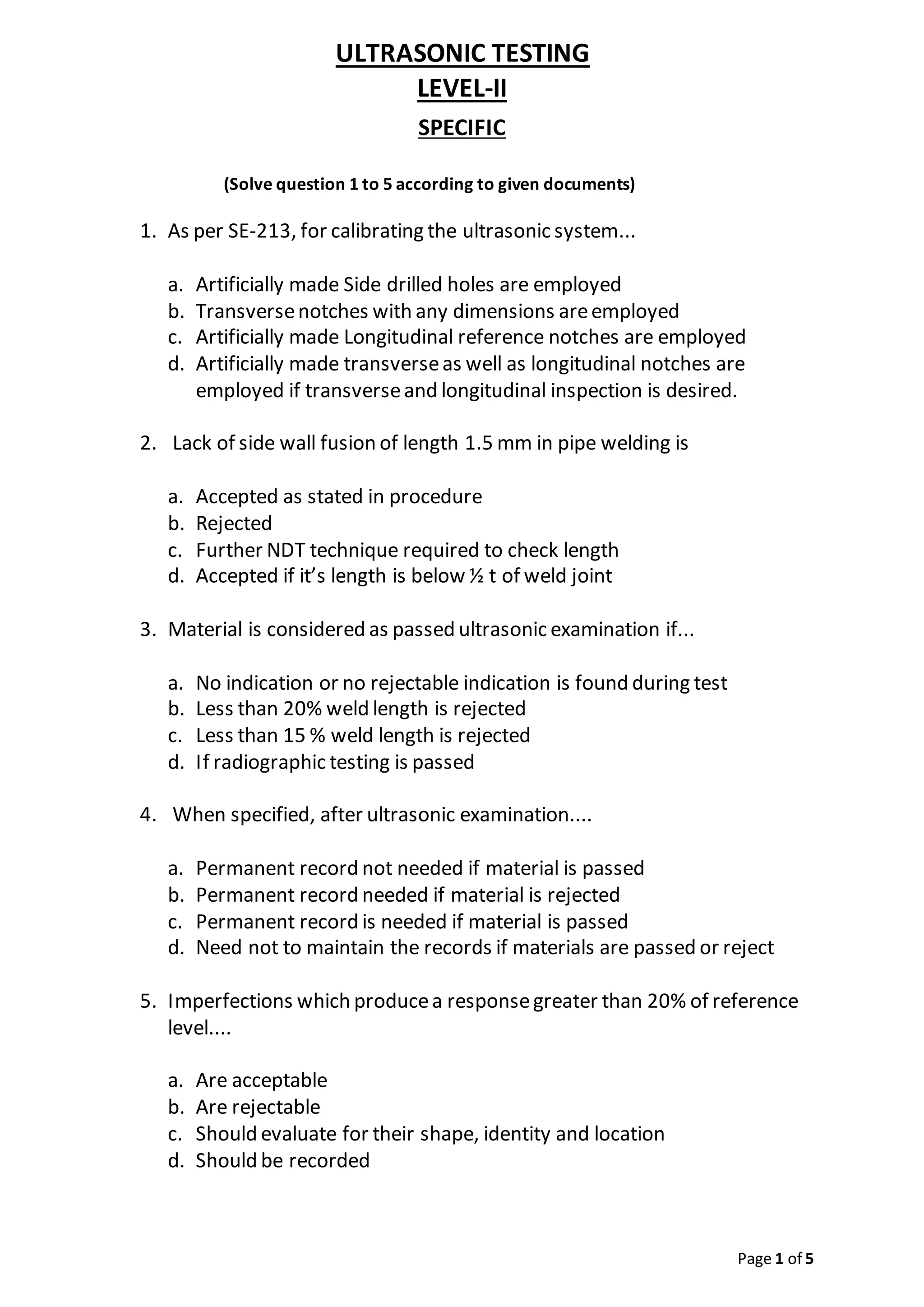

This document provides information about ultrasonic testing including calibration techniques, acceptance criteria, inspection procedures, transducer selection, and defect identification. It consists of 20 multiple choice questions related to these topics, with the correct answers provided. Some key points covered are that artificially made side drilled holes or longitudinal notches are used to calibrate systems, lack of side wall fusion up to 1.5mm is rejected, materials pass if no rejectable indications are found, and records must be kept if materials fail inspection.