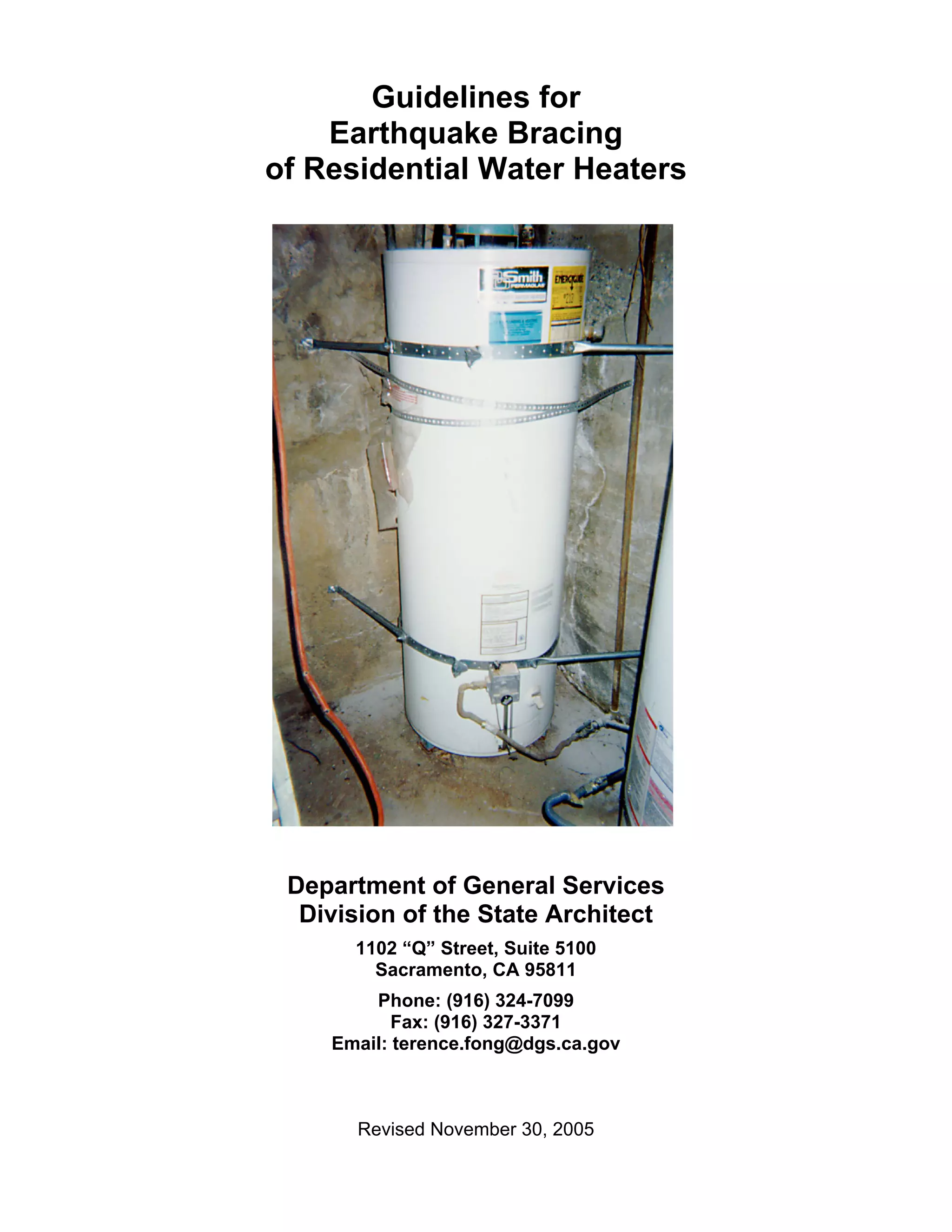

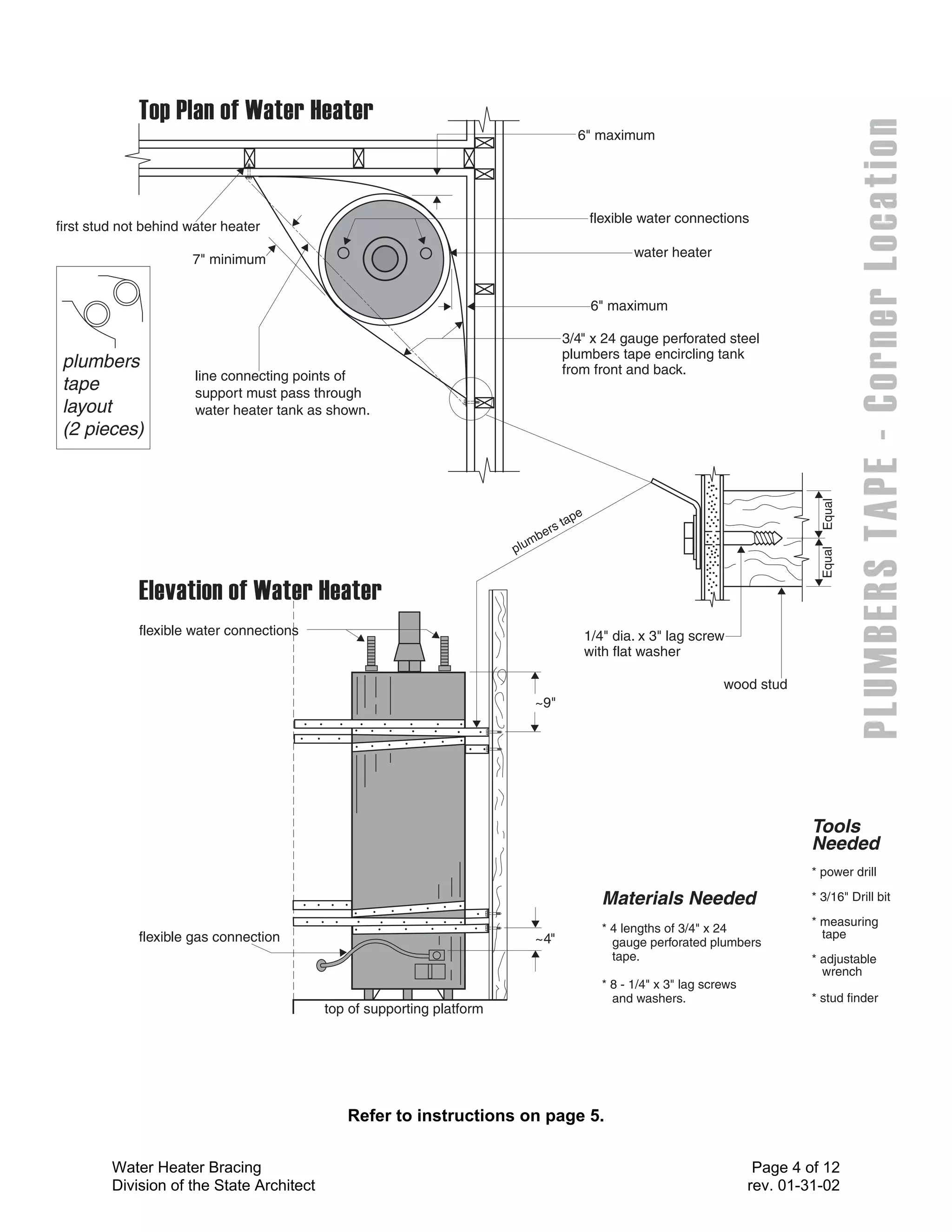

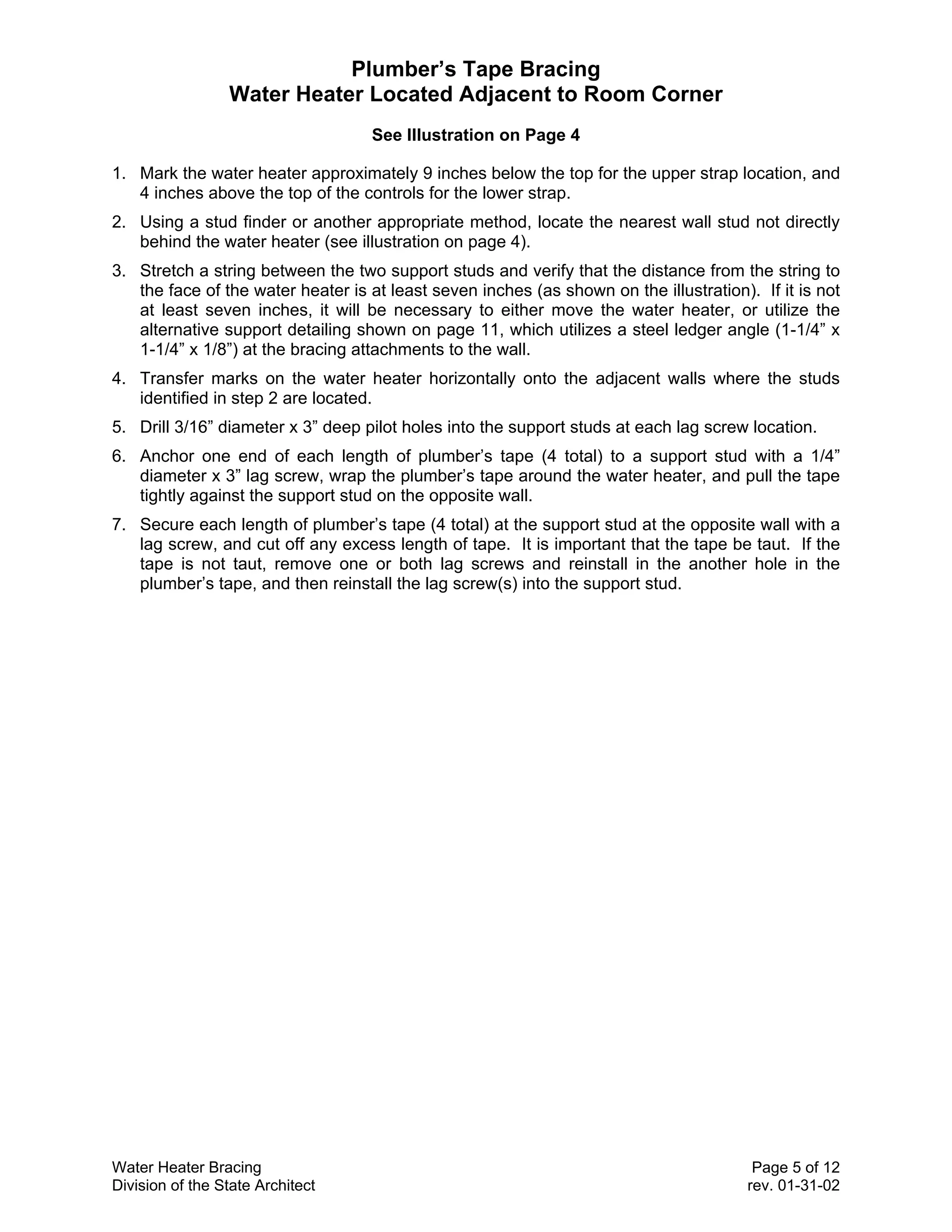

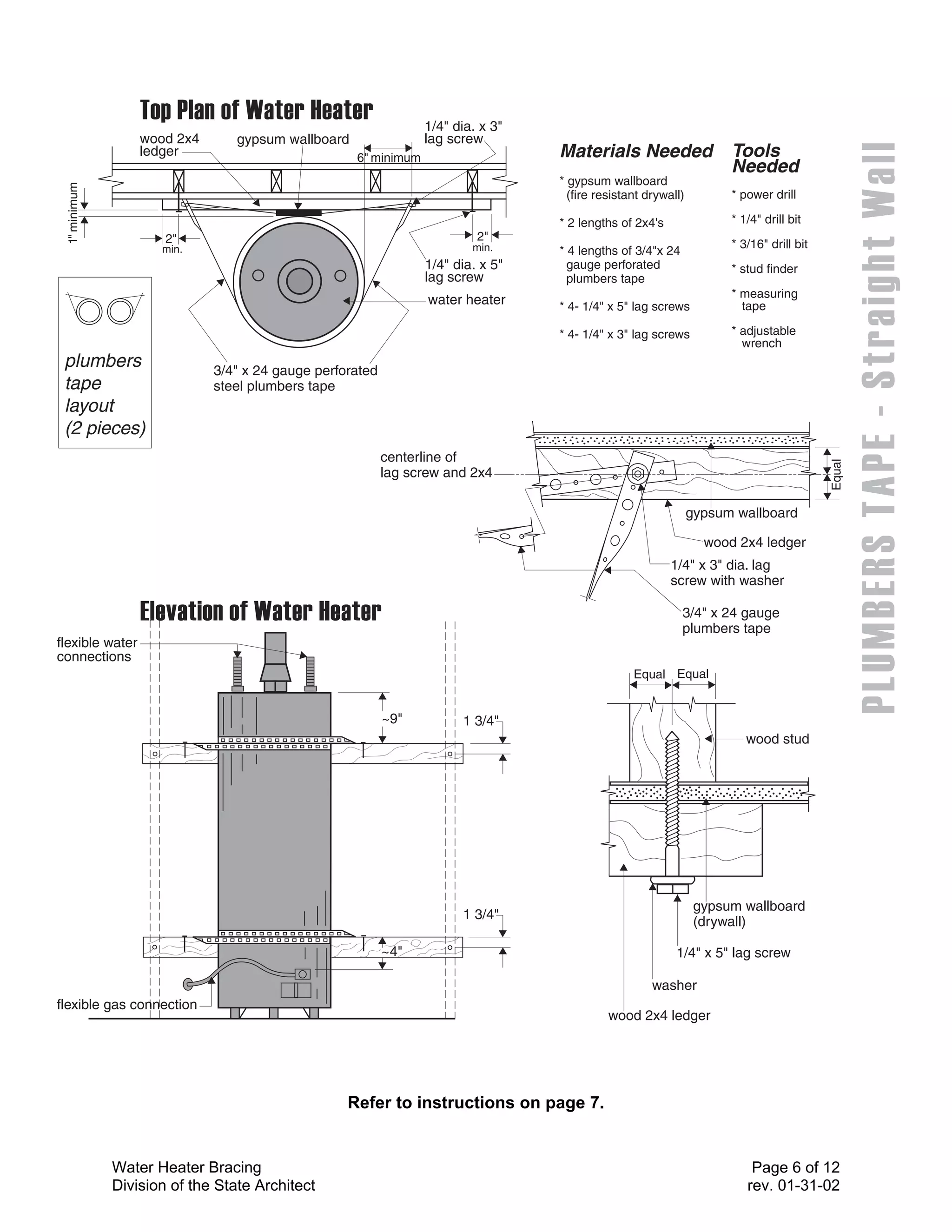

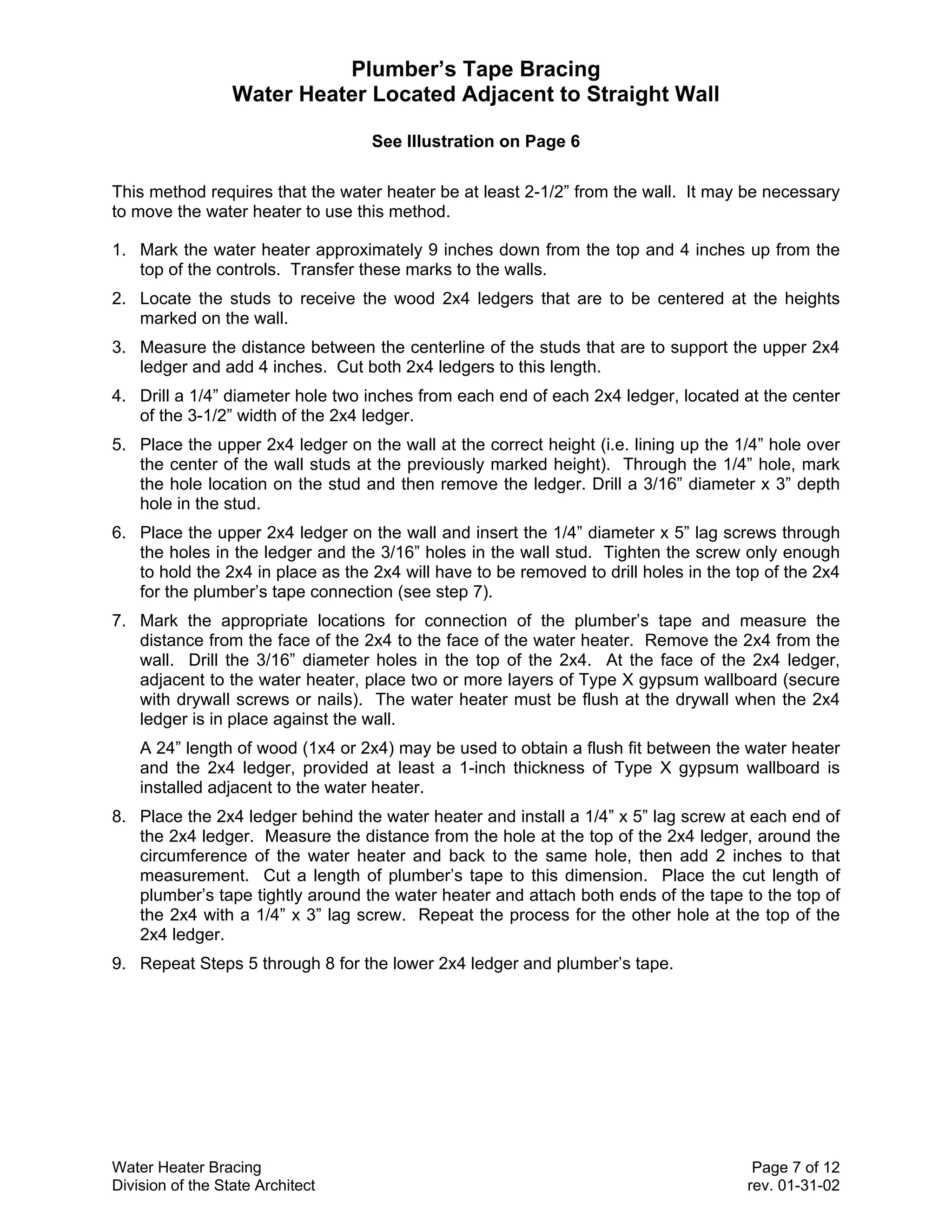

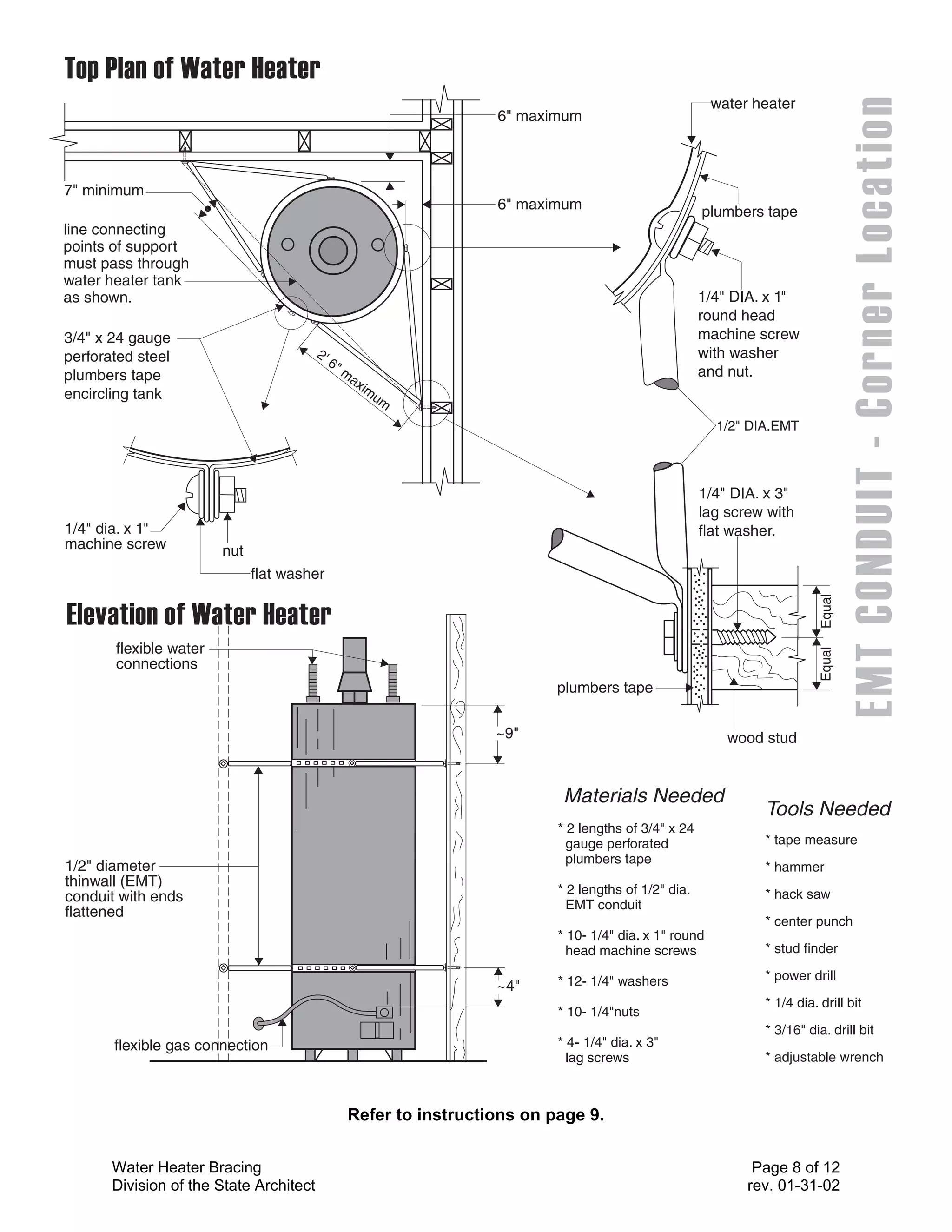

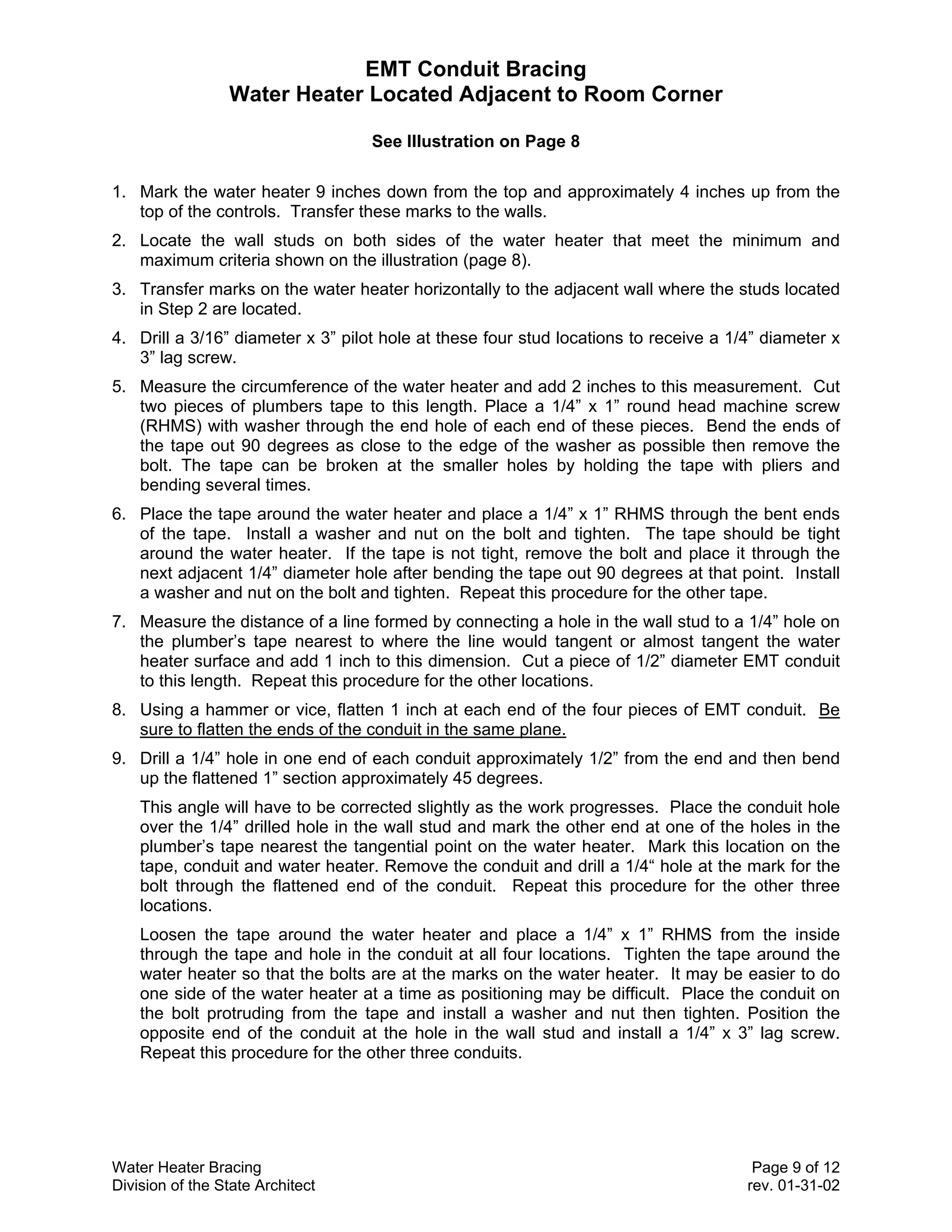

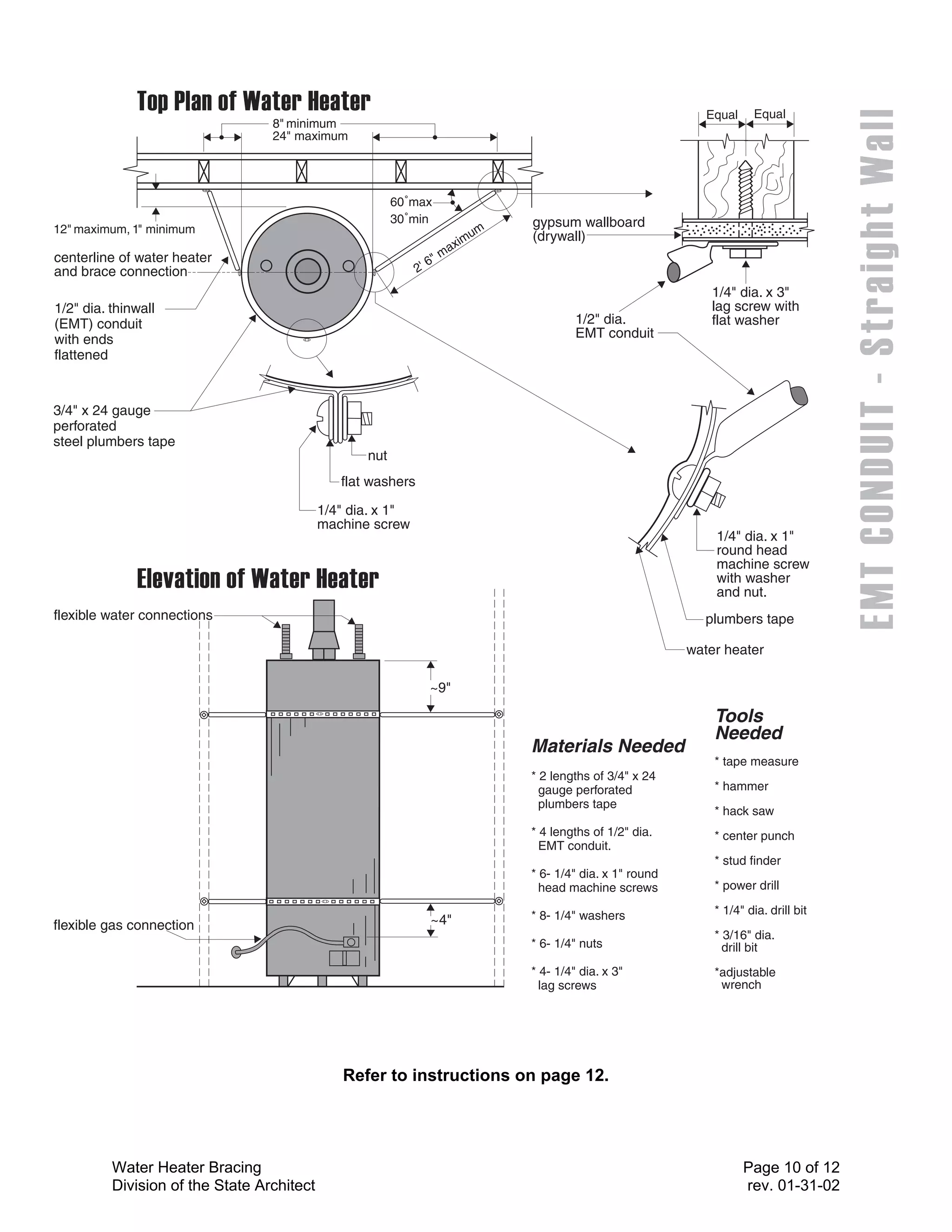

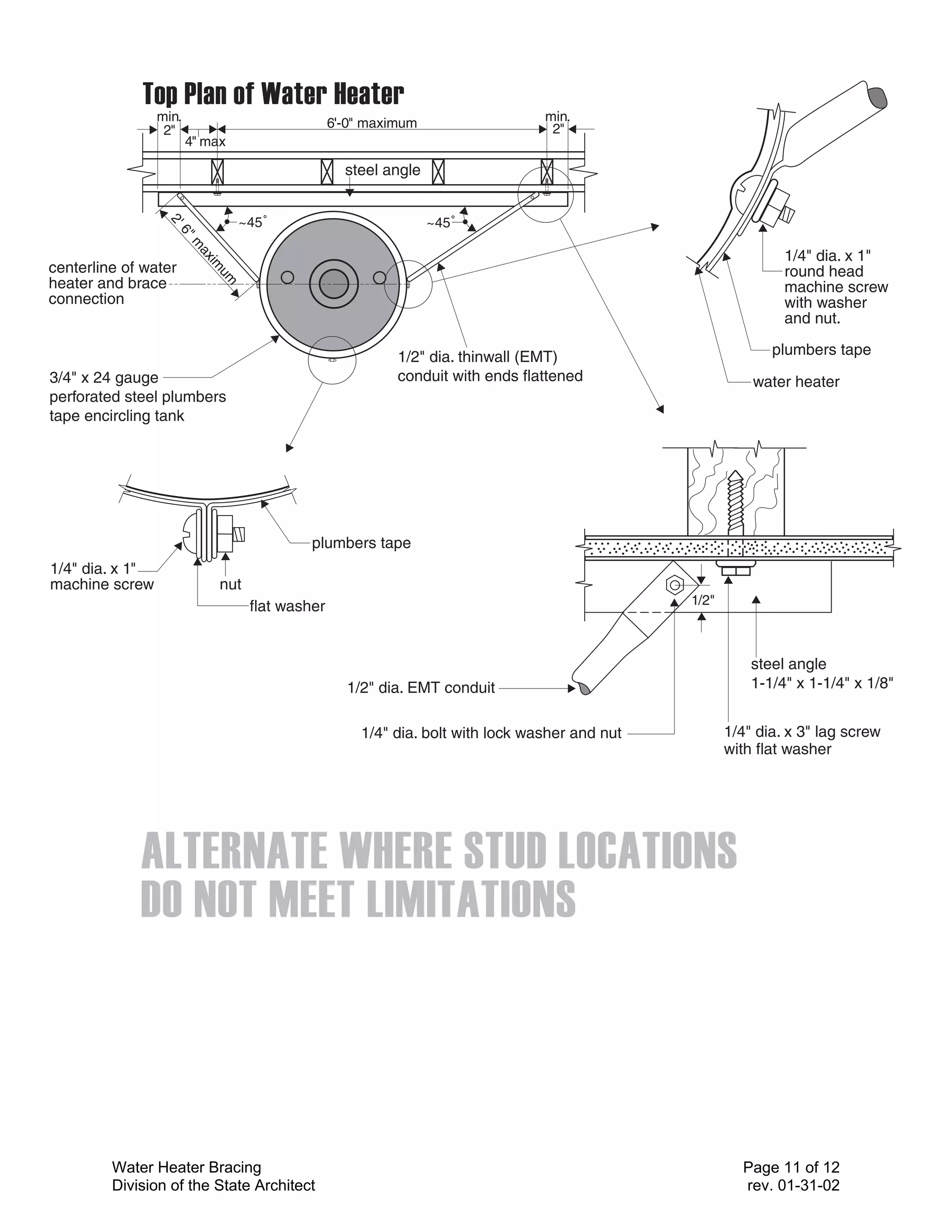

The document provides guidelines for bracing residential water heaters during earthquakes using plumber's tape or EMT conduit. It describes securing the water heater to an adjacent wall using two sets of bracing straps to prevent movement, leaks, and hazards. Methods are illustrated for water heaters near corners or straight walls. The guidelines are intended for water heaters up to 75 gallons, with additional bracing required for larger sizes.