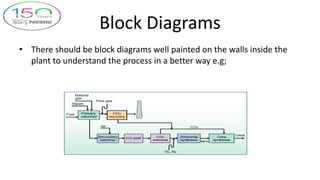

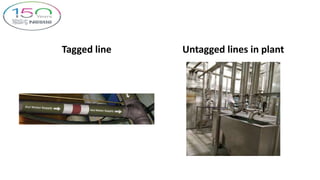

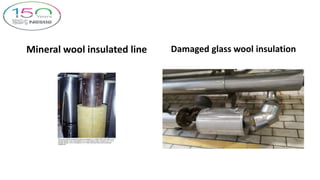

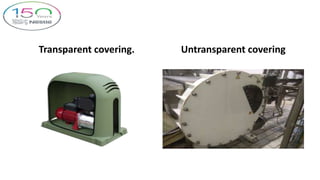

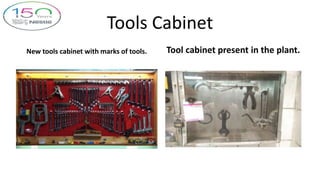

The document outlines various workplace transformations for a dairy and juice plant, including reducing noise, improving temperature control, adding block diagrams and line tagging, installing mineral wool insulation, making motors more transparent for maintenance, and other minor changes. It provides details on implementing noise reduction coatings and dampers, ensuring proper ventilation for temperature control, examples of block diagrams and line tagging standards, replacing damaged insulation with mineral wool, methods for increasing motor transparency, and treating contaminated floor tiles.