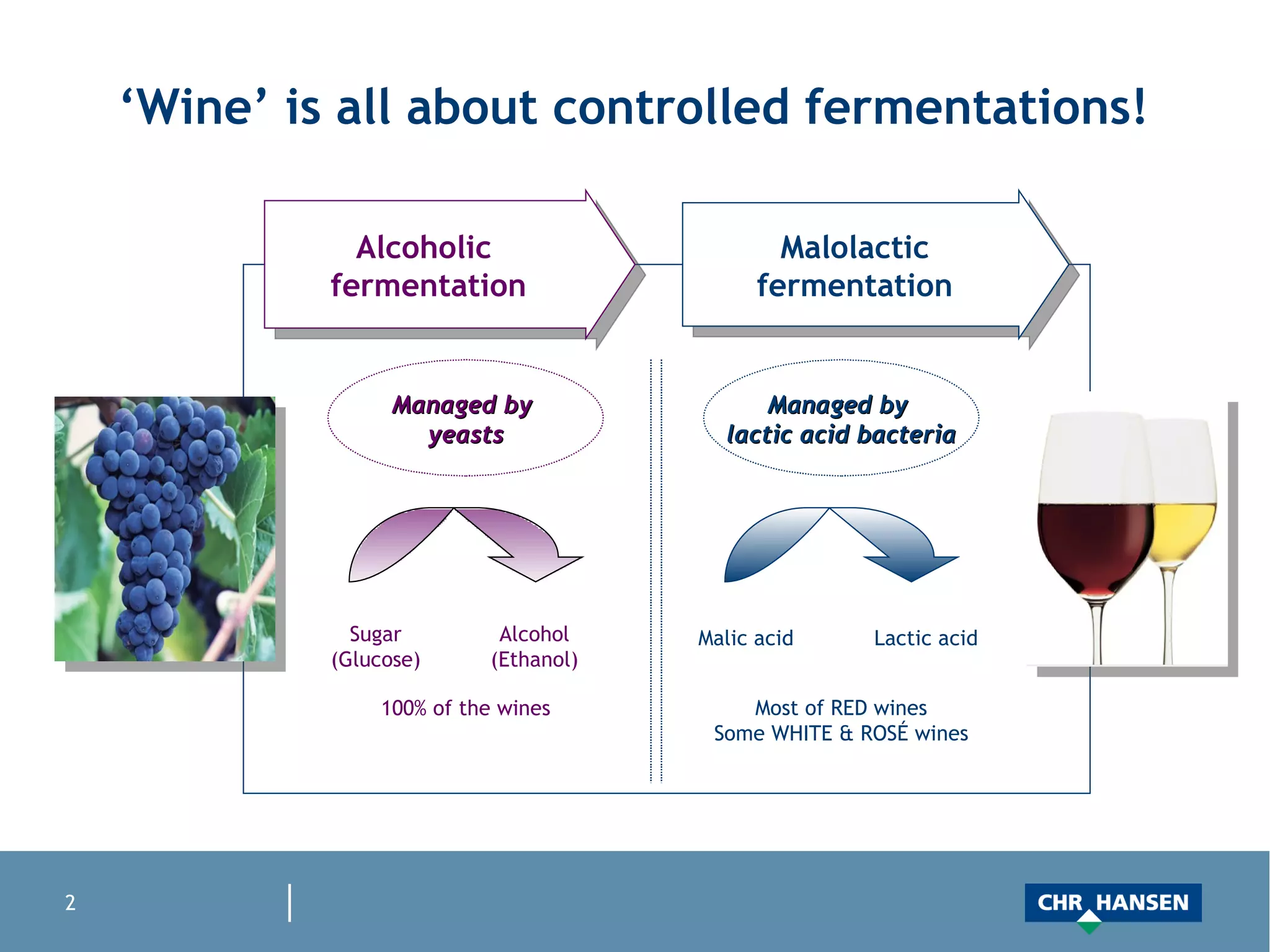

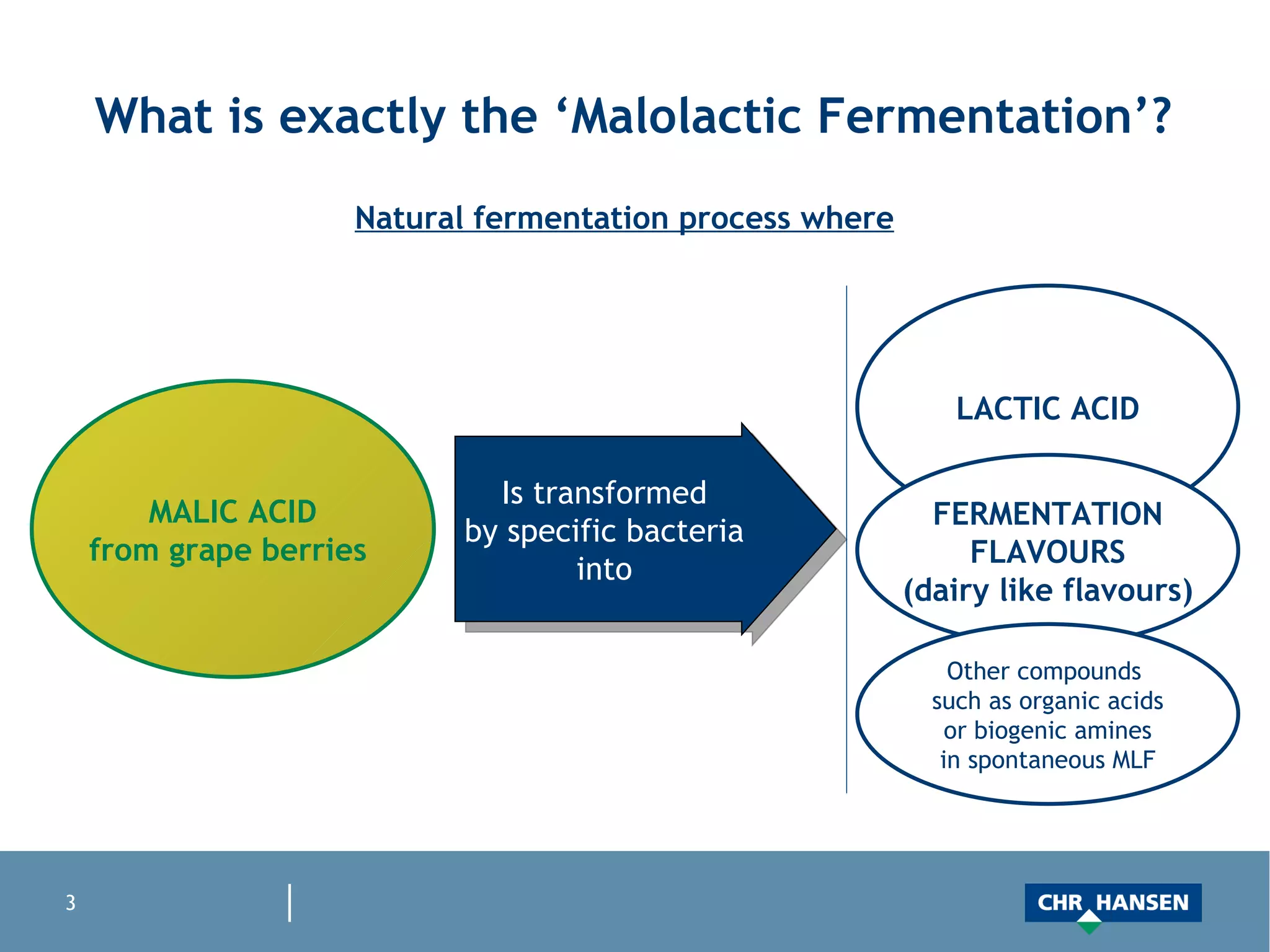

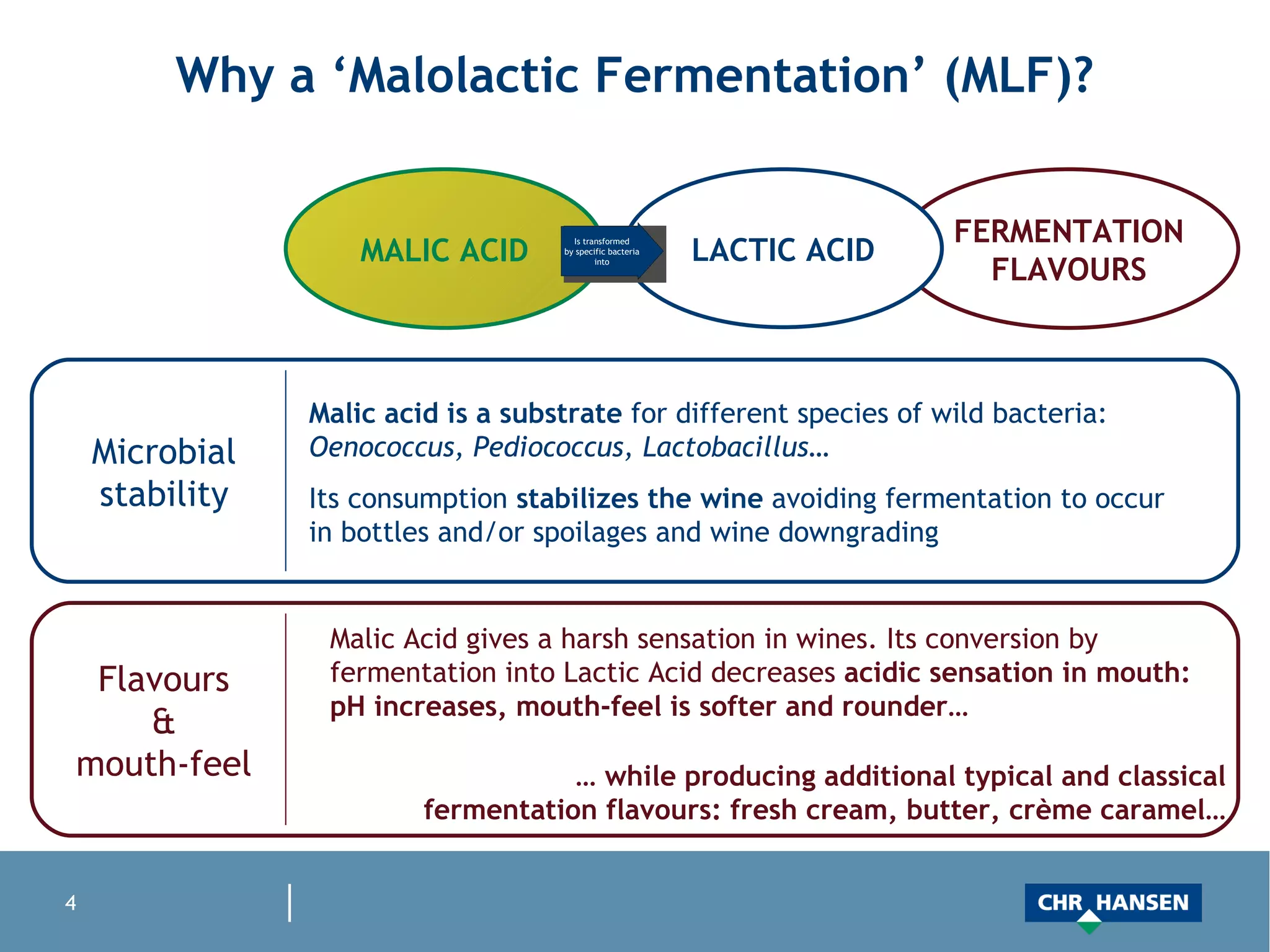

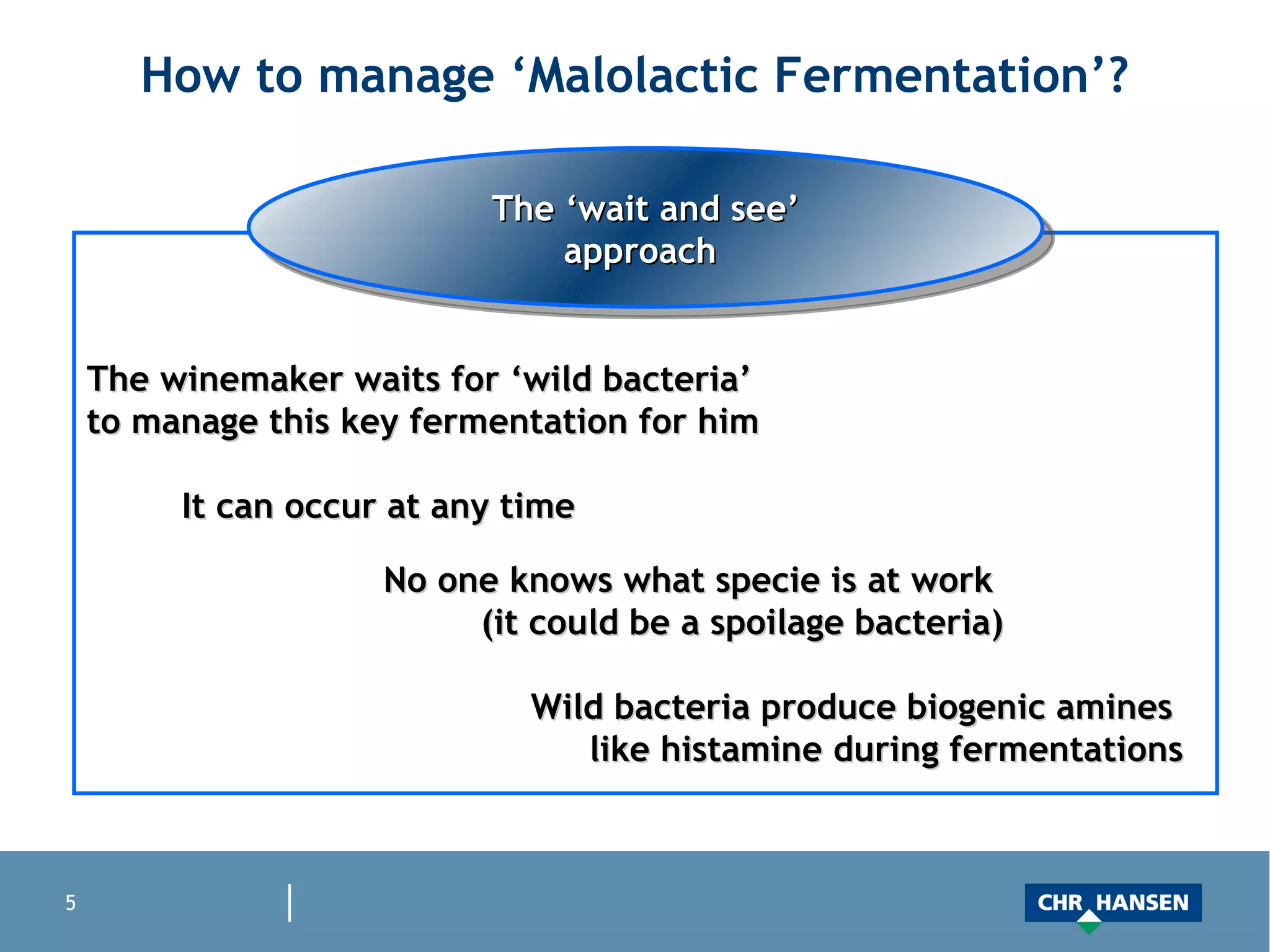

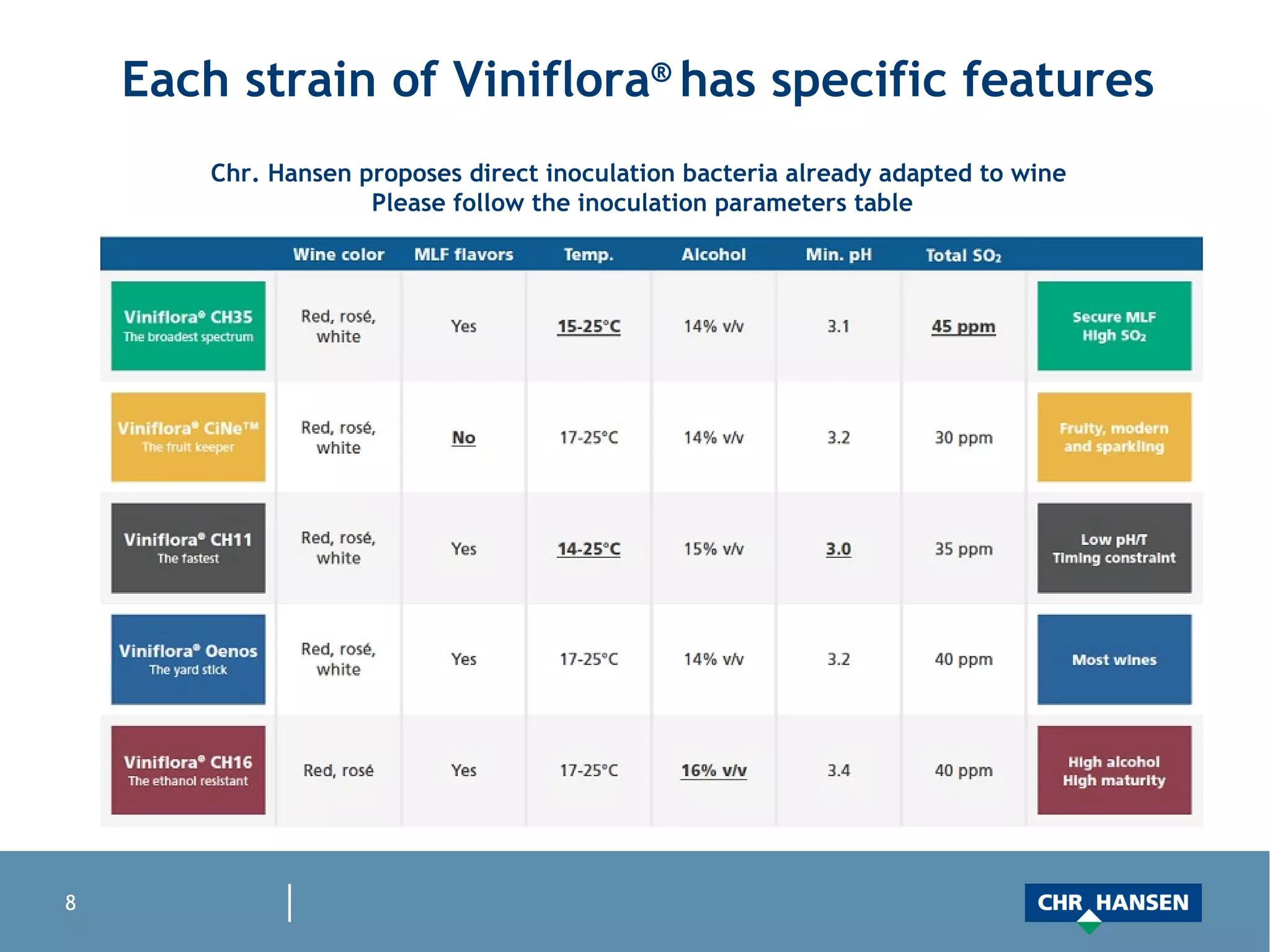

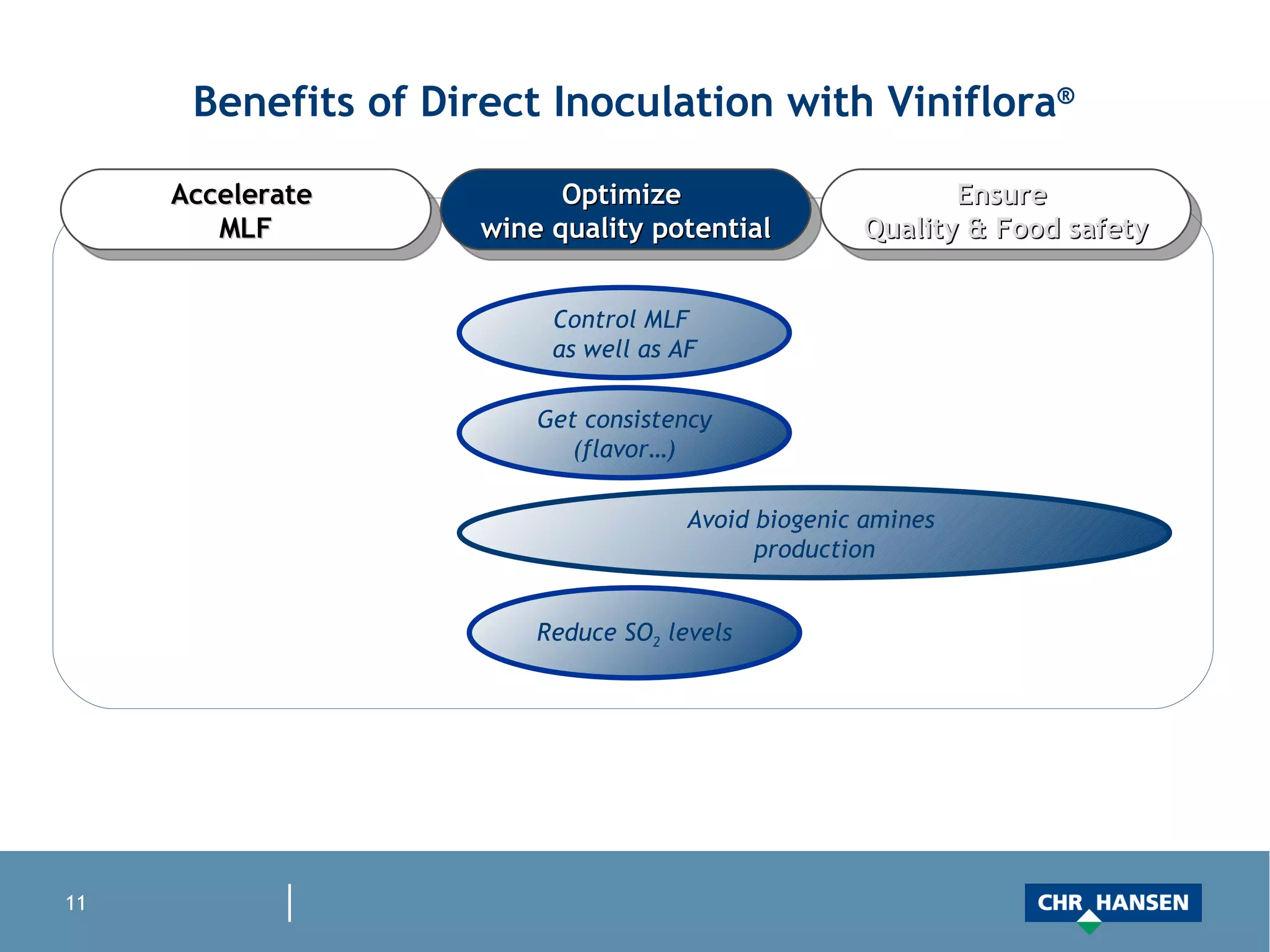

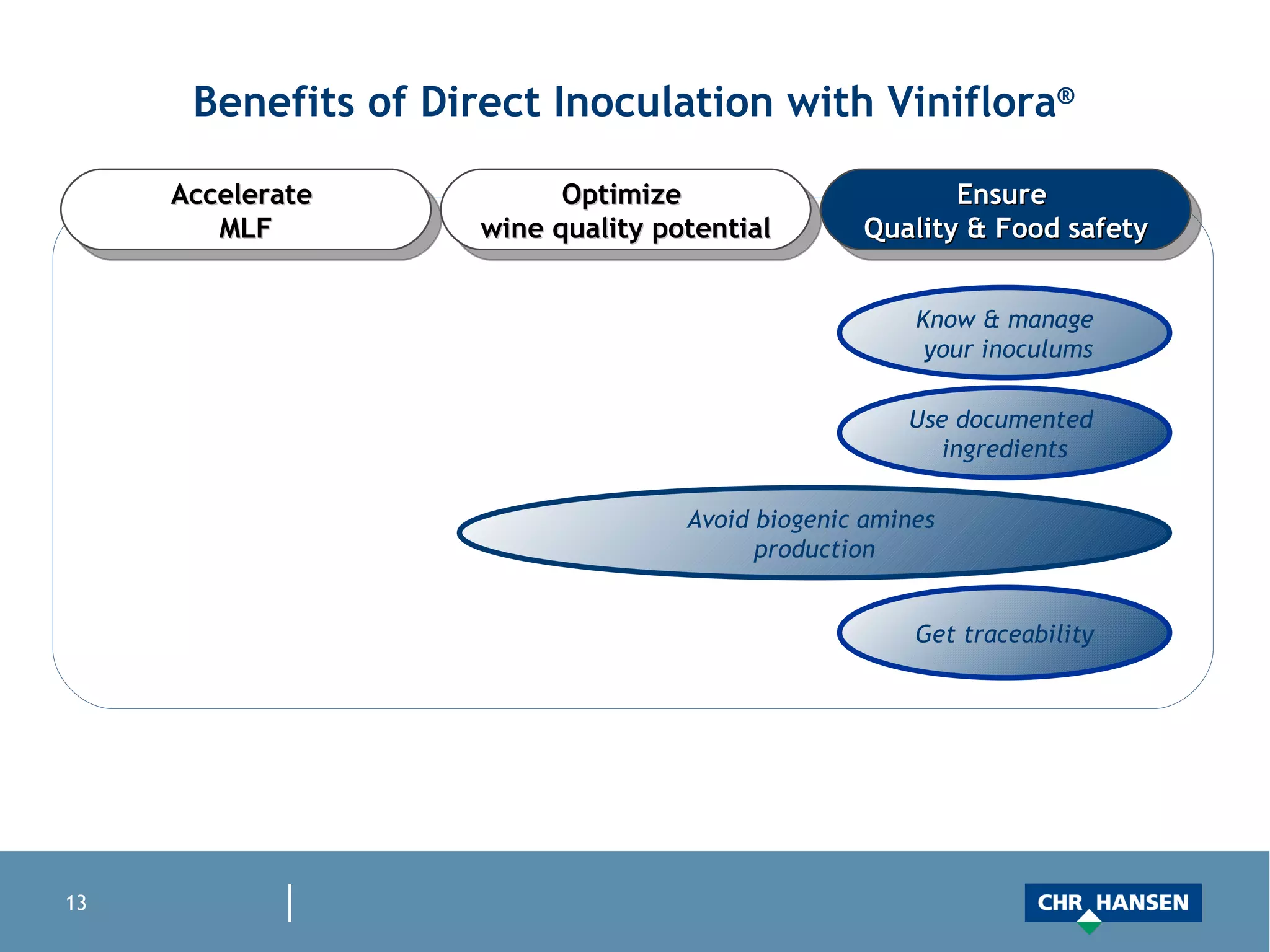

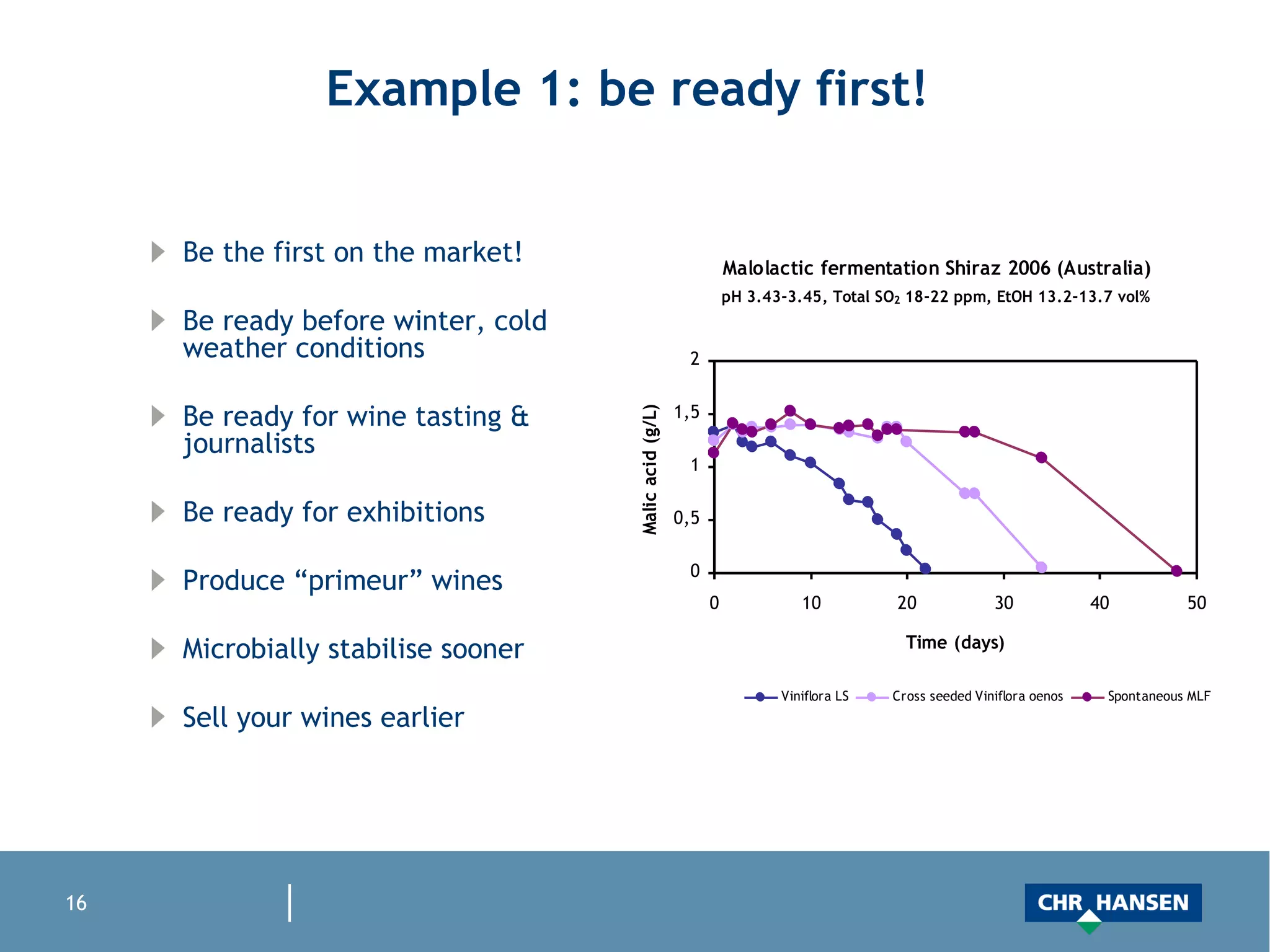

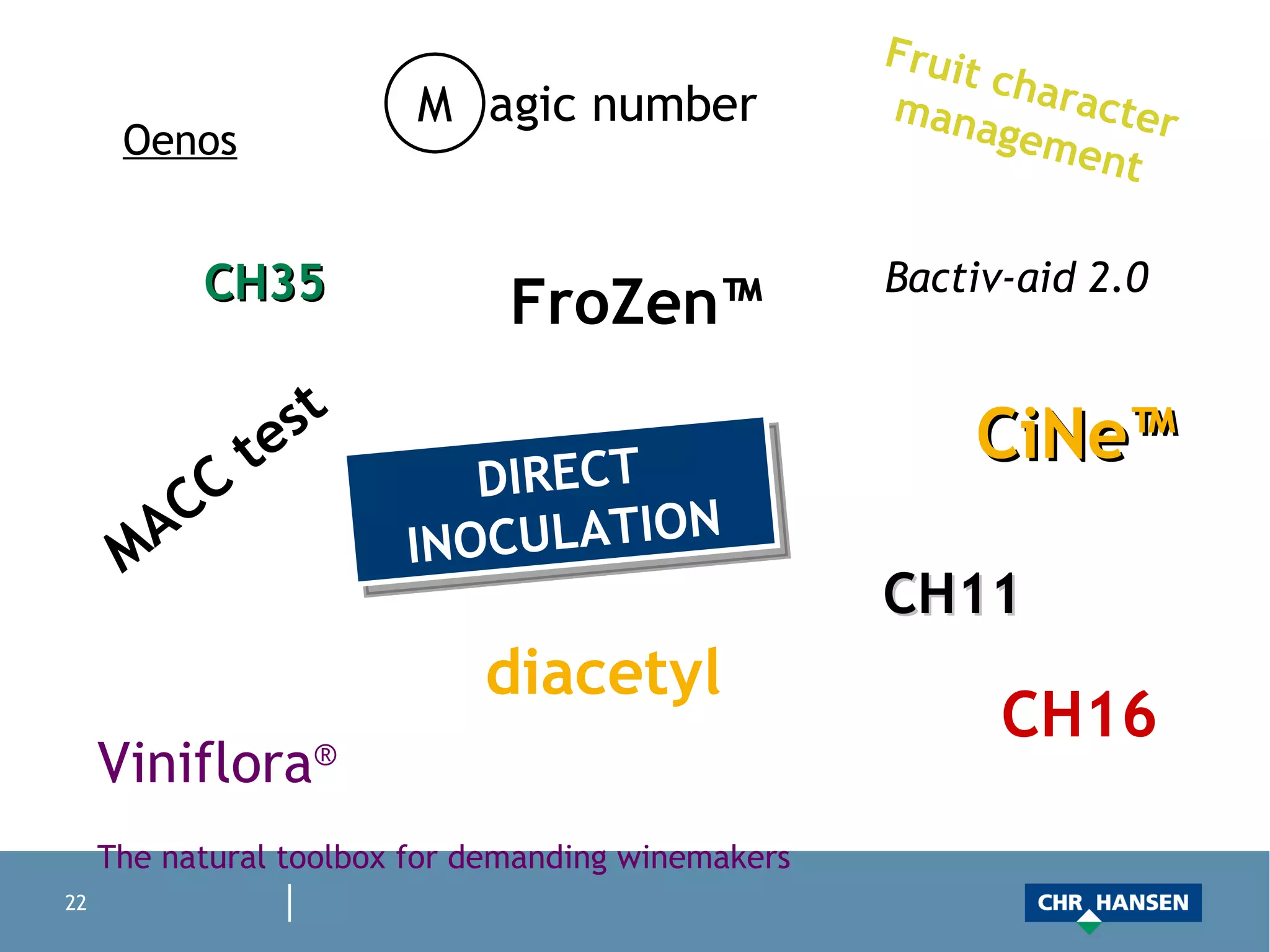

The document discusses malolactic fermentation (MLF) in winemaking and recommends direct inoculation with Viniflora® starter cultures from Chr. Hansen to manage the process. Direct inoculation ensures a controlled and consistent MLF, improves wine quality and food safety by reducing biogenic amine production, and allows winemakers to accelerate MLF and have their wine ready sooner.