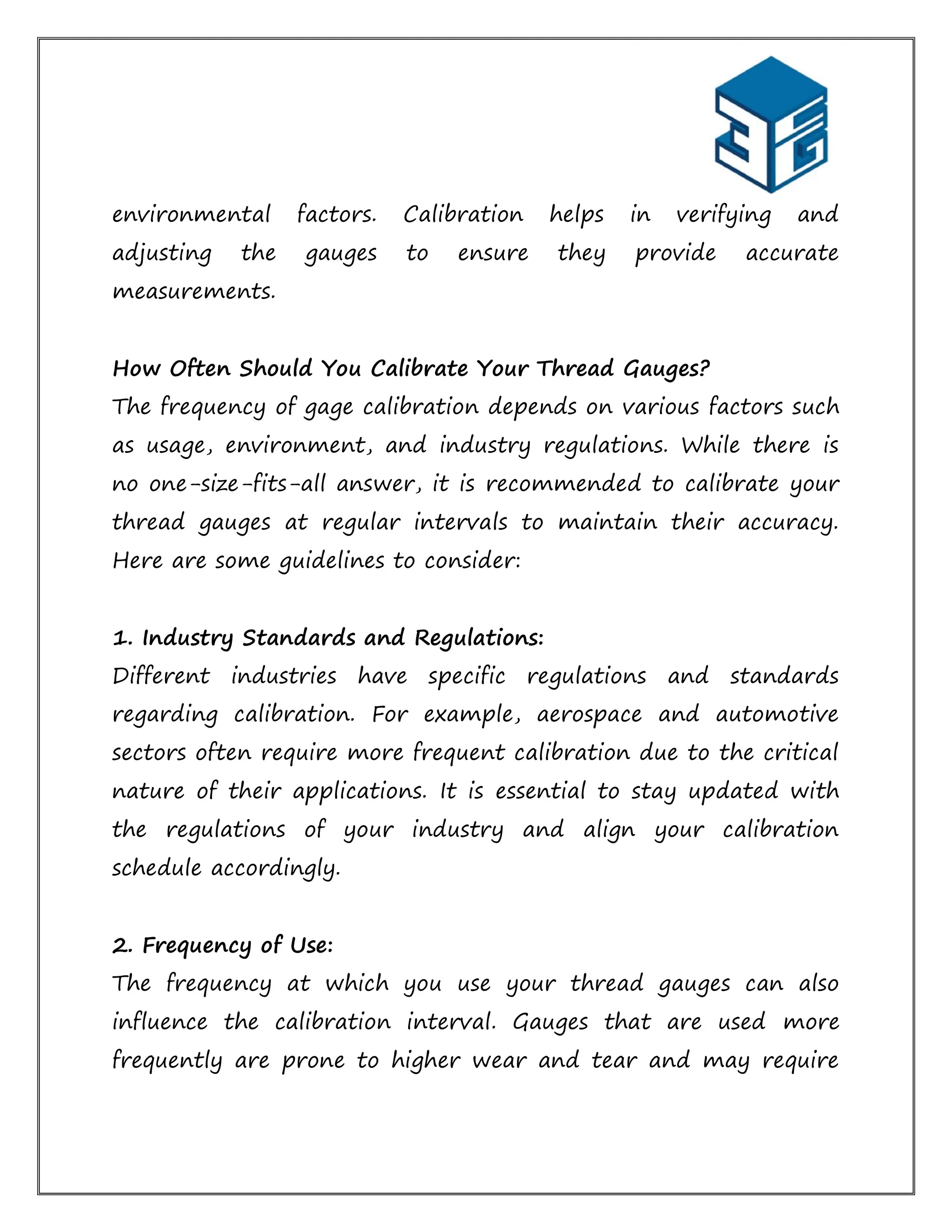

This document emphasizes the importance of regular calibration of thread gauges to ensure accuracy and precision in measurements across various industries such as manufacturing and aerospace. It outlines guidelines for calibration frequency based on industry regulations, usage, environmental conditions, manufacturer's recommendations, and calibration history. Benefits of regular calibration include improved accuracy, compliance with standards, cost savings, and enhanced customer satisfaction.