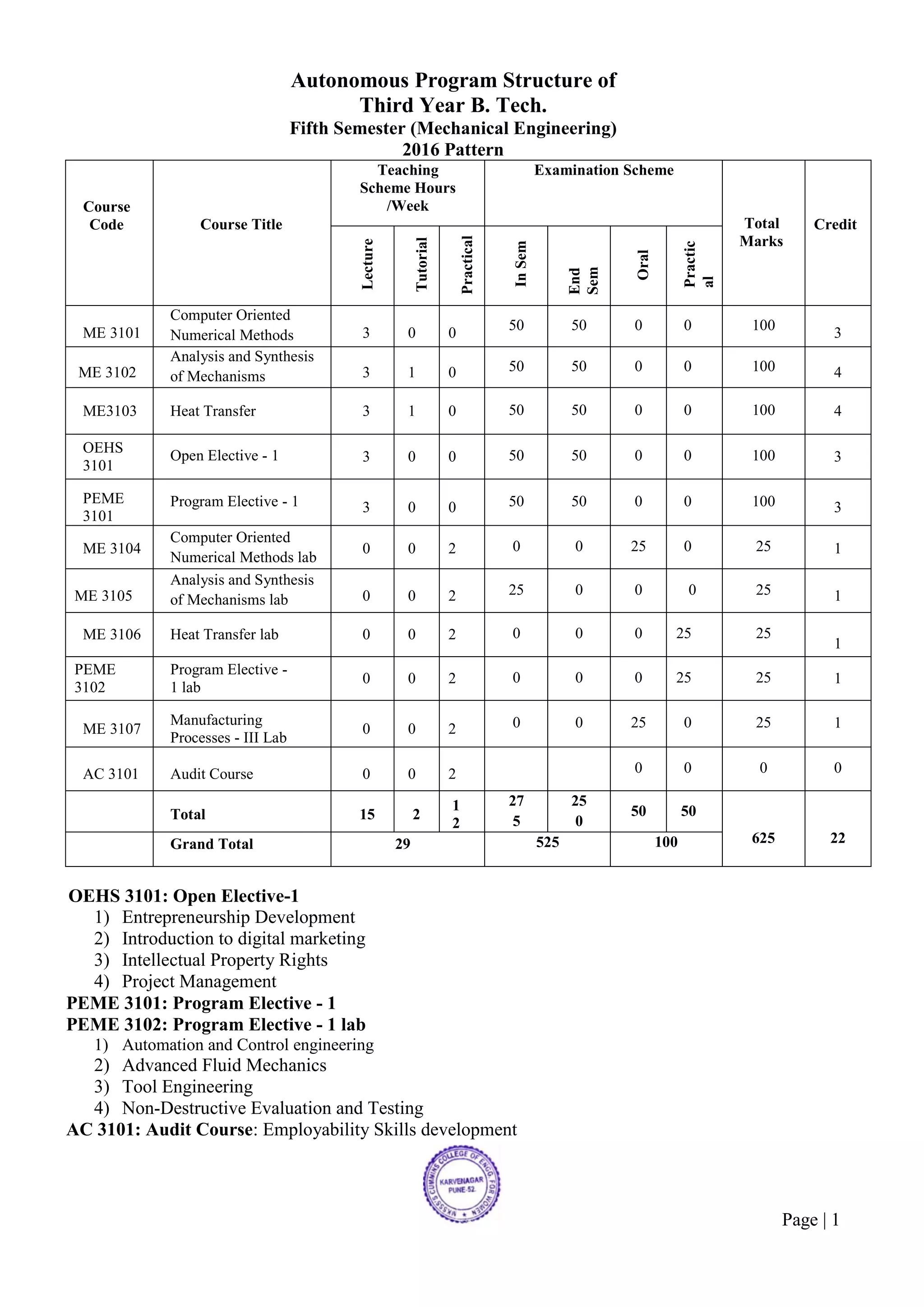

This document provides information on the autonomous program structure for the third year of a B.Tech program in Mechanical Engineering. It lists the courses, codes, credit hours, teaching schemes, and examination schemes for the fifth semester. The courses cover topics like computer oriented numerical methods, analysis and synthesis of mechanisms, heat transfer, open electives, program electives, and associated labs. The document provides details of individual courses including course objectives, outcomes, units, topics covered, textbooks, and other references.