Fighter aircraft conceptual design and V-n diagram analysis

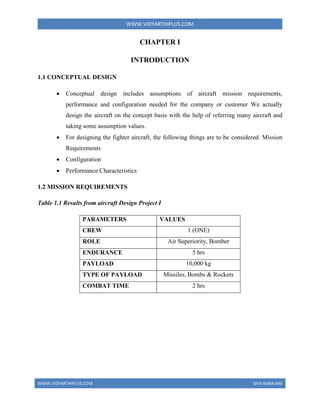

- 1. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI CHAPTER I INTRODUCTION 1.1 CONCEPTUAL DESIGN Conceptual design includes assumptions of aircraft mission requirements, performance and configuration needed for the company or customer We actually design the aircraft on the concept basis with the help of referring many aircraft and taking some assumption values. For designing the fighter aircraft, the following things are to be considered. Mission Requirements Configuration Performance Characteristics 1.2 MISSION REQUIREMENTS Table 1.1 Results from aircraft Design Project I PARAMETERS VALUES CREW 1 (ONE) ROLE Air Superiority, Bomber ENDURANCE 5 hrs PAYLOAD 10,000 kg TYPE OF PAYLOAD Missiles, Bombs & Rockets COMBAT TIME 2 hrs

- 2. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI 1.3 CONFIGURATION Table 1.2 Results from aircraft Design Project I PARAMETERS SHAPES FUSELAGE Conventional WING Delta Wing, Mid Wing TAIL V- Tail LANDING GEAR Conventional ENGINE Turbo Fan Engine 1.4 PERFORMANCE CHARACTERISTICS Table 1.3 Results from aircraft Design Project I PARAMETERS VALUES MAXIMUM SPEED 2.1 mach CRUISE SPEED 2300 ft/s SERVICE CEILING 60000 ft RATE OF CLIMB 1000 ft/s

- 3. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI 1.5 SPECIFICATION OF DESIGNED AIRCRAFT The calculated values of our desired aircrafts as shown in table 1.1 Table 1.4 Results from aircraft Design Project I DESIGN POINT PARAMETERS VALUES Weight Overall Weight 65037.79 lbs Empty Weight 32518.95 lbs Fuel Weight 22322.92 lbs Payload Weight 10000 lbs Performance Cruise speed 1916.67 ft/s Maximum Speed 2300 ft/s Range 12000000 ft Thrust Required 84549.127 lbs Wing Area 416.79ft Span 37.45 ft Root Chord 16.67 ft Tip Chord 1.67 ft Aerofoil Joukowsky 15.6 % and Joukowsky 18.2 %

- 4. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI CHAPTER II V-n DIAGRAM 2.1INTRODUCTION Flight regime of any aircraft includes all permissible combinations of speeds, altitudes, weights, centers of gravity, and configurations. This regime is shaped by aerodynamics, propulsion, structure, and dynamics of aircraft. The borders of this flight regime are called flight envelope or maneuvering envelope. The safety of human onboard is guaranteed by aircraft designer and manufacturer. Pilots are always trained and warned through flight instruction manual not to fly out of flight envelope, since the aircraft is not stable, or not controllable or not structurally strong enough outside the boundaries of flight envelope. A mishap or crash is expected, if an aircraft is flown outside flight envelope. The flight envelope has various types; each of which is usually the allowable variations of one flight parameter versus another parameter. These envelopes are calculated and plotted by flight mechanics engineers and employed by pilots and flight crews. For instance, the load masters of a cargo aircraft must pay extra caution to the center of gravity location whenever they distribute various loads on the aircraft. There are several crashes and mishaps that safety board's report indicated that load master are responsible, since they deployed more loads than allowed, or misplaced the load before take-off. Nose heavy and tail heavy are two flight concepts that pilots are familiar and experienced with, and are trained to deal with them safely. Pilots are using several graphs and charts in their flight operations. Four important envelopes are as follows: 1. Diagram of variations of aircraft lift coefficient versus Mach number (CL – M) 2. Diagram of variations of airspeed versus altitude (V – h) 3. Diagram of variations of center of gravity versus aircraft weight (Xcg – W) 4. Diagram of variations of airspeed versus load factor (V – n) One of the most important diagrams is referred to as flight envelope. This envelope demonstrates the variations of airspeed versus load factor (V – n). In another word, it depicts the aircraft limit load factor as a function of airspeed. One of the primary reasons that this diagram is highly important is that, the maximum load factor; that is extracted from this graph; is a reference number in aircraft structural design.

- 5. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI If the maximum load factor is under-calculated, the aircraft cannot withstand flight load safely. For this reason, it is recommended to structural engineers to recalculate the V-n diagram on their own as a safety factor. In this section, details of the technique to plot the V- n diagram in introduced. Figure 9.10 shows a typical V-n diagram for a GA aircraft. This diagram is, in fact, a combination of two diagrams: 1. The V-n diagram without consideration of gust, 2. The V-n diagram on the effect of gust. In this section, we first have another look on the load factor and then present new concepts on load factor. Then the phenomena of gust and gust load are described. At the end of this section, the technique to plot V – n diagram is completely described. This description is supported by a solved example. 2.2 LOAD FACTOR The load to the aircraft on the ground is naturally produced by the gravity (i.e. 1 times g). But, there are other sources of load to the aircraft during flight; one of which is the acceleration load. This load is usually normalized through load factor (i.e. "n" times g). In another word, aircraft load is expressed as a multiple of the standard acceleration due to gravity (g = 9.81 m/sec2 = 32.17 ft/sec2). n = 𝑳 𝑾 Fig: 2.1 A Typical V-n Diagram for a GA Aircraft.

- 6. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI In some instances of flight such as turn and pull-up, the aircraft must generate a lift force such that it is more than weight. For instance, load factor in a pull-up from equation 9.86 can be re-written as: n = 𝒂 𝒈 + 𝟏 Where "a" is the centrifugal acceleration (V2/R). As this acceleration increases; i.e. airspeed increases or radius of turn decreases; the load factor will increase too. For other flight operations, similar expressions can be drawn. In some instances; especially for missiles; this load factor may get as high as 30. As the table 2.2 illustrates, a low load factor fighter may end up getting targeted by a high load factor missile. Table 2.1. Load factor for various types of aircraft: S.NO AIRCRAFT TYPE MAXIMUM POSITIVE LOAD FACTOR MAXIMUM NEGATIVE LOAD FACTOR 1 Normal (non-acrobatic) 2.5 – 3.8 -1 to -1.5 2 Utility (semi-acrobatic) 4.4 -1.8 3 Acrobatic 6 -3 4 Homebuilt 5 -2 5 Transport 3 – 4 -1 to -2 6 Highly maneuverable 6.5 – 12 -3 to -6 7 Bomber 2 – 4 -1 to -2

- 7. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI 2.3 V – N DIAGRAM WITHOUT GUST EFFECT As figure 9.10 shows, V-n diagram is an envelope that indicates the limits of load factor and speed for a safe flight. It is usually composed of two curves plus few lines. The two curves on the left hand side represent the aerodynamic limit on load factor imposed by stall (CLmax). The expression for the top curve is extracted from stall equation in turn (i.e. equation 9.10) as follows: 𝑽𝒔𝒕 = √ 𝟐𝒏𝒎𝒈 𝝆𝑺𝑪𝑳𝑴𝒂𝒙 Where the value of 𝑛𝑚𝑎𝑥 corresponds to that at point A in figure 9.10. This speed sometimes is referred to as maneuvering speed (VA), and is summarized as: 𝑽𝑨= √𝒏𝑴𝒂𝒙𝑽𝒔 The point A is then called the maneuver point. At this point, both lift coefficient and load factor are simultaneously at their highest possible values. The corner velocity is an interesting velocity for fighter pilots. At speeds less than V*, it is not possible to structurally damage the aircraft due to generation of load factor less than nmax. However, the bank angle is not high enough for a tight turn. In contrast, at speeds greater than V*, maneuverability decreases, since the speed is too high. Thus fighter pilots are recommended to select this speed for much of their maneuvering missions. For majority of the cases; and according to the discussions presented in sections 2.3 and 2.4; this point simultaneously corresponds to the tightest turn and fastest turn of an aircraft. Typical corner velocities of current advanced fighters are around 300 to 350 KEAS. The right hand side of the V – n diagram, vertical line BC, is a high speed limit. This speed is usually selected to be the dive speed. At flight speeds higher than this limit, the dynamic pressure (q) is higher than the design value for the aircraft. At the speed above dive speed, destructive phenomena such as flutter, aileron reversal, and wing divergence, may happen that leads structural damage, or failure, or disintegration. This speed limit (dive speed) is a red-line speed for the aircraft; it should never be exceeded. The dive speed (VD) is usually higher than aircraft maximum speed (Vmax), and the aircraft maximum speed (Vmax) is often higher than aircraft cruising speed (VC). From FAR Part 23, the following regulations have been directly copied:

- 8. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI 𝑉𝐷 ≥ 1.4𝑉𝐶(Normal aircraft) 𝑉𝐷 ≥ 1.5𝑉𝐶(Utility aircraft) 𝑉𝐷 ≥ 1.55𝑉𝐶(Acrobatic aircraft) For High Maneuvering Aircraft: 𝒏𝒑𝒐𝒔 = 𝟔 𝒕𝒐 𝟏𝟐 𝒏𝒏𝒆𝒈 = -3 to -6 Dive Speed: 𝑽𝑫 = 𝟏. 𝟓𝟓 𝑽𝑪 = 𝟐𝟗𝟕𝟎. 𝟖𝟑𝟖𝟓 𝒇𝒕 𝒔 𝑽𝒔 = 𝟐𝟎𝟐. 𝟓𝟑𝟔 𝒇𝒕 𝒔 Top Curve: 𝒏 = 𝑳 𝑾 = 𝟎. 𝟓 𝝆𝑽𝟐 𝑺𝑪𝑳𝒎𝒂𝒙 𝑾 n = 2.437253369x𝟏𝟎−𝟓 𝑽𝟐 For point B n = 6 𝑽 ∗ = 𝟕𝟎𝟏. 𝟔𝟖𝟏𝟗𝟏𝟓𝟏 𝒇𝒕 𝒔 B (6,701.681915) BOTTOM CURVE : V = √ 𝟐𝑾𝑮 𝝆𝑪𝑵𝒎𝒂𝒙 𝑺 𝑪𝑵 = 𝟏. 𝟏 𝑪𝑳𝒎𝒂𝒙 𝑽𝒔 = √ 𝟐𝒏𝒏𝒆𝒈𝑾𝑮 𝝆𝑪𝑵𝒎𝒂𝒙𝑺 𝑪𝑵𝒎𝒂𝒙 = 𝟑. 𝟓𝟐

- 9. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI 𝒏𝒏𝒆𝒈 ≥ 𝟎. 𝟒 𝒏𝒑𝒐𝒔 for normal and utility aircraft. 𝒏𝒏𝒆𝒈 ≥ 𝟎. 𝟓 𝒏𝒑𝒐𝒔 for acrobatic category aircraft. 𝒏𝒏𝒆𝒈 = −𝟎. 𝟓x6 = -3 𝑽𝒔 = 𝟒𝟕𝟑. 𝟎𝟕𝟑𝟖𝟓𝟎𝟔 𝒇𝒕 𝒔 Thus K(-3,473.0738506) -n = −𝑳 𝑾 = 𝟎.𝟓𝝆𝑽𝟐𝑺(−𝑪𝑳𝒎𝒂𝒙) 𝑾 -n = 2.437253369x𝟏𝟎−𝟓 x𝑽𝟐 V = 496.1640404 𝒇𝒕 𝒔 J(-3,496.1640404) Co-ordinates; O (0,0) A (1,202.536) B (6,701.68) F (6,2970.838) G (-3,2970.838) K (-3,473.073) J (--3,496.164)

- 10. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Figure 2.2 V-n diagram for supersonic fighter

- 11. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI CHAPTER III GUST LOAD DIAGRAM 3.1 DESCRIPTION The atmosphere is a dynamic system that encompasses variety of phenomena. Some of these phenomena include turbulence, gust, wind shear, jet stream, mountain wave and thermal flow. In this section, we concentrate on only gust, since it is not predictable, but is happening during most high altitude flights. When an aircraft experiences a gust, the immediate effect is an increase or decrease in the angle of attack. Figure 9.11 shows the geometry of an upward gust. When an upward gust with a velocity of Vg, hits under the nose of an aircraft with the velocity of V, the instantaneous change (increase) in the angle of attack (∆𝛼), is determined through: There are various models for gust prepared by various researchers. Here, we refer to FAR for the gust modeling. According to FAR 232, a GA aircraft must be able to withstand gust with a velocity of 50 ft/sec from sea level up to 20,000 ft. From 20,000 ft to 50,000 ft the gust velocity decreases linearly to 25 ft/sec. an aircraft must safely fly at maneuver speed when encounters a gust with the velocity of 66 ft/sec. The aircraft must carry gust load during dive speed, if the gust speed is 25 ft/sec. These data are employed to plot the gust V-n diagram. FAR recommends using the following equation for modeling the "gust induced load factor" as a function of gust speed: n = 1+ 𝑲𝒈𝑽𝒈𝑬𝑽𝑬𝒂𝝆𝑺 𝟐𝑾 Where kg is a coefficient that is determined by the following expression: 𝑲𝒈 = 𝟎. 𝟖𝟖𝝁𝒈 𝟓. 𝟑𝟑 + 𝝁𝒈 And 𝜇𝑔 is called the aircraft mass ratio and is calculated through: 𝝁𝒈 = 𝟐𝒎 𝝆𝑪𝒂𝑺

- 12. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI where, m=aircraft mass V_GE=aircraft gust equivalent speed V_E=aircraft equivalent speed C ̅=mean aerodynamic chord a = is wing lift curve slope during gust encounter. The gust V-n diagram is plotted using lines based on the equation 9.103 for various speeds (i.e. 25, 50, and 66 ft/sec). Then the intersections between these three lines respectively with maneuver speed (VA), cruising speed (VC), and dive speed (VD) must be marked. The gust V-n diagram is plotted for several altitudes to determine the highest load factor. Figure 3.1. A typical gust V-n diagram

- 13. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI 𝑎 = 2𝜋 1 + 2 𝐴𝑅 For Supersonic Fighter Aircraft: 𝑎 = 30956079638 𝜇𝑔 = 2𝑚 𝜌𝐶̅𝑎𝑆 𝜇𝑔 = 350.5550622 𝐾𝑔 = 0.88𝜇𝑔 5.3 + 𝜇𝑔 𝐾𝑔 = 0.86689354 𝐴𝑡 𝑔𝑢𝑠𝑡 𝑣𝑒𝑙𝑜𝑐𝑖𝑡𝑦 50 𝑓𝑡 𝑠 𝑛 = 1 ± 1.306025022 ∗ 10−3 ∗ 𝑉 𝐴𝑡 𝑔𝑢𝑠𝑡 𝑣𝑒𝑙𝑜𝑐𝑖𝑡𝑦 25 𝑓𝑡 𝑠 𝑛 = 1 ± 6.530125111 ∗ 10−4 ∗ 𝑉 𝐴𝑡 𝑔𝑢𝑠𝑡 𝑣𝑒𝑙𝑜𝑐𝑖𝑡𝑦 66 𝑓𝑡 𝑠 𝑛 = 1 ± 1.723953029 ∗ 10−3 ∗ 𝑉

- 14. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Figure 3.2A typical gust V-n diagram

- 15. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI CHAPTER IV COMBINED GUST AND V-N DIAGRAM 4.1 CRITICAL LOADING PERFORANCE: Section 2.1 technique to plot the basic V-n diagram is introduced. In Section 9.6.3, the technique to plot the gust V-n diagram is presented. This section is about combination technique of basic V-n diagram with gust V-n diagram. Since the gust in the atmosphere is a true story, aircraft designers must predict the gust load and add them to the aircraft regular load (maneuver load), to have a safe and strong structure in flight operations. The maximum combined load factor is usually higher than separate load factor in each diagram. A typical combined V-n diagram for an aircraft is illustrated in figure 9.13. The V-n diagram is unique for each aircraft, and pilots and flight crew are required to fly and operate inside this flight envelope. The following example demonstrates details of the technique to plot the combined V-n diagram for an acrobatic aircraft. Figure 4.1A typical combined V-n diagram for an aircraft

- 16. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Figure 4.2 combined V-n diagram for supersonic aircraft

- 17. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI CHAPTER V SCHRENK’S CURVE 5.1 WING DESCRIPTION Lift varies along the wing span due to the variation in chord length, angle of attack and sweep along the span. Schrenk’s curve defines this lift distribution over the wing span of an aircraft, also called simply as Lift Distribution Curve. Schrenk’s Curve is given by 𝒀 = 𝒀𝟏 + 𝒀𝟐 𝟐 Where y1 is Linear Variation of lift along semi wing span also named as L1 y2 is Elliptic Lift Distribution along the wing span also named as L2 5.2 LINEAR LIFT DISTRIBUTION: 𝐿𝑖𝑓𝑡 𝑎𝑡 𝑟𝑜𝑜𝑡 𝐿𝑅𝑜𝑜𝑡 = 𝝆𝑽𝟐𝑪𝑳𝒄𝒓𝒐𝒐𝒕 𝟐 = 𝟏.𝟐𝟐𝟓 𝑿 𝟔𝟏.𝟕𝟑𝟐𝟗𝟕𝟐𝟖𝟐 𝑿 𝟑.𝟐 𝑿 𝟓.𝟎𝟖𝟏𝟎𝟏𝟔 𝟐 𝑳𝑹𝒐𝒐𝒕 = 𝟑𝟕𝟗𝟓𝟐. 𝟒𝟔𝟓𝟑𝟐 (𝑵 𝒎 ⁄ ) Lift at tip 𝐿𝑇𝑖𝑝 = 𝝆𝑽𝟐𝑪𝑳𝒄𝒕𝒊𝒑 𝟐 = 𝟏.𝟐𝟐𝟓 𝑿 𝟔𝟏.𝟕𝟑𝟐𝟗𝟕𝟐𝟖𝟐 𝑿 𝟑.𝟐 𝑿 𝟎.𝟓𝟎𝟗𝟎 𝟐 𝑳𝑻𝒊𝒑 = 𝟑𝟖𝟎𝟏. 𝟗𝟓𝟕𝟎𝟗𝟖 (𝑵 𝒎 ⁄ )

- 18. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI By representing this lift at sections of root and tip we can get the equation for the wing. Figure 5.1: Linear lift distribution Equation of linear lift distribution for starboard wing 𝑌1 = −𝑚𝑥 + 𝑐 𝑌1 = −(5983.653)𝑥 + 37952.46532 Equation of linear lift distribution for port wing we have to replace x by –x in general, 𝑌1 = (5983.653)𝑥 + 37952.46532 Figure 5.2: Linear Variation of lift along wing semi span 0 5000 10000 15000 20000 25000 30000 35000 40000 0 1 2 3 4 5 6 Linear lift (N/m) Wing Semi Span (m) Linear Variation of Lift along Wing Semi Span Linear Lift distribution Curve

- 19. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI 5.3 ELLIPTIC LIFT DISTRIBUTION: Twice the area under the curve or line will give the lift which will be required to overcome weight Considering an elliptic lift distribution we get 𝑳 𝟐 = 𝑾 𝟐 = 𝝅𝒂𝒃𝟏 𝟒 A = 𝝅𝒂𝒃𝟏 𝟒 Where b1- is Actual lift at root And a- is wing semi span Lift at tip 𝒃𝟏 = 𝟒𝑾 𝟐𝝅𝒂 𝒃𝟏 = (𝟒𝑿𝟐𝟗𝟓𝟎𝟎.𝟔𝟒𝟕𝟐𝟔) (𝟐𝝅 𝑿 𝟓.𝟕𝟎𝟕𝟑) = 3290.6444 Figure 5.3: Elliptic lift distribution EQUATION OF ELLIPTIC LIFT DISTRIBUTION: 𝒀𝟐 = 𝟐𝒃𝟏 𝒂 √(𝒂𝟐 − 𝒙𝟐) 𝒀𝟐 = 𝟏𝟏𝟓𝟑. 𝟏𝟑𝟓𝟖𝟐√(𝟑𝟐. 𝟓𝟕𝟑𝟐𝟕 − 𝒙𝟐)

- 20. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Figure 5.4: Elliptic lift distribution 5.4 CONSTRUCTION OF SCHRENK’S CURVE: Schrenk’s Curve is given by 𝒀 = 𝒀𝟏 + 𝒀𝟐 𝟐 Y= −(𝟓𝟗𝟖𝟑.𝟔𝟓𝟑)𝒙+𝟑𝟕𝟗𝟓𝟐.𝟒𝟔𝟓𝟑𝟐+𝟏𝟏𝟓𝟑.𝟏𝟑𝟓𝟖𝟐√(𝟑𝟐.𝟓𝟕𝟑𝟐𝟕−𝒙𝟐) 𝟐 0 1000 2000 3000 4000 5000 6000 7000 0 1 2 3 4 5 6 Elliptical Lift Distribution (N/m) Wing Semi Span (m) Elliptical Variation of Lift along Wing Semi Span Elliptical lift Distribution curve

- 21. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Table 5.1: Lift distribution table along semi span X 𝒀𝟏 𝒀𝟐 Y 0 37952.47 6581.289 22266.88 0.285365 36244.94 6573.057 21409 0.57073 34537.42 6548.3 20542.86 0.856095 32829.89 6506.828 19668.36 1.14146 31122.36 6448.32 18785.34 1.426825 29414.84 6372.306 17893.57 1.71219 27707.31 6278.15 16992.73 1.997555 25999.79 6165.02 16082.4 2.28292 24292.26 6031.851 15162.06 2.568285 22584.74 5877.279 14231.01 2.85365 20877.21 5699.563 13288.39 3.139015 19169.69 5496.46 12333.07 3.42438 17462.16 5265.031 11363.6 3.709745 15754.64 5001.347 10377.99 3.99511 14047.11 4699.98 9373.547 4.280475 12339.59 4353.113 8346.351 4.56584 10632.06 3948.773 7290.418 4.851205 8924.538 3466.909 6195.724 5.13657 7217.013 2868.717 5042.865 5.421935 5509.488 2055.007 3782.247 5.7073 3801.963 0 1900.981

- 22. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Figure 5.5 Load distribution on wing 0 5000 10000 15000 20000 25000 30000 35000 40000 0 1 2 3 4 5 6 lift Distribution (N/m) Wing Semi Span (m) Schrenk's Curve LINEAR CURVE ELLIPTICAL CURVE SCHRENK CURVE

- 23. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI CHAPTER VI LOAD ESTIMATION ON WING 6.1 DESCRIPTION: The solution methods which follow Euler’s beam bending theory (σ/y=M/I=E/R) use the bending moment values to determine the stresses developed at a particular section of the beam due to the combination of aerodynamic and structural loads in the transverse direction. Most engineering solution methods for structural mechanics problems (both exact and approximate methods) use the shear force and bending moment equations to determine the deflection and slope at a particular section of the beam. Therefore, these equations are to be obtained as analytical expressions in terms of span wise location. The bending moment produced here is about the longitudinal (x) axis. 6.2 LOADS ACTING ON WING: As both the wings are symmetric, let us consider the starboard wing at first. There are three primary loads acting on a wing structure in transverse direction which can cause considerable shear forces and bending moments on it. They are as follows: Lift force (given by Schrenk’s curve) Self-weight of the wing Weight of the power plant Weight of the fuel in the wing 6.3 SHEAR FORCE AND BENDING MOMENT DIAGRAMS DUE TO LOADS ALONG TRANSVERSE DIRECTION AT CRUISE CONDITION: Lift Force given by Schrenk’s Curve: 𝒀 = 𝒀𝟏 + 𝒀𝟐 𝟐 6.3.1 LINEAR LIFT DISTRIBUTION (TRAPEZIUM): 𝑌1 = −(5983.653)𝑥 + 37952.46532 6.3.2ELLIPTIC LIFT DISTRIBUTION (QUARTER ELLIPSE): 𝑌2 = 1153.13582√(32.57327 − 𝑥2)

- 24. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Figure 6.1: Lift distribution (linear) Figure 6.2: Lift distribution (Elliptic) 0 5000 10000 15000 20000 25000 30000 35000 40000 0 1 2 3 4 5 6 Linear lift (N/m) Wing Semi Span (m) Linear Variation of Lift along Wing Semi Span Linear Lift distribution Curve 0 1000 2000 3000 4000 5000 6000 7000 0 1 2 3 4 5 6 Elliptical Lift Distribution (N/m) Wing Semi Span (m) Elliptical Variation of Lift along Wing Semi Span Elliptical lift Distribution curve

- 25. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI 6.3.3 SELF-WEIGHT OF WING (𝒀𝟑): Self-weight of the wing, 𝑾𝑾𝒊𝒏𝒈 𝑾𝑻𝑶 = 𝟎. 𝟎𝟕𝟓𝟗 W(wing) = 0.0759 x 29500.64726 x 9.81 W(wing) = 21965.56244N W(Portwing)= - 10982.78122 N (Acting Downwards) W(Starboard)= - 10982.78122 N (Acting Downwards) Assuming parabolic weight distribution 𝒀𝟑 = 𝒌 (𝒙 − 𝒃 𝟐 ) 𝟐 Where, -10982.78122 = ∫ 𝒌 (𝒙 − 𝒃 𝟐 ) 𝟐 𝒅𝒙 𝟓.𝟕𝟎𝟕𝟑 𝟎 -10982.78122 = 𝒌(𝟓.𝟕𝟎𝟕𝟑)𝟑 𝟑 K = -177.23173 𝒀𝟑 = − 𝟏𝟕𝟕. 𝟐𝟑𝟏𝟕𝟑(𝒙 − 𝟓. 𝟕𝟎𝟕𝟑)𝟐

- 26. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Figure 6.3: Self weight of wing 6.3.4 POWER PLANT WEIGHT: There is no power plant located on wing. Power plant is mounted on Fuselage. So weight of the power plant is negligible. 6.3.5 FUEL WEIGHT: This design has fuel in the wing so we have to consider the weight of the fuel in one the wing. 𝑊(𝐹𝑢𝑒𝑙 𝑤𝑖𝑛𝑔) 2 = 10125.50716 2 (𝐾𝑔) 𝑊(𝐹𝑢𝑒𝑙 𝑤𝑖𝑛𝑔) = 49665.61261 𝑁 -7000 -6000 -5000 -4000 -3000 -2000 -1000 0 0 1 2 3 4 5 6 WEight of empty wing (N/m) Span wise location (m) Self Weight

- 27. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Fig 6.4 Shows slope of the Fuel Weight Again by using general formula for straight line y= mx + c we get, dy = 1.426825 x m Dy= (5210.148434-dy) Where, m = (5210.148434 – 1.426825m) 3.42438 Solving these equation, m = 1073.990572 𝑵 𝒎𝟐 𝒀𝒇 = 𝟏𝟎𝟕𝟑. 𝟗𝟗𝟎𝟓𝟕𝟐𝒙 − 𝟓𝟐𝟏𝟎. 𝟏𝟒𝟖𝟒𝟑𝟒

- 28. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Figure 6.5: Fuel Distribution Figure 6.6: Overall Load distribution -5000 -4500 -4000 -3500 -3000 -2500 -2000 -1500 -1000 -500 0 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 Load acting on wing (N/m) Span wise location (m) Fuel distribution -10000 -5000 0 5000 10000 15000 20000 25000 30000 35000 40000 45000 0 1 2 3 4 5 6 Load acting on wing (N/m) Span wise location (m) Load distribution linear elliptical self weight of wing fuel weight

- 29. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Table 6.1: Loads simplified as point loads Curve / component Area enclosed / structural weight (N) Centroid (from wing root) y1/2 119152.5073 3.631640234 m y2/2 14750.32319 2.422253351 m Wing 10982.78122 1.426825 m Fuel 49665.61261 1.71219 m 6.4 REACTION FORCE AND BENDING MOMENT CALCULATIONS: The wing is fixed at one end and free at other end. Fig 6.7 Shows Fighter Aircraft Wing as Cantilever beam Σ v, Then, VA-119152.5073-14750.32319+10982.78122+49665.61261=0 VA= 73254.43666 N ΣM , Then, MA - (119152.5073x3.631640234) - (14750.32319x2.422253351) + (10982.78122x1.426825) + (49665.61261x1.71219) = 0 MA = 367740.5881N/m

- 30. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Now we know VA and MA, using this we can find out shear force and Bending moment. 6.5 SHEAR FORCE: 𝑆𝐹𝐵𝐶 = ∫ ( 𝑦1 + 𝑦2 2 − 𝑦3) 𝑑𝑥 − 𝑉𝐴 𝑆𝐹𝐵𝐶 = ∫ ( −(5983.653)𝑥 + 37952.46532 + 1153.13582√(32.57327 − 𝑥2) 2 + 177.23173(𝑥 − 5.7073)2 ) 𝑑𝑥 − 73254.43666 𝑺𝑭𝑩𝑪 = −𝟏𝟒𝟗𝟓. 𝟗𝟏𝟑𝟐𝟓x(𝒙𝟐 ) + 𝟏𝟖𝟗𝟕𝟔. 𝟐𝟑𝟐𝟔𝟔𝒙 + 𝟓𝟕𝟔. 𝟓𝟔𝟕𝟗𝟏 [𝒙√(𝟑𝟐. 𝟓𝟕𝟑𝟐𝟕 − 𝒙𝟐) + 𝟑𝟐. 𝟓𝟕𝟑𝟐𝟕𝒔𝒊𝒏−𝟏 ( 𝒙 𝟓.𝟕𝟎𝟕𝟑 )] + 𝟏𝟕𝟕. 𝟐𝟑𝟏𝟕𝟑 [ 𝒙𝟑 𝟑 − 𝟓. 𝟕𝟎𝟕𝟑𝒙𝟐 + 𝟑𝟐. 𝟓𝟕𝟑𝟐𝟕𝒙] − 𝟕𝟑𝟐𝟓𝟒. 𝟒𝟑𝟔𝟔𝟔 𝑆𝐹𝐶𝐷 = 𝑆𝐹𝐵𝐶 + ∫ 𝑦𝑓 𝑑𝑥 𝑆𝐹𝐶𝐷 = 𝑆𝐹𝐵𝐶 + ∫(1073.990572𝑥 − 5210.148434) 𝑑𝑥 𝑺𝑭𝑪𝑫 = 𝑺𝑭𝑩𝑪 + (𝟓𝟑𝟔. 𝟗𝟗𝟓𝟐𝟖𝟔𝒙𝟐 − 𝟓𝟐𝟏𝟎. 𝟏𝟒𝟖𝟒𝟑𝟒𝒙) 𝑺𝑭𝑫𝑬 = 𝑺𝑭𝑪𝑫 + (𝟓𝟑𝟔. 𝟗𝟗𝟓𝟐𝟖𝟔𝒙𝟐 − 𝟓𝟐𝟏𝟎. 𝟏𝟒𝟖𝟒𝟑𝟒𝒙) + 𝟒𝟗𝟔𝟔𝟓. 𝟔𝟏𝟐𝟔𝟏 By using the corresponding values of x in appropriate equations we get the plot of shear force. Fig 6.8 Shear Force Acting on wing

- 31. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI 6.6 BENDING MOMENT: 𝐵𝑀𝐵𝐶 = ∬ {( 𝑦1 + 𝑦2 2 − 𝑦3) 𝑑𝑥 − 𝑉𝐴} 𝑑𝑥2 + 𝑀𝐴 𝑩𝑴𝑩𝑪 = −𝟕𝟑𝟐𝟓𝟒. 𝟒𝟑𝟔𝟔𝒙 − 𝟏𝟗𝟗𝟒. 𝟓𝟓𝟏𝒙𝟑 + 𝟏𝟖𝟗𝟕𝟔. 𝟐𝟑𝟐𝟔𝟔𝒙𝟐 + 𝟐𝟖𝟖. 𝟐𝟖𝟑𝟗𝟓𝟓 [𝒙 (𝒙√(𝟑𝟐. 𝟓𝟕𝟑𝟐𝟕 − 𝒙𝟐)) + 𝟑𝟐. 𝟓𝟕𝟑𝟐𝟕 𝐬𝐢𝐧−𝟏 ( 𝒙 𝟓. 𝟕𝟎𝟕𝟑 )] + 𝟓𝟗. 𝟎𝟕(𝟑𝟐. 𝟓𝟕𝟑𝟐𝟕 − 𝒙𝟐)𝟏.𝟓 − 𝟏𝟕𝟕. 𝟐𝟑𝟏𝟕𝟑 [ 𝒙𝟒 𝟏𝟐 + 𝟏𝟔. 𝟐𝟖𝟔𝟔𝟑𝟓𝒙𝟐 − 𝟏. 𝟗𝟎𝟐𝟒𝟑𝟑𝒙𝟑 ] + 𝟑𝟔𝟕𝟕𝟒𝟎. 𝟓𝟖𝟖𝟏 𝐵𝑀𝐶𝐷 = ∬ {( 𝑦1 + 𝑦2 2 − 𝑦3) 𝑑𝑥 + 𝑦𝑓𝑢𝑒𝑙 − 𝑉𝐴} 𝑑𝑥2 + 𝑀𝐴 𝐵𝑀𝐶𝐷 = 𝐵𝑀𝐵𝐶 + ∬ 𝑦𝑓 𝑑𝑥2 𝑩𝑴𝑫𝑬 = 𝑩𝑴𝑪𝑫 + 𝟑𝟓𝟕. 𝟗𝟗𝟔𝟖𝟓𝟕𝟑𝒙𝟑 − 𝟐𝟔𝟎𝟓. 𝟎𝟕𝟒𝟐𝟏𝟕𝒙𝟐 𝑩𝑴𝑬𝑨 = 𝑩𝑴𝑫𝑬 − [𝟑𝟓𝟕. 𝟗𝟗𝟔𝟖𝟓𝟕𝟑𝒙𝟑 − 𝟐𝟔𝟎𝟓. 𝟎𝟕𝟒𝟐𝟏𝟕𝒙𝟐] + 𝟒𝟗𝟔𝟔𝟓. 𝟔𝟏𝟐𝟔𝟏𝒙 Fig 6.9 Shows Bending Moment Acting on Wing 0 500000 1000000 1500000 2000000 2500000 3000000 3500000 4000000 4500000 -8 -6 -4 -2 0 2 4 6 8 Bending moment (Nm) Location in wing m Bending moment diagram

- 32. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI CHAPTER VII C.G CALCULATION 7.1 DESCRIPTION: The weight of an airplane changes in the flight due to consumption of fuel and dropping off / release of armament or supplies. Further, the payload and the amount of fuel carried by the airplane may vary from flight to flight. These factors lead to change in the location of the Centre of gravity (c.g.) of the airplane. The shift in the c.g location affects the stability and controllability of the airplane. Hence, this chapter deals with the methods to obtain the weights of various components of the airplane and calculation of the c.g location under various operating conditions. The weight of entire airplane can be sub divided into empty weight and useful load. The empty weight can be further subdivided into weights of: (i) Structures group (ii) Propulsion group and (iii) Equipment group. The weights in the above three groups can be further subdivided as follows. 1) The structures group consists of the following components. wing horizontal tail /canard vertical tail fuselage landing gear (main and nose/tail wheel) arresting gear and catapult gear for ship based airplanes nacelle, engine pod and air intake.

- 33. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI 2) The propulsion group consists of the following components: engine as installed; reduction gear for turboprop engine propeller for piston and turboprop engines exhaust system cooling provisions engine controls starting system fuel system and tanks 3) The equipment group consists of the following items: flight controls auxiliary power unit (APU) instruments hydraulic, pneumatic, electrical, armament, air conditioning, anti-icing and other systems avionics furnishings in passenger airplanes photographic equipment in reconnaissance/patrol airplanes; weapon deployment equipment and armament loading and handling systems in military airplanes. The sum of the weights of structures, propulsion and equipment groups constitutes the total empty weight. 4) The useful load consists of : Crew Fuel (usable and trapped) Oil Payload ( passengers, cargo and baggage in transport airplane) Ammunition, expendable weapons and other items in military airplanes.

- 34. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Table 7.1 Component weights and c.g values of various aircrafts ITEM FIGHTERS TRANSPORTS AND BOMBERS GENERAL AVIATION MULTIPLIER APPROXIMATE C.G LOCATION WING 44 49 12 Sexposed m2 40 % MAC HORIZONTAL TAIL 20 27 10 Sexposed m2 40 % MAC VERTICAL TAIL 26 27 10 Sexposed m2 40 % MAC FUSELAGE 23 24 7 Swetted m2 40-50 % LENGTH LANDING GEAR 0.033 0.045 NAVY 0.043 0.057 TOGW - INSTALLED ENGINE 1.3 1.3 1.4 ENGINE WEIGHT - ALL ELSE EMPTY 0.17 0.17 0.10 TOGW 40-50 % LENGTH

- 35. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Table 7.2 Component weights and c.g values of the aircraft ITEM WEIGHT (W) (kg) C.G LOCATION (x) (m) W.x (kg.m) FUSELAGE GROUP 1812.7076 9.464 17155.46473 WING GROUP 1703.2395 1.35 2299.3733 INSTALLED ENGINE 1846 - 1846 HORIZONTAL TAIL 82.8766 0.4597 38.0983 VERTICAL TAIL 17.2121 0.27041 4.6543 ALL ELSE EMPTY 11086.4243 9.464 104921.9186 LANDING GEAR 973.5195 - 973.5195 ARMAMENTS ∑W = 17521.9796 ∑x = 21.19011 ∑W.x = 127239.0288 𝐶𝑂𝐺 = Σ𝑊𝐸𝐿𝐸𝑀𝐸𝑁𝑇. 𝐶𝑂𝐺𝐸𝐿𝐸𝑀𝐸𝑁𝑇 Σ𝑊𝐸𝐿𝐸𝑀𝐸𝑁𝑇 𝐶𝑂𝐺 = 127239.0288 17521.9796 𝐶𝑂𝐺 = 7.26168 𝑚

- 36. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Fig 7.1 Position of Center of Gravity

- 37. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI CHAPTER VIII DETAILED STRUCTURAL LAYOUTS 8.1 FUNCTION OF THE STRUCTURE: The primary functions of an aircraft‟s structure can be basically broken down into the following: To transmit and resist applied loads. To provide and maintain aerodynamic shape. To protect its crew, passenger, payload, systems, etc. For the vast majority of aircraft, this leads to use of a semi-monocoque design (i.e. a thin, stressed outer shell with additional stiffening members) for the wing, fuselage & empennage. These notes will discuss the structural layout possibilities for each of these main areas, i.e. wing, fuselage & empennage. 8.2 WING STRUCTURAL LAYOUT: 8.2.1 Specific Roles of Wing (Main wing) Structure: The specified structural roles of the wing (or main plane) are: To transmit: wing lift to the root via the main span wise beam Inertia loads from the power plants, undercarriage, etc., to the main beam. Aerodynamic loads generated on the aerofoil, control surfaces & flaps to the main beam. To react against: Landing loads at attachment points Loads from pylons/stores Wing drag and thrust loads To provide: Fuel tank age space Torsional rigidity to satisfy stiffness and aero-elastic requirements.

- 38. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI To fulfill these specific roles, a wing layout will conventionally compromise: Span wise members (known as spars or booms) Chord wise members(ribs) A covering skin Stringers Fig 8.1 Structural Components Of Wing 8.3 BASIC FUNCTIONS OF WING STRUCTURAL MEMBERS The structural functions of each of these types of members may be considered independently as: 8.3.1 SPARS Form the main span wise beam Transmit bending and torsional loads Produce a closed-cell structure to provide resistance to torsion, shear and tension loads.

- 39. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI In particular: Webs – resist shear and torsional loads and help to stabilize the skin. Flanges - resist the compressive loads caused by wing bending. 8.3.2SKIN: To form impermeable aerodynamics surface Transmit aerodynamic forces to ribs & stringers Resist shear torsion loads (with spar webs). React axial bending loads (with stringers). 8.3.3 STRINGERS: Increase skin panel buckling strength by dividing into smaller length sections. React axial bending loads 8.3.4 RIBS: Maintain the aerodynamic shape Act along with the skin to resist the distributed aerodynamic pressure loads Distribute concentrated loads into the structure & redistribute stress around any discontinuities Increase the column buckling strength of the stringers through end restraint Increase the skin panel buckling strength. 8.3.5 SPARS: These usually comprise thin aluminium alloy webs and flanges, sometimes with separate vertical stiffeners riveted on to the webs. Types of spars: In the case of a two or three spar box beam layout, the front spar should be located as far forward as possible to maximize the wing box size, though this is subject to there being: Adequate wing depth for reacting vertical shear loads. Adequate nose space for LE devices, de-icing equipment, etc. This generally results in the front spar being located at 12% to 18% of the chord length. For a single spar D-nose layout, the spar will usually located at the maximum thickness position of the aerofoil section (typically between 30% & 40% along the chord length).

- 40. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI For the standard box beam layout, the rear spar will be located as for aft as possible, once again to maximize the wing box size, but positioning will be limited by various space requirements for flaps, control surfaces, spoilers etc. This usually results in a location somewhere between about 55%and 70% of the chord length. If any intermediate spars are used, they would tend to be spaced uniformly unless there are specific pick-up point requirements. 8.4 FUSELAGE STRUCTURE: The fundamental purpose of the fuselage structure is to provide an envelope to support the payload, crew, equipment, systems and (possibly) the power-plant. Furthermore, it must react against the in-flight maneuver, pressurization and gust loads; also the landing gear and possibly any power-plant loads. It must be also be able to transmit control and trimming loads from the stability and control surfaces throughout the rest of the structure Fuselage contributes very little to lift and produces more drag but it is an important structural member/component. It is the connecting member to all load producing components such as wing, horizontal tail, vertical tail, landing gear etc. and thus redistributes the load. It also serves the purpose of housing or accommodating practically all equipment, accessories and systems in addition to carrying the payload. Because of large amount of equipment inside the fuselage, it is necessary to provide sufficient number of cutouts in the fuselage for access and inspection purposes. These cutouts and discontinuities result in fuselage design being more complicated, less precise and often less efficient in design. As a common member to which other components are attached, thereby transmitting the loads, fuselage can be considered as a long hollow beam. The reactions produced by the wing, tail or landing gear may be considered as concentrated loads at the respective attachment points. The balancing reactions are provided by the inertia forces contributed by the weight of the fuselage structure and the various components inside the fuselage. These reaction forces are distributed all along the length of the fuselage, though need not be uniformly. Unlike the wing, which is subjected to mainly unsymmetrical load, the fuselage is much simpler for structural analysis due to its symmetrical cross-section and symmetrical loading. The main load in the case of fuselage is the shear load because the load acting on the wing is transferred to the fuselage skin in the form of shear only. The structural design of both wing and fuselage begin with shear force and bending moment diagrams for the respective members. The maximum bending stress

- 41. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI produced in each of them is checked to be less than the yield stress of the material chosen for the respective member.. 8.5 FUSELAGE LAYOUT CONCEPTS: There are two main categories of layout concept in common use; Mass boom and longeron layout Semi-monocoque layout 8.5.1 MASS BOOM & LONGERON LAYOUT This is fundamentally very similar to the mass-boom wing-box concept discussed in previous section. It is used when the overall structural loading is relatively low or when there are extensive cut-outs in the shell. The concept comprises four or more continuous heavy booms (longeron), reacting against any direct stresses caused by applied vertical and lateral bending loads. Frames or solid section 8.5.2 SEMI-MONOCOQUE LAYOUT The semi-monocoque is the most often used construction for modern, high-performance aircraft. Semi-monocoqueliterally means half a single shell. Here, internal braces as well as the skin itself carry the stress. The vertical structural members are referred to as bulkheads, frames, and formers. The heavier vertical members are located at intervals to allow for concentrated loads. These members are also found at points where fittings are used to attach other units, such as the wings and stabilizers. Primary bending loads are taken by the longerons, which usually extend across several points of support. The longerons are supplemented by other longitudinal members known as stringers. Stringers are more numerous and lightweight than longerons. The stringers are smaller and lighter than longerons and serve as fill-ins. They have some rigidity but are chiefly used for giving shape and for attachment of skin. The strong, heavy longerons hold the bulkheads and formers. The bulkheads and formers hold the stringers. All of these join together to form a rigid fuselage framework. Stringers and longerons prevent tension and compression stresses from bending the fuselage. The skin is attached to the longerons, bulkheads, and other structural members and carries part of the load.

- 42. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI CHAPTER IX MATERIAL SELECTION 9.1 DESCRIPTION: Aircraft structures are basically unidirectional. This means that one dimension, the length, is much larger than the others - width or height. For example, the span of the wing and tail spars is much longer than their width and depth; the ribs have a much larger chord length than height and/or width; a whole wing has a span that is larger than its chords or thickness; and the fuselage is much longer than it is wide or high. Even a propeller has a diameter much larger than its blade width and thickness, etc.... For this simple reason, a designer chooses to use unidirectional material when designing for an efficient strength to weight structure. Unidirectional materials are basically composed of thin, relatively flexible, long fibers which are very strong in tension (like a thread, a rope, a stranded steel wire cable, etc.). An aircraft structure is also very close to a symmetrical structure. Those mean the up and down loads are almost equal to each other. The tail loads may be down or up depending on the pilot raising or dipping the nose of the aircraft by pulling or pushing the pitch control; the rudder may be deflected to the right as well as to the left (side loads on the fuselage). The gusts hitting the wing may be positive or negative, giving the up or down loads which the occupant experiences by being pushed down in the seat or hanging in the belt. Because of these factors, the designer has to use a structural material that can withstand both tension and compression. Unidirectional fibers may be excellent in tension, but due to their small cross section, they have very little inertia (we will explain inertia another time) and cannot take much compression. They will escape the load by bucking away. As in the illustration, you cannot load a string, or wire, or chain in compression.

- 43. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI In order to make thin fibers strong in compression, they are "glued together" with some kind of an "embedding". In this way we can take advantage of their tension strength and are no longer penalized by their individual compressionweakness because, as a whole, they become compression resistant as they help each other to not buckle away. The embedding is usually a lighter, softer "resin" holding the fibers together and enabling them to take the required compression loads. This is a very good structural material. 9.2 WOOD: Historically, wood has been used as the first unidirectional structural raw material. They have to be tall and straight and their wood must be strong and light. The dark bands (late wood) contain many fibers, whereas the light bands (early wood) contain much more "resin". Thus the wider the dark bands, the stronger and heavier the wood. If the dark bands are very narrow and the light bands quite wide, the wood is light but not very strong. To get the most efficient strength to weight ratio for wood we need a definite numbers of bands per inch.

- 44. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Some of our aircraft structures are two-dimensional (length and width are large with respect to thickness). Plywood is often used for such structures. Several thin boards (foils) are glued together so that the fibers of the various layers cross over at different angles (usually 90 degrees today years back you could get them at 30 and 45 degrees as well). Plywood makes excellent "shear webs" if the designer knows how to use plywood efficiently. (We will learn the basis of stress analysis sometime later.) Today good aircraft wood is very hard to come by. Instead of using one good board for our spars, we have to use laminations because large pieces of wood are practically unavailable, and we no longer can trust the wood quality. From an availability point of view, we simply need a substitute for what nature has supplied us with until now. 9.3 ALUMINIUM ALLOYS: So, since wood may not be as available as it was before, we look at another material which is strong, light and easily available at a reasonable price (there's no point in discussing Titanium - it's simply too expensive). Aluminum alloys are certainly one answer. We will discuss the properties of those alloys which are used in light plane construction in more detail later. For the time being we will look at Aluminum as a construction material. 9.4 EXTRUDED ALUMINIUM ALLOYS: Due to the manufacturing process for Aluminum we get a unidirectional material quite a bit stronger in the lengthwise direction than across. And even better, it is not only strong in tension but also in compression. Comparing extrusions to wood, the tension and compression characteristics are practically the same for aluminum alloys so that the linear stress analysis applies. Wood, on the other hand, has a tensile strength about twice as great as its compression strength; accordingly, special stress analysis methods must be used and a good understanding of wood under stress is essential if stress concentrations are to be avoided!

- 45. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI Aluminium alloys, in thin sheets (.016 to .125 of an inch) provide an excellent two dimensional material used extensively as shear webs - with or without stiffeners - and also as tension/compression members when suitably formed (bent).It is worthwhile to remember that aluminium is an artificial metal. There is no aluminium ore in nature. Aluminium is manufactured by applying electric power to bauxite (aluminium oxide) to obtain the metal, which is then mixed with various strength-giving additives. (In a later article, we will see which additives are used, and why and how we can increase aluminum’s strength by cold work hardening or by tempering.) All the commonly used aluminium alloys are available from the shelf of dealers. When requested with the purchase, you can obtain a "mill test report" that guarantees the chemical and physical properties as tested to accepted specifications. As a rule of thumb, aluminium is three times heavier, but also three times stronger than wood. Steel is again three times heavier and stronger than aluminium. 9.5 STEEL: The next material to be considered for aircraft structure will thus be steel, which has the same weight-to-strength ratio of wood or aluminium. Apart from mild steel which is used for brackets needing little strength, we are mainly using a chrome-molybdenum alloy called AISI 413ON or 4140. The common raw materials available are tubes and sheet metal. Steel, due to its high density, is not used as shear webs like aluminium sheets or plywood. Where we would need, say.100" plywood, a .032 inch aluminium sheet would be required, but only a .010 steel sheet would be required, which is just too thin to handle with any hope of a nice finish. That is why a steel fuselage uses tubes also as diagonals to carry the shear in compression or tension and the whole structure is then covered with fabric (light weight) to give it the required aerodynamic shape or desired look. It must be noted that this method involves two techniques: steel work and fabric covering. . 9.6 COMPOSITE MATERIALS: The designer of composite aircraft simply uses fibers in the desired direction exactly where and in the amount required. The fibers are embedded in resin to hold them in place and provide the required support against buckling. Instead of plywood or sheet metal which allows single curvature only, the composite designer uses cloth where the fibers are laid in two directions .(the woven thread and weft) also embedded in resin.

- 46. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI This has the advantage of freedom of shape in double curvature as required by optimum aerodynamic shapes and for very appealing look (importance of aesthetics). Today's fibers (glass, nylon, Kevlar, carbon, whiskers or single crystal fibers of various chemical compositions) are very strong, thus the structure becomes very light. The drawback is very little stiffness. The structure needs stiffening which is achieved either by the usual discreet stiffeners, -or more elegantly with a sandwich structure: two layers of thin uni- or bi-directional fibers are held apart by a lightweight core (foam or "honeycomb"). This allows the designer to achieve the required inertia or stiffness. From an engineering standpoint, this method is very attractive and supported by many authorities because it allows new developments which are required in case of war. But this method also has its drawbacks for homebuilding: A mold is needed, and very strict quality control is a must for the right amount of fibers and resin and for good adhesion between both to prevent too "dry" or "wet" a structure. Also the curing of the resin is quite sensitive to temperature, humidity and pressure. Finally, the resins are active chemicals which will not only produce the well-known allergies but also the chemicals that attack our body (especially the eyes and lungs) and they have the unfortunate property of being cumulatively damaging and the result (in particular deterioration of the eye) shows up only years after initial contact. Another disadvantage of the resins is their limited shelf life, i.e., if the resin is not used within the specified time lapse after manufacturing, the results may be unsatisfactory and unsafe. 9.7 HEAVY AIRCRAFT RAW MATERIALS: MAGNESIUM: An expensive material. Castings are the only readily available forms. Special precaution must be taken when machining magnesium because this metal burns when hot. TITANIUM: A very expensive material. Very tough material and difficult to machine. CARBON FIBERS: Still very expensive materials. KEVLAR FIBERS: Very expensive and also critical to work with because it is hard to "soak" in the resin.

- 47. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI CHAPTER X THREE VIEW DIAGRAM TOP VIEW: FRONT VIEW: SIDE VIEW: Fig: 10.1 Three View Diagram of the Aircraft

- 48. WWW.VIDYARTHIPLUS.COM WWW.VIDYARTHIPLUS.COM SIVA RANAJANI CHAPTER XI CONCLUSION: The Conceptual Design phase of an aircraft is probably the most interesting and intriguing phase of aircraft design. It is a clear indication of the compromise that has to be made between various divisions of an Aircraft design center, and yet satisfy an incredible number of real-world constraints and design specifications. Aircraft design involves a variety of the field of Aerospace engineering like structures, performance, aerodynamics, stability etc. Among this we went through the structure part in this project which has enabled us to get a taste of what it is to design a real aircraft. The fantasies of the flying world seem to be much more than what we thought. With this design project as the base, we will strive to progress in the field of airplane design and maintenance. We convey our heartfelt gratitude to all of them who have provided their helping hand in the completion of this project.