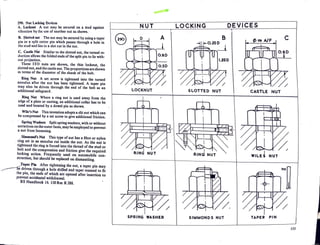

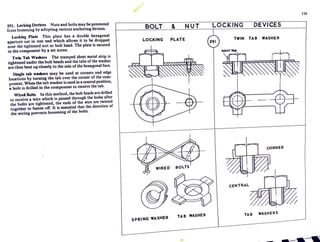

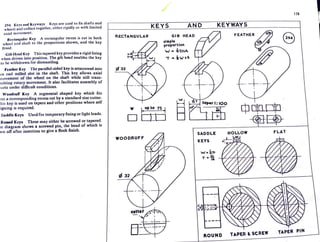

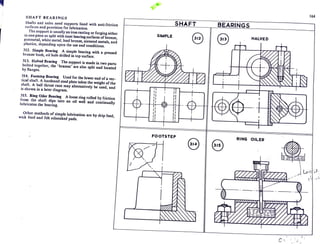

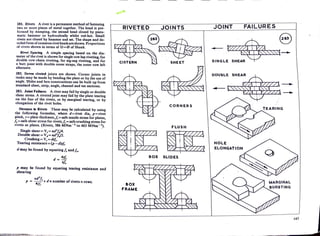

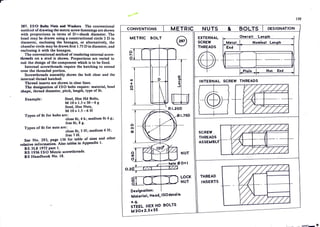

The document discusses various types of mechanical fastenings, including rivets, bolts, nuts, and machine screws, detailing their forms, proportions, and applications in engineering. It covers joint failures, methodologies for calculating stresses in riveted joints, and conventional designation for ISO screws and bolts. Additionally, it introduces locking devices for nuts and bolts, along with key types for securing shafts and wheels in mechanical assemblies.

![I

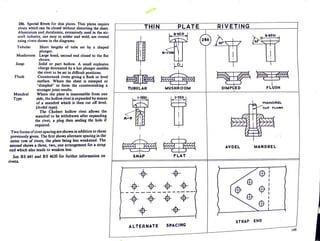

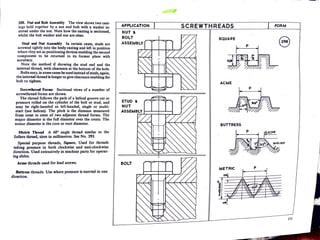

289. Machine Screws ISO machine screws take the

form shown in the diagrams. The proportions are given

in terms of the shank diameter.

Countersunk bead machine screws are used whena flush

finish is required on the outer surface. The head is either

slotted as shown, for use with a plain flat screwdriver or

recessed. A recessed head has a crossed closed slot're-

quiring the use of a Philips screwdriver.

Raised countersunk head screws give a small projection

of the head beyond the general surface.

Pao head screws require no countersinking and all the

head projects beyond the plate surface.

Cl!eese bead screws also give ahead projection beyond

the plate surface.

Square Head Set Screw is often used to fix collars,

gears and wheels to shafts, though the head can give·

imbalance~

Grub screws, slotted for screwdriver give a non-projec-

tion finish, and are useful for fixing collars, wheels, gib

strips.

Hexagon Socket screws have that shape recess in the

head, weakening the head less than the slot, and are

·tightened by the use of a hexagon socket key. This is a

piece of hexagonal sectioned rod with rightangled bend

to give torque.

Cap socket screws are the shape shown~ and are used

for securing covers and flanges which is counterbored to

take the caphead giving a 1lush finish.

COU11tersunk bead screws also have hexagonal sockets

for use with a key.

The ends ofmachine screws may be rolled, chamfcr~d,

radiuscd, ,coned, cup, w point, dog as suited to the special

purpose. h h

TabJes in Appendix I give the size A/F oft e exagon

socket relative to the head size of various socket.screws.

152

MACHINE SCREWS

COUNTERSUNK RAISED CSK PAN CHEESE e

20 20 20

1.75 D 1 1.75 D 0.'40 0.25D

1.60 ·i

r" .f ~0.25

0.25D-I 1.0-25D1 IJ_ I059._-<{ lo--0.25

J 0.3D

1

,1 I I 17 , . ~ - .7 r- I

I 0.6~

-'----- - - -

_.,,, ........,,...,. I'

VI 0 .ro IV I II 11 11 11

.:c

,

z

11 I I 11

l&J

D 11 I I 11 11 .J

SQ HP SET SCREW 1·1 GRUB SCREW

II CAP

SOCKET SCREWS

1.25D _1 SLOTTED I.SD

-1t: GRUB

I I I I

I I I I

~!> -}.7J

.&

o1 II o.;m 1 ~.2so II I

-R0:1SD11l']

rT'"' ~t_-_;;

I / 1.25D

SCREW

ENDS

D _11

45° II

IN

D-1

:t~

ROLLED

:c

t;

z

l&J

J

D

I II u y

CHAMFER

"

~, LV

z

l&J

_J

II u b ~up

RAOIUSED CONE

,_,,_... ·~-ti-'.""J~](https://image.slidesharecdn.com/conventions-240525204353-62a6a121/85/TECHNICAL-DRAWING-CONVENTIONS-LISTSS-pdf-7-320.jpg)