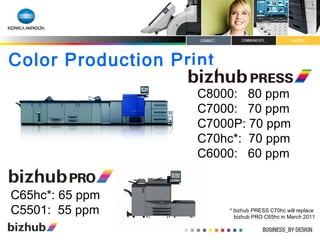

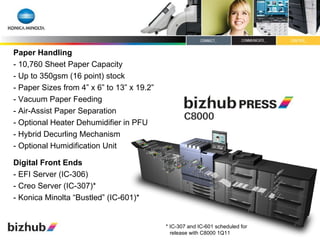

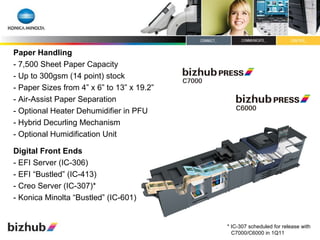

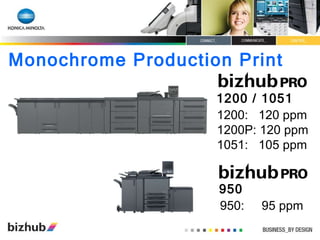

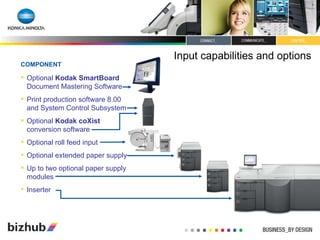

The document provides an overview of production print products from Konica Minolta and Kodak, including specifications and features. Konica Minolta offers various digital presses and monochrome printers ranging from 55 to 120 pages per minute, using technologies like Simitri toner and image processing. They have paper capacities up to 14,000 sheets and finishing options including stapling, binding and folding. Kodak's Digimaster series includes monochrome systems from 110 to 300 pages per minute, with inputs, processing, printing and sophisticated finishing capabilities.