Embed presentation

Download as PDF, PPTX

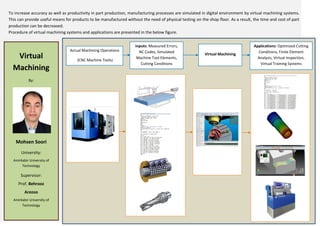

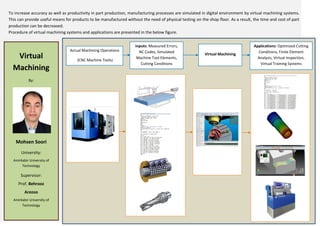

Virtual machining systems simulate manufacturing processes digitally to increase accuracy and productivity while decreasing time and costs. This allows products to be tested virtually without physical prototyping. The process involves simulating machine tools and cutting conditions as inputs to validate operations before actual machining. Applications include optimizing cutting conditions, finite element analysis, virtual inspection, and training systems.