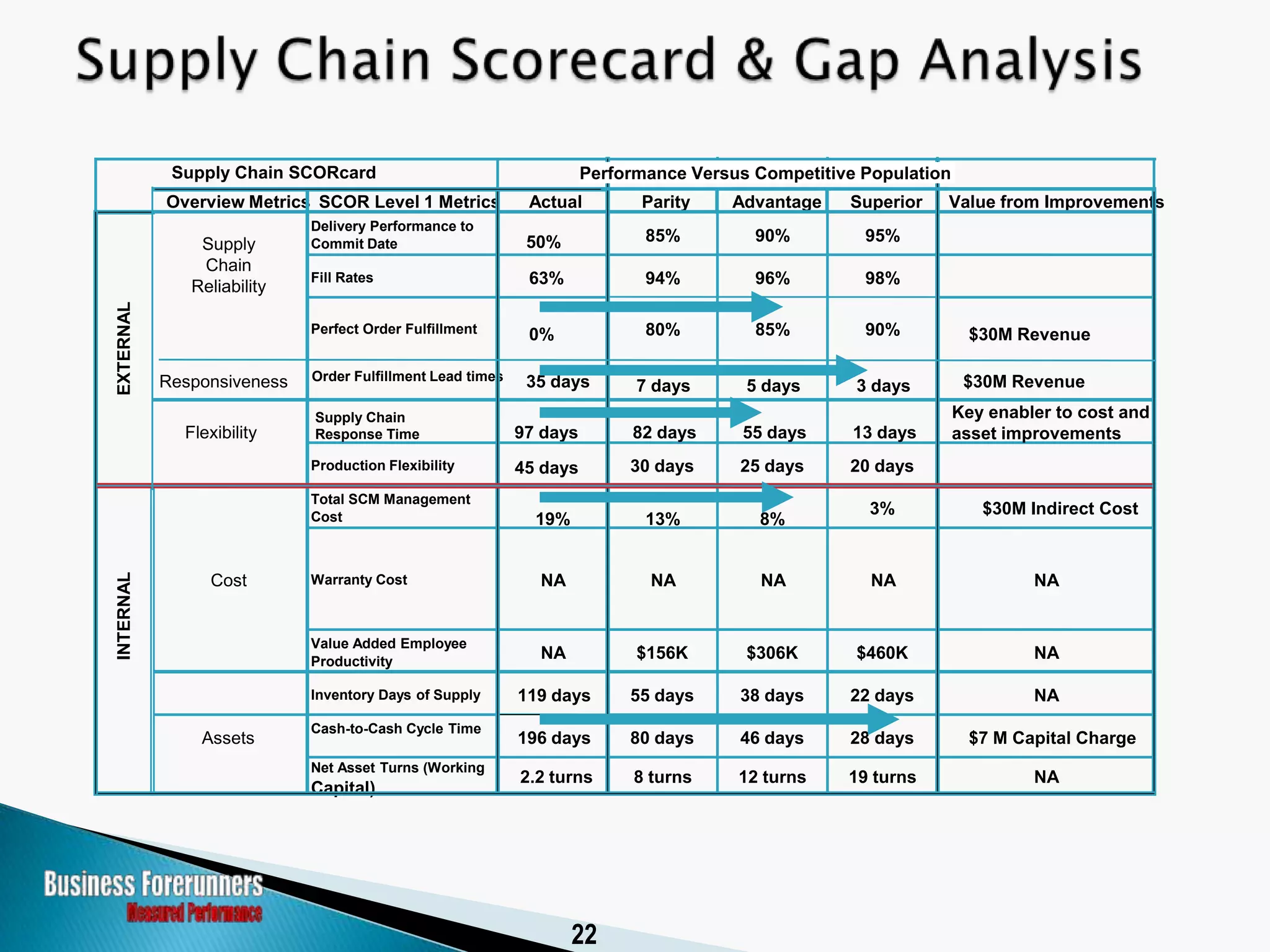

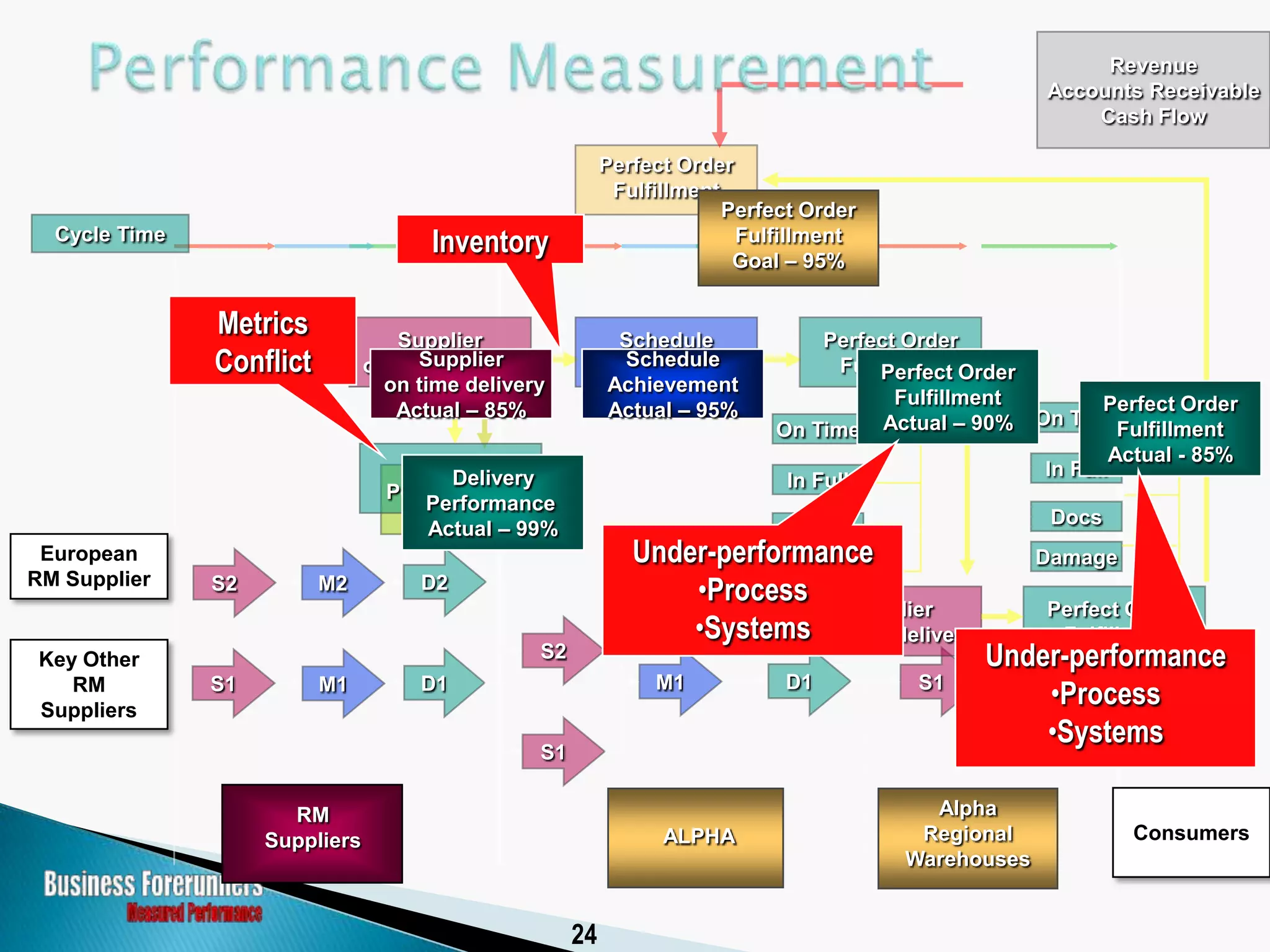

Utilization of specific metrics like Order Fulfillment and Supply Chain Reliability to measure performance against competitive benchmarks.

Utilization of specific metrics like Order Fulfillment and Supply Chain Reliability to measure performance against competitive benchmarks.

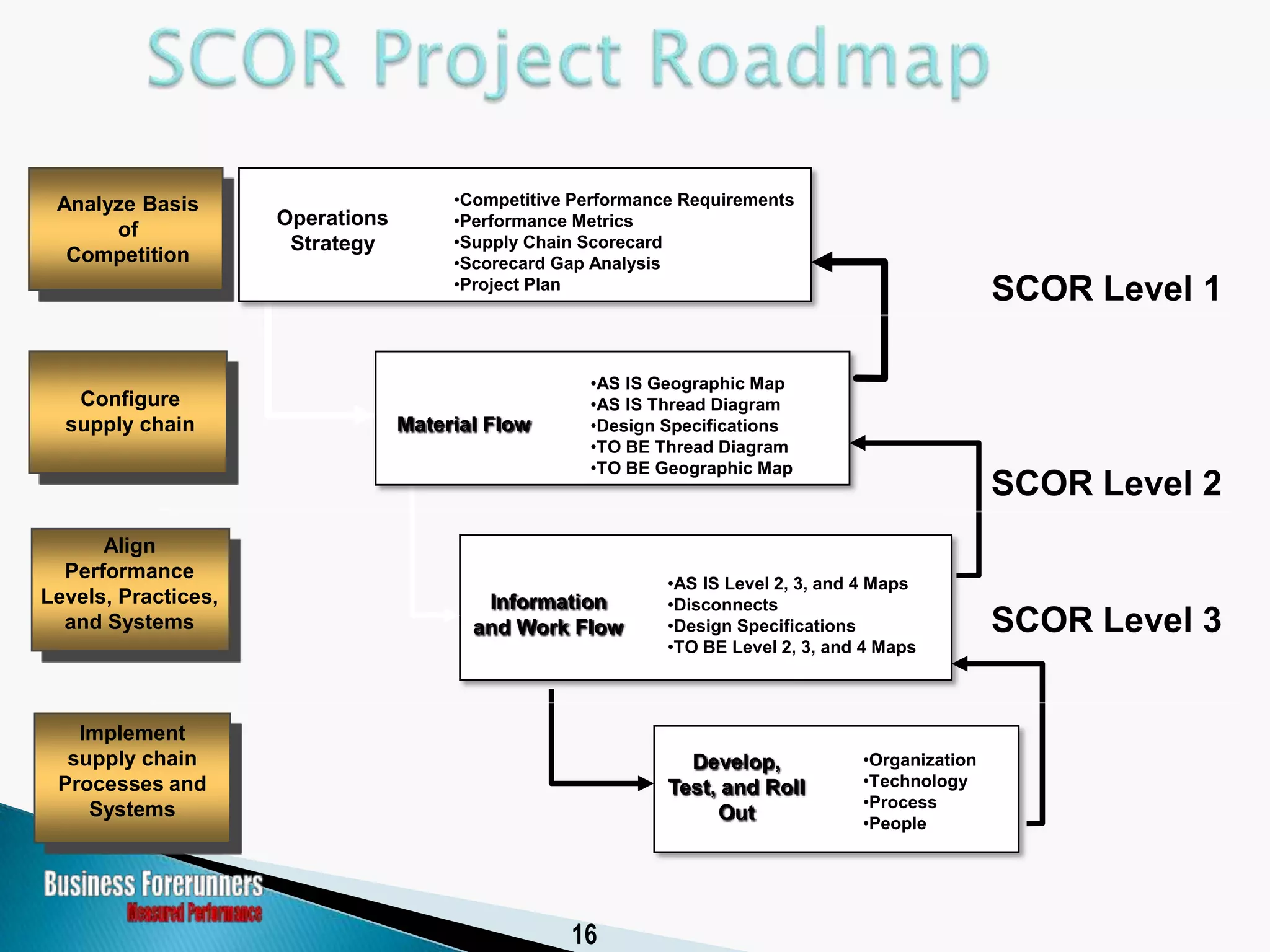

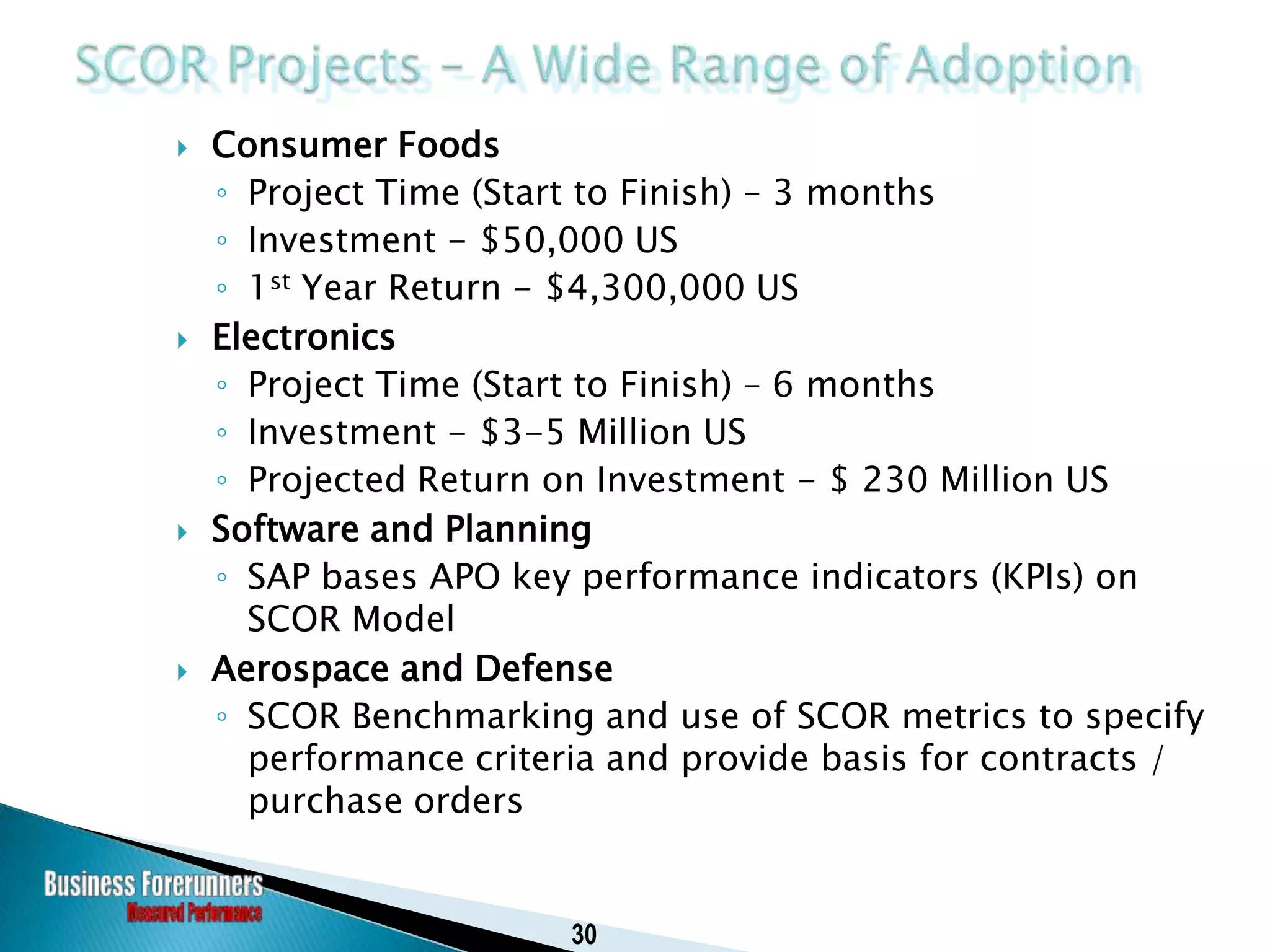

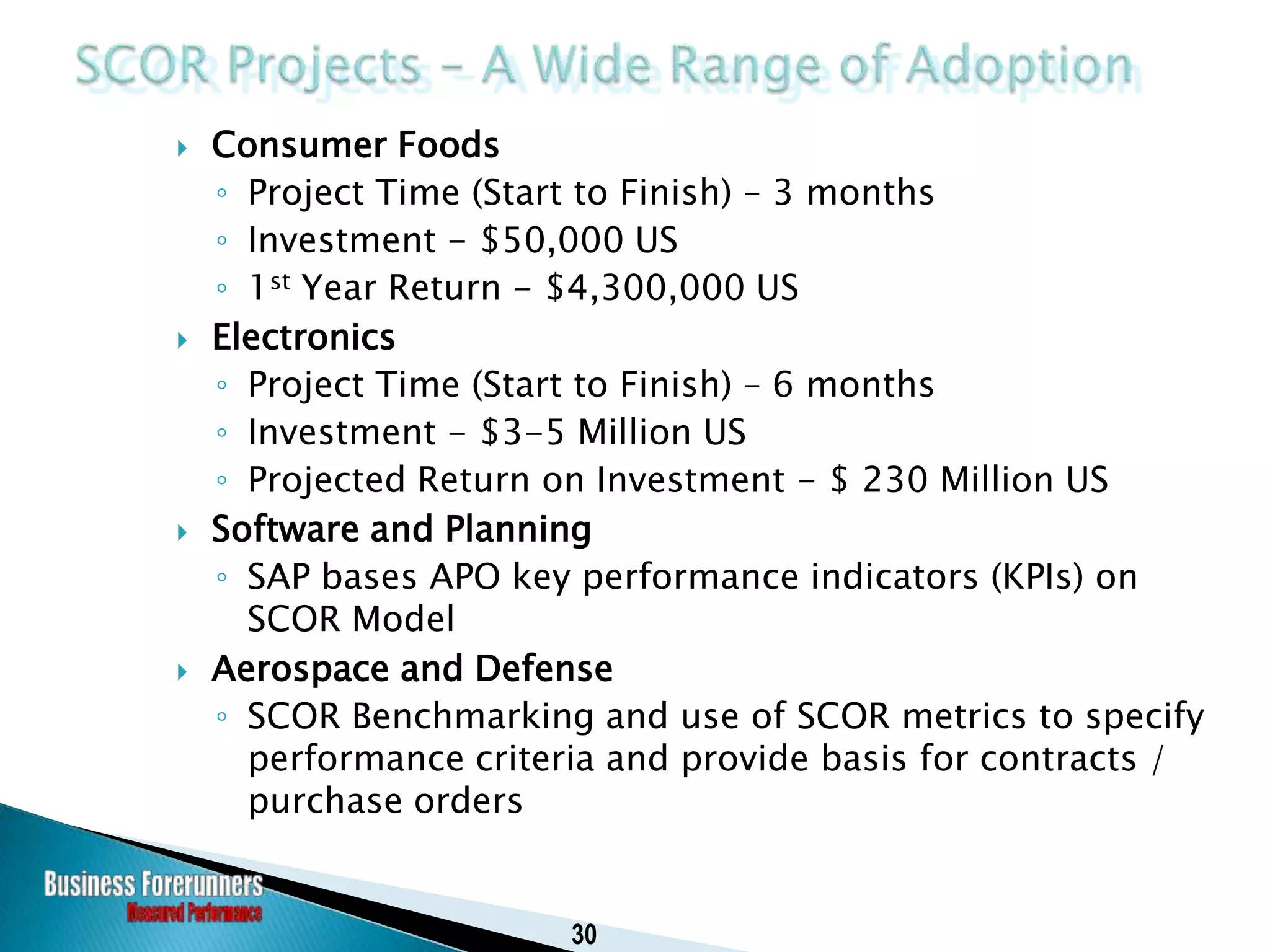

Implementation strategies for SCOR model in various sectors including academia and consulting with an emphasis on curriculum and performance evaluation.

Utilization of specific metrics like Order Fulfillment and Supply Chain Reliability to measure performance against competitive benchmarks.

Implementation strategies for SCOR model in various sectors including academia and consulting with an emphasis on curriculum and performance evaluation.