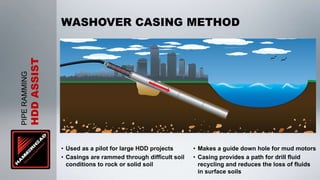

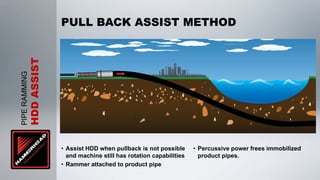

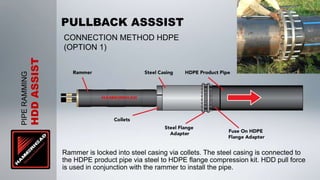

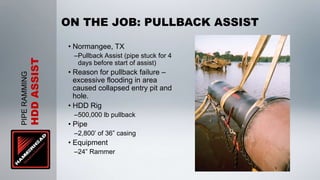

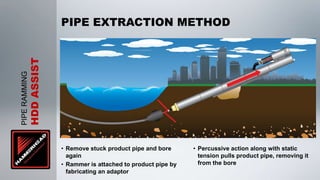

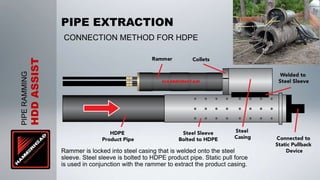

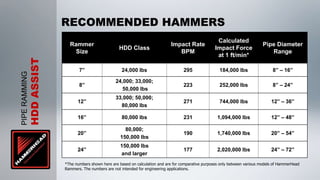

This document describes HDD assist methods using pipe rammers to help with problematic horizontal directional drills. It outlines four main methods - washover casings, pullback assist, pipe extraction, and drill stem recovery. For each method it provides details on the process and equipment used as well as examples of jobs where each method helped complete challenging HDD projects.