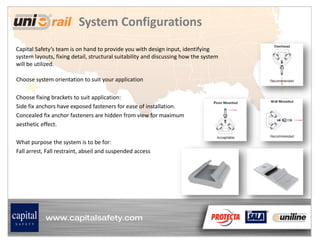

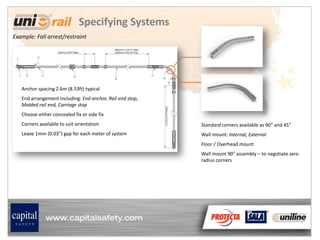

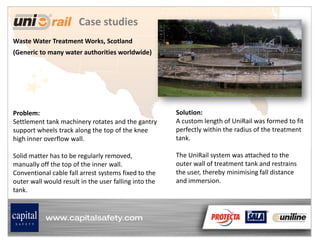

The document discusses a UniRail anchorage system that provides fall protection for workers. It is made of extruded aluminum alloy and can be used for fall arrest, restraint, rope access, and abseiling. The system is flexible and can be installed on various structures. It includes rails, joints, corners, carriages, and fixings. Case studies describe installations on unique structures like operas houses and water treatment plants that required customized rail configurations to provide worker safety.