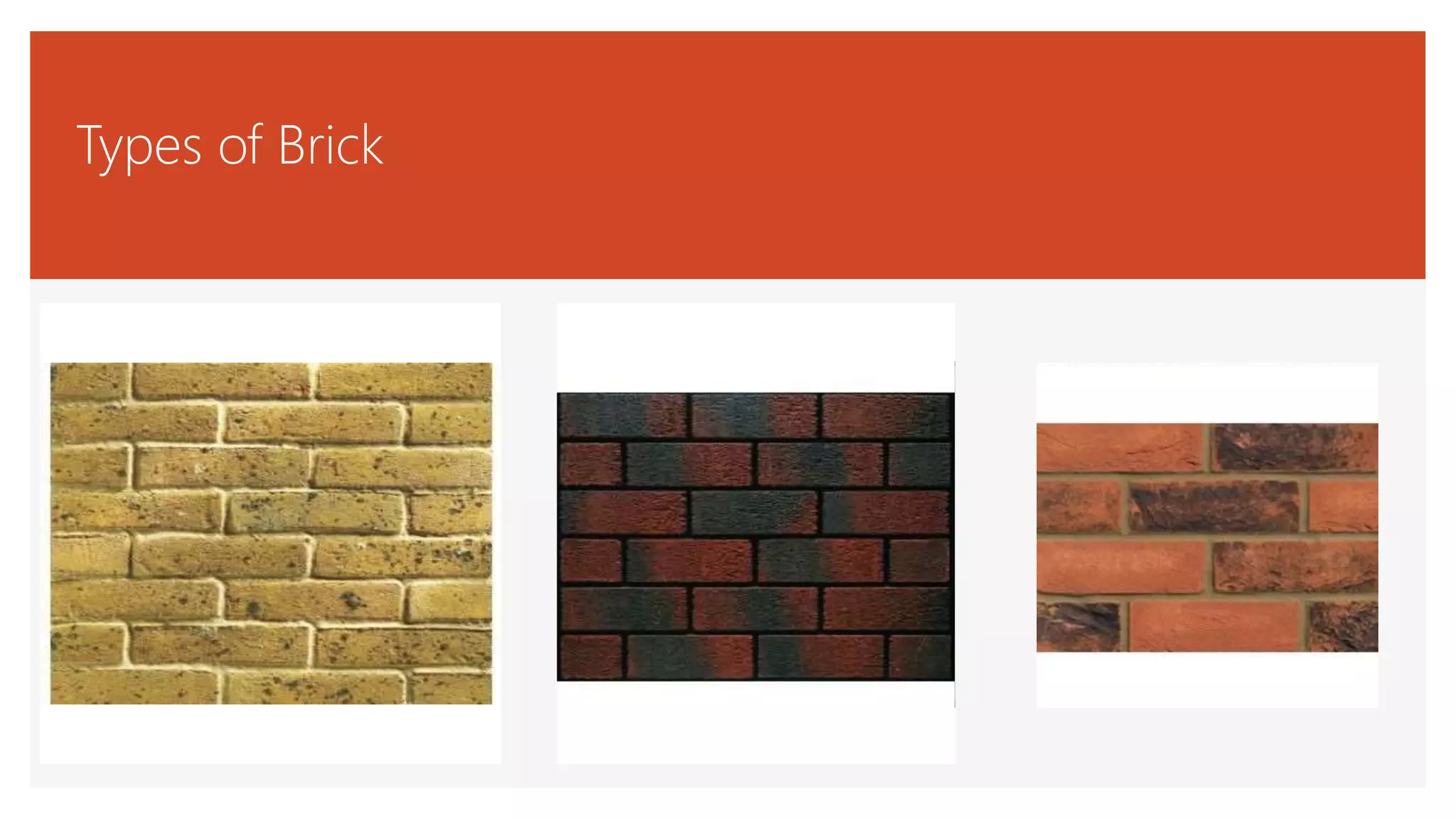

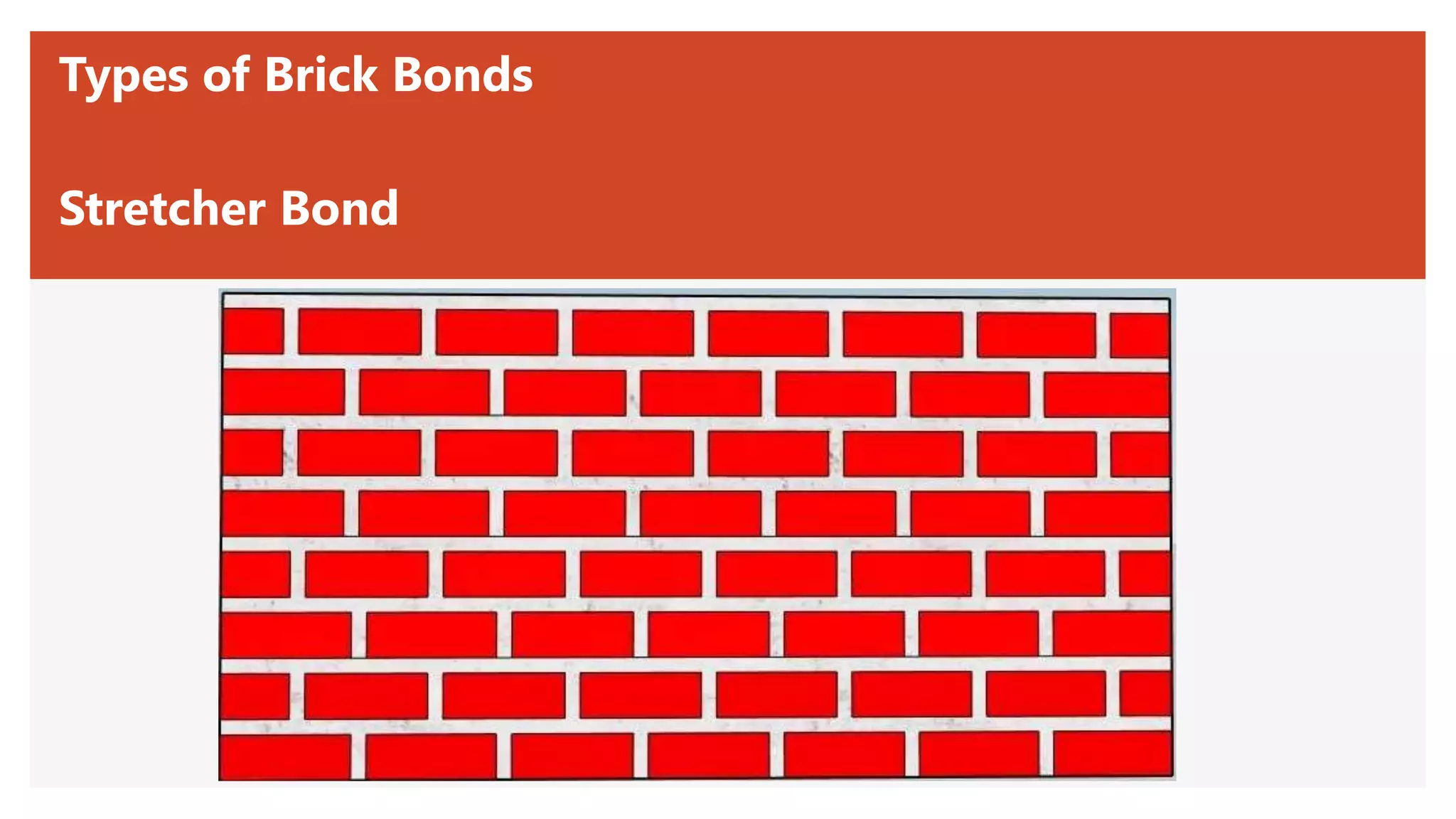

This document discusses different types of bricks and blocks, their uses in construction, and bonding patterns. It describes engineering bricks in Classes A and B, various types of standard bricks, and hollow and solid concrete blocks that come in different densities. Bonding patterns covered include stretcher, header, English, Flemish, English garden wall, stacked, raked, zig zag, and more. Videos provide additional information on bricks and their uses in building foundations and structures.