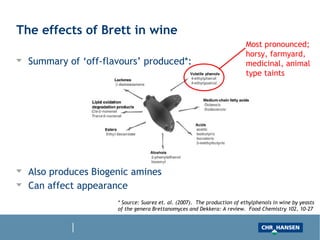

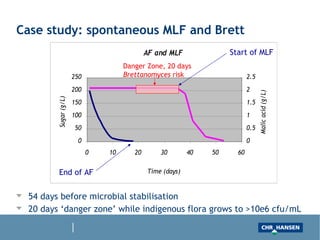

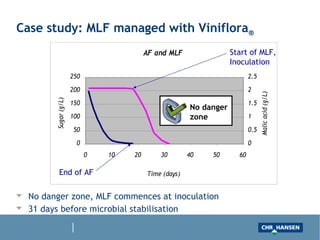

This document discusses Brettanomyces yeast which can contaminate wine and produce off-flavors. Malolactic fermentation (MLF) is identified as a critical stage for Brettanomyces control. Inoculating wine with Viniflora during MLF can help control the start and speed of MLF, inhibit Brettanomyces growth, and reduce the window of opportunity for Brettanomyces contamination compared to spontaneous MLF. A case study demonstrates how spontaneous MLF led to 20 days of increased Brettanomyces risk versus inoculated MLF with Viniflora which began MLF immediately with no risk period. Other factors like commercial yeast strains and winery hygiene also impact Brettanomyces control