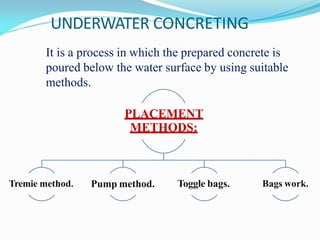

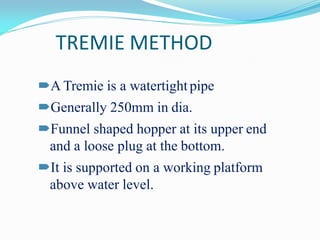

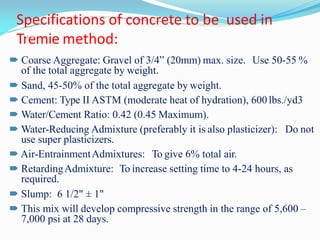

The document discusses different methods for underwater concrete placement, specifically the tremie method. It describes how the tremie method works, including using a watertight pipe filled from the top and emptied from the bottom to place concrete underwater without displacing water. Specifications for concrete mixes suitable for tremie placement are also provided, noting aggregate size, cement type, water-cement ratio, and admixture requirements.