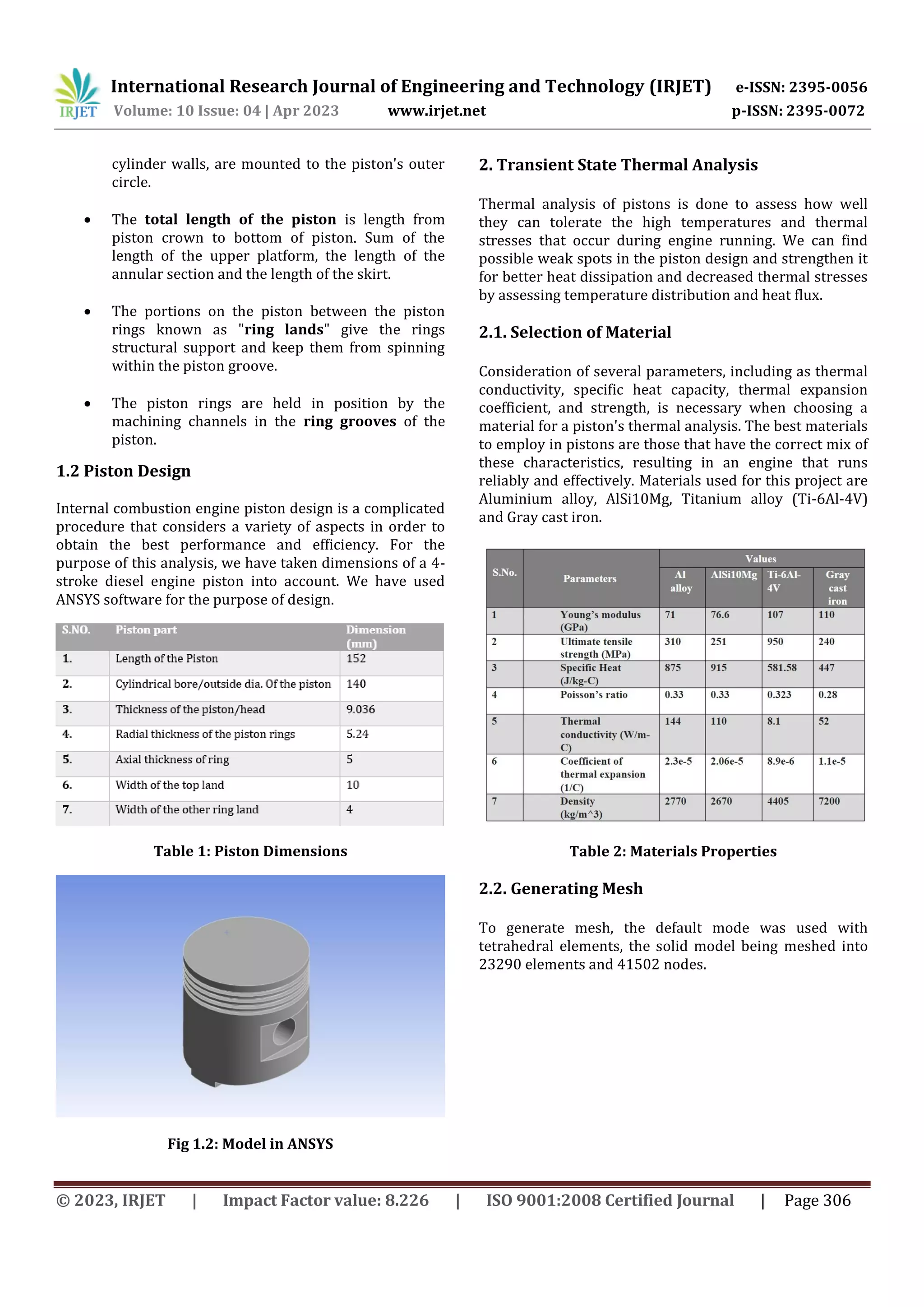

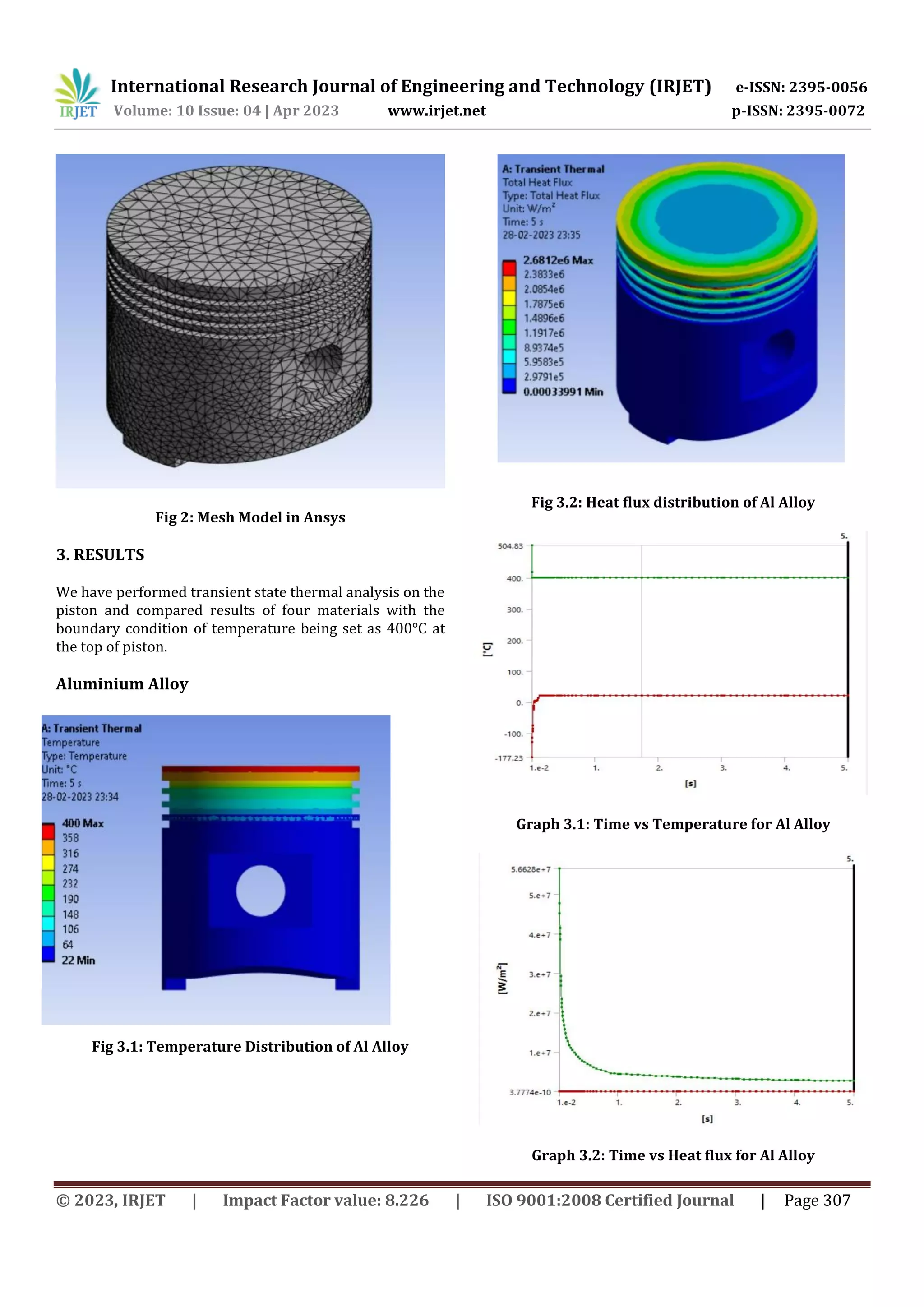

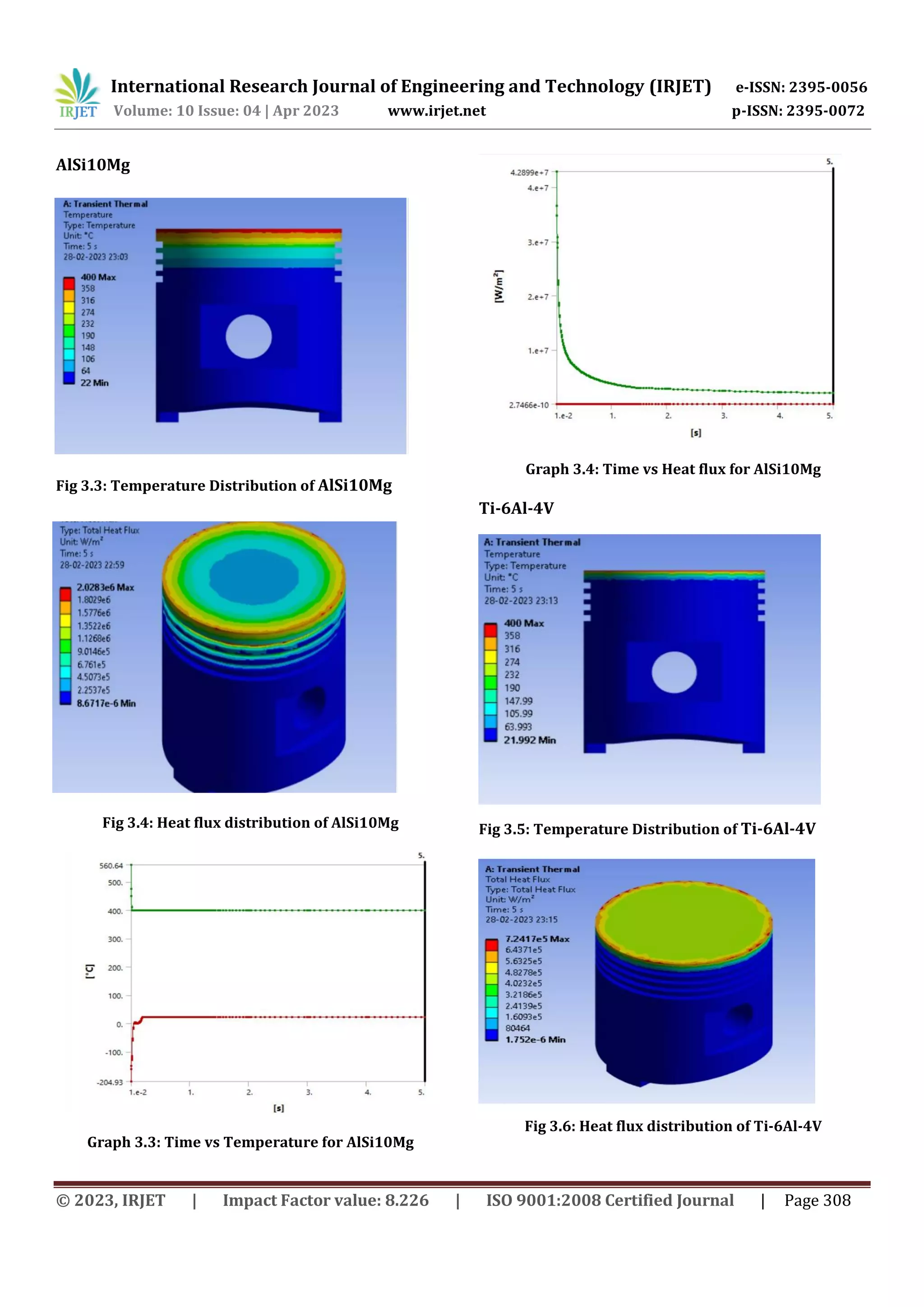

This document summarizes a study that uses ANSYS software to conduct a transient thermal analysis of a 4-stroke diesel engine piston made of four different materials: aluminum alloy, AlSi10Mg, titanium alloy, and gray cast iron. The study simulates the temperature distribution and heat flux within the piston under varying operating conditions for each material. The results show that the aluminum alloy piston has the highest maximum heat flux value, while the titanium alloy piston has the lowest maximum heat flux value. These findings can help engineers select the optimal material for a piston design based on its ability to withstand thermal stresses during engine operation.

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN: 2395-0072

© 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page 311

VARIOUS MATERIALS” International Research

Journal of Modernization in Engineering

Technology and Science,

Volume:03/Issue:05/May-2021, Impact Factor-

5.354, PAGE 3035-3044

5. Prashant Kumar, PG Scholar, Abhishek Bhandari,

Sunil Kumar Chaturvedi,” Design and thermal

analysis of ic engine piston design using catia and

Ansys software” SSRG International Journal of

Mechanical Engineering Volume 6 Issue 10, 12-19,

October 2019 ISSN: 2348 – 8360

6. Atthuru Kalyan , Dr. D. R. Srinivasan,” Static and

Thermal Analysis of a Piston with Different

Thermal Barrier Coatings”, International Journal of

Scientific Engineering and Research (IJSER) ISSN

(Online): 2347-3878 Impact Factor (2020): 6.733

7. Thirakavinod Kumar, B. Ravisekhar,“Thermal &

Static Analysis On IC Engine Piston Using Fea”,

IJATES,Issn2348-7550,Volume 4, Issue No.

12,December-2016, Page. No. 225-231

8. Yash Dhamecha, Vaibhav Saptarshi, Shubham

Parikh, Tejasve Parnami,” Design and Analysis of

Piston using Different Materials”, International

Research Journal of Engineering and Technology

(IRJET) e-ISSN: 2395-0056 Volume: 07 Issue: 12 |

Dec 2020 p-ISSN: 2395-0072

9. Ajay Raj Singh*, Dr. Pushpendra Kumar Sharma,

Design, Analysis and Optimization of Three

Aluminium Piston Alloys Using FEA “Journal of

Engineering Research and Applications

www.ijera.com ISSN : 2248-9622, Vol. 4, Issue 1(

Version 3, January 2014, pp.94-102

10. A.R. Bhagat , Y.M.Jibhakate “Thermal Analysis And

Optimization of I.C. Engine Piston Using finite

Element Method “International Journal of Modern

Engineering Research (IJMER) vol.2, Issue.4, July-

Aug 2012 pp-2919-2919 ISSN: 2249-6645

11. Mr.Jadhav Vishal, Dr. R.K. Jain, Mr. Yoge A.ndra

S.Chauhan,” DESIGN AND ANALYSIS OF

ALUMINUM ALLOY PISTON USING CAE TOOLS”,

“INTERNATIONAL JOURNAL OF ENGINEERING

SCIENCES & RESEARCH TECHNOLOGY, ISSN:

2277-9655 Impact Factor: 4.116 [Vishal*et al.,

5(7): July, 2016] ISSN: 2277-9655 IC™ Value: 3.00

12. PAGADALA SIDDIRAJU, KOPPULA

VENKATESWARAREDDY “DESIGN AND ANALYSIS

OF THE PISTON BY USING FIVE DIFFERENT

MATERIALS”, INTERNATIONAL JOURNAL OF

ADVANCE SCIENTIFIC RESEARCH AND

ENGINEERING TRENDS || Volume 6 || Issue 2 ||

February 2021 || ISSN (Online) 2456-0774

13. Subodh Kumar , SRCEM, Banmore M.P. India; C. S.

Koli, SRCEM, Banmore M.P. India “A Review Paper

on Thermal Analysis of Piston by Finite Element

Analysis” IJSRD - International Journal for

Scientific Research & Development| Vol. 5, Issue

12, 2018 | ISSN (online): 2321-0613

14. Pathipati Vasu, Dr.M.Sri Rama Murthy,

P.S.Amarnadh, “Design and Analysis of IC Engine

Piston with Different Materials”, International

Journal of Research e-ISSN: 2348-6848 p-ISSN:

2348-795X Volume 05 Issue 07 March 2018

15. V G Cioată, I Kiss, V Alexa and S A Rațiu,

“Mechanical and thermal analysis of the internal

combustion engine piston using Ansys”

International Conference on Applied Sciences

(ICAS2016), V G Cioată et al 2017 IOP Conf. Ser.:

Mater. Sci. Eng. 163 012043

16. Valentin Mereuta,” Static and Thermal Analysis of

Piston using FEM Analysis” International Journal

for Research in Applied Science & Engineering

Technology (IJRASET) ISSN: 2321-9653; IC Value:

45.98; SJ Impact Factor :6.887 Volume 6 Issue I,

January 2018

17. J. Srikanth, Mr. A. Jithendra Kumar, “Modeling and

Static Thermal Analysis of IC Engine Piston by

using Different Materials”, International Journal of

Applied Sciences, Engineering and Management

ISSN 2320 – 3439, Vol. 06, No. 02, April 2017, pp.

265 – 272

18. Kunal Saurabh1*, Saurabh Kumar Rai1, Shravan

Yadav1, Sanjay Kumar Yadav1 , AkhandPratap

Singh1, “A Review Paper on Design Analysis of

Internal Combustion Component, International

journal of adavance research in science and

engineering vol no.6 Special issue no.2, december

2017,ISSIN 2319-8354

19. Satish Sharma, P.S. Dhakar,” A Review Study of

Steady State Thermal Analysis of Piston by Finite

Element Method (FEM)” International Journal of

I.C. Engines and Gas Turbines Vol. 3: Issue 1](https://image.slidesharecdn.com/irjet-v10i444-230610121512-280bea45/75/Transient-state-thermal-analysis-of-a-4-stroke-CI-engine-Piston-7-2048.jpg)