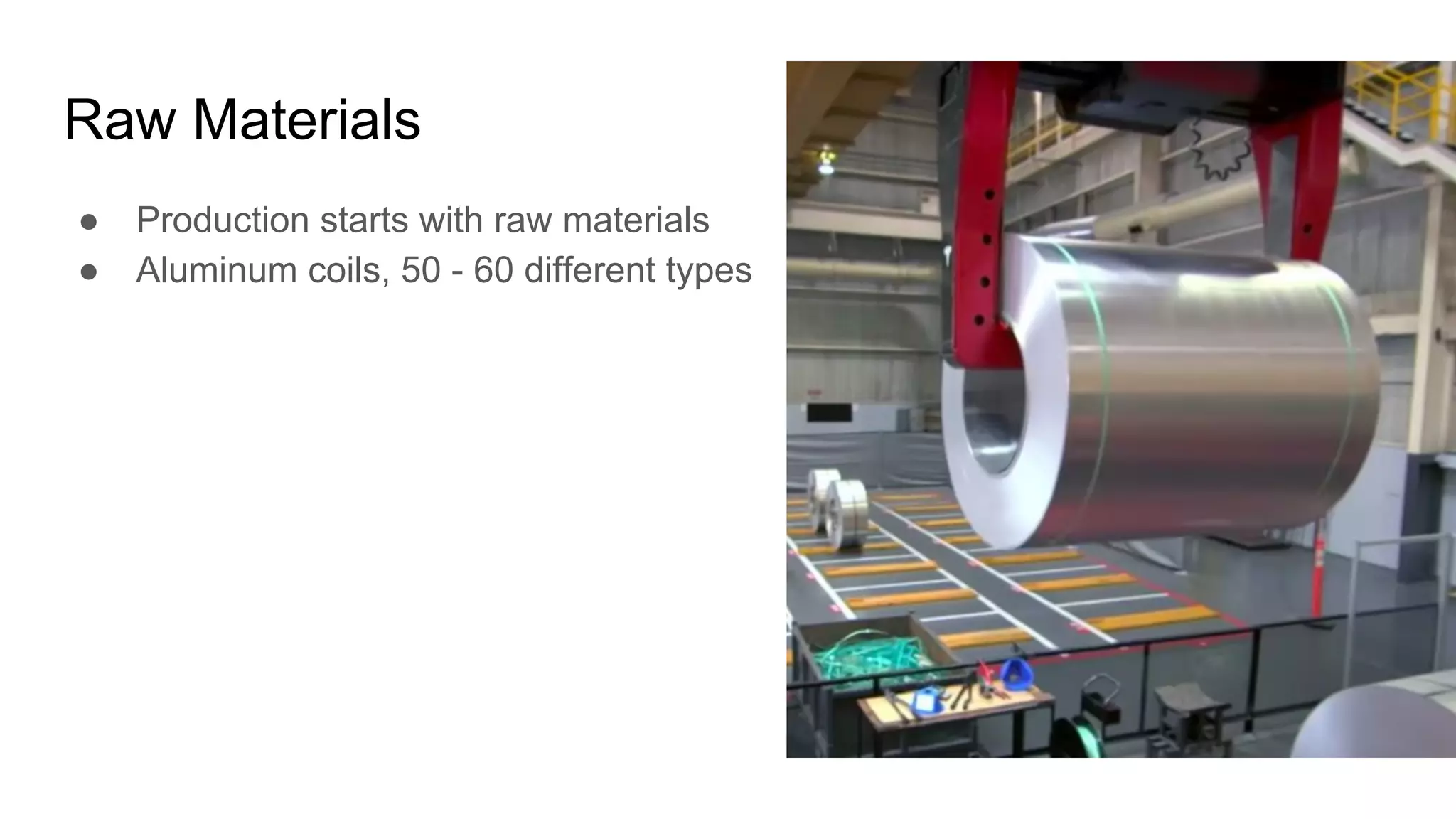

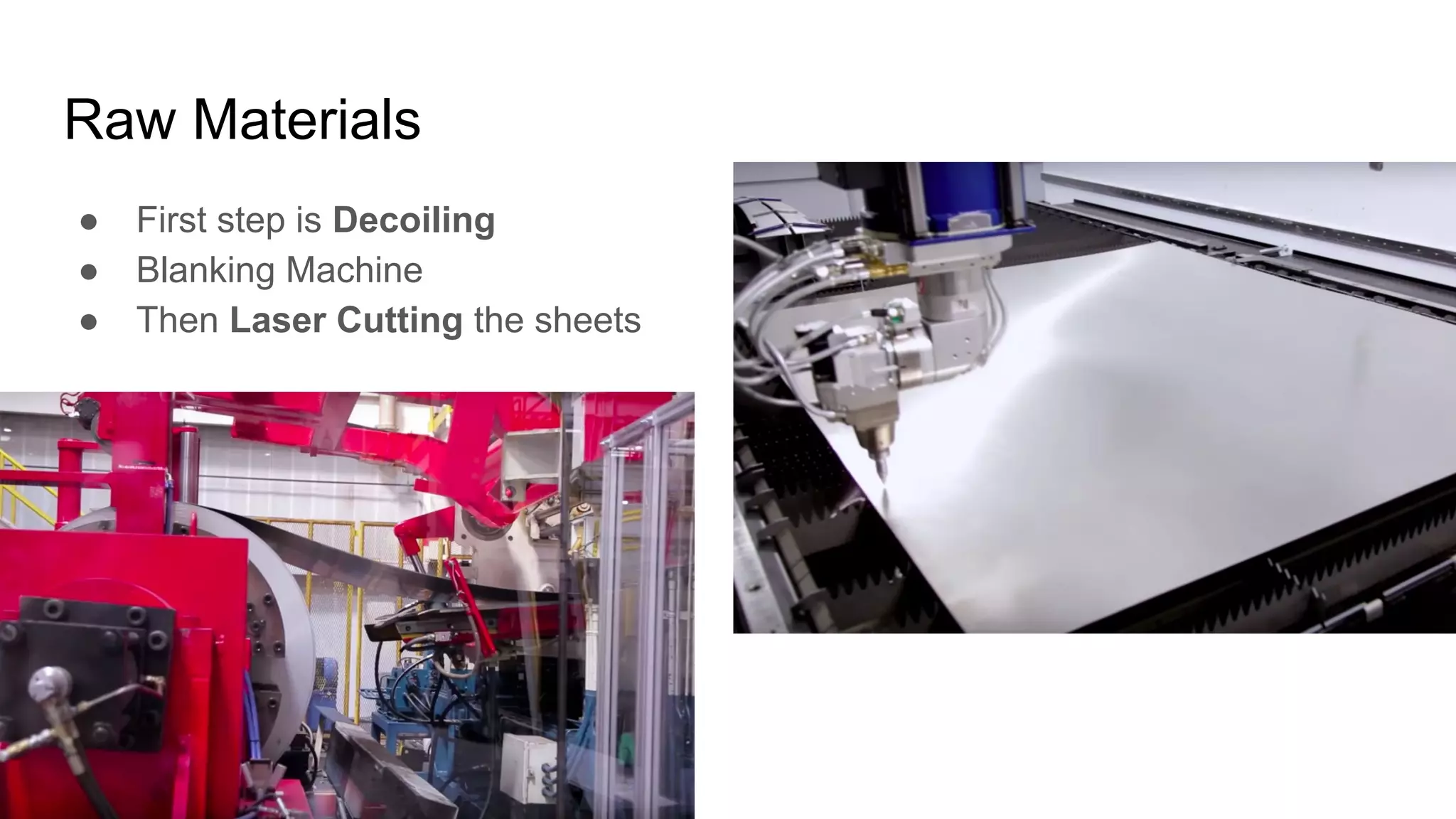

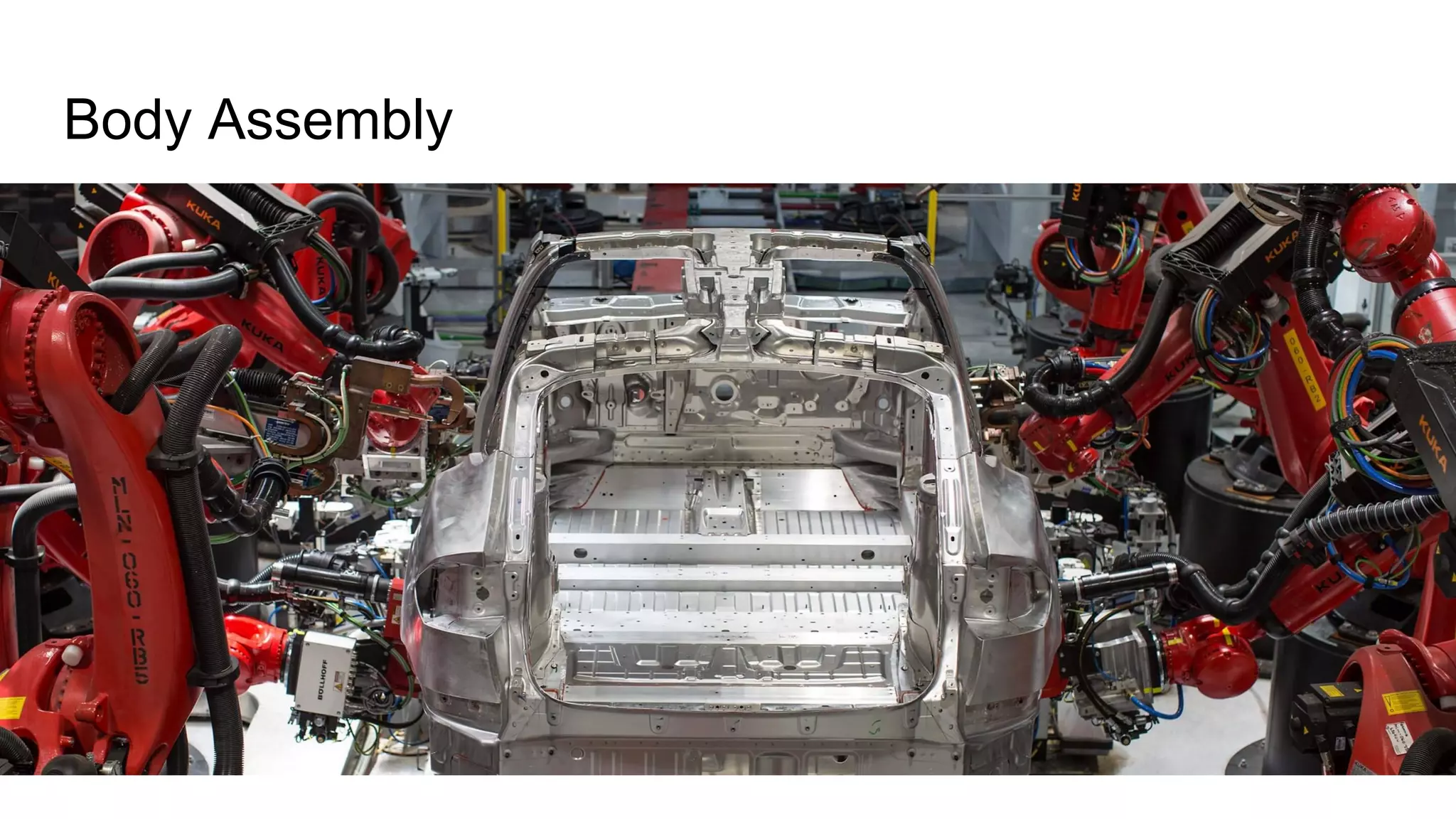

The document summarizes the automation processes used in Tesla's Model S assembly line. It discusses how 98% of the aluminum body is assembled using a tandem press line and robots install side parts. It also describes the painting process which includes pretreatment, primer, base, and clear coats. Finally, it notes that while automation is used, some tasks like door and panel installation still require manual work and that over-automating simple tasks can increase costs.