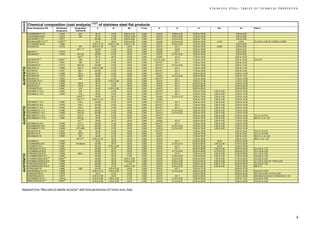

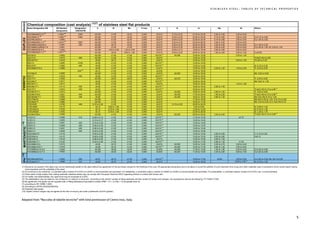

The document provides tables of technical properties for stainless steel flat products, including chemical composition, mechanical properties, and physical properties. It aims to assist readers in selecting the appropriate stainless steel grade for applications. The tables reflect data from stainless steel development associations across Europe and adhere to relevant European standards. Some additional American grades are also included for information. The publisher disclaims liability for any issues resulting from use of the provided information.

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

Mechanical properties of stainless steel flat products

DESIGNATIONS

GRADES

Product Form Thickness Heat Treatment Hardness Proof strength Tensile strength Elongation after fracture Impact energy (ISO-V)

( )

(1) max (5) (13)

Rp0,2 A80mm A KV

EN HRB HB or HV [MPa] [%] [%] [J]

AISI/ASTM Rm

[N°] max max min. min min min

(14) (15) (2) (3) th>10mm

th<3mm th 3mm

[mm] (transverse) [MPa] (longitudinal) (transverse)

(tr. and long.) (tr. and long.)

C 8 350

45 45

1.4372 (I) 201 H 13,5 AT 90 (30) 241 (42) 330 from 750 to 950

100 60

P (4) 75 330 40 40

C 8 340

from 680 to 880 45 45

1.4373 (I) 202 H 13,5 AT 90 (30) 241 (42) 320

100 60

(4)

P 75 320 from 600 to 800 35 35

C 8 300

from 650 to 850 45 45

1.4371 (I) H 13,5 AT 280

100 60

P (4) 75 280 from 630 to 830 35 35

C 8 AT 300

(I)

1.4597 from 580 to 780 40 40

H 13,5 300 100 60

AUSTENITIC

(I)

1.4369 C 4 AT 340 from 750 to 950 35 35

1.4310 (I) 301 C 8 AT 85 (19) 217 (42) 250 from 600 to 950 40 40

301 L (45) AT 100 241 220 * min 550 45 *

C 3 230

1.4319 (I) AT from 550 to 750 45

H 6 230 45

C 8 350

from 650 to 850 35 40

1.4318 (I) 301 LN H 13,5 AT 100 (42) 241 (42) 330

90 60

P (4) 75 330 from 630 to 830 45 45

85 (30) 276 * (30) 50 * (30)

302 (35) AT 201 (42) 621 108 (31)

80 (31) 241 * (31) 60 * (31)

1.4305 (I) 303 P (4) 75 AT 190 from 500 to 700 35 35

C 8 80 (19) 230 from 540 to 750

45 (16) 45 (16)

1.4301 (I) 304 H 13,5 AT 80 (20) 210

from 520 to 720 100 60

(4) (21)

AUSTENITIC

P 75 149 210 45 45

C 8 290

1.4311 (I) 304 LN H 13,5 AT 95 (42) 217 (42) 270 from 550 to 750 40 40

100 60

P (4) 75 270

C 6 230 from 530 to 740

(III)

45 (16) 45 (16)

1.4948 304 H H 12 AT 92 (42) 201 (42) 210 100 60

from 510 to 710

P 75 190 45 45

(19)

C 8 79 220

from 520 to 700

1.4307 (I) 304 L H 13,5 AT 79 (20) 200 45 45

100 60

P (4) 75 143 (21) 200 from 500 to 700

C 8 79 (19) 220

from 520 to 700

1.4306 (I) 304 L H 13,5 AT 79 (20) 200 45 45

100 60

(4) (21)

P 75 143 200 from 500 to 700

C 8 290

1.4315 (I) 304 N H 13,5 AT 85 (20) 217 (42) 270 from 500 to 750 40 40 100 60

P (4) 75 270

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

7](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-9-320.jpg)

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

Mechanical properties of stainless steel flat products

DESIGNATIONS

GRADES

Product Form Thickness Heat Treatment Hardness Proof strength Tensile strength Elongation after fracture Impact energy (ISO-V)

( )

(1) max (5) (13)

Rp0,2 A80mm A KV

EN HRB HB or HV [MPa] [%] [%] [J]

AISI/ASTM Rm

[N°] max max min. min min min

(14) (15) (2) (3) th>10mm

th<3mm th 3mm

[mm] (transverse) [MPa] (longitudinal) (transverse)

(tr. and long.) (tr. and long.)

1.4303 (I) 305 C 8 AT 80 (30) 183 (42) 220 from 500 to 650 45 45

1.4828 (II) (32)

75 AT 223 (17) 230 * from 550 to 750 28 (26) 30 30 (46)

(II) (32) (30) (17) (26)

1.4833 75 AT 85 192 210 * from 500 to 700 33 35 30 (46)

309 S

1.4845 (II)

310 S (32)

75 AT 95 (42)

192 (17)

210 * from 500 to 700 33 (26)

35 30 (46)

1.4841 (II)

314 75 AT 223 (17) 230 * from 550 to 750 28 (26) 30 30 (46)

AUSTENITIC

C 8 79 (19) 240

from 530 to 680 40 40

1.4401 (I) 316 H 13,5 AT 79 (20) 220

100 60

P (4) 75 149 (21) 220 from 520 to 670 45 45

(19)

C 8 79 240

from 550 to 700 40 40

1.4436 (I) 316 H 13,5 AT 79 (20) 220

100 60

(4)

P 75 149 (21) 220 from 530 to 730 40 40

316 N (35) AT 85 (20) 217 (42) 331 * 621 48 *

316 H (45) AT 95 217 205 * min 515 40 *

C 8 79 (19) 240

from 530 to 680 40 40

1.4404 (I) 316 L H 13,5 AT 79 (20) 220

100 60

(4) (21)

P 75 146 220 from 520 to 670 45 45

(19)

C 8 79 240

from 550 to 700 40 40

1.4435 (I) 316 L H 13,5 AT 79 (20) 220

100 60

P (4) 75 146 (21) 220 from 520 to 670 45 45

AUSTENITIC

C 8 79 (19) 240

from 550 to 700 40 40

1.4432 (I) 316 L H 13,5 AT 79 (20) 220

100 60

(4) (21)

P 75 146 220 from 520 to 670 45 45

C 8 300

1.4406 (I) 316 LN H 13,5 AT 95 (42) 217 (42) 280 from 580 to 780 40 40

100 60

P (4) 75 280

C 8 300

35 35

1.4429 (I) 316 LN H 13,5 AT 95 (42) 217 (42) 280 from 580 to 780

100 60

(4)

P 75 280 40 40

C 8 240

from 540 to 690

1.4571 (I) 316 Ti H 13,5 AT 95 (42) 217 (42) 220 40 40

100 60

P (4) 75 220 from 520 to 670

1.4580 (I) 316 Cb P (4) 75 AT 95 (42) 217 (42) 220 from 520 to 720 40 40 100 60

317 (35) AT 85 (30) 160 (21) 276 * from 586 to 621 from 45 to 50 * 149

C 8 240

from 550 to 700 35 35

1.4438 (I) 317 L H 13,5 AT 85 (20) 217 (42) 220

100 60

P (4) 75 80 (31) 220 from 520 to 720 40 40

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

8](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-10-320.jpg)

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

Mechanical properties of stainless steel flat products

DESIGNATIONS

GRADES

Product Form Thickness Heat Treatment Hardness Proof strength Tensile strength Elongation after fracture Impact energy (ISO-V)

( )

(1) max (5) (13)

Rp0,2 A80mm A KV

EN HRB HB or HV [MPa] [%] [%] [J]

AISI/ASTM Rm

[N°] max max min. min min min

(14) (15) (2) (3) th>10mm

th<3mm th 3mm

[mm] (transverse) [MPa] (longitudinal) (transverse)

(tr. and long.) (tr. and long.)

C 8 290

from 570 to 770 35 35

1.4434 (I) 317 LN H 13,5 AT 95 (42) 217 (42) 270

100 60

P (4) 75 270 from 540 to 740 40 40

C 8 290

35 35

1.4439 (I) 317 LMN H 13,5 AT 96 (42) 223 (42) 270 from 580 to 780

100 60

(4)

P 75 270 40 40

C 8 80 (19) 220

from 520 to 720

1.4541 (I) 321 H 13,5 AT 80 (20) 200 40 40

100 60

P (4) 75 160 (21) 200 from 500 to 700

(II) (32) (42) (17) (26) (46)

1.4878 321 H 75 AT 95 215 190 * from 500 to 720 40 40 45

AUSTENITIC

C 8 85 (19) 220

from 520 to 720

(I) (20)

1.4550 347 H 13,5 AT 85 200 40 40

100 60

P (4) 75 160 (21) 200 from 500 to 700

347 H (45) AT 92 201 205 * min 515 40 *

1.4335 (I) P 75 AT 200 from 470 to 670 40 40 100 60

1.4466 (I) 310 MoLN P (4) 75 AT 95 (42) 217 (42) 250 from 540 to 740 40 40 100 60

1.4361 (I) P (4) 75 AT 220 from 530 to 730 40 40 100 60

1.4563 (I) P (4) 75 AT from 70 to 90 (48)

220 from 500 to 700 40 40 100 60

1.4537 (I) P (4) 75 AT 290 from 600 to 800 40 40 100 60

C 8 240

from 530 to 730 35 35

1.4539 (I) 904 L H 13,5 AT 90 (42) 220

100 60

(4)

P 75 220 from 520 to 720 35 35

C 8 320

AUSTENITIC

35 35

1.4547 (I) H 13,5 AT 96 (42) 223 (42) 300 from 650 to 850

100 60

(4)

P 75 300 40 40

C 8 430

(I)

1.4652 H 13,5 AT 430 from 750 to 1000 40 40 100 60

P 75 430 100 60

1.4659 (I) P (4) 75 AT 420 from 800 to 1000 40 100 60

1.4529 (I) P (4) 75 AT 300 from 650 to 850 40 40 100 60

C 6

1.4565 (I) H 10 AT 420 from 800 to 950 30 30 120 90

P 40

1.4864 (II)

330 (35) AT 223 (17) 230 * from 550 to 750 28 (26) 30 30 (47)

(II) (32)

1.4835 75 AT 95 (42) 210 (17) 310 * from 650 to 850 37 (26) 40

1.4876 (II) (32)

AT 86 (49) (50) 192 (17) 170 * from 450 to 680 28 (26) 30 30 (47)

1.4877 (II)

AT 95 (22) 223 (17) 180 * from 500 to 750 30 * (22)

(II) (32)

1.4818 AT 95 (42) 210 (17) 290 * from 600 to 800 30 (26) 40

(II) (32)

1.4854 AT 95 (42) 210 (17) 300 * from 650 to 850 40 (26) 40

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

9](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-11-320.jpg)

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

Mechanical properties of stainless steel flat products

DESIGNATIONS

GRADES

Product Form Thickness Heat Treatment Hardness Proof strength Tensile strength Elongation after fracture Impact energy (ISO-V)

( )

(1) max (5) (13)

Rp0,2 A80mm A KV

EN HRB HB or HV [MPa] [%] [%] [J]

AISI/ASTM Rm

[N°] max max min. min min min

(14) (15) (2) (3) th>10mm

th<3mm th 3mm

[mm] (transverse) [MPa] (longitudinal) (transverse)

(tr. and long.) (tr. and long.)

(23) (44)

C 8 500 20 20

from 700 to 950

1.4462 (I) 2205 H 13,5 AT 31 (33) 293 (42) 460 (23) (44) 25 25

100 60

P 75 460 (23) (44) from 640 to 840 25 25

C 8 450 (23) (44)

from 650 to 850 20 20

1.4362 (I) 2304 H 13,5 AT 32 (33) 290 (42) 400 (23) (44)

100 60

(23) (44)

P 75 400 from 630 to 800 25 25

(23) (44)

C 8 420

from 600 to 850 20 20

1.4655 (I) H 13,5 AT 400 (23) (44)

100 60

P 75 400 (23) (44) from 630 to 800 25 25

550 (23) (44)

DUPLEX

C 8

from 750 to 1000 15 15

1.4410 (I) 2507 H 13,5 AT 32 (33) 310 (42) 530 (23) (44)

100 60

P 75 530 (23) (44) from 730 to 930 20 20

(23) (44)

C 8 550

from 750 to 1000 17 17

1.4507 (I) 255 H 13,5 AT 32 (33) 302 (42) 530 (23) (44)

100 60

P 75 530 (23) (44) from 730 to 930 25 25

1.4501 (I) P 75 AT 270 (42) 530 (23) (44) from 730 to 930 25 25 100 60

C 8

450 (23) (44) from 700 to 900

1.4424 (I) H 13,5 AT 25 25 100 60

(23) (44)

P 75 400 from 680 to 900

C 8 650 (23) (44) from 800 to 1050

1.4477 (I) H 13,5 AT 550 (23) (44) 20 20

from 750 to 1000 100 60

(23) (44)

P 75 550

C 8

320 * 20

1.4003 (I) H 13,5 A 89 (42) 183 (42) from 450 to 650 100 (37)

P 25 (18) 280 * 18

C 8

1.4512 (I) 409 A 75 (30) 220 * from 380 to 560 25

H 13,5

FERRITIC

C 8

320 * 23

1.4516 (I) H 13,5 A from 450 to 650 150 (34)

P 25 (18) 280 * 20

C 8 250 *

1.4000 (I) 410 S H 13,5 A 89 (42) 183 (42) 230 * from 400 to 600 19

P 25 (18) 230 *

C 8 250 *

1.4002 (I) 405 H 13,5 A 75 (20) 230 * from 400 to 600 17

(18) (21)

P 25 150 230 *

C 8 420 * 16

1.4589 (I) A from 550 to 750

H 13 , 5 380 * 14

429 (35) A 80 163 276 * 483 30 *

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

10](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-12-320.jpg)

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

Mechanical properties of stainless steel flat products

DESIGNATIONS

GRADES

Product Form Thickness Heat Treatment Hardness Proof strength Tensile strength Elongation after fracture Impact energy (ISO-V)

( )

(1) max (5) (13)

Rp0,2 A80mm A KV

EN HRB HB or HV [MPa] [%] [%] [J]

AISI/ASTM Rm

[N°] max max min. min min min

(14) (15) (2) (3) th>10mm

th<3mm th 3mm

[mm] (transverse) [MPa] (longitudinal) (transverse)

(tr. and long.) (tr. and long.)

1.4595 (I) C 8 A 220 * from 380 to 560 25

FERRITIC

C 8 280 * 20

85 (30) from 450 to 600

1.4016 (I) 430 H 13,5 A 260 * 18

P 25 (18) 160 (21) 260 * from 430 to 630 20

1.4520 (I) C 8 A 200 * from 380 to 530 24

1.4511 (I) C 8 A 240 * from 420 to 600 23

1.4017 (I) C 8 A 350 * from 500 to 750 12

C 8

1.4113 (I) 434 A 83 (30) 280 * from 450 to 630 18

H 13,5

(I)

1.4513 C 8 A 220 * from 400 to 550 23

C 8

1.4510 (I) 439 A 89 (42) 183 (42) 240 * from 420 to 600 23

H 13,5

C 8 320 * from 420 to 640

1.4521 (I) 444 H 13,5 A 96 (42) 217 (42) 300 * from 400 to 600 20

FERRITIC

P 13,5 300 * from 420 to 620

1.4526 (I) 436 C 8 A 300 * from 480 to 560 25

1.4509 (I) C 8 A 250 * from 430 to 630 18

1.4590 (I) C 8 A 250 * from 400 to 550 23

(II) (32)

1.4749 446 12 A 212 (17) 280 * from 500 to 700 13 (26) 15 (28) 15 (29)

(II) (32)

1.4713 13,5 A 192 (17) 220 * from 420 to 620 20 (28) 15 (29)

(II) (32)

1.4724 13,5 A 192 (17) 250 * from 450 to 650 13 (26) 15 (28) 15 (29)

(II) (32)

1.4762 A 223 (17) 280 * from 520 to 720 13 (26) 15 (28) 15 (29)

1.4592 (I) C 8 A 450 * from 550 to 700 20

C 8

A 90 (6) 200 (6) 205 * (41) max 600 20

410 H 13,5

1.4006 (I)

QT550 400 * from 550 to 750 15 upon

P (4) (7) 75

QT650 450 * from 650 to 850 12 agreement

C 8 max 650 20

90 (6) 200 (6)

H 13,5 A max 650 20

1.4024 (I) P 75

upon

P 75 QT550 400 * from 550 to 750 15

agreement

MARTENSITIC

P 75 QT650 450 * from 650 to 850 12

C 3 QT from 44 to 50 (24) from 440 to 530 (25)

C 8

A 95 (6) 225 (6) 345 * (19) max 700 15

1.4021 (I) 420 H 13,5

QT650 450 * from 650 to 850 12 upon

P (4) (7) 75

QT750 550 * from 750to 950 10 agreement

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

11](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-13-320.jpg)

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

Mechanical properties of stainless steel flat products

DESIGNATIONS

GRADES

Product Form Thickness Heat Treatment Hardness Proof strength Tensile strength Elongation after fracture Impact energy (ISO-V)

( )

(1) max (5) (13)

Rp0,2 A80mm A KV

EN HRB HB or HV [MPa] [%] [%] [J]

AISI/ASTM Rm

[N°] max max min. min min min

(14) (15) (2) (3) th>10mm

th<3mm th 3mm

[mm] (transverse) [MPa] (longitudinal) (transverse)

(tr. and long.) (tr. and long.)

C 3 QT from 45 to 51 (24) from 450 to 550 (25)

C 8

1.4028 (I) 420 A 97 (6) 235 (6) 345 * (19) max 740 15

H 13,5

(4) (7)

P 75 QT800 600 * from 800 to 1000 10

C 3 QT from 47 to 53 (24) from 480 to 580 (25)

1.4031 (I) 420 C 8

A 98 (6) 240 (6) 345 * (19) max 760 12

H 13,5

C 8

1.4034 (I) 420 A 99 (6) 245 (6) 345 * (19) max 780 12

H 13,5

C 8

1.4116 (I) A 100 (6) 280 (6) max 850 12

H 13,5

C 8

100 (6) 280 (6) max 850 12

1.4110 (I) H 13,5 A

P 75

MARTENSITIC

C 3 QT from 46 to 52 (24) from 450 to 560 (25)

1.4419 (I) C 4

(6)

A 97 235 (6) max 760 15

H 6,5

(24) (25)

C 3 QT from 47 to 53 from 480 to 580

1.4122 (I) C 8

A 100 (6) 280 (6) max 900 12

H 13,5

QT780 630 * from 780 to 980 15

1.4313 (I) P (4) 75 70

QT900 800 * from 900 to 1100 11

(I) (4)

1.4418 P 75 QT840 660 * from 840 to 1100 14 55

H 13,5 A 100 (6) 300 (6)

1.4422 (I) 550 * from 750 to 950 15 100

(25)

P 75 QT650 max 300

H 13,5 A 100 (6) 300 (6)

1.4423 (I) 550 * from 750 to 950 15 100

P 75 QT650 max 300 (25)

AT (8) 35 (38) 1000 * (20) 1275 5

C 8 P1300 (9) 1150 * 1300 3

P900 (9) 700 * 900 6

1.4542 (I) 630 P1070 (10) 1000 * from 1070 to 1270 8 10

PH

P950 (10) 800 * from 950 to 1150 10 12

P 50

P850 (10) 600 * from 850 to 1050 12 14

SR630 (11) 1050

AT (8) (12) 92 (43) max 380 * (43) 1030 19

1.4568 (I) 631 C 8

P1450 (9) 1310 * 1450 2

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

12](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-14-320.jpg)

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

(23) If, in the case of strip in rolling widths < 300mm, longitudinal test pieces are taken, minimum proof strength values are reduced by 15 MPa

(24) HRC hardness

(25) HV hardness

(26) Elongation after fracture A% for thicknesses 0.5 ≤ s < 3 mm (longitudinal, transverse)

(27) For thicknesses exceeding 25 mm (duplex grades), mechanical properties may be agreed upon

(28) Elongation after fracture A% for thicknesses s ≥ 3 mm (longitudinal)

(29) Elongation after fracture A% for thicknesses s ≥ 3 mm (transverse)

(30) Value for Strip/Sheet formats according to AISI manual, December 1974 edition; supplement, March 1979

(31) Value for Plate format according to AISI manual, December 1974 edition; supplement, March 1979

(32) Product form: flat products (in general)

(33) Hardness (HRC) according to ASTM A 240 / A 240 M-05a

(34) Impact energy KV at room temperature in accordance with NF A 35-573, May 1990

(35) Properties according to AISI manual, December 1974 edition; supplement, March 1979

(36) Properties according to ASTM A 176-99 (reapproved 2004)

(37) Value according to SEW 400, 1997

(38) Hardness value (HRC) for Sheet format according to AISI manual, December 1974 edition; supplement, March 1979

(39) IZOD impact test [J]

(40) Solely for martensitic and PH types, the number after the letters identifies a specific heat treatment as per tables A.2 and A.3 of EN 10088-2, June 2005

(41) According to ASTM A 176-99 (reapproved 2004)

(42) According to ASTM A 240 / A 240 M-05a. In the absence of an equivalent Type, reference is made to the UNS number

(43) According to ASTM A 693-93

(44) Only note (15) in the column heading applies

(45) Properties according to ASTM A 240 / A 240 M-05a

(46) Impact energy KU at room temperature in accordance with NF A 35-578, October 1991

(47) Value at room temperature in accordance with NF A 35-578, October 1991

(48) Value for guidance purposes according to ASTM B 709-04

(49) Value according to ASTM B 409-01

(50) Value for Sheet and Strip formats. For Strip format with thickness between 0.13 and 0.25 mm, the maximum HRB value is 88

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

14](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-16-320.jpg)

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

Physical properties of stainless steels

GRADES DESIGNATIONS MODULUS OF MEAN COEFFICIENT OF THERMAL THERMAL ELECTRICAL

DENSITY SPECIFIC HEAT

( ) ELASTICITY EXPANSION CONDUCTIVITY RESISTIVITY

EN

AISI/ASTM at 20°C at 20°C [10-6xK-1] at 20°C at 20°C at 20°C

[N°]

[kg/dm3] [GPa] 20°C 200°C 20°C 400°C [W/(m xK)] [J/(kgxK)] 2

[ xmm )/m]

(I) (a) (b) (e)

1.4372 201 7,8 200 15,7 17,5 15 500 0,70

(I) (f) (b) (d)

1.4373 202 7,8 200 17,5 18,4 15 503 0,70

(I)

1.4371 7,8 200 17,5 18,5 15 500 0,70

(I)

1.4597 7,8 200 16,5 17,0 15 500 0,73

(I)

1.4369 7,9 190 17,0 18,5 15 500 0,70

(I)

1.4310 301 7,9 200 17,0 18,0 15 500 0,73

(I)

1.4319 7,9 200 16,5 17,5 15 500 0,73

(I)

1.4318 301LN (301L) 7,9 200 16,5 17,5 15 500 0,73

(h) (a) (b) (c)

302 8,06 193 17,2 17,8 16,3 503 0,72

AUSTENITIC

NON MAGNETIC

(I)

1.4305 303 7,9 200 16,5 17,5 15 500 0,73

(I)

1.4301 304 7,9 200 16,5 17,5 15 500 0,73

(I)

1.4311 304LN 7,9 200 16,5 17,5 15 500 0,73

(IV)

1.4948 304H 7,9 200 16,9 17,8 17 450 0,71

(I)

1.4307 304L 7,9 200 16,5 18,0 15 500 0,73

(I)

1.4306 304L 7,9 200 16,5 17,5 15 500 0,73

(I)

1.4315 304N 7,9 200 16,5 17,5 15 500 0,73

(I)

1.4303 305 7,9 200 16,5 17,5 15 500 0,73

(I) (i) (r)

1.4567 7,9 200 17,2 18,1 11,3 503 0,72 (e)

(h) (a) (b) (c)

308 8,06 193 17,3 17,8 15,3 503 0,72

(II) (s)

1.4828 7,9 200 16,5 17,5 15 500 0,85

(II) (r)

1.4833 309S 7,9 200 16,0 17,5 15 500 0,78

(h) (a) (b) (c)

310 8,06 200 15,9 16,2 14,2 503 0,78

(II) (r)

1.4845 310S 7,9 200 15,5 17,0 15 500 0,85

(II) (r)

1.4841 314 7,9 200 15,5 17,0 15 500 0,90

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

16](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-18-320.jpg)

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

Physical properties of stainless steels

GRADES DESIGNATIONS MODULUS OF MEAN COEFFICIENT OF THERMAL THERMAL ELECTRICAL

DENSITY SPECIFIC HEAT

( ) ELASTICITY EXPANSION CONDUCTIVITY RESISTIVITY

EN

AISI/ASTM at 20°C at 20°C [10-6xK-1] at 20°C at 20°C at 20°C

[N°]

[kg/dm3] [GPa] 20°C 200°C 20°C 400°C [W/(m xK)] [J/(kgxK)] 2

[ xmm )/m]

(I)

1.4401 316 8,0 200 16,5 17,5 15 500 0,75

(I)

1.4436 316 8,0 200 16,5 17,5 15 500 0,75

(h) (a) (b) (c)

316F 8,06 200 16,5 17,5 14,4 486 0,74

(h)

316N 8,06 196 (n.r.) (n.r.) (n.r.) 503 0,74

(t) (u) (v) (z)

316H 8,03 193 15,9 16,2 16,3 500 0,74

(I)

1.4404 316L 8,0 200 16,5 17,5 15 500 0,75

(I)

1.4435 316L 8,0 200 16,5 17,5 15 500 0,75

(I)

1.4432 316L 8,0 200 16,5 17,5 15 500 0,75

(I)

1.4406 316LN 8,0 200 16,5 17,5 15 500 0,75

NON MAGNETIC

(I)

1.4429 316LN 8,0 200 16,5 17,5 15 500 0,75

AUSTENITIC

(I)

1.4571 316Ti 8,0 200 17,5 18,5 15 500 0,75

(I)

1.4580 316Cb 8,0 200 17,5 18,5 15 500 0,75

(h) (a) (b) (c)

317 8,06 193 16,0 16,2 16,3 503 0,74

(I)

1.4438 317L 8,0 200 16,5 17,5 14 500 0,85

(I)

1.4434 317LN 8,0 200 16,5 17,5 15 500 0,75

(I)

1.4439 317 LMN 8,0 200 16,5 17,5 14 500 0,85

(I)

1.4541 321 7,9 200 16,5 17,5 15 500 0,73

(II) (I)

1.4878 321H 7,9 200 17,0 18,0 15 500 0,73

(I)

1.4550 347 7,9 200 16,5 17,5 15 500 0,73

(t) (u)

347H 8,03 193 16,6 18,2 (v) 16,1 (z)

500 0,72

(I)

1.4335 7,9 195 16,1 16,9 14 450 0,85

(I) (m) (n)

1.4466 310MoLN 8,0 195 15,7 17,0 14 500 0,80

(I)

1.4361 7,7 200 (n.r.) (n.r.) 14 (n.r.) (n.r.)

(q)

1.4570 7,9 200 16,5 17,5 15 500 0,70

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

17](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-19-320.jpg)

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

Physical properties of stainless steels

GRADES DESIGNATIONS MODULUS OF MEAN COEFFICIENT OF THERMAL THERMAL ELECTRICAL

DENSITY SPECIFIC HEAT

( ) ELASTICITY EXPANSION CONDUCTIVITY RESISTIVITY

EN

AISI/ASTM at 20°C at 20°C [10-6xK-1] at 20°C at 20°C at 20°C

[N°]

[kg/dm3] [GPa] 20°C 200°C 20°C 400°C [W/(m xK)] [J/(kgxK)] [ xmm

2

)/m]

(I)

1.4578 8,0 200 (n.r.) (n.r.) (n.r.) (n.r.) (n.r.)

(I)

1.4563 8,0 195 16,1 16,9 12 450 1,00

(I)

1.4537 8,1 195 (n.r.) (n.r.) 14 500 0,85

(I)

1.4539 904L 8,0 195 16,1 16,9 12 450 1,00

AUSTENITIC

(I)

1.4547 8,0 195 17,0 18,0 14 500 0,85

NON MAGNETIC

(I)

1.4652 8,0 190 15,4 16,2 8,6 500 0,78

(I)

1.4659 8,2 190 15,5 16,3 12 450 1,00

(I)

1.4529 8,1 195 16,1 16,9 12 450 1,00

(I)

1.4565 8,0 190 15,5 16,8 12 450 0,92

(II) (r)

1.4864 330 8,0 196 15,0 16,0 12,5 550 1,00

(II)

1.4835 7,8 (n.r.) 17,0 18,0 15 500 0,85

(II) (g)

1.4876 8,0 196 15,0 16,0 12 550 1,00

(II)

1.4877 8,0 (n.r.) 15,5 16,5 12 450 0,96

(II)

1.4818 7,8 (n.r.) 16,5 18,0 15 500 0,85

(II)

1.4854 7,9 (n.r.) 15,5 16,5 11 450 1,00

(h) (a) (c)

384 8,06 193 17,2 (n.r.) 16,3 503 0,79

(I)

1.4460 329 7,8 200 13,5 (n.r.) 15 500 0,80

FERROMAGNETIC

(I) (g)

1.4462 2205 7,8 200 13,5 14,0 15 500 0,80

DUPLEX

(I) (n)

1.4362 2304 7,8 200 13,5 14,0 15 500 0,80

(I)

1.4655 7,8 200 13,5 (n.r.) 15 500 0,80

(I) (m) (n)

1.4410 2507 7,8 200 12,5 13,5 15 500 0,80

(I) (m) (n)

1.4507 255 7,8 200 12,5 13,5 15 500 0,80

(I)

1.4501 7,8 200 13,5 (n.r.) 15 500 0,80

(I)

1.4424 7,8 200 13,5 (n.r.) 13 475 0,80

(I)

1.4477 7,7 200 12,0 (n.r.) 13 470 0,80

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

18](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-20-320.jpg)

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

Physical properties of stainless steels

GRADES DESIGNATIONS MODULUS OF MEAN COEFFICIENT OF THERMAL THERMAL

DENSITY SPECIFIC HEAT ELECTRICAL RESISTIVITY

( ) ELASTICITY EXPANSION CONDUCTIVITY

EN

AISI/ASTM at 20°C at 20°C [10-6xK-1] at 20°C at 20°C at 20°C

[N°]

[kg/dm3] [GPa] 20°C 200°C 20°C 400°C [W/(m xK)] [J/(kgxK)] [ xmm

2

)/m]

(I)

1.4003 7,7 220 10,8 11,6 25 430 0,60

1.4512 (I) 409 7,7 220 11,0 12,0 25 460 0,60

1.4516 (I) 7,7 220 10,5 (m) 11,5 (n) 30 460 0,60

(I)

1.4000 410S 7,7 220 11,0 12,0 30 460 0,60

1.4002 (I) 405 7,7 220 11,0 12,0 30 460 0,60

FERRITIC

(I)

1.4589 7,7 220 11,0 12,0 25 460 0,60

429 (h) 7,78 200 10,3 (a) (n.r.) 25,7 (c) 460 0,59

(I)

1.4595 7,7 220 10,8 11,6 30 460 0,60

1.4016 (I) 430 7,7 220 10,0 10,5 25 460 0,60

1.4105 (I) 430F 7,7 220 10,5 10,5 25 460 0,70

FERROMAGNETIC

(I)

1.4520 7,7 220 10,8 11,6 20 430 0,70

1.4511 (I) 7,7 220 10,0 10,5 25 460 0,60

1.4017 (I) 7,7 220 10,2 (m) 10,8 (n) 30 460 0,70

(I)

1.4113 434 7,7 220 10,5 10,5 25 460 0,70

1.4513 (I) 7,7 220 10,5 10,5 25 460 0,70

1.4510 (I) 439 7,7 220 10,0 10,5 25 460 0,60

442 (h) 7,78 200 10,2 (a) (n.r.) 21,7 (c) 460 0,64

(I)

FERRITIC

1.4521 444 7,7 220 10,8 11,6 23 430 0,80

1.4526 (I) 436 7,7 220 11,7 (m) 12,1 (n) 30 440 0,70

(I)

1.4509 7,7 220 10,0 10,5 25 460 0,60

1.4590 (I) 7,7 220 (n.r.) (n.r.) 26 460 0,60

(II) (r)

1.4749 446 7,7 200 10,0 11,0 17 500 0,70

1.4713 (II) 7,7 (n.r.) 11,5 12,0 23 450 0,70

1.4724 (II) 7,7 (n.r.) 10,5 11,5 21 500 0,75

1.4762 (II) 7,7 (n.r.) 10,5 11,5 17 500 1,10

1.4592 (I) 7,7 220 (n.r.) (n.r.) 17 440 0,67

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

19](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-21-320.jpg)

![STAINLESS STEEL: TABLES OF TECHNICAL PROPERTIES

Physical properties of stainless steels

GRADES DESIGNATIONS MODULUS OF MEAN COEFFICIENT OF THERMAL THERMAL

DENSITY SPECIFIC HEAT ELECTRICAL RESISTIVITY

( ) ELASTICITY EXPANSION CONDUCTIVITY

EN

AISI/ASTM at 20°C at 20°C [10-6xK-1] at 20°C at 20°C at 20°C

[N°]

[kg/dm3] [GPa] 20°C 200°C 20°C 400°C [W/(m xK)] [J/(kgxK)] [ xmm

2

)/m]

1.4006 (I) 410 7,7 215 11,0 12,0 30 460 0,60

1.4024 (I) 7,7 216 11,0 12,0 30 460 0,60

FERROMAGNETIC

414 (h) 7,78 200 10,4 (a) 11,0 (b) 25 (c) 460 0,70

(I)

1.4005 416 7,7 215 11,0 12,0 30 460 0,60

1.4029 (I) 416 7,7 215 9,9 (a) 11,0 (b) 30 460 0,55

(I)

1.4021 420 7,7 215 11,0 12,0 30 460 0,60

1.4028 (I) 420 7,7 215 11,0 12,0 30 460 0,65

(I)

1.4031 420 7,7 215 11,0 12,0 30 460 0,55

(I)

1.4034 420 7,7 215 11,0 12,0 30 460 0,55

MARTENSITIC

420F (h) 7,78 200 10,3 (a) (n.r.) 25,2 (p) 460 0,55

(I)

1.4116 7,7 215 11,0 11,5 30 460 0,65

422 (h) 7,78 (n.r.) 11,2 (a) 11,4 (b) 23,9 (c) 460 (n.r.)

(I)

1.4104 7,7 215 10,5 10,5 25 460 0,70

(I)

1.4057 431 7,7 215 10,5 10,5 25 460 0,70

1.4109 (I) 440A 7,7 215 11,0 11,5 30 460 0,65

1.4112 (I) 440B 7,7 215 10,8 11,6 15 430 0,80

(I)

1.4125 440C 7,7 215 10,8 11,6 15 430 0,80

1.4110 (I) 7,7 215 11,0 12,0 30 460 0,62

1.4419 (I) 7,7 215 11,0 12,0 30 460 0,62

FERROMAGNETIC

(I)

1.4122 7,7 215 10,8 11,6 15 430 0,80

1.4313 (I) 7,7 200 10,9 11,6 25 430 0,60

(I)

1.4418 7,7 200 10,8 11,6 15 430 0,80

(I)

1.4422 7,7 200 10,8 11,6 16 450 0,75

1.4423 (I) 7,7 200 10,8 11,6 16 450 0,75

(I) (a) (b)

1.4542 630 7,8 200 10,8 11,6 16 500 0,71

1.4568 (I) 631 7,8 200 11,0 (a) 11,6 (b) 16 500 0,80

PH

magnetic

Non

(*)

1.4980 (III) 660 8,0 203 (s) 17,5 18,0 13 490 0,91 (o)

Adapted from “Raccolta di tabelle tecniche” with kind permission of Centro Inox, Italy.

20](https://image.slidesharecdn.com/tablestechnicalpropertiesen-111124030506-phpapp01/85/Tables-technical-properties_en-22-320.jpg)