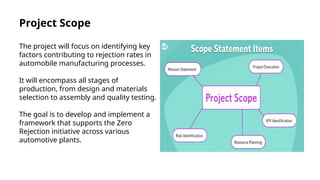

The document outlines the zero rejection quality management approach aimed at minimizing defects in automobile manufacturing, enhancing customer satisfaction, and reducing operational costs. It identifies the challenges of high rejection rates in the automotive industry, proposing a comprehensive strategy to mitigate these issues through a phased implementation plan that includes detailed analysis, employee training, and continuous monitoring. The expected outcomes include improved production efficiency, reduced rejection rates, and increased customer retention, positioning the company as a leader in quality manufacturing.