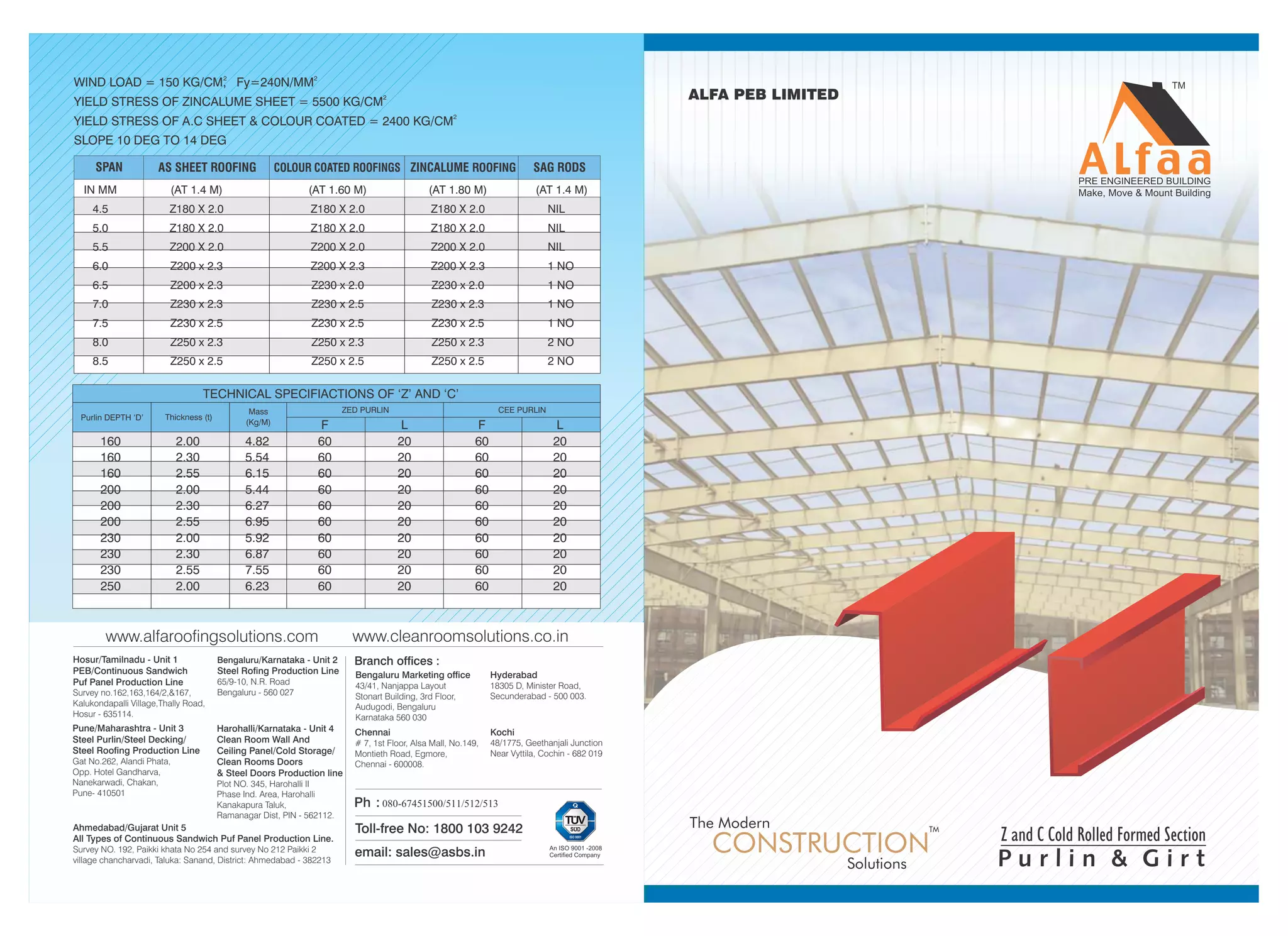

This document provides technical specifications for roofing materials and purlins. It includes the wind load, yield stresses for different sheet materials, slope recommendations, sheet and purlin sizes for different spans, and the mass of purlin profiles. Purlin depths and thicknesses are specified. Connection details are shown for lap joints, simple connections and double flange braces.