Yale e108 erc20 30 agf lift truck service repair manual

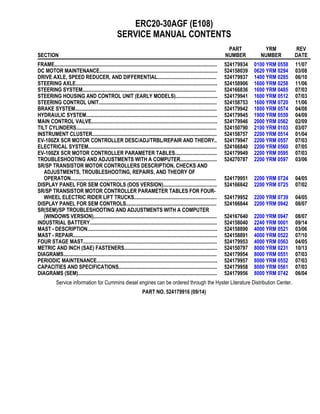

- 1. ERC20-30AGF (E108) SERVICE MANUAL CONTENTS SECTION PART NUMBER YRM NUMBER REV DATE FRAME............................................................................................................................ 524179934 0100 YRM 0558 11/07 DC MOTOR MAINTENANCE.......................................................................................... 524158039 0620 YRM 0294 03/08 DRIVE AXLE, SPEED REDUCER, AND DIFFERENTIAL............................................. 524179937 1400 YRM 0285 06/10 STEERING AXLE............................................................................................................ 524158906 1600 YRM 0258 11/06 STEERING SYSTEM...................................................................................................... 524166836 1600 YRM 0485 07/03 STEERING HOUSING AND CONTROL UNIT (EARLY MODELS)................................ 524179941 1600 YRM 0512 07/03 STEERING CONTROL UNIT.......................................................................................... 524158753 1600 YRM 0720 11/06 BRAKE SYSTEM............................................................................................................ 524179942 1800 YRM 0574 04/08 HYDRAULIC SYSTEM.................................................................................................... 524179945 1900 YRM 0559 04/09 MAIN CONTROL VALVE................................................................................................ 524179946 2000 YRM 0562 02/09 TILT CYLINDERS........................................................................................................... 524150790 2100 YRM 0103 03/07 INSTRUMENT CLUSTER............................................................................................... 524158757 2200 YRM 0514 01/04 EV-100ZX SCR MOTOR CONTROLLER DESC/ADJ/TRBL/REPAIR AND THEORY.. 524179947 2200 YRM 0557 07/03 ELECTRICAL SYSTEM.................................................................................................. 524166840 2200 YRM 0560 07/05 EV-100ZX SCR MOTOR CONTROLLER PARAMETER TABLES................................ 524179949 2200 YRM 0595 07/03 TROUBLESHOOTING AND ADJUSTMENTS WITH A COMPUTER............................ 524270787 2200 YRM 0597 03/06 SR/SP TRANSISTOR MOTOR CONTROLLERS DESCRIPTION, CHECKS AND ADJUSTMENTS, TROUBLESHOOTING, REPAIRS, AND THEORY OF OPERATON............................................................................................................... 524179951 2200 YRM 0724 04/05 DISPLAY PANEL FOR SEM CONTROLS (DOS VERSION)......................................... 524166842 2200 YRM 0725 07/02 SR/SP TRANSISTOR MOTOR CONTROLLER PARAMETER TABLES FOR FOUR- WHEEL ELECTRIC RIDER LIFT TRUCKS............................................................... 524179952 2200 YRM 0739 04/05 DISPLAY PANEL FOR SEM CONTROLS..................................................................... 524166844 2200 YRM 0942 08/07 SR(SEM)/SP TROUBLESHOOTING AND ADJUSTMENTS WITH A COMPUTER (WINDOWS VERSION).............................................................................................. 524167640 2200 YRM 0947 08/07 INDUSTRIAL BATTERY................................................................................................. 524158040 2240 YRM 0001 09/14 MAST - DESCRIPTION................................................................................................... 524158890 4000 YRM 0521 03/06 MAST - REPAIR.............................................................................................................. 524158891 4000 YRM 0522 07/10 FOUR STAGE MAST...................................................................................................... 524179953 4000 YRM 0563 04/05 METRIC AND INCH (SAE) FASTENERS....................................................................... 524150797 8000 YRM 0231 10/13 DIAGRAMS..................................................................................................................... 524179954 8000 YRM 0551 07/03 PERIODIC MAINTENANCE............................................................................................ 524179957 8000 YRM 0552 07/03 CAPACITIES AND SPECIFICATIONS........................................................................... 524179958 8000 YRM 0561 07/03 DIAGRAMS (SEM).......................................................................................................... 524179956 8000 YRM 0742 06/04 Service information for Cummins diesel engines can be ordered through the Hyster Literature Distribution Center. PART NO. 524179916 (09/14)

- 2. 100 YRM 558 Description General This section has a description and the service procedures for the parts of the frame. These parts include the frame, counterweight assembly, overhead guard, hood and seat assembly, access panels, and label positions. The proce- dure for removing the traction motor is also described in this section. Description MAIN FRAME The main frame is a single weldment. See Figure 1. The main frame has mounts for the following: • Counterweight • Overhead guard • Battery restraint and hood • Seat plate (with optional seat brake) • Tilt cylinders • Steering axle • Drive axle assembly • Cowl assembly • Floor pedals and floor plates • Side step and fender weldments • Hydraulic tank • Pump and motor assemblies (steer, lift, and traction motors) • Control valves and levers The hood is part of the operator and battery restraint system. The seat is also part of the operator restraint system. The floor plates are removed for access to the steering motor. A panel in the bottom of the battery compartment is removed for access to the traction mo- tor and the hydraulic pump motor. The electronic con- troller and contactors are attached to the frame. A panel in the counterweight is removed for access to the con- troller and contactors. See Figure 16. For the location of the Master Controller and Electro-Hydraulics Valve Driver Module, see the section Electro-hydraulic Con- trol Valve 2000 YRM 1224. WARNING The battery must fit the battery compartment so that the battery restraint will operate correctly. A loose battery can cause serious injury and property damage if the lift truck overturns. Adjust the spacer plate to prevent the battery from moving more than 13 mm (0.5 in.) forward or backward. The lift trucks are equipped with an adjustable spacer plate in the battery compartment. See Figure 2. Adjust the spacer plate to control the movement of the battery in the forward and backward directions. Tighten the jam nuts on the adjustment capscrew to prevent the adjust- ment from changing. WARNING Maximum clearance between the battery and bat- tery compartment width is 13 mm (0.5 in.). Maxi- mum clearance between the battery and the spacer plate is also 13 mm (0.5 in.). The Battery Specifica- tions chart shows the minimum size compartment allowed. The weight of the battery is a large part of the coun- terweight system on an electric lift truck. Make sure that the battery is within the weight limits indicated on the Nameplate. Each model of lift truck has a cast-iron counterweight that provides the additional weight nec- essary for the indicated capacity. A slot in the overhead guard permits removal of the battery without removing the overhead guard. 1

- 3. Description 100 YRM 558 Figure 1. Lift Truck Frame 2

- 4. 100 YRM 558 Description Legend for Figure 1 NOTE: OPTIONAL SIDE PANELS FOR BATTERY COMPARTMENT NOT SHOWN. 1. COWL 2. BATTERY COMPARTMENT ACCESS COVERS 3. BATTERY SPACER PLATE* 4. BATTERY SPACER PLATE** 5. SIDE STEP AND FENDER WELDMENT 6. FRAME 7. FLOOR MATS 8. FLOOR PLATES (COVERS) * BATTERY SPACER PLATE USED ON NEWER LIFT TRUCK MODELS ** BATTERY SPACER PLATE USED ON OLDER LIFT TRUCK MODELS 1. BATTERY COMPARTMENT 2. BATTERY 3. BULKHEAD 4. SPACER PLATE 5. ADJUSTMENT CAPSCREW 6. JAM NUTS Figure 2. Battery Spacer Plate OTHER FRAME WELDMENTS These frame parts are the right-hand and left-hand side step and fender weldments and the cowl weld- ment. See Figure 1. Each part is a weldment fastened to the main frame to make the frame assembly. The cowl weldment is a mount for the front of the overhead guard, the steering column assembly, the release linkage of the parking brake, and the instrument panel with light switches. The display panel is on the right side of the steering column and attached to the instru- ment panel for lift truck models with SEM (Separately Excited Motor), SCR (Silicon Controlled Rectifier), and AC (Alternating Current) electronic controllers and contactors. See Figure 3, Figure 4, Figure 5, Figure 6, and Figure 7. OVERHEAD GUARD WARNING Do not operate the lift truck without the overhead guard correctly fastened to the lift truck. The overhead guard is a weldment that fastens to the main frame and cowl to help protect the operator from falling objects. See Figure 5, Figure 6, Figure 7, or Figure 9. 3

- 5. Description 100 YRM 558 A. STANDARD SEM DISPLAY PANEL B. PREMIUM SEM DISPLAY PANEL Figure 3. SEM Display Panel NOTE: FOR LIFT TRUCK MODELS WITH AC ELECTRONIC CONTROLLERS AND CONTACTORS, BOTH THE STANDARD AND PREMIUM DISPLAY PANELS LOOK IDENTICAL. THE ONLY DIFFERENCE IS IN THE DISPLAY SOFTWARE AND THE RESULTING FUNCTIONALITY. Figure 4. AC Display Panel 4

- 6. 100 YRM 558 Overhead Guard Replacement Overhead Guard Replacement REMOVE WARNING Do not weld, drill, grind, or cut the overhead guard for mounts, lights, or accessories. The strength of the overhead guard can be reduced. 1. Remove the battery from the truck. See How to Change Battery in your vehicle’s Periodic Main- tenance or Operating Manual. 2. Access to the capscrews that hold the rear legs of the overhead guard to the frame is from the bat- tery compartment. Remove the capscrews, wash- ers, and nuts that fasten each leg. See Figure 5, Figure 6, Figure 7, Figure 8, and Figure 9. 3. Remove the capscrews, washers, and nuts that hold each front leg of the overhead guard to the cowl. Disconnect any electric wires from under the cowl that go through the front legs of the overhead guard. When the overhead guard is lifted from the frame, make sure these electric wires move through the holes in the frame at the front and rear so that they are not damaged. 4. Use a lifting device or another person to help lift the overhead guard from the lift truck. INSTALL Put the overhead guard on the lift truck. Install any electric wires from the overhead guard legs through the holes in the frame. Install the capscrews, wash- ers, and nuts that hold each front leg to the frame. Tighten capscrews to 55 N•m (41 lbf ft). Install the capscrews, washers, and nuts that hold the rear legs to the frame. For lift truck models ERC20-30AGF (ERC040-065RF/ZF, ERC040-065RG/ZG) (E108), tighten the capscrews to 68 N•m (50 lbf ft). For lift truck models ERC20-30AGF (ERC040-065GH) (A908), tighten the capscrews to 90 N•m (66 lbf ft). Install the battery. See How to Change Battery in your vehicle’s Periodic Maintenance or Operating Manual. 5

- 7. Overhead Guard Replacement 100 YRM 558 Figure 5. Overhead Guard, Steering Column, and Display Panel, Truck Models ERC20-30AGF (ERC040-065RF/ZF) (E108) 6

- 8. 100 YRM 558 Overhead Guard Replacement Legend for Figure 5 NOTE: DISPLAY PANELS SHOWN ARE FOR LIFT TRUCKS WITH SCR ELECTRONIC CONTROLLERS AND CONTACTORS. A. STEERING CONTROL UNIT USED ON EARLY MODEL LIFT TRUCKS B. STEERING CONTROL UNIT USED ON LATER MODEL LIFT TRUCKS 1. OVERHEAD GUARD 2. STEERING WHEEL 3. ON-DEMAND STEERING COMPONENTS (NOT ALL UNITS) 4. HORN SWITCH CONNECTOR 5. COLUMN COVER 6. COLUMN FRAME 7. STEERING CONTROL UNIT 8. LATCH MECHANISM 9. OPTIONAL PREMIUM DISPLAY PANEL 10. REGULAR DISPLAY PANEL* 11. CAPSCREW 12. WASHER 13. NUT 14. SCREW 15. OVERHEAD GUARD HANDLE 16. HORN SWITCH CONNECTOR 17. STEERING COLUMN 18. STEERING COLUMN NUT *CURTIS METER SHOWN. PANEL AVAILABLE WITH OPTIONAL GENERAL ELECTRIC™ METER. 7

- 9. Overhead Guard Replacement 100 YRM 558 Figure 6. Overhead Guard, Steering Column, and Display Panel, Truck Models ERC20-30AGF (ERC040-065RG/ZG) (E108) 8

- 10. 100 YRM 558 Overhead Guard Replacement Legend for Figure 6 NOTE: DISPLAY PANELS SHOWN ARE FOR LIFT TRUCKS WITH SEM ELECTRONIC CONTROLLERS AND CONTACTORS. 1. STEERING WHEEL 2. SHIFT LEVER MECHANISM 3. COLUMN COVER 4. LATCH MECHANISM 5. STEERING CONTROL UNIT 6. COLUMN FRAME 7. ON-DEMAND STEERING COMPONENTS 8. DISPLAY PANEL (PREMIUM DISPLAY PANEL SHOWN) 9. OVERHEAD GUARD 10. CAPSCREW 11. WASHER 12. NUT 13. SCREW 14. OVERHEAD GUARD HANDLE 15. HORN SWITCH CONNECTOR 16. HORN BUTTON 17. STEERING COLUMN 18. STEERING COLUMN NUT 9

- 11. Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL. NO WAITING NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it.

- 12. Overhead Guard Replacement 100 YRM 558 Figure 7. Overhead Guard, Steering Column, and Display Panel, Truck Models ERC20-30AGF (ERC040-065GH) (A908) 10

- 13. 100 YRM 558 Overhead Guard Replacement Legend for Figure 7 NOTE: DISPLAY PANELS SHOWN ARE FOR LIFT TRUCKS WITH AC ELECTRONIC CONTROLLERS AND CON- TACTORS. NOTE: OVERHEAD GUARD FOR LIFT TRUCK MODELS ERC040-065GH (A908) SHOWN. SEE FIGURE 8 FOR OVERHEAD GUARD USED ON ERC20-30AGF (A908) MODELS. 1. ON-DEMAND STEERING COMPONENTS 2. SHIFT LEVER MECHANISM 3. STEERING WHEEL 4. DISPLAY PANEL 5. COLUMN COVER 6. COLUMN FRAME 7. STEERING CONTROL UNIT 8. COWL WELDMENT 9. DASH 10. COLUMN MOUNT 11. OVERHEAD GUARD 12. LATCH MECHANISM 13. CAPSCREW 14. WASHER 15. NUT 16. SCREW 17. OVERHEAD GUARD HANDLE 18. HORN SWITCH CONNECTOR 19. HORN BUTTON 20. STEERING COLUMN 21. STEERING COLUMN NUT Figure 8. Overhead Guard, Lift Truck Models ERC20-30AGF (A908) Legend for Figure 8 1. OVERHEAD GUARD 2. PLUG 3. NUT 4. LOCKWASHER 5. CAPSCREW 6. WASHER 7. HANDLE 8. SCREW 11

- 14. Battery and Operator Restraint System, Hood and Seat Brake, and Seat Assembly Replacement 100 YRM 558 1. FRONT LEG, OVERHEAD GUARD 2. SETSCREW 3. ATTACHMENT PLATE 4. REAR LEG, OVERHEAD GUARD 5. COUNTERWEIGHT 6. TOW PIN 7. BOLT Figure 9. Overhead Guard and Counterweight Battery and Operator Restraint System, Hood and Seat Brake, and Seat Assembly Replacement BATTERY RESTRAINT SYSTEM WARNING On units with a shorter frame, the gas spring for the hood can raise the hood at a rapid rate and cause an injury. Do NOT bend over hood when raising hood. A battery restraint system is installed as a safety de- vice. See Figure 10. The function of the battery re- straint system, when correctly locked in the down posi- tion, is to hold the battery in the battery compartment if an accident causes the lift truck to tip over. The bat- tery restraint is a steel weldment that is connected to the frame with a hinge. A sliding latch mechanism (see Fig- ure 10.) locks the battery restraint in the down position for operation. The latch, at the top center of the coun- terweight, unlocks the battery restraint from the frame, so that the battery restraint can be raised to the up po- sition for access to the battery. The battery restraint is also the support for the hood. A gas spring helps lift the hood assembly. A rod is used to hold the hood in the up position on units with a longer frame. The oper- ator must hold the hood assembly with one hand. Use the other hand to move the rod to the storage position. Lower the hood and battery restraint assembly to the operating position. Make sure that the battery restraint is correctly locked to the frame for operation of the lift truck. 12