https://eauditor.app/2025/11/07/warehouse-manual-handling-risk-assessment/

Perform Warehouse Manual Handling Risk Assessment using eAuditor

A Warehouse Manual Handling Risk Assessment is a systematic evaluation of tasks that involve lifting, carrying, pushing, pulling, or otherwise physically moving materials within a warehouse. Its primary goal is to identify potential ergonomic hazards and reduce the risk of musculoskeletal injuries among warehouse staff.

Warehouse Manual Handling Risk Assessment ()

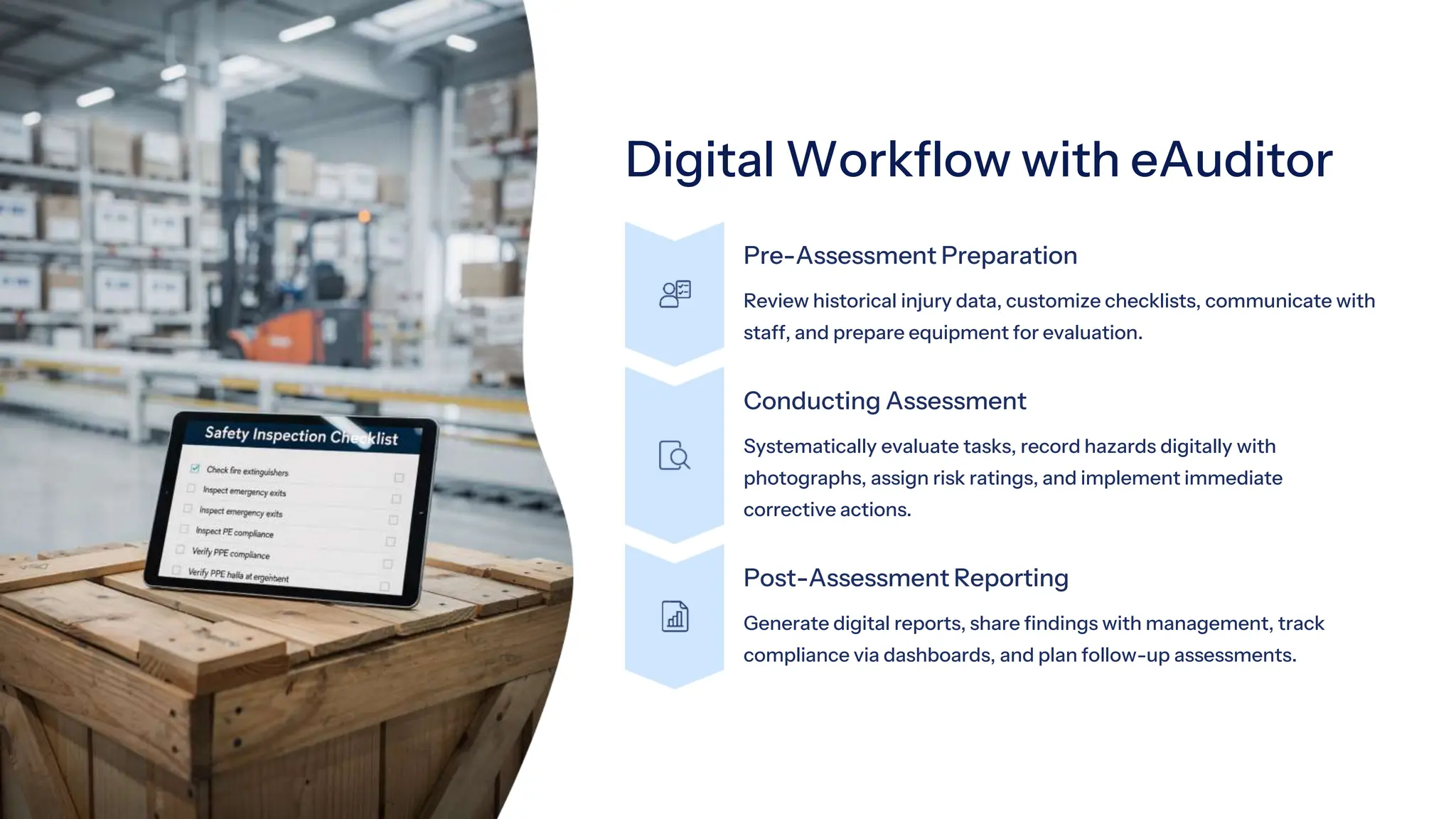

Performing a Warehouse Manual Handling Risk Assessment using eAuditor ensures a thorough evaluation of all tasks involving lifting, carrying, pushing, or pulling materials within a warehouse environment. The primary objective is to identify potential hazards associated with manual handling, assess their risks, and implement preventive measures to reduce the likelihood of musculoskeletal injuries, improve workplace safety, and maintain operational efficiency. Using eAuditor for this assessment provides a structured, digital approach that allows real-time documentation, photographic evidence, assignment of corrective actions, and generation of comprehensive reports for accountability and continuous improvement.

Purpose

A Warehouse Manual Handling Risk Assessment using eAuditor proactively manages and mitigates risks associated with manual handling tasks. Specific objectives include:

Hazard Identification: Detect tasks that may pose a risk due to weight, awkward posture, repetition, or environmental constraints.

Risk Evaluation: Assess the likelihood and severity of injury for each identified manual handling task to prioritize interventions.

Preventive Measures: Recommend safe handling techniques, mechanical aids, training, and workplace modifications to reduce risks.

Regulatory Compliance: Ensure adherence to occupational health and safety regulations concerning manual handling in warehouses.

Continuous Improvement: Utilize findings to improve staff training programs, standard operating procedures (SOPs), and workflow design.

By achieving these objectives, the assessment ensures staff safety, reduces workplace injuries, and supports operational efficiency.

Scope

The Warehouse Manual Handling Risk Assessment encompasses all tasks and operational areas where manual handling occurs. The scope includes:

Lifting and Carrying: Tasks involving picking, lifting, or transporting goods manually.

Pushing and Pulling: Movement of trolleys, carts, or other materials requiring physical effort.

Repetitive Tasks: Tasks performed frequently, which may cause strain or fatigue.

Posture and Ergonomics: Assessment of body positions, bending, twisting, and stretching during tasks.

Mechanical Aids: Evaluation of forklifts, pallet jacks, hoists, and other devices used to assist manual handling.