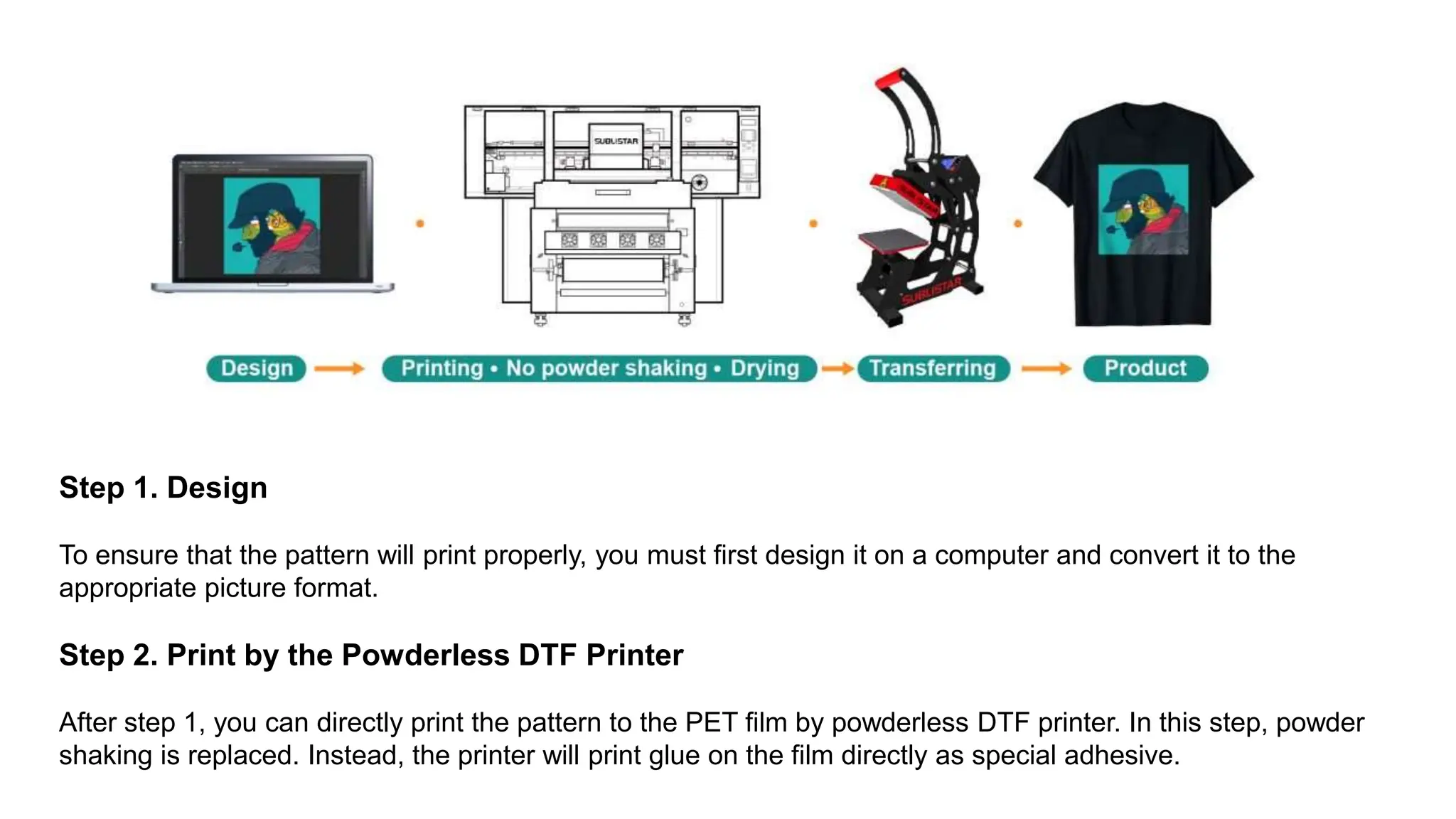

The powderless DTF printer represents a significant advancement in t-shirt printing by eliminating the need for hot melt powder, resulting in a smoother and more breathable finish on printed materials. This innovation simplifies the printing process, lowers operating costs, and expands application possibilities across diverse substrates, including fabrics and hard materials. The market expects powderless DTF printers to become standard in digital printing by 2024, offering enhanced quality and environmental benefits.