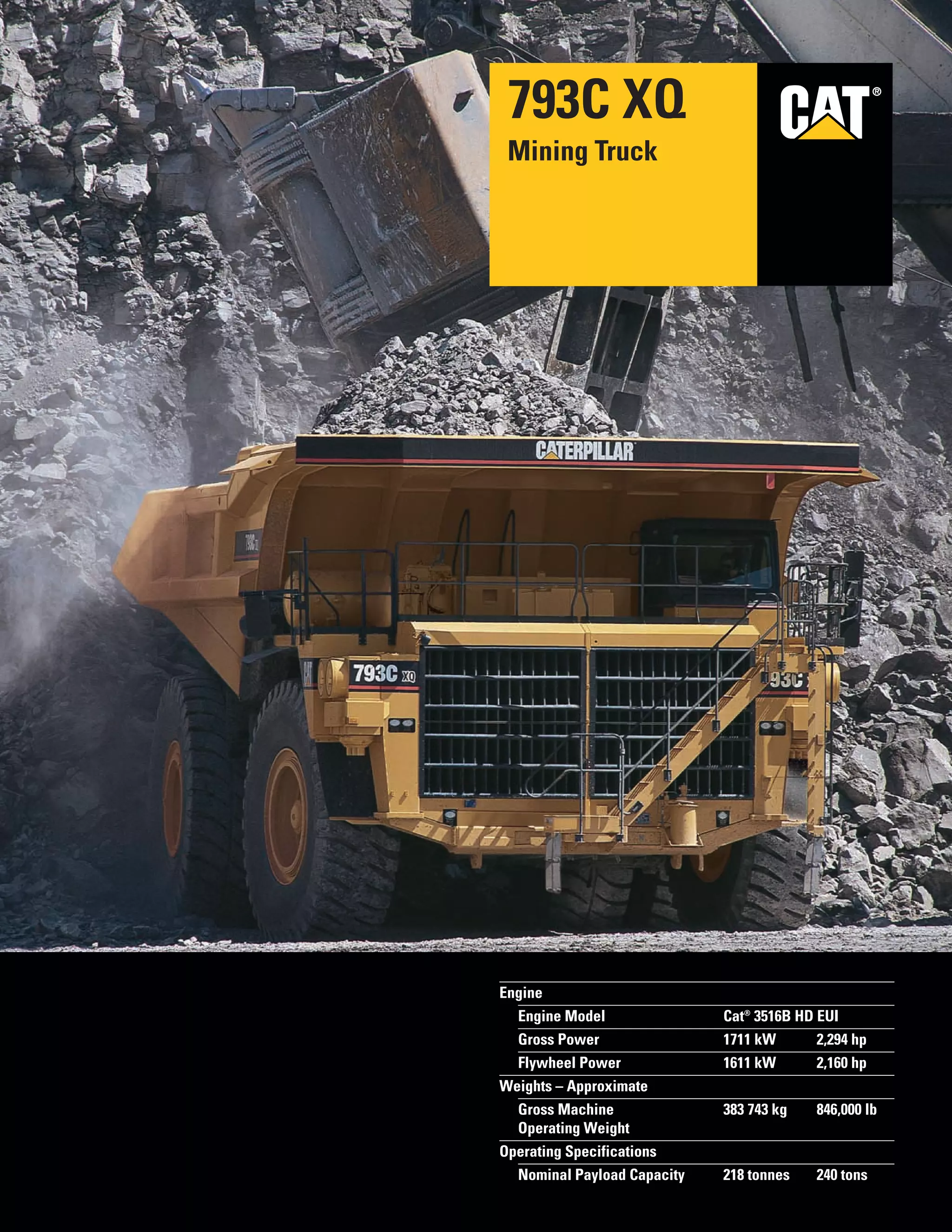

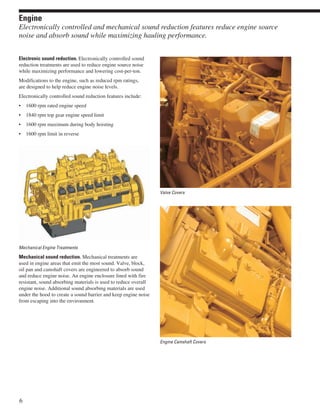

The document describes the Caterpillar 793C XQ mining truck. It has been designed with extensive sound reduction features to minimize environmental noise in mining operations located near residential areas. Some key features include an electronically controlled engine limited to 1600 rpm, hydraulically driven dual fan cooling system, high efficiency muffler, and sound dampening materials throughout. The 793C XQ is estimated to produce a static sound power level of approximately 110 dB(A) compared to 121 dB(A) for the standard 793C truck. The extra quiet design allows more trucks to operate without exceeding noise limits.