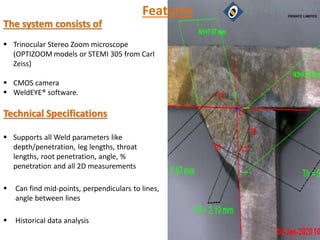

The document highlights the WeldEye® system by QS Metrology, designed for advanced weld penetration inspection in the automotive industry. It features extensive dimensional measurement capabilities, custom user parameters, and automatic pass/fail criteria, catering to several major OEM standards. Additionally, it offers detailed reporting options and includes advanced technical components like stereo microscopes and CMOS cameras.