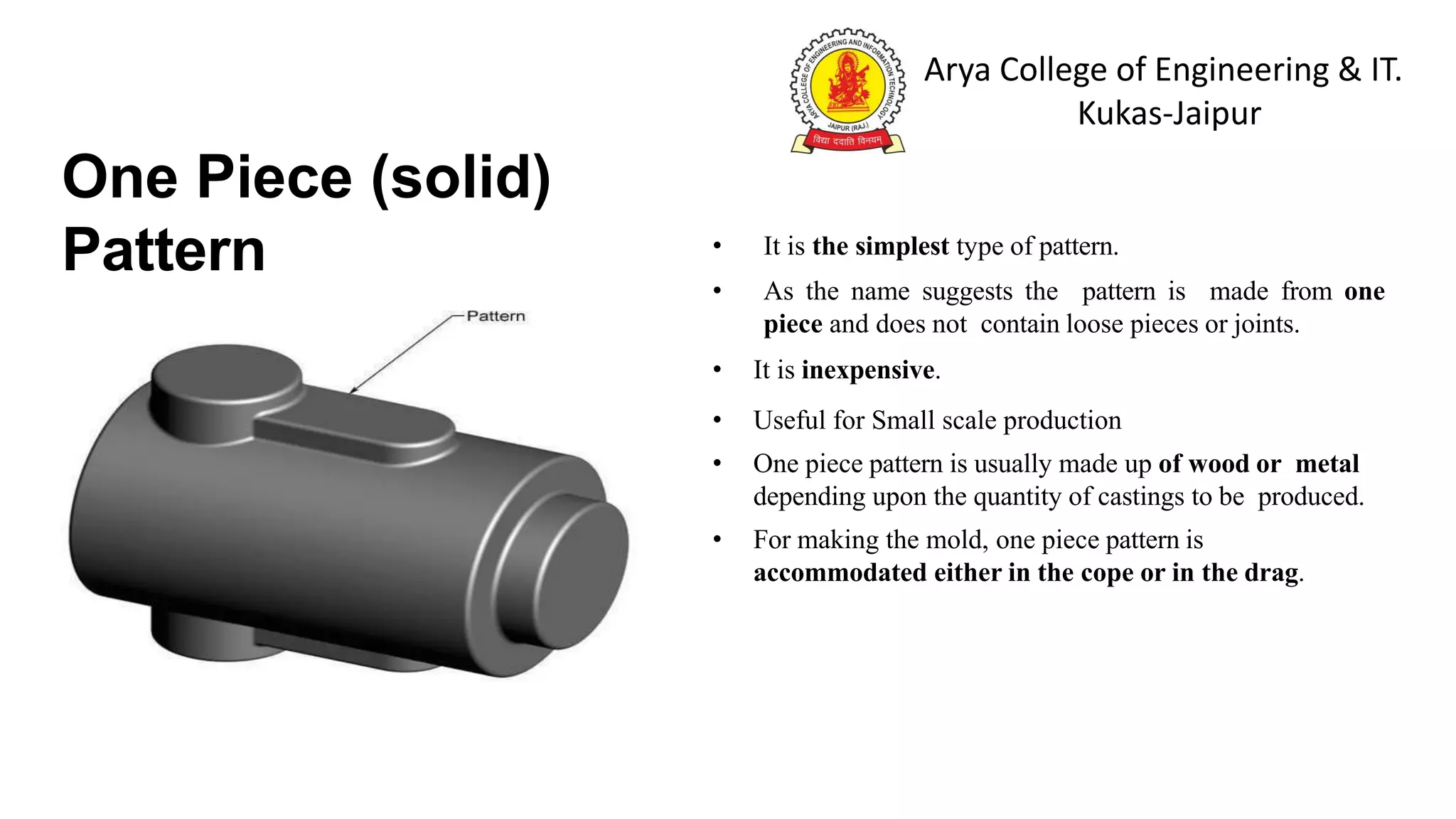

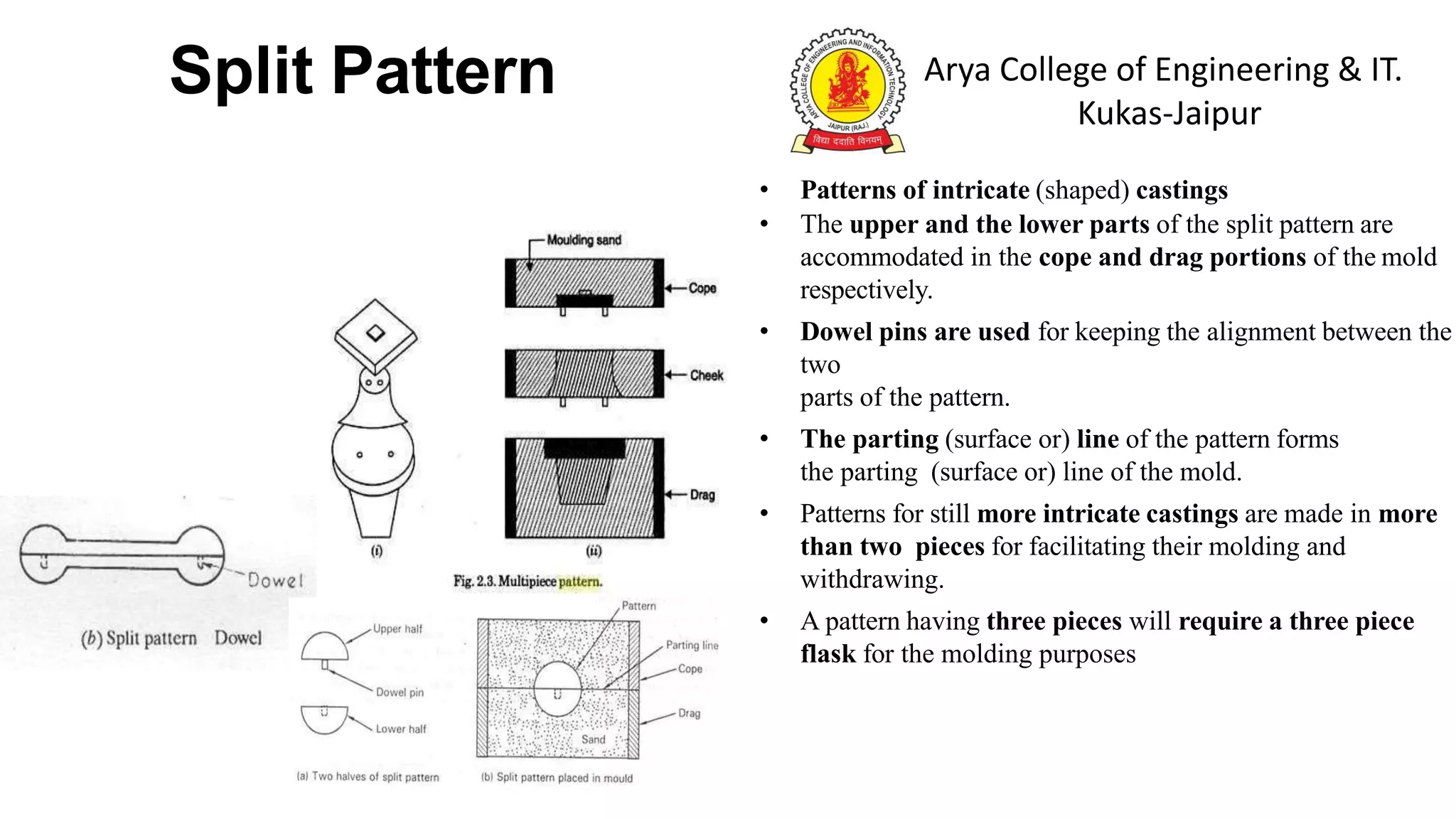

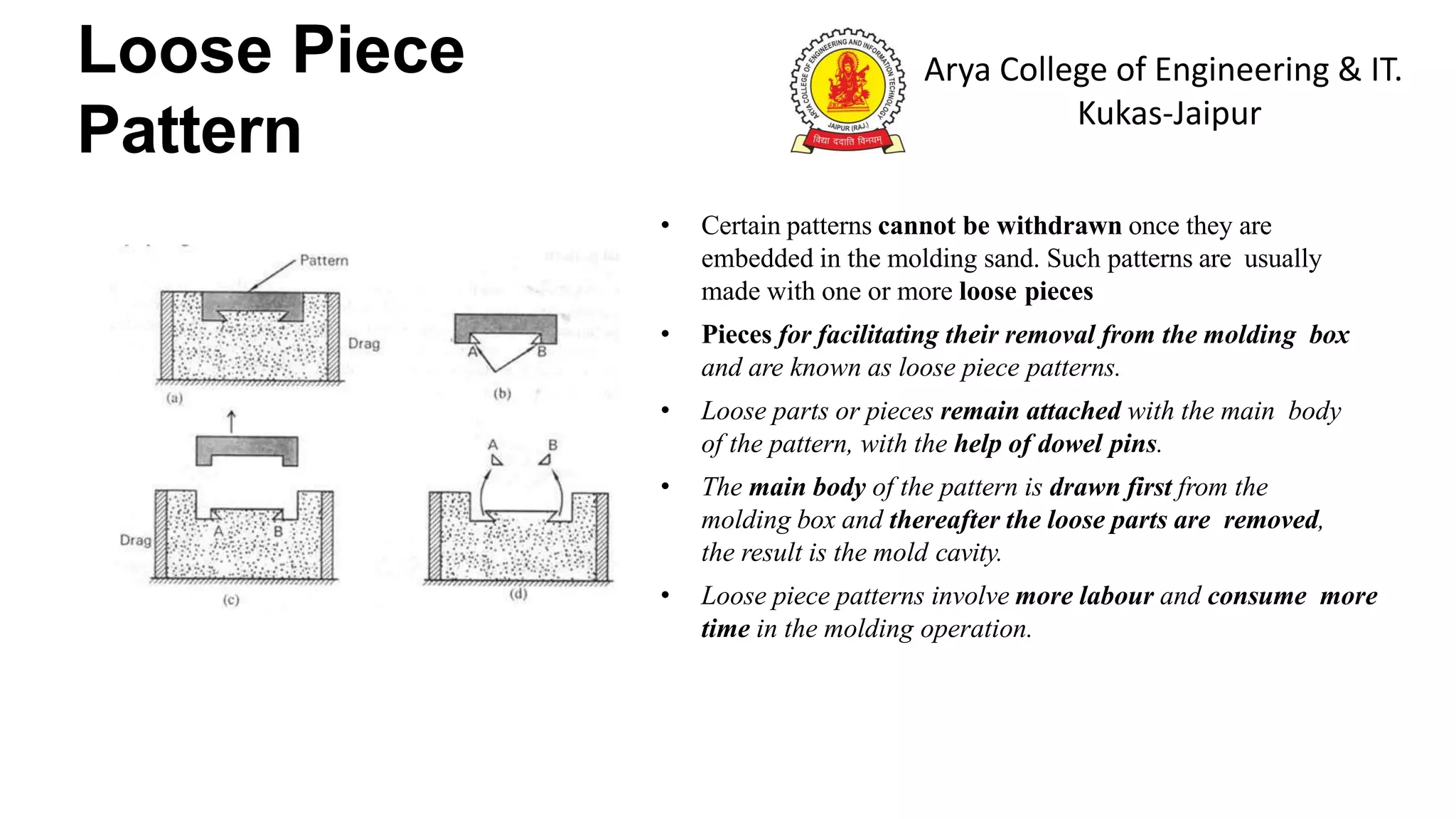

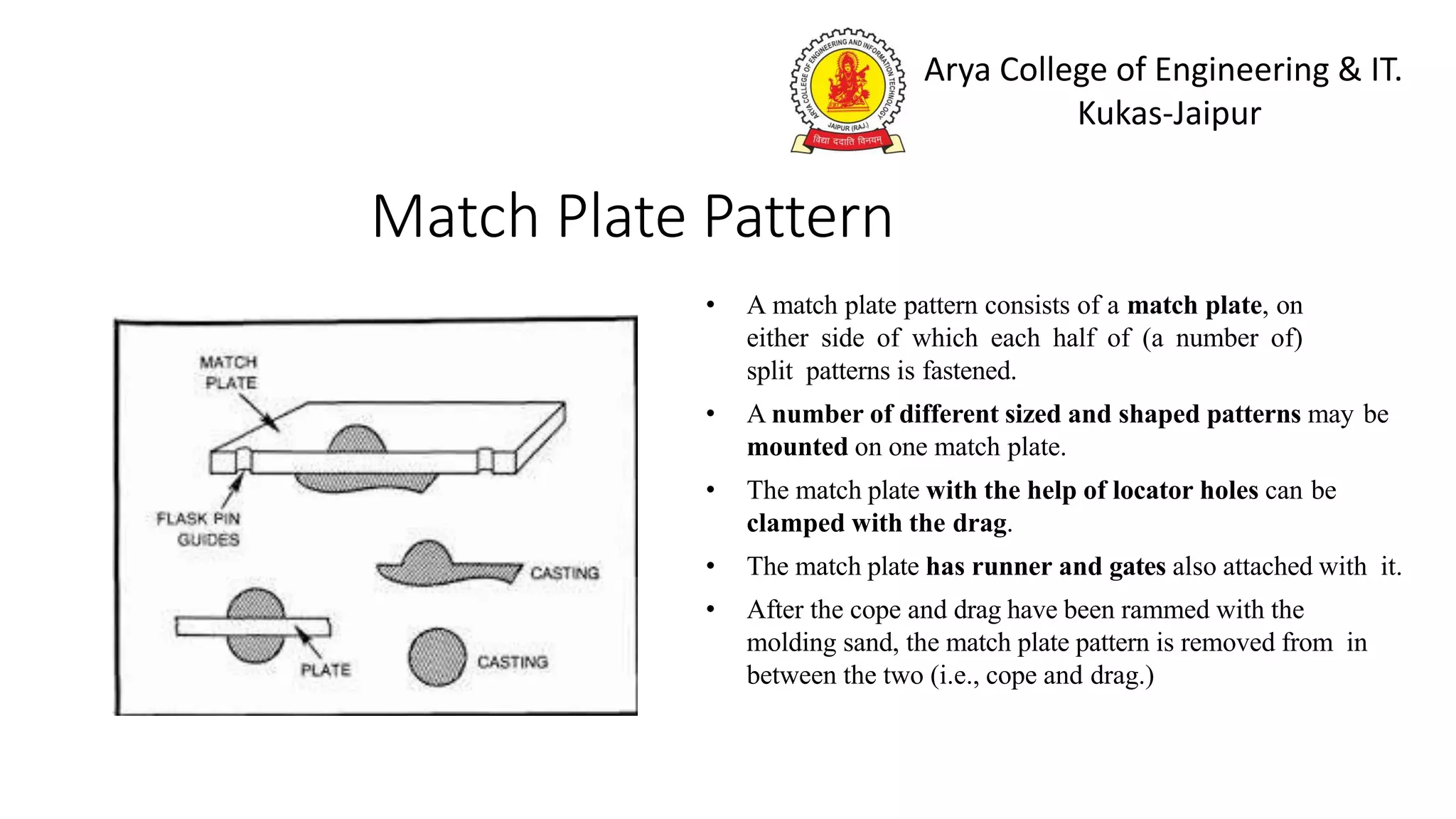

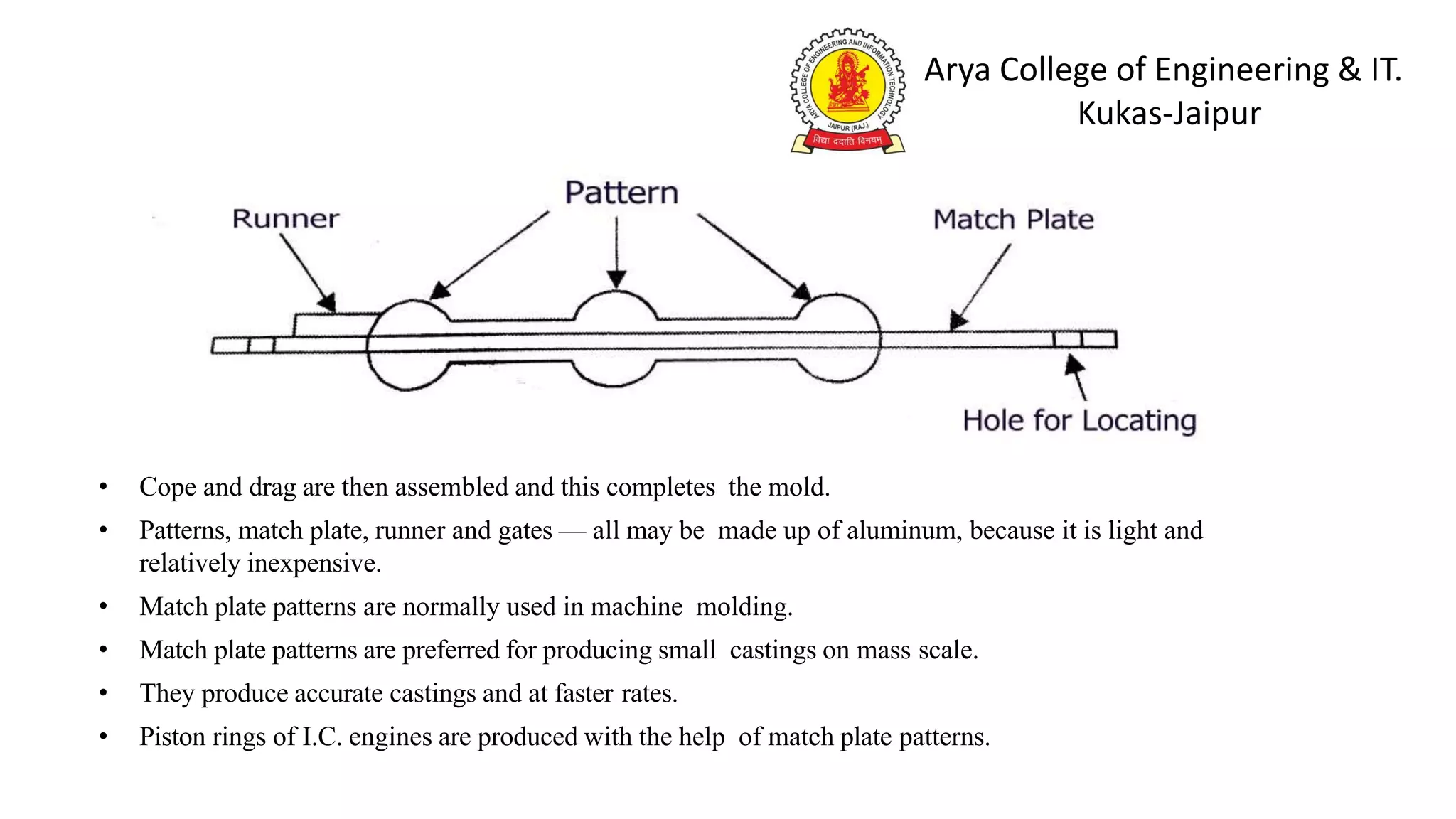

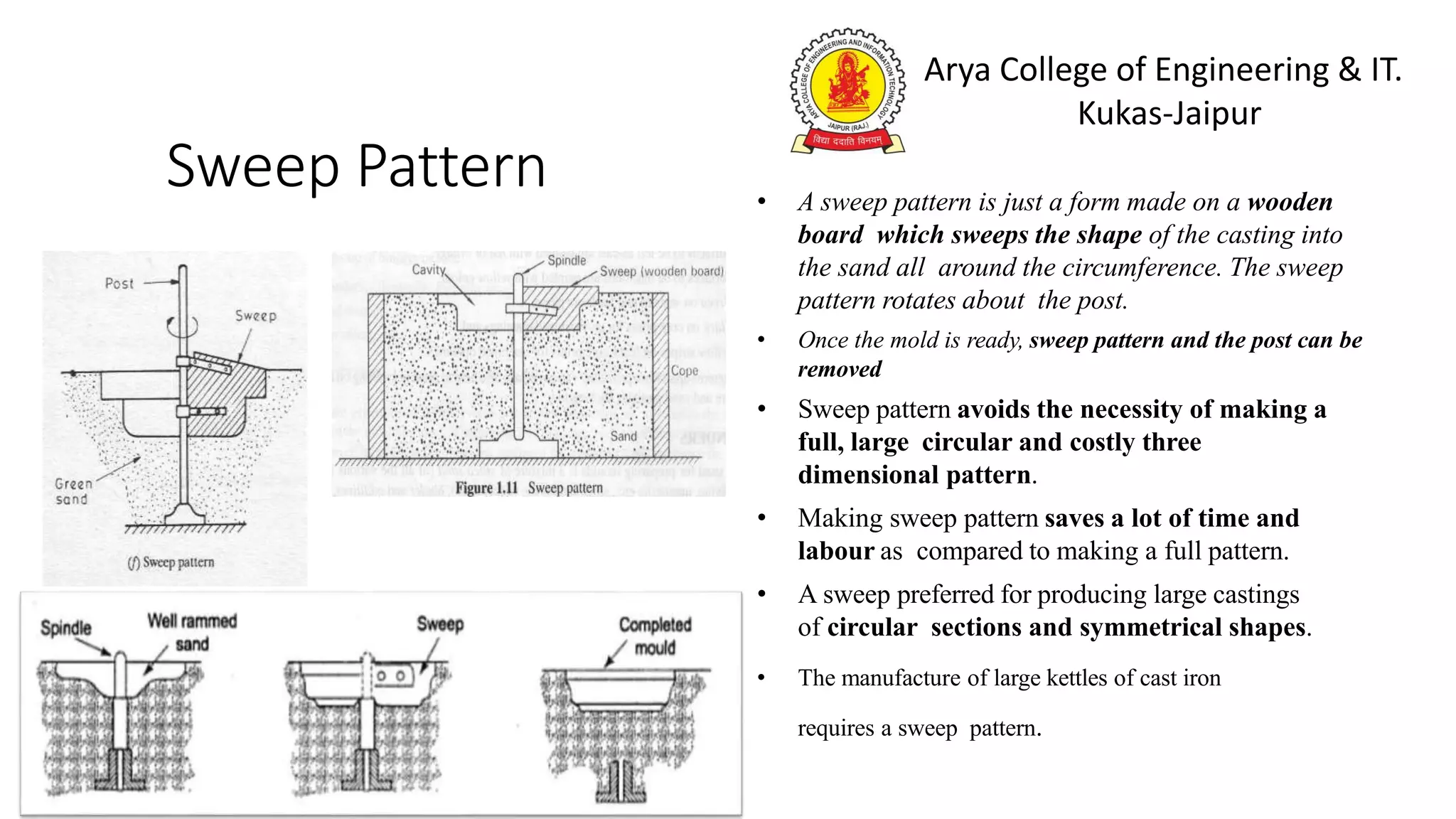

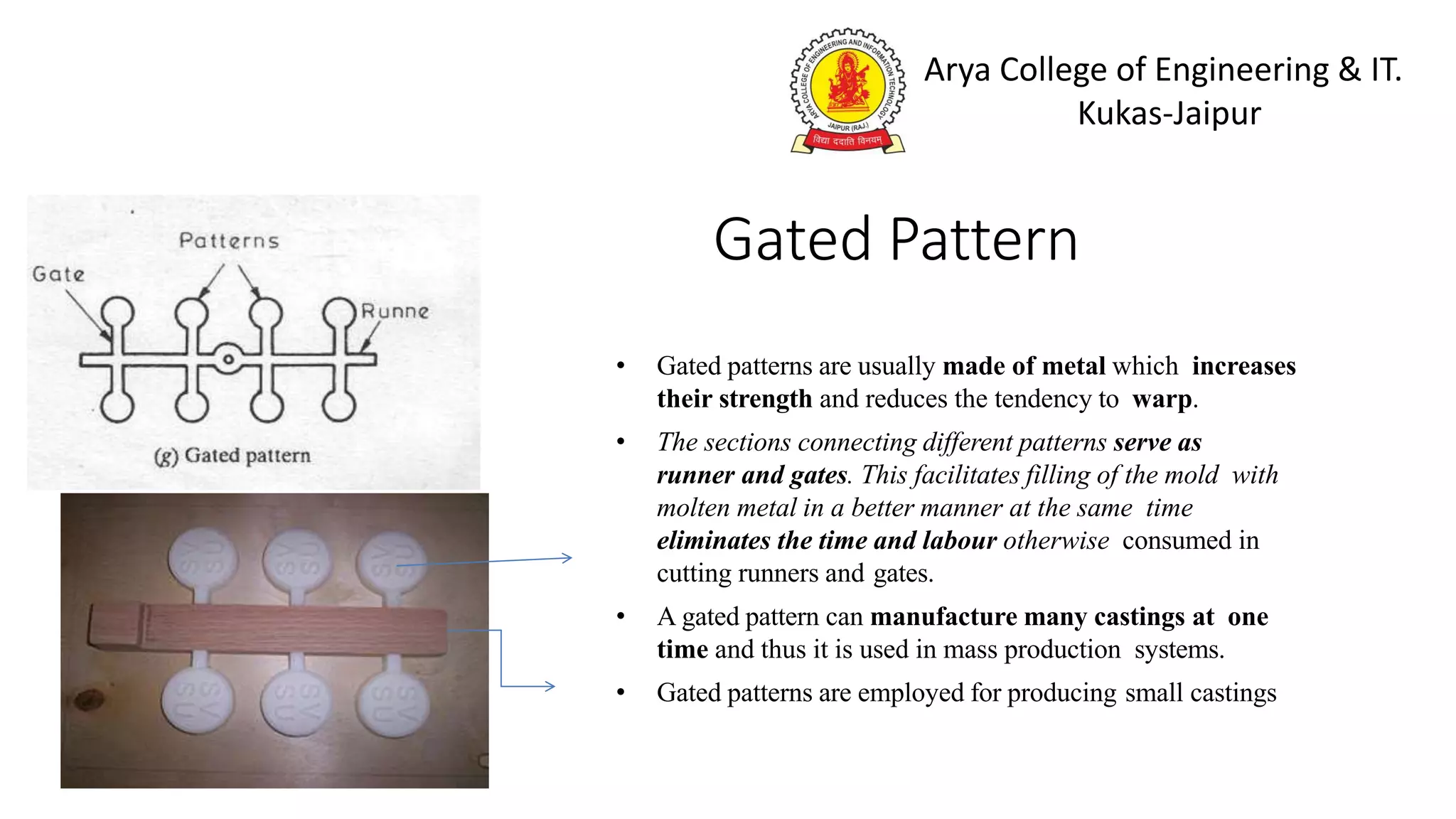

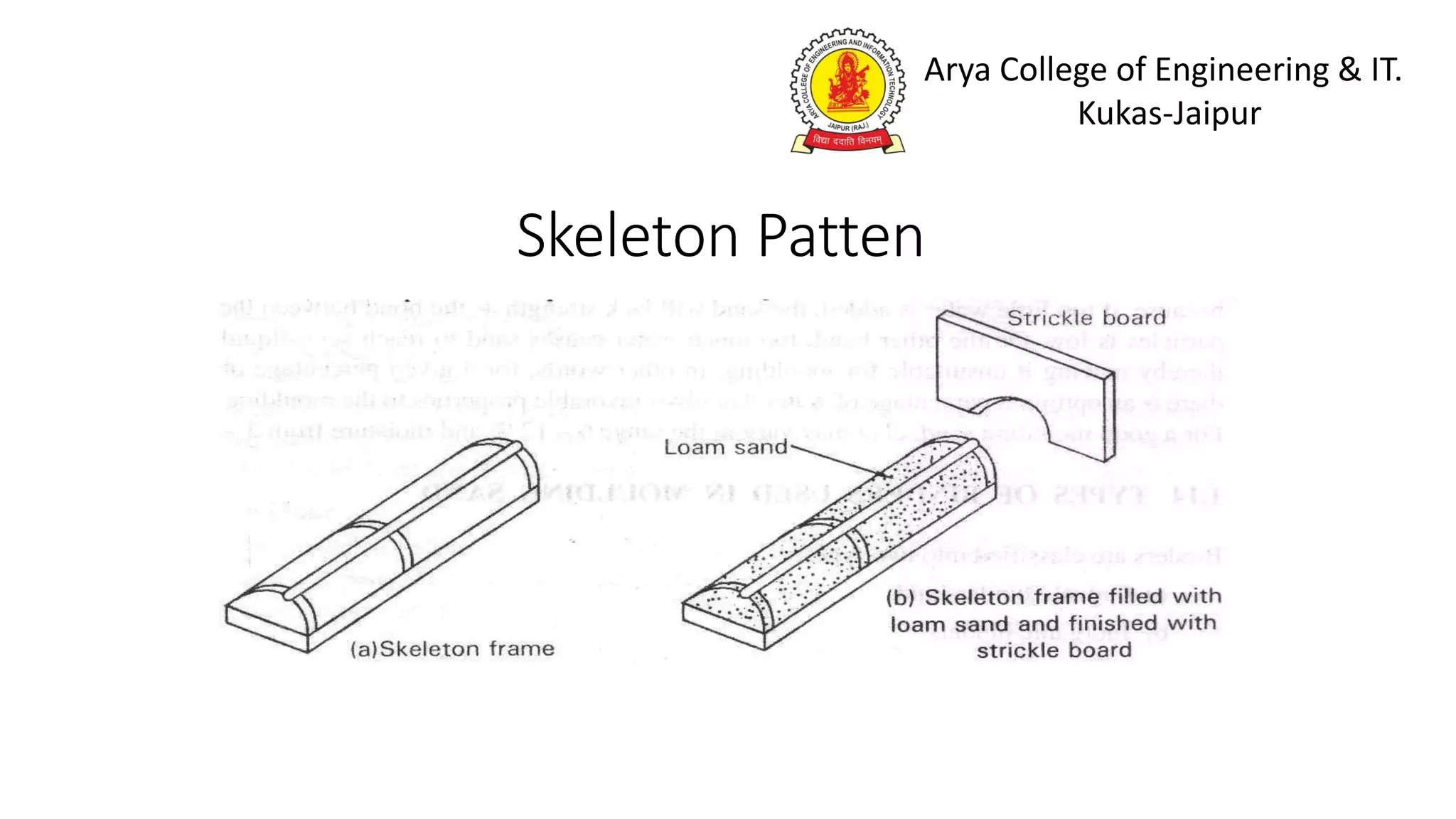

The document discusses different types of patterns used in casting processes. It describes that a pattern is a replica of the object being cast and influences casting quality. The main types discussed are one-piece, split, loose-piece, match plate, sweep, gated, and skeleton patterns. Each type has advantages for different casting sizes, quantities, or shapes. A pattern prepares the mold cavity and may include cores, runners and gates. Properly made patterns reduce defects and costs.