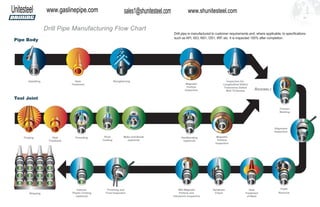

The document outlines the manufacturing flow chart for drill pipe production. It involves various steps like forging, heat treatment, threading, inspection and finishing. Drill pipe is manufactured according to customer requirements and applicable specifications. It undergoes 100% inspection after completion to ensure quality.