Recommended

PPT

supplement-6-e28093-spc12345 essence.ppt

PPT

supplement-6-e28093-spc for beginners.ppt

PPT

supplement-6-e28093-spc.ppt- SPC_ Operation Management

PPT

PPT

PPTX

Statistical process control (spc)

PPTX

"Quality for Performance" (Kualitas untuk Kinerja) adalah sebuah konsep manaj...

PPTX

Statistical process control spc enginering

PPT

PPTX

SPC_Material.pptx from maruti centre of excellence

PPT

Effective Process Control

PPT

Unit 3 Total Quality Management _SPC.ppt

PPTX

PPTX

PPTX

Chap06 sampling and sampling distributions

PDF

DOC

Chapter 7 sampling distributions

PPTX

Chapters 14 and 15 presentation

PDF

Sampling Method Chapter 8 | Statistic sampling

PPT

business and economics statics principles

PPT

process monitoring for quality engineering

PPTX

PPTX

Statistical quality control presentation

PPTX

PPTX

PPTX

Statistics (GE 4 CLASS).pptx

PPTX

Sampling and statistical inference

PPTX

Chap01 describing data; graphical

More Related Content

PPT

supplement-6-e28093-spc12345 essence.ppt

PPT

supplement-6-e28093-spc for beginners.ppt

PPT

supplement-6-e28093-spc.ppt- SPC_ Operation Management

PPT

PPT

PPTX

Statistical process control (spc)

PPTX

"Quality for Performance" (Kualitas untuk Kinerja) adalah sebuah konsep manaj...

PPTX

Statistical process control spc enginering

Similar to Week 12 (StatisticalProcessControl)-StatisticalProcessControl-StatisticalProcessControl.ppt

PPT

PPTX

SPC_Material.pptx from maruti centre of excellence

PPT

Effective Process Control

PPT

Unit 3 Total Quality Management _SPC.ppt

PPTX

PPTX

PPTX

Chap06 sampling and sampling distributions

PDF

DOC

Chapter 7 sampling distributions

PPTX

Chapters 14 and 15 presentation

PDF

Sampling Method Chapter 8 | Statistic sampling

PPT

business and economics statics principles

PPT

process monitoring for quality engineering

PPTX

PPTX

Statistical quality control presentation

PPTX

PPTX

PPTX

Statistics (GE 4 CLASS).pptx

PPTX

Sampling and statistical inference

PPTX

Chap01 describing data; graphical

Week 12 (StatisticalProcessControl)-StatisticalProcessControl-StatisticalProcessControl.ppt 1. © 2008 Prentice Hall, Inc. S6 – 1

Statistical Process Control

Statistical Process Control

2. © 2008 Prentice Hall, Inc. S6 – 2

Outline

Outline

Statistical Process Control (SPC)

Statistical Process Control (SPC)

Control Charts for Variables

Control Charts for Variables

The Central Limit Theorem

The Central Limit Theorem

Setting Mean Chart Limits (x-Charts)

Setting Mean Chart Limits (x-Charts)

Setting Range Chart Limits (R-Charts)

Setting Range Chart Limits (R-Charts)

Using Mean and Range Charts

Using Mean and Range Charts

Control Charts for Attributes

Control Charts for Attributes

Managerial Issues and Control Charts

Managerial Issues and Control Charts

3. © 2008 Prentice Hall, Inc. S6 – 3

Outline – Continued

Outline – Continued

Process Capability

Process Capability

Process Capability Ratio

Process Capability Ratio (C

(Cp

p)

)

Process Capability Index

Process Capability Index (C

(Cpk

pk )

)

Acceptance Sampling

Acceptance Sampling

Operating Characteristic Curve

Operating Characteristic Curve

Average Outgoing Quality

Average Outgoing Quality

4. © 2008 Prentice Hall, Inc. S6 – 4

Variability is inherent

Variability is inherent

in every process

in every process

Natural or common causes

Natural or common causes

(As long as the distribution remains within specified limits, the

(As long as the distribution remains within specified limits, the

process is said to be “in control” & natural variations can be

process is said to be “in control” & natural variations can be

tolerated)

tolerated)

Special or assignable causes

Special or assignable causes

(These can be traced to a specific reason.)

(These can be traced to a specific reason.)

Provides a statistical signal when assignable

Provides a statistical signal when assignable

causes are present

causes are present

Detect and eliminate assignable causes of

Detect and eliminate assignable causes of

variation

variation

Statistical Process Control

Statistical Process Control

5. © 2008 Prentice Hall, Inc. S6 – 5

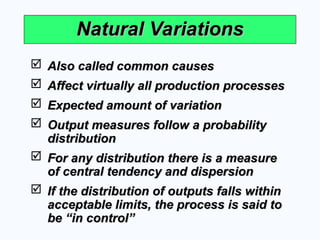

Natural Variations

Natural Variations

Also called common causes

Also called common causes

Affect virtually all production processes

Affect virtually all production processes

Expected amount of variation

Expected amount of variation

Output measures follow a probability

Output measures follow a probability

distribution

distribution

For any distribution there is a measure

For any distribution there is a measure

of central tendency and dispersion

of central tendency and dispersion

If the distribution of outputs falls within

If the distribution of outputs falls within

acceptable limits, the process is said to

acceptable limits, the process is said to

be “in control”

be “in control”

6. © 2008 Prentice Hall, Inc. S6 – 6

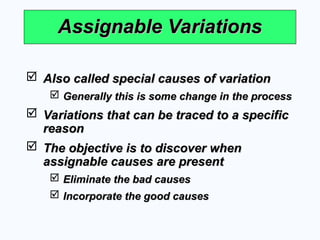

Assignable Variations

Assignable Variations

Also called special causes of variation

Also called special causes of variation

Generally this is some change in the process

Generally this is some change in the process

Variations that can be traced to a specific

Variations that can be traced to a specific

reason

reason

The objective is to discover when

The objective is to discover when

assignable causes are present

assignable causes are present

Eliminate the bad causes

Eliminate the bad causes

Incorporate the good causes

Incorporate the good causes

7. © 2008 Prentice Hall, Inc. S6 – 7

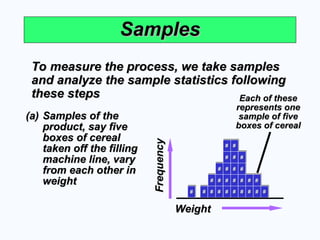

Samples

Samples

To measure the process, we take samples

To measure the process, we take samples

and analyze the sample statistics following

and analyze the sample statistics following

these steps

these steps

(a)

(a) Samples of the

Samples of the

product, say five

product, say five

boxes of cereal

boxes of cereal

taken off the filling

taken off the filling

machine line, vary

machine line, vary

from each other in

from each other in

weight

weight

Frequency

Frequency

Weight

Weight

#

#

#

#

#

# #

#

#

#

#

#

#

#

#

#

#

#

#

# #

# #

#

#

# #

# #

#

#

#

#

# #

# #

#

#

# #

# #

#

#

# #

# #

#

#

#

Each of these

Each of these

represents one

represents one

sample of five

sample of five

boxes of cereal

boxes of cereal

8. © 2008 Prentice Hall, Inc. S6 – 8

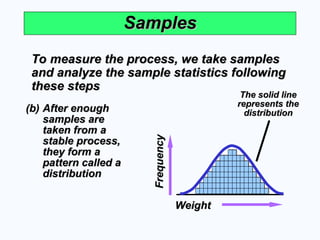

Samples

Samples

To measure the process, we take samples

To measure the process, we take samples

and analyze the sample statistics following

and analyze the sample statistics following

these steps

these steps

(b)

(b) After enough

After enough

samples are

samples are

taken from a

taken from a

stable process,

stable process,

they form a

they form a

pattern called a

pattern called a

distribution

distribution

The solid line

The solid line

represents the

represents the

distribution

distribution

Frequency

Frequency

Weight

Weight

9. © 2008 Prentice Hall, Inc. S6 – 9

Samples

Samples

To measure the process, we take samples

To measure the process, we take samples

and analyze the sample statistics following

and analyze the sample statistics following

these steps

these steps

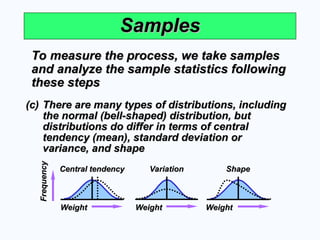

(c)

(c) There are many types of distributions, including

There are many types of distributions, including

the normal (bell-shaped) distribution, but

the normal (bell-shaped) distribution, but

distributions do differ in terms of central

distributions do differ in terms of central

tendency (mean), standard deviation or

tendency (mean), standard deviation or

variance, and shape

variance, and shape

Weight

Weight

Central tendency

Central tendency

Weight

Weight

Variation

Variation

Weight

Weight

Shape

Shape

Frequency

Frequency

10. © 2008 Prentice Hall, Inc. S6 – 10

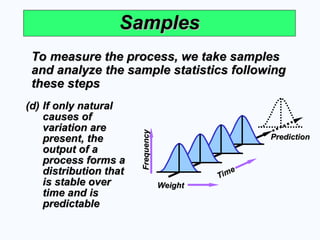

Samples

Samples

To measure the process, we take samples

To measure the process, we take samples

and analyze the sample statistics following

and analyze the sample statistics following

these steps

these steps

(d)

(d) If only natural

If only natural

causes of

causes of

variation are

variation are

present, the

present, the

output of a

output of a

process forms a

process forms a

distribution that

distribution that

is stable over

is stable over

time and is

time and is

predictable

predictable

Weight

Weight

Time

Time

Frequency

Frequency

Prediction

Prediction

11. © 2008 Prentice Hall, Inc. S6 – 11

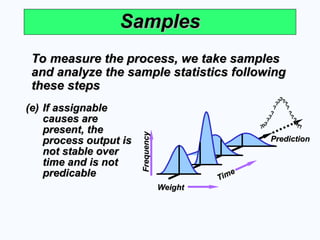

Samples

Samples

To measure the process, we take samples

To measure the process, we take samples

and analyze the sample statistics following

and analyze the sample statistics following

these steps

these steps

(e)

(e) If assignable

If assignable

causes are

causes are

present, the

present, the

process output is

process output is

not stable over

not stable over

time and is not

time and is not

predicable

predicable

Weight

Weight

Time

Time

Frequency

Frequency

Prediction

Prediction

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

??

?

12. © 2008 Prentice Hall, Inc. S6 – 12

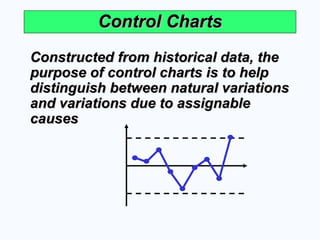

Control Charts

Control Charts

Constructed from historical data, the

Constructed from historical data, the

purpose of control charts is to help

purpose of control charts is to help

distinguish between natural variations

distinguish between natural variations

and variations due to assignable

and variations due to assignable

causes

causes

13. © 2008 Prentice Hall, Inc. S6 – 13

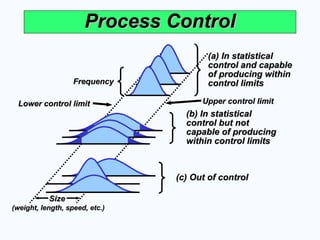

Process Control

Process Control

Frequency

Frequency

(weight, length, speed, etc.)

(weight, length, speed, etc.)

Size

Size

Lower control limit

Lower control limit Upper control limit

Upper control limit

(a) In statistical

(a) In statistical

control and capable

control and capable

of producing within

of producing within

control limits

control limits

(b) In statistical

(b) In statistical

control but not

control but not

capable of producing

capable of producing

within control limits

within control limits

(c) Out of control

(c) Out of control

14. © 2008 Prentice Hall, Inc. S6 – 14

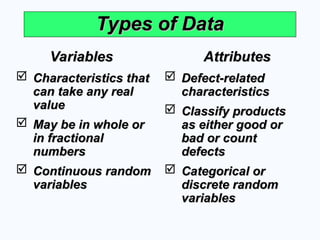

Types of Data

Types of Data

Characteristics that

Characteristics that

can take any real

can take any real

value

value

May be in whole or

May be in whole or

in fractional

in fractional

numbers

numbers

Continuous random

Continuous random

variables

variables

Variables

Variables Attributes

Attributes

Defect-related

Defect-related

characteristics

characteristics

Classify products

Classify products

as either good or

as either good or

bad or count

bad or count

defects

defects

Categorical or

Categorical or

discrete random

discrete random

variables

variables

15. © 2008 Prentice Hall, Inc. S6 – 15

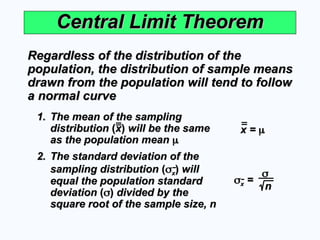

Central Limit Theorem

Central Limit Theorem

Regardless of the distribution of the

Regardless of the distribution of the

population, the distribution of sample means

population, the distribution of sample means

drawn from the population will tend to follow

drawn from the population will tend to follow

a normal curve

a normal curve

1.

1. The mean of the sampling

The mean of the sampling

distribution

distribution (

(x

x)

) will be the same

will be the same

as the population mean

as the population mean

x =

x =

n

n

x

x =

=

2.

2. The standard deviation of the

The standard deviation of the

sampling distribution

sampling distribution (

(

x

x)

) will

will

equal the population standard

equal the population standard

deviation

deviation (

(

)

) divided by the

divided by the

square root of the sample size, n

square root of the sample size, n

16. © 2008 Prentice Hall, Inc. S6 – 16

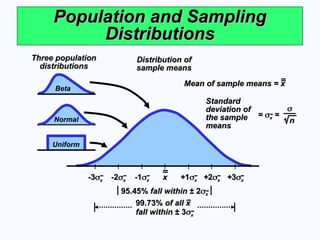

Population and Sampling

Population and Sampling

Distributions

Distributions

Three population

Three population

distributions

distributions

Beta

Normal

Uniform

Distribution of

Distribution of

sample means

sample means

Standard

Standard

deviation of

deviation of

the sample

the sample

means

means

=

=

x

x =

=

n

n

Mean of sample means = x

Mean of sample means = x

| | | | | | |

-

-3

3

x

x -

-2

2

x

x -

-1

1

x

x x

x +

+1

1

x

x +

+2

2

x

x +

+3

3

x

x

99.73%

99.73% of all x

of all x

fall within

fall within ± 3

± 3

x

x

95.45%

95.45% fall within

fall within ± 2

± 2

x

x

17. © 2008 Prentice Hall, Inc. S6 – 17

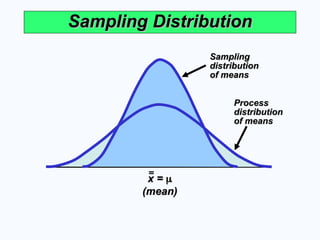

Sampling Distribution

Sampling Distribution

x =

x =

(mean)

(mean)

Sampling

Sampling

distribution

distribution

of means

of means

Process

Process

distribution

distribution

of means

of means

18. © 2008 Prentice Hall, Inc. S6 – 18

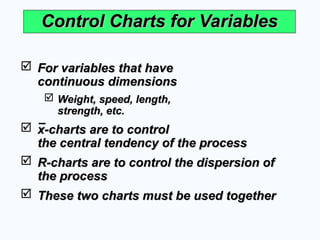

Control Charts for Variables

Control Charts for Variables

For variables that have

For variables that have

continuous dimensions

continuous dimensions

Weight, speed, length,

Weight, speed, length,

strength, etc.

strength, etc.

x-charts are to control

x-charts are to control

the central tendency of the process

the central tendency of the process

R-charts are to control the dispersion of

R-charts are to control the dispersion of

the process

the process

These two charts must be used together

These two charts must be used together

19. © 2008 Prentice Hall, Inc. S6 – 19

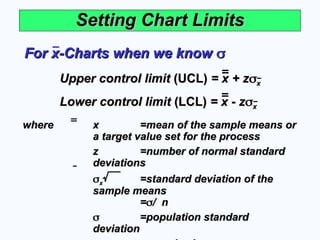

Setting Chart Limits

Setting Chart Limits

For x-Charts when we know

For x-Charts when we know

Upper control limit

Upper control limit (UCL)

(UCL) = x + z

= x + z

x

x

Lower control limit

Lower control limit (LCL)

(LCL) = x - z

= x - z

x

x

where

where x

x =

=mean of the sample means or

mean of the sample means or

a target value set for the process

a target value set for the process

z

z =

=number of normal standard

number of normal standard

deviations

deviations

x

x =

=standard deviation of the

standard deviation of the

sample means

sample means

=

=

/ n

/ n

=

=population standard

population standard

deviation

deviation

20. © 2008 Prentice Hall, Inc. S6 – 20

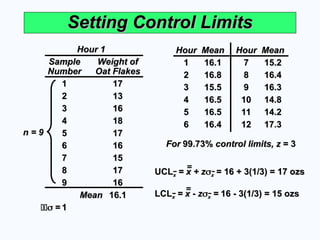

Setting Control Limits

Setting Control Limits

Hour 1

Hour 1

Sample

Sample Weight of

Weight of

Number

Number Oat Flakes

Oat Flakes

1

1 17

17

2

2 13

13

3

3 16

16

4

4 18

18

5

5 17

17

6

6 16

16

7

7 15

15

8

8 17

17

9

9 16

16

Mean

Mean 16.1

16.1

=

= 1

1

Hour

Hour Mean

Mean Hour

Hour Mean

Mean

1

1 16.1

16.1 7

7 15.2

15.2

2

2 16.8

16.8 8

8 16.4

16.4

3

3 15.5

15.5 9

9 16.3

16.3

4

4 16.5

16.5 10

10 14.8

14.8

5

5 16.5

16.5 11

11 14.2

14.2

6

6 16.4

16.4 12

12 17.3

17.3

n = 9

n = 9

LCL

LCLx

x = x - z

= x - z

x

x =

= 16 - 3(1/3) = 15 ozs

16 - 3(1/3) = 15 ozs

For

For 99.73%

99.73% control limits, z

control limits, z = 3

= 3

UCL

UCLx

x = x + z

= x + z

x

x = 16 + 3(1/3) = 17 ozs

= 16 + 3(1/3) = 17 ozs

21. © 2008 Prentice Hall, Inc. S6 – 21

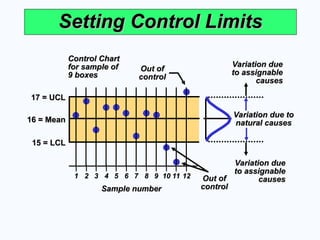

Setting Control Limits

Setting Control Limits

17 = UCL

17 = UCL

15 = LCL

15 = LCL

16 = Mean

16 = Mean

Control Chart

Control Chart

for sample of

for sample of

9 boxes

9 boxes

Sample number

Sample number

|

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

|

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12

Variation due

Variation due

to assignable

to assignable

causes

causes

Variation due

Variation due

to assignable

to assignable

causes

causes

Variation due to

Variation due to

natural causes

natural causes

Out of

Out of

control

control

Out of

Out of

control

control

22. © 2008 Prentice Hall, Inc. S6 – 22

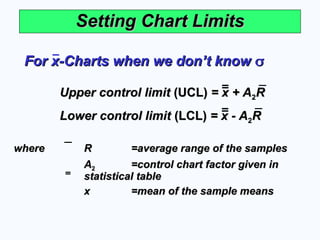

Setting Chart Limits

Setting Chart Limits

For x-Charts when we don’t know

For x-Charts when we don’t know

Lower control limit

Lower control limit (LCL)

(LCL) = x - A

= x - A2

2R

R

Upper control limit

Upper control limit (UCL)

(UCL) = x + A

= x + A2

2R

R

where

where R

R =

=average range of the samples

average range of the samples

A

A2

2 =

=control chart factor given in

control chart factor given in

statistical table

statistical table

x

x =

=mean of the sample means

mean of the sample means

23. © 2008 Prentice Hall, Inc. S6 – 23

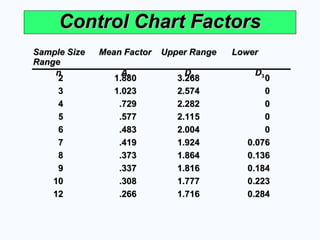

Control Chart Factors

Control Chart Factors

Sample Size

Sample Size Mean Factor

Mean Factor Upper Range

Upper Range Lower

Lower

Range

Range

n

n A

A2

2 D

D4

4 D

D3

3

2

2 1.880

1.880 3.268

3.268 0

0

3

3 1.023

1.023 2.574

2.574 0

0

4

4 .729

.729 2.282

2.282 0

0

5

5 .577

.577 2.115

2.115 0

0

6

6 .483

.483 2.004

2.004 0

0

7

7 .419

.419 1.924

1.924 0.076

0.076

8

8 .373

.373 1.864

1.864 0.136

0.136

9

9 .337

.337 1.816

1.816 0.184

0.184

10

10 .308

.308 1.777

1.777 0.223

0.223

12

12 .266

.266 1.716

1.716 0.284

0.284

24. © 2008 Prentice Hall, Inc. S6 – 24

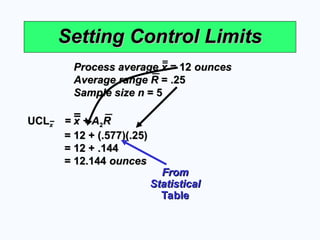

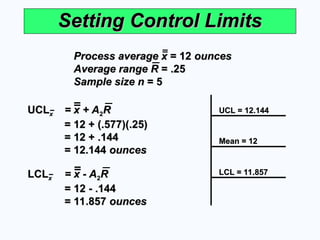

Setting Control Limits

Setting Control Limits

Process average x

Process average x = 12

= 12 ounces

ounces

Average range R

Average range R = .25

= .25

Sample size n

Sample size n = 5

= 5

25. © 2008 Prentice Hall, Inc. S6 – 25

Setting Control Limits

Setting Control Limits

UCL

UCLx

x = x + A

= x + A2

2R

R

= 12 + (.577)(.25)

= 12 + (.577)(.25)

= 12 + .144

= 12 + .144

= 12.144

= 12.144 ounces

ounces

Process average x

Process average x = 12

= 12 ounces

ounces

Average range R

Average range R = .25

= .25

Sample size n

Sample size n = 5

= 5

From

From

Statistical

Statistical

Table

Table

26. © 2008 Prentice Hall, Inc. S6 – 26

Setting Control Limits

Setting Control Limits

UCL

UCLx

x = x + A

= x + A2

2R

R

= 12 + (.577)(.25)

= 12 + (.577)(.25)

= 12 + .144

= 12 + .144

= 12.144

= 12.144 ounces

ounces

LCL

LCLx

x = x - A

= x - A2

2R

R

= 12 - .144

= 12 - .144

= 11.857

= 11.857 ounces

ounces

Process average x

Process average x = 12

= 12 ounces

ounces

Average range R

Average range R = .25

= .25

Sample size n

Sample size n = 5

= 5

UCL = 12.144

UCL = 12.144

Mean = 12

Mean = 12

LCL = 11.857

LCL = 11.857

27. © 2008 Prentice Hall, Inc. S6 – 27

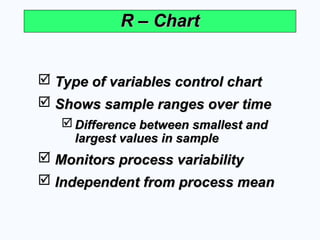

R – Chart

R – Chart

Type of variables control chart

Type of variables control chart

Shows sample ranges over time

Shows sample ranges over time

Difference between smallest and

Difference between smallest and

largest values in sample

largest values in sample

Monitors process variability

Monitors process variability

Independent from process mean

Independent from process mean

28. © 2008 Prentice Hall, Inc. S6 – 28

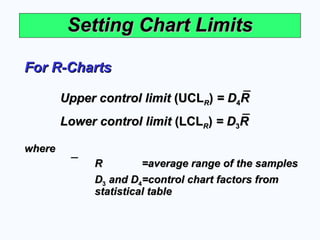

Setting Chart Limits

Setting Chart Limits

For R-Charts

For R-Charts

Lower control limit

Lower control limit (LCL

(LCLR

R)

) = D

= D3

3R

R

Upper control limit

Upper control limit (UCL

(UCLR

R)

) = D

= D4

4R

R

where

where

R

R =

=average range of the samples

average range of the samples

D

D3

3 and D

and D4

4=

=control chart factors from

control chart factors from

statistical table

statistical table

29. © 2008 Prentice Hall, Inc. S6 – 29

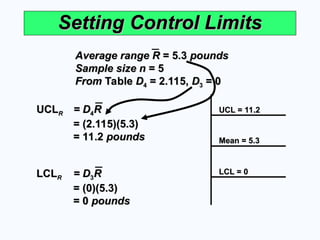

Setting Control Limits

Setting Control Limits

UCL

UCLR

R = D

= D4

4R

R

= (2.115)(5.3)

= (2.115)(5.3)

= 11.2

= 11.2 pounds

pounds

LCL

LCLR

R = D

= D3

3R

R

= (0)(5.3)

= (0)(5.3)

= 0

= 0 pounds

pounds

Average range R

Average range R = 5.3

= 5.3 pounds

pounds

Sample size n

Sample size n = 5

= 5

From

From Table

Table D

D4

4 = 2.115,

= 2.115, D

D3

3 = 0

= 0

UCL = 11.2

UCL = 11.2

Mean = 5.3

Mean = 5.3

LCL = 0

LCL = 0

30. © 2008 Prentice Hall, Inc. S6 – 30

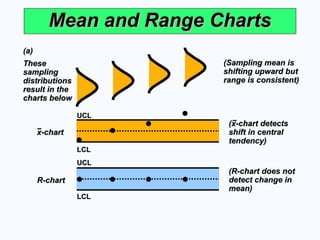

Mean and Range Charts

Mean and Range Charts

(a)

(a)

These

These

sampling

sampling

distributions

distributions

result in the

result in the

charts below

charts below

(Sampling mean is

(Sampling mean is

shifting upward but

shifting upward but

range is consistent)

range is consistent)

R-chart

R-chart

(R-chart does not

(R-chart does not

detect change in

detect change in

mean)

mean)

UCL

UCL

LCL

LCL

x-chart

x-chart

(x-chart detects

(x-chart detects

shift in central

shift in central

tendency)

tendency)

UCL

UCL

LCL

LCL

31. © 2008 Prentice Hall, Inc. S6 – 31

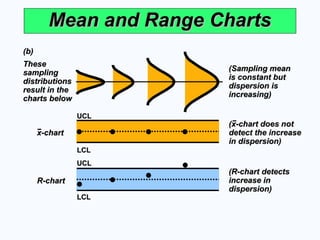

Mean and Range Charts

Mean and Range Charts

R-chart

R-chart

(R-chart detects

(R-chart detects

increase in

increase in

dispersion)

dispersion)

UCL

UCL

LCL

LCL

(b)

(b)

These

These

sampling

sampling

distributions

distributions

result in the

result in the

charts below

charts below

(Sampling mean

(Sampling mean

is constant but

is constant but

dispersion is

dispersion is

increasing)

increasing)

x-chart

x-chart

(x-chart does not

(x-chart does not

detect the increase

detect the increase

in dispersion)

in dispersion)

UCL

UCL

LCL

LCL

32. © 2008 Prentice Hall, Inc. S6 – 32

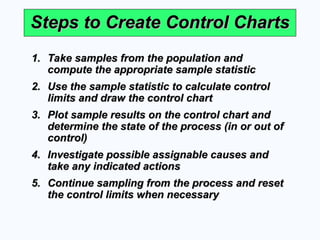

Steps to Create Control Charts

Steps to Create Control Charts

1.

1. Take samples from the population and

Take samples from the population and

compute the appropriate sample statistic

compute the appropriate sample statistic

2.

2. Use the sample statistic to calculate control

Use the sample statistic to calculate control

limits and draw the control chart

limits and draw the control chart

3.

3. Plot sample results on the control chart and

Plot sample results on the control chart and

determine the state of the process (in or out of

determine the state of the process (in or out of

control)

control)

4.

4. Investigate possible assignable causes and

Investigate possible assignable causes and

take any indicated actions

take any indicated actions

5.

5. Continue sampling from the process and reset

Continue sampling from the process and reset

the control limits when necessary

the control limits when necessary

33. © 2008 Prentice Hall, Inc. S6 – 33

Manual and Automated

Manual and Automated

Control Charts

Control Charts

34. © 2008 Prentice Hall, Inc. S6 – 34

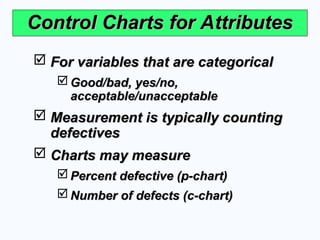

Control Charts for Attributes

Control Charts for Attributes

For variables that are categorical

For variables that are categorical

Good/bad, yes/no,

Good/bad, yes/no,

acceptable/unacceptable

acceptable/unacceptable

Measurement is typically counting

Measurement is typically counting

defectives

defectives

Charts may measure

Charts may measure

Percent defective (p-chart)

Percent defective (p-chart)

Number of defects (c-chart)

Number of defects (c-chart)

35. © 2008 Prentice Hall, Inc. S6 – 35

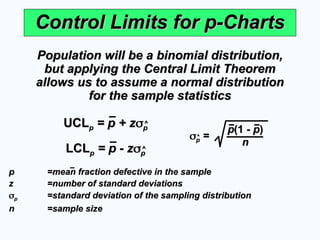

Control Limits for p-Charts

Control Limits for p-Charts

Population will be a binomial distribution,

Population will be a binomial distribution,

but applying the Central Limit Theorem

but applying the Central Limit Theorem

allows us to assume a normal distribution

allows us to assume a normal distribution

for the sample statistics

for the sample statistics

UCL

UCLp

p = p + z

= p + z

p

p

^

^

LCL

LCLp

p = p - z

= p - z

p

p

^

^

p

p =

=mean fraction defective in the sample

mean fraction defective in the sample

z

z =

=number of standard deviations

number of standard deviations

p

p =

=standard deviation of the sampling distribution

standard deviation of the sampling distribution

n

n =

=sample size

sample size

^

^

p

p(1 -

(1 - p

p)

)

n

n

p

p =

=

^

^

36. © 2008 Prentice Hall, Inc. S6 – 36

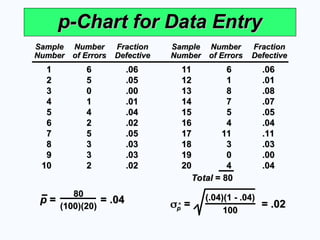

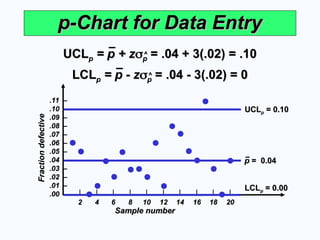

p-Chart for Data Entry

p-Chart for Data Entry

Sample

Sample Number

Number Fraction

Fraction Sample

Sample Number

Number Fraction

Fraction

Number

Number of Errors

of Errors Defective

Defective Number

Number of Errors

of Errors Defective

Defective

1

1 6

6 .06

.06 11

11 6

6 .06

.06

2

2 5

5 .05

.05 12

12 1

1 .01

.01

3

3 0

0 .00

.00 13

13 8

8 .08

.08

4

4 1

1 .01

.01 14

14 7

7 .07

.07

5

5 4

4 .04

.04 15

15 5

5 .05

.05

6

6 2

2 .02

.02 16

16 4

4 .04

.04

7

7 5

5 .05

.05 17

17 11

11 .11

.11

8

8 3

3 .03

.03 18

18 3

3 .03

.03

9

9 3

3 .03

.03 19

19 0

0 .00

.00

10

10 2

2 .02

.02 20

20 4

4 .04

.04

Total

Total = 80

= 80

(.04)(1 - .04)

(.04)(1 - .04)

100

100

p

p =

= = .02

= .02

^

^

p

p = = .04

= = .04

80

80

(100)(20)

(100)(20)

37. © 2008 Prentice Hall, Inc. S6 – 37

.11

.11 –

.10

.10 –

.09

.09 –

.08

.08 –

.07

.07 –

.06

.06 –

.05

.05 –

.04

.04 –

.03

.03 –

.02

.02 –

.01

.01 –

.00

.00 –

Sample number

Sample number

Fraction

defective

Fraction

defective

| | | | | | | | | |

2

2 4

4 6

6 8

8 10

10 12

12 14

14 16

16 18

18 20

20

p-Chart for Data Entry

p-Chart for Data Entry

UCL

UCLp

p = p + z

= p + z

p

p = .04 + 3(.02) = .10

= .04 + 3(.02) = .10

^

^

LCL

LCLp

p = p - z

= p - z

p

p = .04 - 3(.02) = 0

= .04 - 3(.02) = 0

^

^

UCL

UCLp

p = 0.10

= 0.10

LCL

LCLp

p = 0.00

= 0.00

p

p = 0.04

= 0.04

38. © 2008 Prentice Hall, Inc. S6 – 38

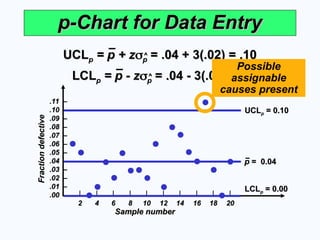

p-Chart for Data Entry

p-Chart for Data Entry

.11

.11 –

.10

.10 –

.09

.09 –

.08

.08 –

.07

.07 –

.06

.06 –

.05

.05 –

.04

.04 –

.03

.03 –

.02

.02 –

.01

.01 –

.00

.00 –

Sample number

Sample number

Fraction

defective

Fraction

defective

| | | | | | | | | |

2

2 4

4 6

6 8

8 10

10 12

12 14

14 16

16 18

18 20

20

UCL

UCLp

p = p + z

= p + z

p

p = .04 + 3(.02) = .10

= .04 + 3(.02) = .10

^

^

LCL

LCLp

p = p - z

= p - z

p

p = .04 - 3(.02) = 0

= .04 - 3(.02) = 0

^

^

UCL

UCLp

p = 0.10

= 0.10

LCL

LCLp

p = 0.00

= 0.00

p

p = 0.04

= 0.04

Possible

assignable

causes present

39. © 2008 Prentice Hall, Inc. S6 – 39

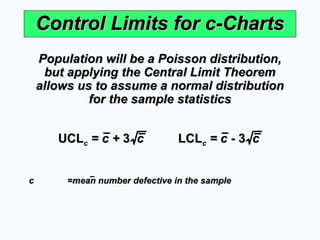

Control Limits for c-Charts

Control Limits for c-Charts

Population will be a Poisson distribution,

Population will be a Poisson distribution,

but applying the Central Limit Theorem

but applying the Central Limit Theorem

allows us to assume a normal distribution

allows us to assume a normal distribution

for the sample statistics

for the sample statistics

c

c =

=mean number defective in the sample

mean number defective in the sample

UCL

UCLc

c = c +

= c + 3

3 c

c LCL

LCLc

c = c

= c -

- 3

3 c

c

40. © 2008 Prentice Hall, Inc. S6 – 40

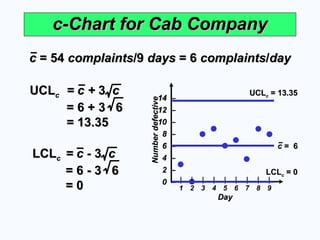

c-Chart for Cab Company

c-Chart for Cab Company

c

c = 54

= 54 complaints

complaints/9

/9 days

days = 6

= 6 complaints

complaints/

/day

day

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

Day

Day

Number

defective

Number

defective

14

14 –

12

12 –

10

10 –

8

8 –

6

6 –

4 –

2 –

0

0 –

UCL

UCLc

c = c +

= c + 3

3 c

c

= 6 + 3 6

= 6 + 3 6

= 13.35

= 13.35

LCL

LCLc

c = c -

= c - 3

3 c

c

= 6 - 3 6

= 6 - 3 6

= 0

= 0

UCL

UCLc

c = 13.35

= 13.35

LCL

LCLc

c = 0

= 0

c

c = 6

= 6

41. © 2008 Prentice Hall, Inc. S6 – 41

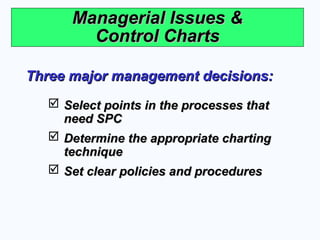

Managerial Issues &

Managerial Issues &

Control Charts

Control Charts

Select points in the processes that

Select points in the processes that

need SPC

need SPC

Determine the appropriate charting

Determine the appropriate charting

technique

technique

Set clear policies and procedures

Set clear policies and procedures

Three major management decisions:

Three major management decisions:

42. © 2008 Prentice Hall, Inc. S6 – 42

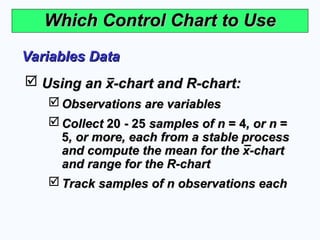

Which Control Chart to Use

Which Control Chart to Use

Using an x-chart and R-chart:

Using an x-chart and R-chart:

Observations are variables

Observations are variables

Collect

Collect 20 - 25

20 - 25 samples of n

samples of n = 4

= 4, or n

, or n =

=

5

5, or more, each from a stable process

, or more, each from a stable process

and compute the mean for the x-chart

and compute the mean for the x-chart

and range for the R-chart

and range for the R-chart

Track samples of n observations each

Track samples of n observations each

Variables Data

Variables Data

43. © 2008 Prentice Hall, Inc. S6 – 43

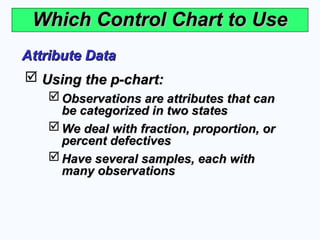

Which Control Chart to Use

Which Control Chart to Use

Using the p-chart:

Using the p-chart:

Observations are attributes that can

Observations are attributes that can

be categorized in two states

be categorized in two states

We deal with fraction, proportion, or

We deal with fraction, proportion, or

percent defectives

percent defectives

Have several samples, each with

Have several samples, each with

many observations

many observations

Attribute Data

Attribute Data

44. © 2008 Prentice Hall, Inc. S6 – 44

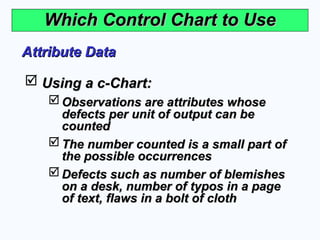

Which Control Chart to Use

Which Control Chart to Use

Using a c-Chart:

Using a c-Chart:

Observations are attributes whose

Observations are attributes whose

defects per unit of output can be

defects per unit of output can be

counted

counted

The number counted is a small part of

The number counted is a small part of

the possible occurrences

the possible occurrences

Defects such as number of blemishes

Defects such as number of blemishes

on a desk, number of typos in a page

on a desk, number of typos in a page

of text, flaws in a bolt of cloth

of text, flaws in a bolt of cloth

Attribute Data

Attribute Data

45. © 2008 Prentice Hall, Inc. S6 – 45

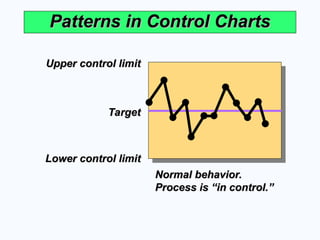

Patterns in Control Charts

Patterns in Control Charts

Normal behavior.

Normal behavior.

Process is “in control.”

Process is “in control.”

Upper control limit

Upper control limit

Target

Target

Lower control limit

Lower control limit

46. © 2008 Prentice Hall, Inc. S6 – 46

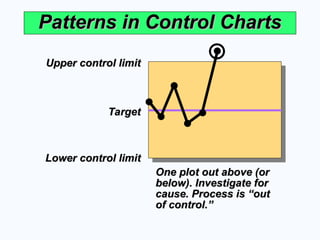

Patterns in Control Charts

Patterns in Control Charts

Upper control limit

Upper control limit

Target

Target

Lower control limit

Lower control limit

One plot out above (or

One plot out above (or

below). Investigate for

below). Investigate for

cause. Process is “out

cause. Process is “out

of control.”

of control.”

47. © 2008 Prentice Hall, Inc. S6 – 47

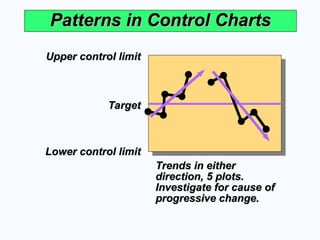

Upper control limit

Upper control limit

Target

Target

Lower control limit

Lower control limit

Patterns in Control Charts

Patterns in Control Charts

Trends in either

Trends in either

direction, 5 plots.

direction, 5 plots.

Investigate for cause of

Investigate for cause of

progressive change.

progressive change.

48. © 2008 Prentice Hall, Inc. S6 – 48

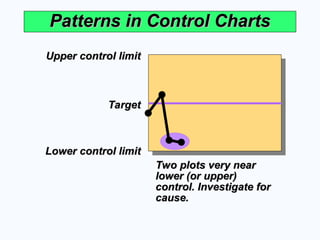

Patterns in Control Charts

Patterns in Control Charts

Upper control limit

Upper control limit

Target

Target

Lower control limit

Lower control limit

Two plots very near

Two plots very near

lower (or upper)

lower (or upper)

control. Investigate for

control. Investigate for

cause.

cause.

49. © 2008 Prentice Hall, Inc. S6 – 49

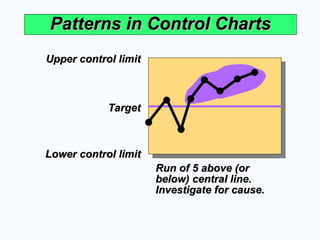

Patterns in Control Charts

Patterns in Control Charts

Upper control limit

Upper control limit

Target

Target

Lower control limit

Lower control limit

Run of 5 above (or

Run of 5 above (or

below) central line.

below) central line.

Investigate for cause.

Investigate for cause.

50. © 2008 Prentice Hall, Inc. S6 – 50

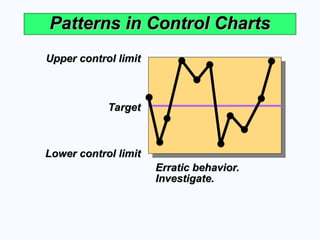

Patterns in Control Charts

Patterns in Control Charts

Upper control limit

Upper control limit

Target

Target

Lower control limit

Lower control limit

Erratic behavior.

Erratic behavior.

Investigate.

Investigate.

51. © 2008 Prentice Hall, Inc. S6 – 51

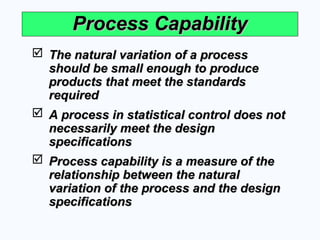

Process Capability

Process Capability

The natural variation of a process

The natural variation of a process

should be small enough to produce

should be small enough to produce

products that meet the standards

products that meet the standards

required

required

A process in statistical control does not

A process in statistical control does not

necessarily meet the design

necessarily meet the design

specifications

specifications

Process capability is a measure of the

Process capability is a measure of the

relationship between the natural

relationship between the natural

variation of the process and the design

variation of the process and the design

specifications

specifications

52. © 2008 Prentice Hall, Inc. S6 – 52

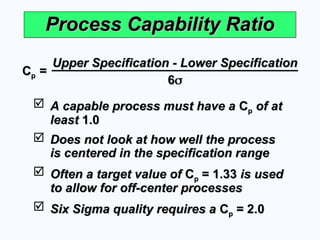

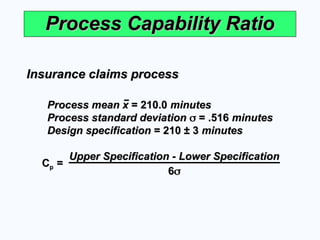

Process Capability Ratio

Process Capability Ratio

C

Cp

p =

=

Upper Specification - Lower Specification

Upper Specification - Lower Specification

6

6

A capable process must have a

A capable process must have a C

Cp

p of at

of at

least

least 1.0

1.0

Does not look at how well the process

Does not look at how well the process

is centered in the specification range

is centered in the specification range

Often a target value of

Often a target value of C

Cp

p = 1.33

= 1.33 is used

is used

to allow for off-center processes

to allow for off-center processes

Six Sigma quality requires a

Six Sigma quality requires a C

Cp

p = 2.0

= 2.0

53. © 2008 Prentice Hall, Inc. S6 – 53

Process Capability Ratio

Process Capability Ratio

C

Cp

p =

=

Upper Specification - Lower Specification

Upper Specification - Lower Specification

6

6

Insurance claims process

Insurance claims process

Process mean x

Process mean x = 210.0

= 210.0 minutes

minutes

Process standard deviation

Process standard deviation

= .516

= .516 minutes

minutes

Design specification

Design specification = 210 ± 3

= 210 ± 3 minutes

minutes

54. © 2008 Prentice Hall, Inc. S6 – 54

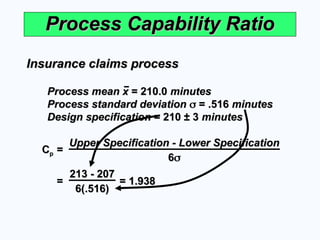

Process Capability Ratio

Process Capability Ratio

C

Cp

p =

=

Upper Specification - Lower Specification

Upper Specification - Lower Specification

6

6

Insurance claims process

Insurance claims process

Process mean x

Process mean x = 210.0

= 210.0 minutes

minutes

Process standard deviation

Process standard deviation

= .516

= .516 minutes

minutes

Design specification

Design specification = 210 ± 3

= 210 ± 3 minutes

minutes

= = 1.938

= = 1.938

213 - 207

213 - 207

6(.516)

6(.516)

55. © 2008 Prentice Hall, Inc. S6 – 55

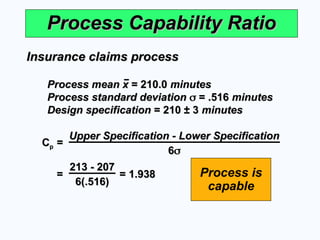

Process Capability Ratio

Process Capability Ratio

C

Cp

p =

=

Upper Specification - Lower Specification

Upper Specification - Lower Specification

6

6

Insurance claims process

Insurance claims process

Process mean x

Process mean x = 210.0

= 210.0 minutes

minutes

Process standard deviation

Process standard deviation

= .516

= .516 minutes

minutes

Design specification

Design specification = 210 ± 3

= 210 ± 3 minutes

minutes

= = 1.938

= = 1.938

213 - 207

213 - 207

6(.516)

6(.516)

Process is

capable

56. © 2008 Prentice Hall, Inc. S6 – 56

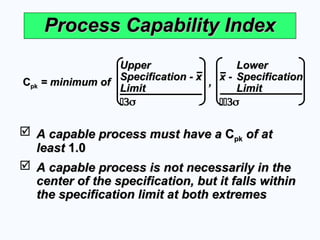

Process Capability Index

Process Capability Index

A capable process must have a

A capable process must have a C

Cpk

pk of at

of at

least

least 1.0

1.0

A capable process is not necessarily in the

A capable process is not necessarily in the

center of the specification, but it falls within

center of the specification, but it falls within

the specification limit at both extremes

the specification limit at both extremes

C

Cpk

pk = minimum of ,

= minimum of ,

Upper

Upper

Specification - x

Specification - x

Limit

Limit

Lower

Lower

x -

x - Specification

Specification

Limit

Limit

57. © 2008 Prentice Hall, Inc. S6 – 57

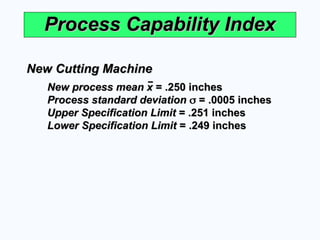

Process Capability Index

Process Capability Index

New Cutting Machine

New Cutting Machine

New process mean x

New process mean x = .250 inches

= .250 inches

Process standard deviation

Process standard deviation

= .0005 inches

= .0005 inches

Upper Specification Limit

Upper Specification Limit = .251 inches

= .251 inches

Lower Specification Limit

Lower Specification Limit = .249 inches

= .249 inches

58. © 2008 Prentice Hall, Inc. S6 – 58

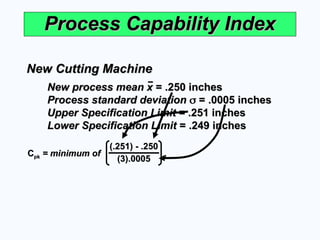

Process Capability Index

Process Capability Index

New Cutting Machine

New Cutting Machine

New process mean x

New process mean x = .250 inches

= .250 inches

Process standard deviation

Process standard deviation

= .0005 inches

= .0005 inches

Upper Specification Limit

Upper Specification Limit = .251 inches

= .251 inches

Lower Specification Limit

Lower Specification Limit = .249 inches

= .249 inches

C

Cpk

pk = minimum of ,

= minimum of ,

(.251) - .250

(.251) - .250

(3).0005

(3).0005

59. © 2008 Prentice Hall, Inc. S6 – 59

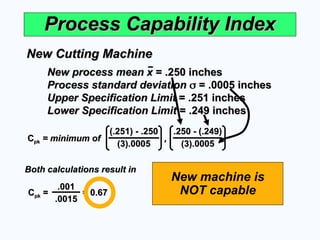

Process Capability Index

Process Capability Index

New Cutting Machine

New Cutting Machine

New process mean x

New process mean x = .250 inches

= .250 inches

Process standard deviation

Process standard deviation

= .0005 inches

= .0005 inches

Upper Specification Limit

Upper Specification Limit = .251 inches

= .251 inches

Lower Specification Limit

Lower Specification Limit = .249 inches

= .249 inches

C

Cpk

pk = = 0.67

= = 0.67

.001

.001

.0015

.0015

New machine is

NOT capable

C

Cpk

pk = minimum of ,

= minimum of ,

(.251) - .250

(.251) - .250

(3).0005

(3).0005

.250 - (.249)

.250 - (.249)

(3).0005

(3).0005

Both calculations result in

Both calculations result in

60. © 2008 Prentice Hall, Inc. S6 – 60

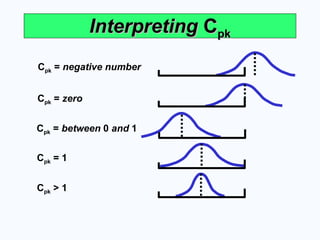

Interpreting

Interpreting C

Cpk

pk

Cpk = negative number

Cpk = zero

Cpk = between 0 and 1

Cpk = 1

Cpk > 1

61. © 2008 Prentice Hall, Inc. S6 – 61

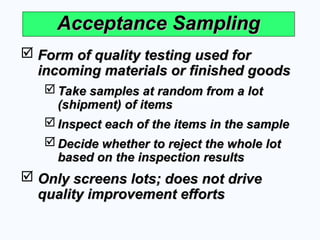

Acceptance Sampling

Acceptance Sampling

Form of quality testing used for

Form of quality testing used for

incoming materials or finished goods

incoming materials or finished goods

Take samples at random from a lot

Take samples at random from a lot

(shipment) of items

(shipment) of items

Inspect each of the items in the sample

Inspect each of the items in the sample

Decide whether to reject the whole lot

Decide whether to reject the whole lot

based on the inspection results

based on the inspection results

Only screens lots; does not drive

Only screens lots; does not drive

quality improvement efforts

quality improvement efforts

62. © 2008 Prentice Hall, Inc. S6 – 62

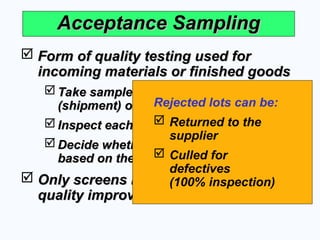

Acceptance Sampling

Acceptance Sampling

Form of quality testing used for

Form of quality testing used for

incoming materials or finished goods

incoming materials or finished goods

Take samples at random from a lot

Take samples at random from a lot

(shipment) of items

(shipment) of items

Inspect each of the items in the sample

Inspect each of the items in the sample

Decide whether to reject the whole lot

Decide whether to reject the whole lot

based on the inspection results

based on the inspection results

Only screens lots; does not drive

Only screens lots; does not drive

quality improvement efforts

quality improvement efforts

Rejected lots can be:

Returned to the

supplier

Culled for

defectives

(100% inspection)

63. © 2008 Prentice Hall, Inc. S6 – 63

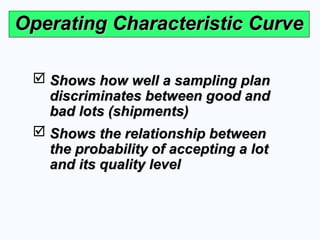

Operating Characteristic Curve

Operating Characteristic Curve

Shows how well a sampling plan

Shows how well a sampling plan

discriminates between good and

discriminates between good and

bad lots (shipments)

bad lots (shipments)

Shows the relationship between

Shows the relationship between

the probability of accepting a lot

the probability of accepting a lot

and its quality level

and its quality level

64. © 2008 Prentice Hall, Inc. S6 – 64

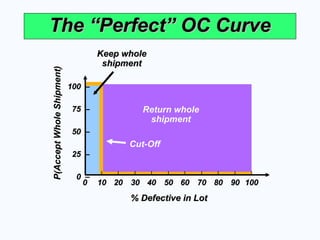

The “Perfect” OC Curve

The “Perfect” OC Curve

Return whole

shipment

% Defective in Lot

% Defective in Lot

P(Accept

Whole

Shipment)

P(Accept

Whole

Shipment)

100

100 –

75

75 –

50

50 –

25

25 –

0

0 –

| | | | | | | | | | |

0

0 10

10 20

20 30

30 40

40 50

50 60

60 70

70 80

80 90

90 100

100

Cut-Off

Keep whole

Keep whole

shipment

shipment

65. © 2008 Prentice Hall, Inc. S6 – 65

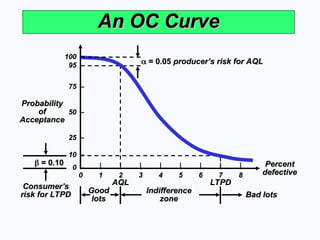

An OC Curve

An OC Curve

Probability

Probability

of

of

Acceptance

Acceptance

Percent

Percent

defective

defective

| | | | | | | | |

0

0 1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8

100

100 –

95

95 –

75

75 –

50

50 –

25

25 –

10

10 –

0

0 –

= 0.05

= 0.05 producer’s risk for AQL

producer’s risk for AQL

= 0.10

= 0.10

Consumer’s

Consumer’s

risk for LTPD

risk for LTPD

LTPD

LTPD

AQL

AQL

Bad lots

Bad lots

Indifference

Indifference

zone

zone

Good

Good

lots

lots

66. © 2008 Prentice Hall, Inc. S6 – 66

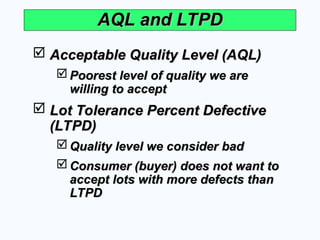

AQL and LTPD

AQL and LTPD

Acceptable Quality Level (AQL)

Acceptable Quality Level (AQL)

Poorest level of quality we are

Poorest level of quality we are

willing to accept

willing to accept

Lot Tolerance Percent Defective

Lot Tolerance Percent Defective

(LTPD)

(LTPD)

Quality level we consider bad

Quality level we consider bad

Consumer (buyer) does not want to

Consumer (buyer) does not want to

accept lots with more defects than

accept lots with more defects than

LTPD

LTPD

67. © 2008 Prentice Hall, Inc. S6 – 67

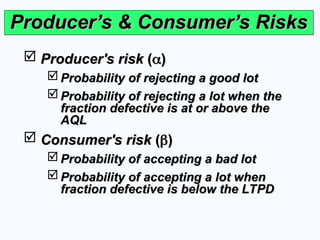

Producer’s & Consumer’s Risks

Producer’s & Consumer’s Risks

Producer's risk

Producer's risk (

(

)

)

Probability of rejecting a good lot

Probability of rejecting a good lot

Probability of rejecting a lot when the

Probability of rejecting a lot when the

fraction defective is at or above the

fraction defective is at or above the

AQL

AQL

Consumer's risk

Consumer's risk (

(

)

)

Probability of accepting a bad lot

Probability of accepting a bad lot

Probability of accepting a lot when

Probability of accepting a lot when

fraction defective is below the LTPD

fraction defective is below the LTPD

68. © 2008 Prentice Hall, Inc. S6 – 68

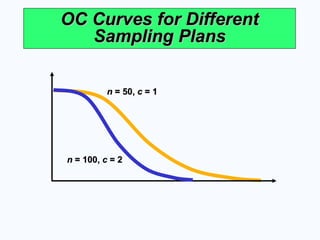

OC Curves for Different

OC Curves for Different

Sampling Plans

Sampling Plans

n

n = 50,

= 50, c

c = 1

= 1

n

n = 100,

= 100, c

c = 2

= 2

69. © 2008 Prentice Hall, Inc. S6 – 69

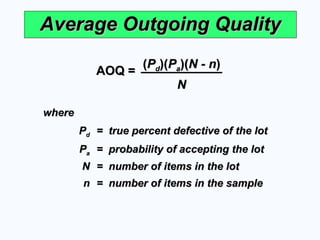

Average Outgoing Quality

Average Outgoing Quality

where

where

P

Pd

d = true percent defective of the lot

= true percent defective of the lot

P

Pa

a = probability of accepting the lot

= probability of accepting the lot

N

N = number of items in the lot

= number of items in the lot

n

n = number of items in the sample

= number of items in the sample

AOQ =

AOQ = (

(P

Pd

d)(

)(P

Pa

a)(

)(N - n

N - n)

)

N

N

70. © 2008 Prentice Hall, Inc. S6 – 70

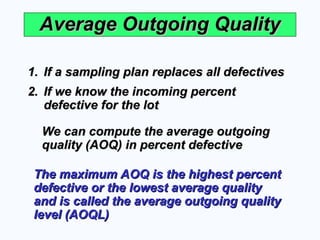

Average Outgoing Quality

Average Outgoing Quality

1.

1. If a sampling plan replaces all defectives

If a sampling plan replaces all defectives

2.

2. If we know the incoming percent

If we know the incoming percent

defective for the lot

defective for the lot

We can compute the average outgoing

We can compute the average outgoing

quality (AOQ) in percent defective

quality (AOQ) in percent defective

The maximum AOQ is the highest percent

The maximum AOQ is the highest percent

defective or the lowest average quality

defective or the lowest average quality

and is called the average outgoing quality

and is called the average outgoing quality

level (AOQL)

level (AOQL)

71. © 2008 Prentice Hall, Inc. S6 – 71

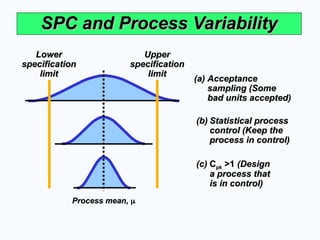

SPC and Process Variability

SPC and Process Variability

(a)

(a) Acceptance

Acceptance

sampling (Some

sampling (Some

bad units accepted)

bad units accepted)

(b)

(b) Statistical process

Statistical process

control (Keep the

control (Keep the

process in control)

process in control)

(c)

(c) C

Cpk

pk >1

>1 (Design

(Design

a process that

a process that

is in control)

is in control)

Lower

Lower

specification

specification

limit

limit

Upper

Upper

specification

specification

limit

limit

Process mean,

Process mean,

72. © 2008 Prentice Hall, Inc. S6 – 72

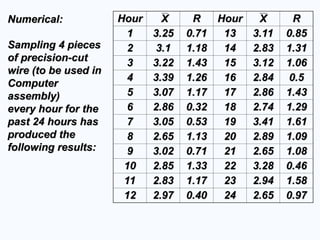

Numerical:

Numerical:

Sampling 4 pieces

Sampling 4 pieces

of precision-cut

of precision-cut

wire (to be used in

wire (to be used in

Computer

Computer

assembly)

assembly)

every hour for the

every hour for the

past 24 hours has

past 24 hours has

produced the

produced the

following results:

following results:

Hour

Hour X

X R

R Hour

Hour X

X R

R

1

1 3.25

3.25 0.71

0.71 13

13 3.11

3.11 0.85

0.85

2

2 3.1

3.1 1.18

1.18 14

14 2.83

2.83 1.31

1.31

3

3 3.22

3.22 1.43

1.43 15

15 3.12

3.12 1.06

1.06

4

4 3.39

3.39 1.26

1.26 16

16 2.84

2.84 0.5

0.5

5

5 3.07

3.07 1.17

1.17 17

17 2.86

2.86 1.43

1.43

6

6 2.86

2.86 0.32

0.32 18

18 2.74

2.74 1.29

1.29

7

7 3.05

3.05 0.53

0.53 19

19 3.41

3.41 1.61

1.61

8

8 2.65

2.65 1.13

1.13 20

20 2.89

2.89 1.09

1.09

9

9 3.02

3.02 0.71

0.71 21

21 2.65

2.65 1.08

1.08

10

10 2.85

2.85 1.33

1.33 22

22 3.28

3.28 0.46

0.46

11

11 2.83

2.83 1.17

1.17 23

23 2.94

2.94 1.58

1.58

12

12 2.97

2.97 0.40

0.40 24

24 2.65

2.65 0.97

0.97

73. © 2008 Prentice Hall, Inc. S6 – 73

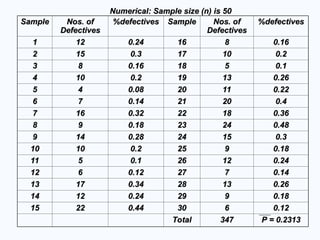

Sample

Sample Nos. of

Nos. of

Defectives

Defectives

%defectives

%defectives Sample

Sample Nos. of

Nos. of

Defectives

Defectives

%defectives

%defectives

1

1 12

12 0.24

0.24 16

16 8

8 0.16

0.16

2

2 15

15 0.3

0.3 17

17 10

10 0.2

0.2

3

3 8

8 0.16

0.16 18

18 5

5 0.1

0.1

4

4 10

10 0.2

0.2 19

19 13

13 0.26

0.26

5

5 4

4 0.08

0.08 20

20 11

11 0.22

0.22

6

6 7

7 0.14

0.14 21

21 20

20 0.4

0.4

7

7 16

16 0.32

0.32 22

22 18

18 0.36

0.36

8

8 9

9 0.18

0.18 23

23 24

24 0.48

0.48

9

9 14

14 0.28

0.28 24

24 15

15 0.3

0.3

10

10 10

10 0.2

0.2 25

25 9

9 0.18

0.18

11

11 5

5 0.1

0.1 26

26 12

12 0.24

0.24

12

12 6

6 0.12

0.12 27

27 7

7 0.14

0.14

13

13 17

17 0.34

0.34 28

28 13

13 0.26

0.26

14

14 12

12 0.24

0.24 29

29 9

9 0.18

0.18

15

15 22

22 0.44

0.44 30

30 6

6 0.12

0.12

Total

Total 347

347 P = 0.2313

P = 0.2313

Numerical: Sample size (n) is 50

Numerical: Sample size (n) is 50

74. © 2008 Prentice Hall, Inc. S6 – 74

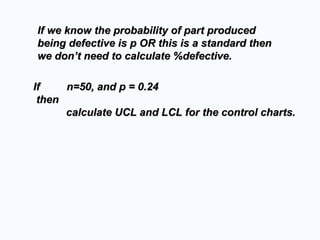

If we know the probability of part produced

If we know the probability of part produced

being defective is p OR this is a standard then

being defective is p OR this is a standard then

we don’t need to calculate %defective.

we don’t need to calculate %defective.

If n=50, and p = 0.24

If n=50, and p = 0.24

then

then

calculate UCL and LCL for the control charts.

calculate UCL and LCL for the control charts.

Editor's Notes #4 Points which might be emphasized include:

- Statistical process control measures the performance of a process, it does not help to identify a particular specimen produced as being “good” or “bad,” in or out of tolerance.

- Statistical process control requires the collection and analysis of data - therefore it is not helpful when total production consists of a small number of units

- While statistical process control can not help identify a “good” or “bad” unit, it can enable one to decide whether or not to accept an entire production lot. If a sample of a production lot contains more than a specified number of defective items, statistical process control can give us a basis for rejecting the entire lot. The issue of rejecting a lot which was actually good can be raised here, but is probably better left to later. #12 Students should understand both the concepts of natural and assignable variation, and the nature of the efforts required to deal with them. #13 This slide helps introduce different process outputs.

It can also be used to illustrate natural and assignable variation. #14 Once the categories are outlined, students may be asked to provide examples of items for which variable or attribute inspection might be appropriate. They might also be asked to provide examples of products for which both characteristics might be important at different stages of the production process. #15 This slide introduces the difference between “natural” and “assignable” causes.

The next several slides expand the discussion and introduce some of the statistical issues. #17 It may be useful to spend some time explicitly discussing the difference between the sampling distribution of the means and the mean of the process population. #35 Instructors may wish to point out the calculation of the standard deviation reflects the binomial distribution of the population #38 There is always a focus on finding and eliminating problems. But control charts find any process changed, good or bad. The clever company will be looking at Operator 3 and 19 as they reported no errors during this period. The company should find out why (find the assignable cause) and see if there are skills or processes that can be applied to the other operators.

#39 Instructors may wish to point out the calculation of the standard deviation reflects the Poisson distribution of the population where the standard deviation equals the square root of the mean #45 Ask the students to imagine a product, and consider what problem might cause each of the graph configurations illustrated. #46 Ask the students to imagine a product, and consider what problem might cause each of the graph configurations illustrated. #47 Ask the students to imagine a product, and consider what problem might cause each of the graph configurations illustrated. #48 Ask the students to imagine a product, and consider what problem might cause each of the graph configurations illustrated. #49 Ask the students to imagine a product, and consider what problem might cause each of the graph configurations illustrated. #50 Ask the students to imagine a product, and consider what problem might cause each of the graph configurations illustrated. #61 Here again it is useful to stress that acceptance sampling relates to the aggregate, not the individual unit. You might also discuss the decision as to whether one should take only a single sample, or whether multiple samples are required. #62 Here again it is useful to stress that acceptance sampling relates to the aggregate, not the individual unit. You might also discuss the decision as to whether one should take only a single sample, or whether multiple samples are required. #63 You can use this and the next several slides to begin a discussion of the “quality” of the acceptance sampling plans. You will find additional slides on “consumer’s” and “producer’s” risk to pursue the issue in a more formal manner in subsequent slides. #66 Once the students understand the definition of these terms, have them consider how one would go about choosing values for AQL and LTPD. #67 This slide introduces the concept of “producer’s” risk and “consumer’s” risk. The following slide explores these concepts graphically. #68 This slide presents the OC curve for two possible acceptance sampling plans. #69 It is probably important to stress that AOQ is the average percent defective, not the average percent acceptable. #70 It is probably important to stress that AOQ is the average percent defective, not the average percent acceptable. #71 This may be a good time to stress that an overall goal of statistical process control is to “do it better,” i.e., improve over time.