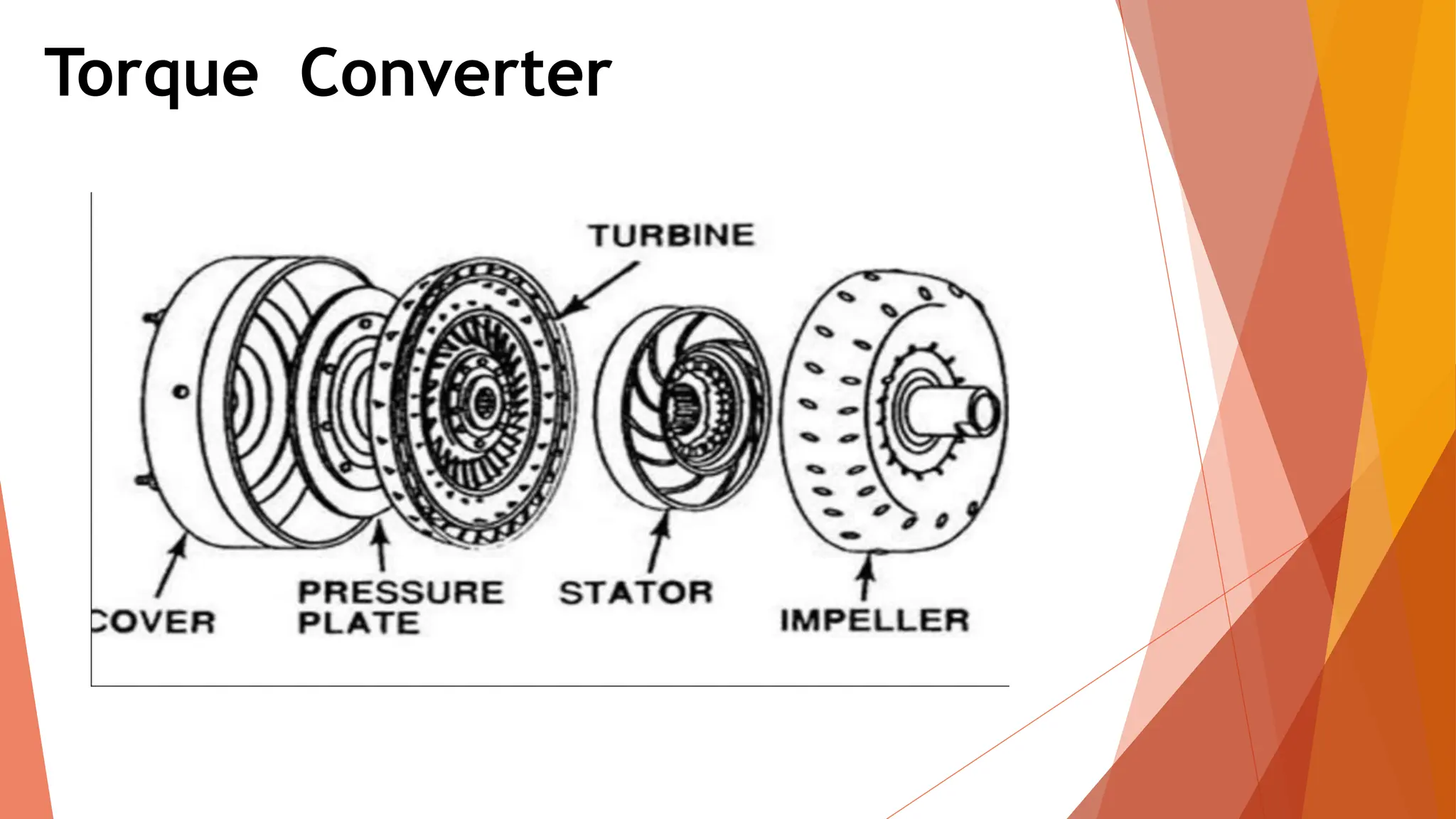

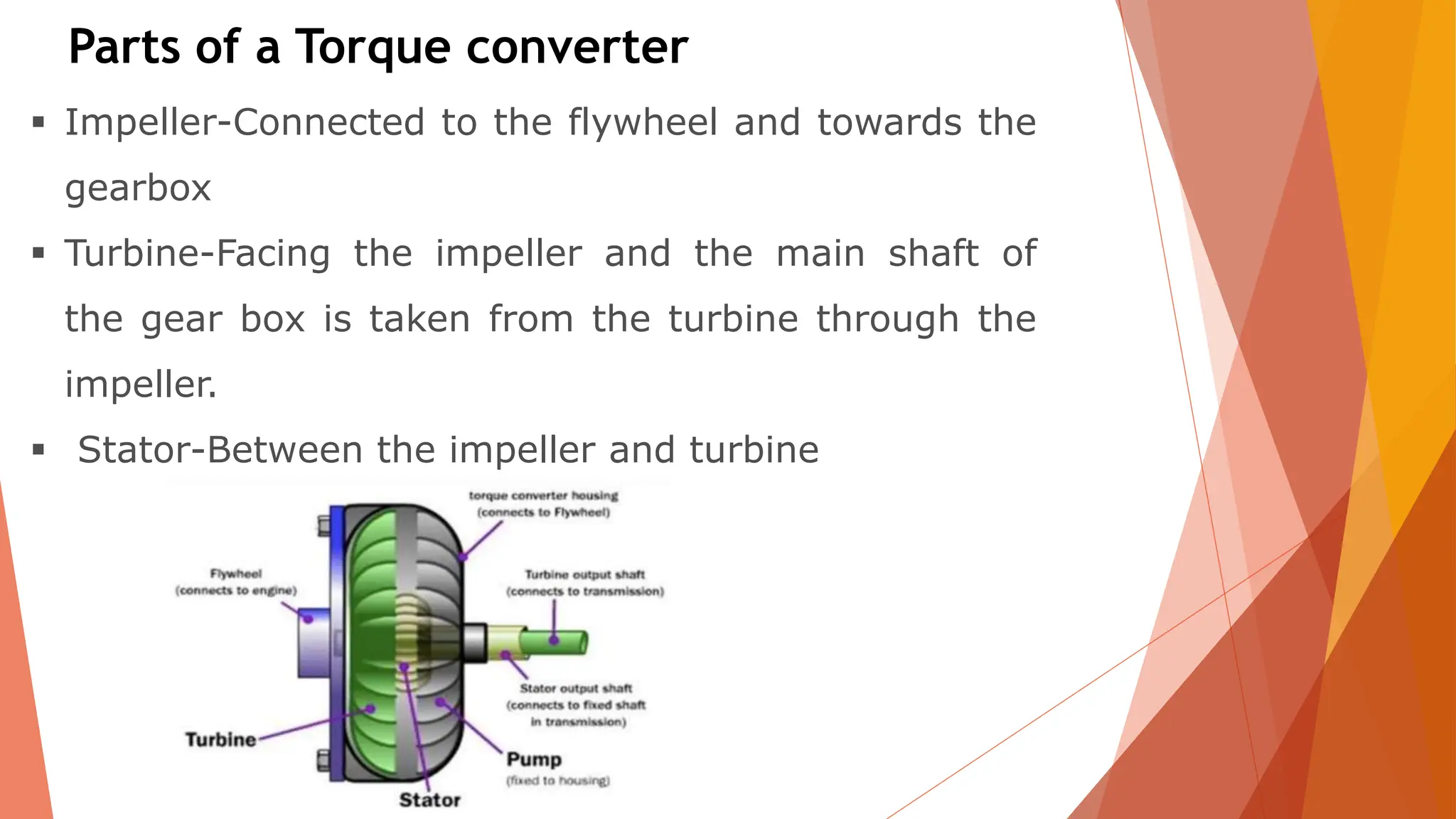

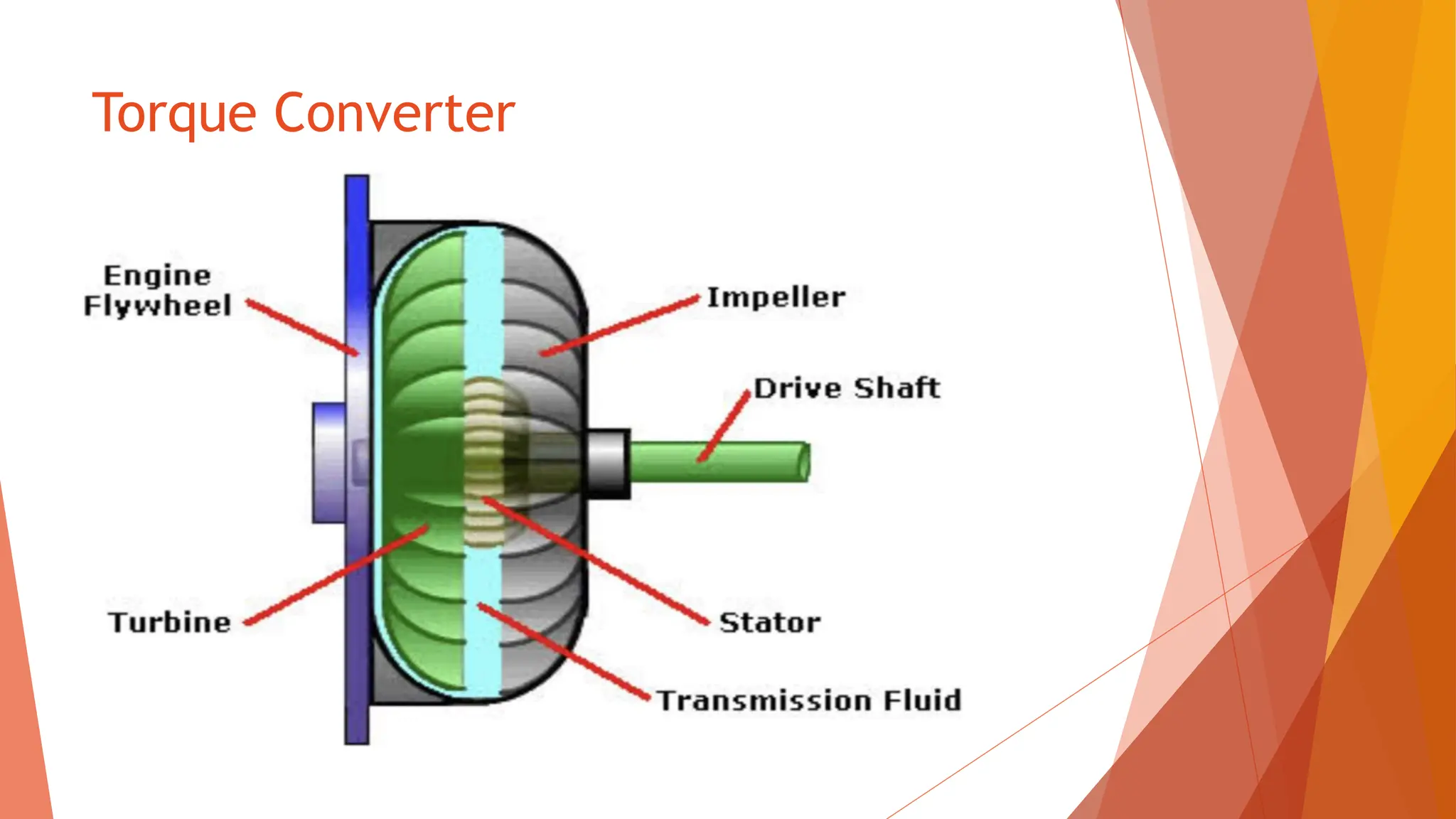

The document presents an overview of torque converters, detailing their function, parts, and operational phases within automatic transmissions. It explains how torque converters replace clutches, transmit and multiply torque, and outlines potential failure problems such as overheating and clutch breakage. The presentation is delivered by students from the Mechanical Engineering department at Karmaveer Bhaurao Patil College of Engineering, Satara.