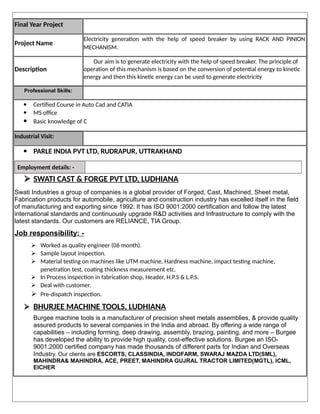

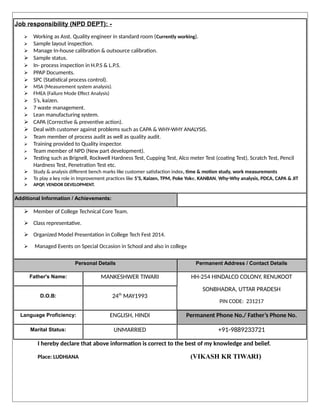

Vikash Kumar Tiwari is seeking a challenging position where he can utilize his technical skills and experience to facilitate organizational growth. He has a B.Tech in Mechanical Engineering from IIMT Engineering College with over 70% marks. His experience includes working as a quality engineer at Swati Cast & Forge Pvt Ltd and currently as an assistant quality engineer at Burjee Machine Tools. In these roles, he has experience with inspection, testing, calibration, quality control systems like SPC, PPAP documentation, and customer interaction. He is proficient in AutoCAD, CATIA and has participated in various college technical projects.